Process for treating sludge and manufacturing bioorganically-augmented high nitrogen-containing inorganic fertilizer

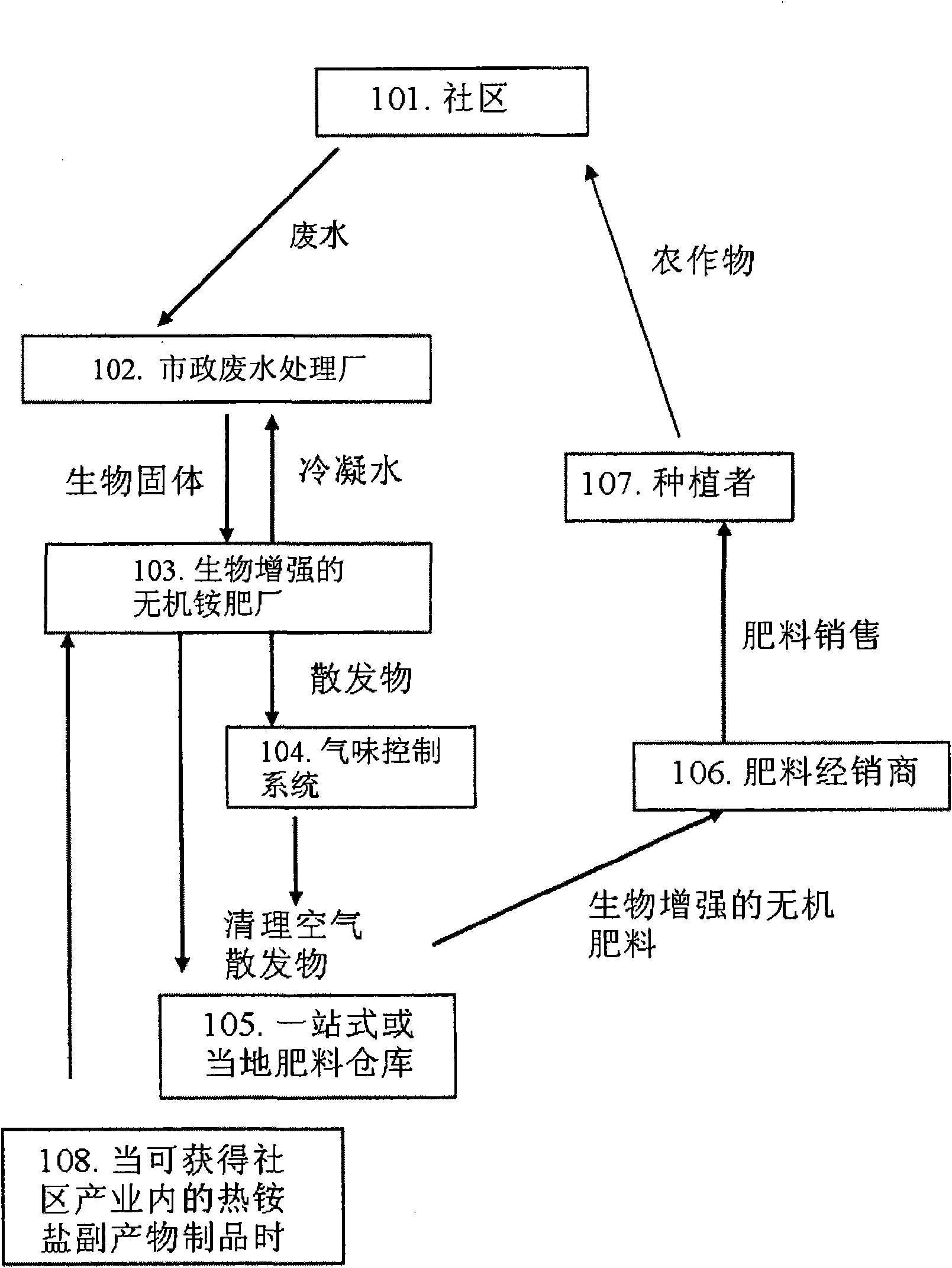

一种污泥、混合料的技术,应用在生物废物制成的肥料、有机肥料、污水/污泥肥料等方向,能够解决不能满足等问题,达到减少物流的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

