Material solubiliser reactor for hydrolysis and/or wet fermentation and waste treatment plant with such a solubiliser and reactor

A technology of waste treatment equipment and dissolver, applied in the field of material dissolvers and reactors for hydrolysis and/or wet leaching, as well as waste treatment equipment with such material dissolvers and reactors, can solve damage, Wear and other problems, to prevent overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

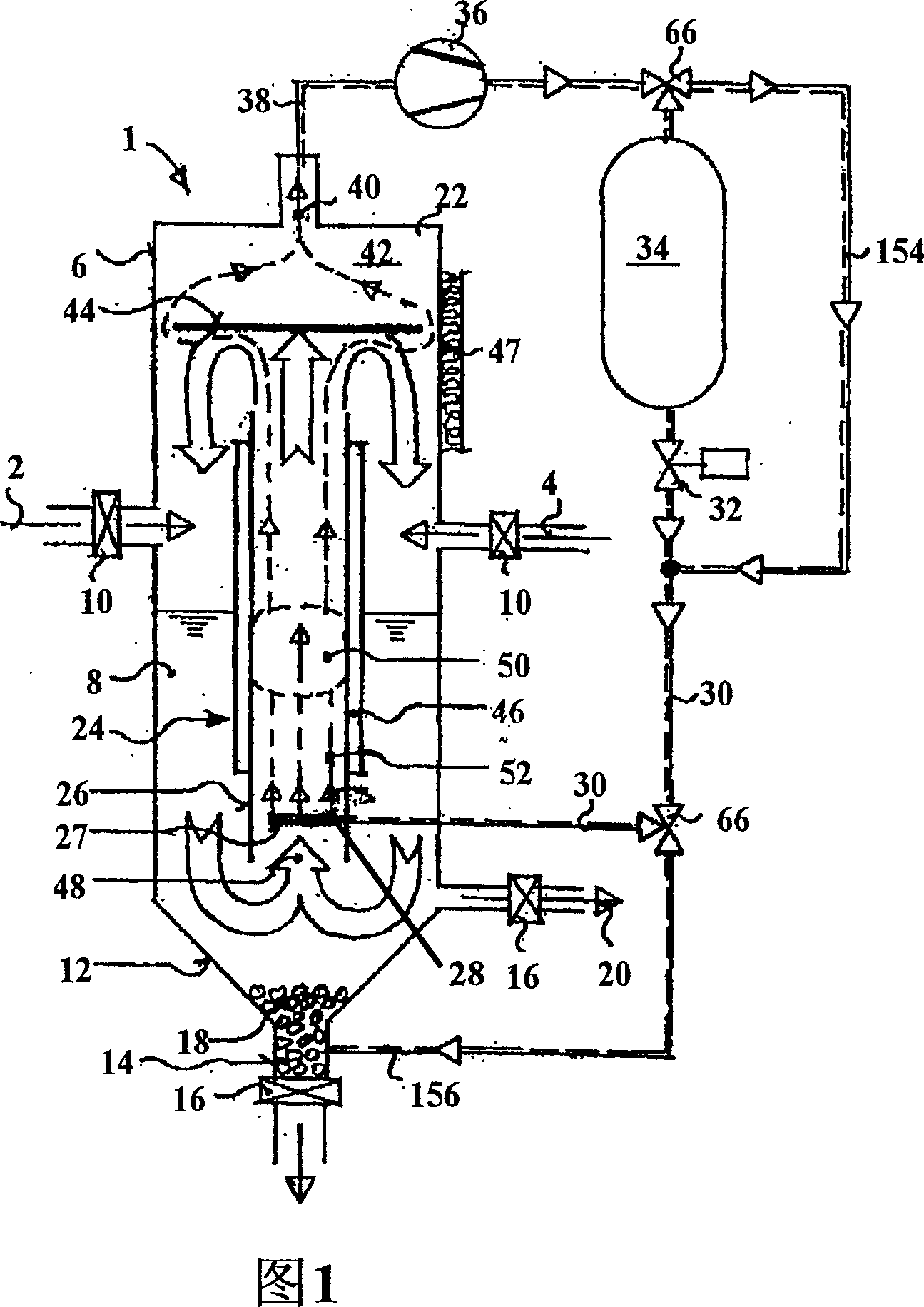

[0098]Fig. 1 shows the basic structure of the material dissolver 1, in this material dissolver, the inoculum material 2 conveyed, preferably the organic component of rubbish is dissolved in the dilution liquid such as dilution water 4, thereby in the material dissolver 1 Mixture 8 having a dry matter content of about 5-10%. The waste mixture fed to the material dissolver 1 preferably has a particle size of at most approximately 80 mm. The garbage 2 and the dilution water 4 are transported to the material dissolution container 6 through the feed gate 10 respectively. The bottom 12 of the material dissolution container is conical and opens at a discharge opening 14 to a discharge gate 16 , through which impurities / heavy material 18 deposited on the conical bottom 12 can be discharged. In the region of the conical bottom 12 a further discharge sluice 16 is formed, through which the organic-containing suspension 20 decomposed in the material dissolver 1 is discharged and treated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com