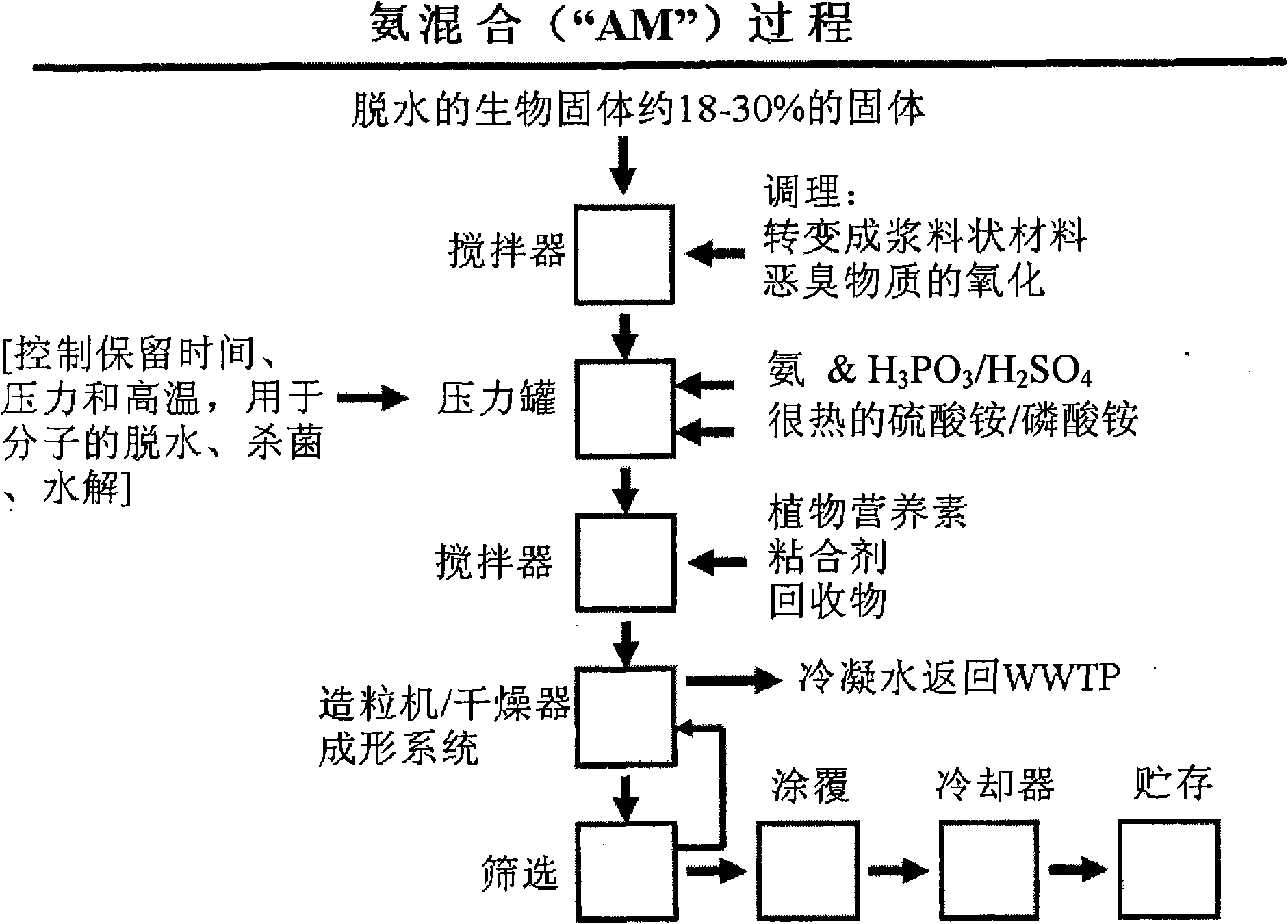

Method used

Image

Examples

preparation example Construction

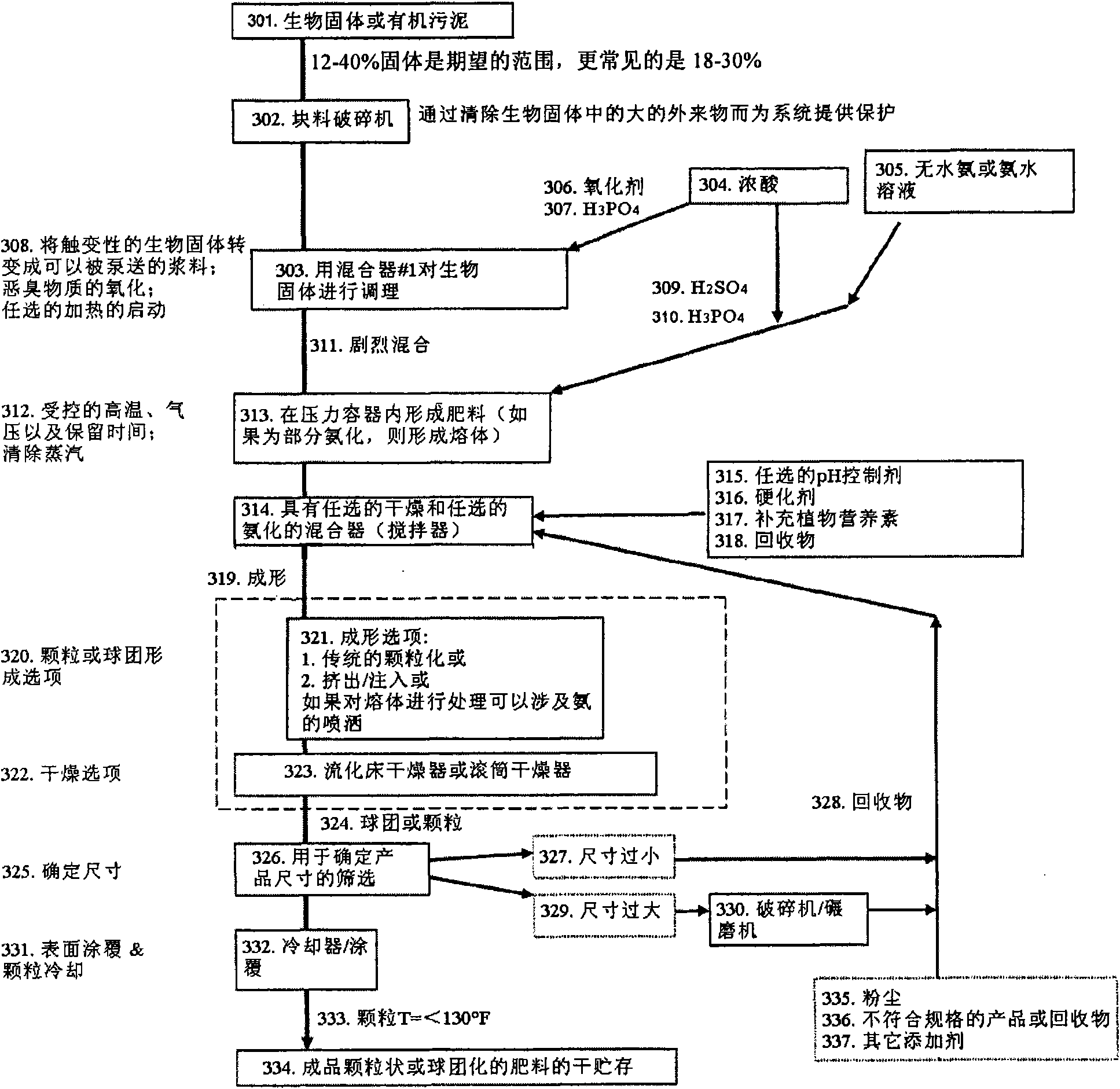

[0092] The remainder of the process for forming 319 in the preparation 320 of pellets or granules includes standard fertilizer granulation techniques dedicated to high volume throughput plants. Especially in smaller throughput plants (which are considered to be those producing less than 25 t / d), pellet or granule products can involve several innovative technologies, such as: Either milling or spheroidizing the pellets or granules after extrusion, or involving simplification of the discharge from the pelletizer or pellet mill. When using a pelletizer or pelletizer, it is preferred to feed some recyclate 228 to the second mixer 314 as well as the pelletizer to adjust the percent moisture present in the mix. To the level that agglomeration or nucleation can occur during particle formation, such as: seed material in a dry state, i.e., dry fines 327, and fines produced by a crusher or mill 330, or low specification or recycled fertilizer product materials.

[0093] Other preferre...

Embodiment 1

[0113] In this example, if Figure 4 and Figure 10 As shown in the diagram, anaerobically decomposed biosolids previously dehydrated to 22% are directly received via a conveyor adjacent to the wastewater treatment plant. In the receiving area of the fertilizer production plant, incoming biosolids first pass through a lumpbuster device, which screens out large foreign rocks or metals, before entering a large surge tank (capacity 24,000 gallons). Biosolids leaving the surge tank goes to a positive displacement pump which then pumps the sludge at 6600 lb / hr to the first agitator (twin shaft) for conditioning and mixing .

[0114] The established production plant can produce an average of 3 tons of 22% wet biosolids per hour, and within 1 year, the production plant operates at 90% efficiency. In order to ensure this output, on the basis of inputting 3.3 tons of wet biosolids per hour, the factory generates 3.8 tons of dry finished fertilizer products per hour (the ratio of s...

Embodiment 2

[0129] In Example 2, the same 3.3 tons of biosolids per hour are treated in the AM process as described in the preferred embodiment of the invention, however, all anhydrous ammonia is added to the pressure vessel to The ammonification is complete and ammonium sulphate salts are formed in the fertilizer mix. Although the fertilizer mix was not as fluid when formed as a melt, high head pressure and mechanical agitation were sufficient to allow the hot fertilizer mix to exit the pressure vessel as desired. In Example 2, no additional ammonia was sprayed into the mixer #2, or granulator. The remainder of this example is the same as described in Example 1 for the production of a small amount of fertilizer

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid containing ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com