Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

511results about "Vapor flow control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

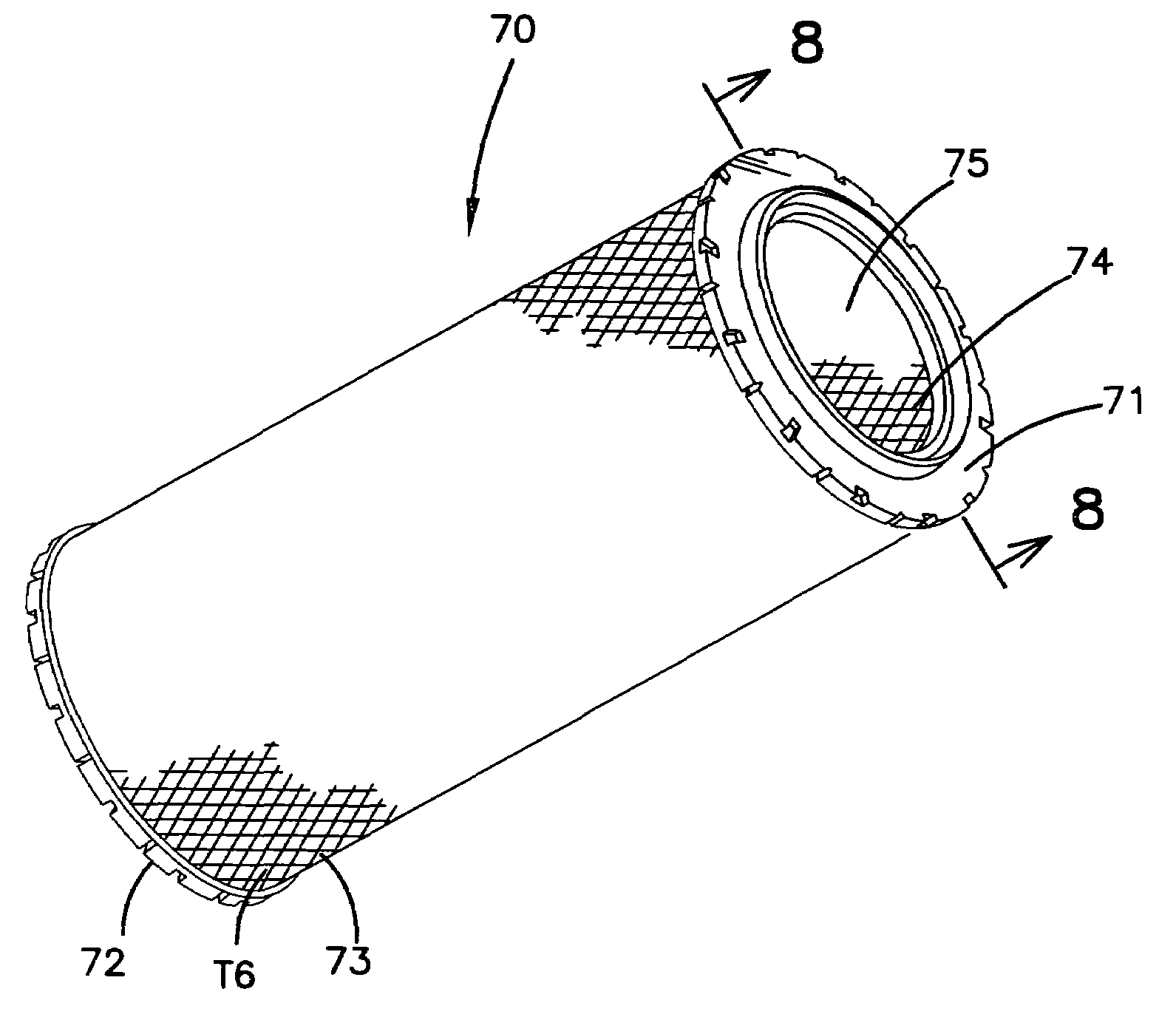

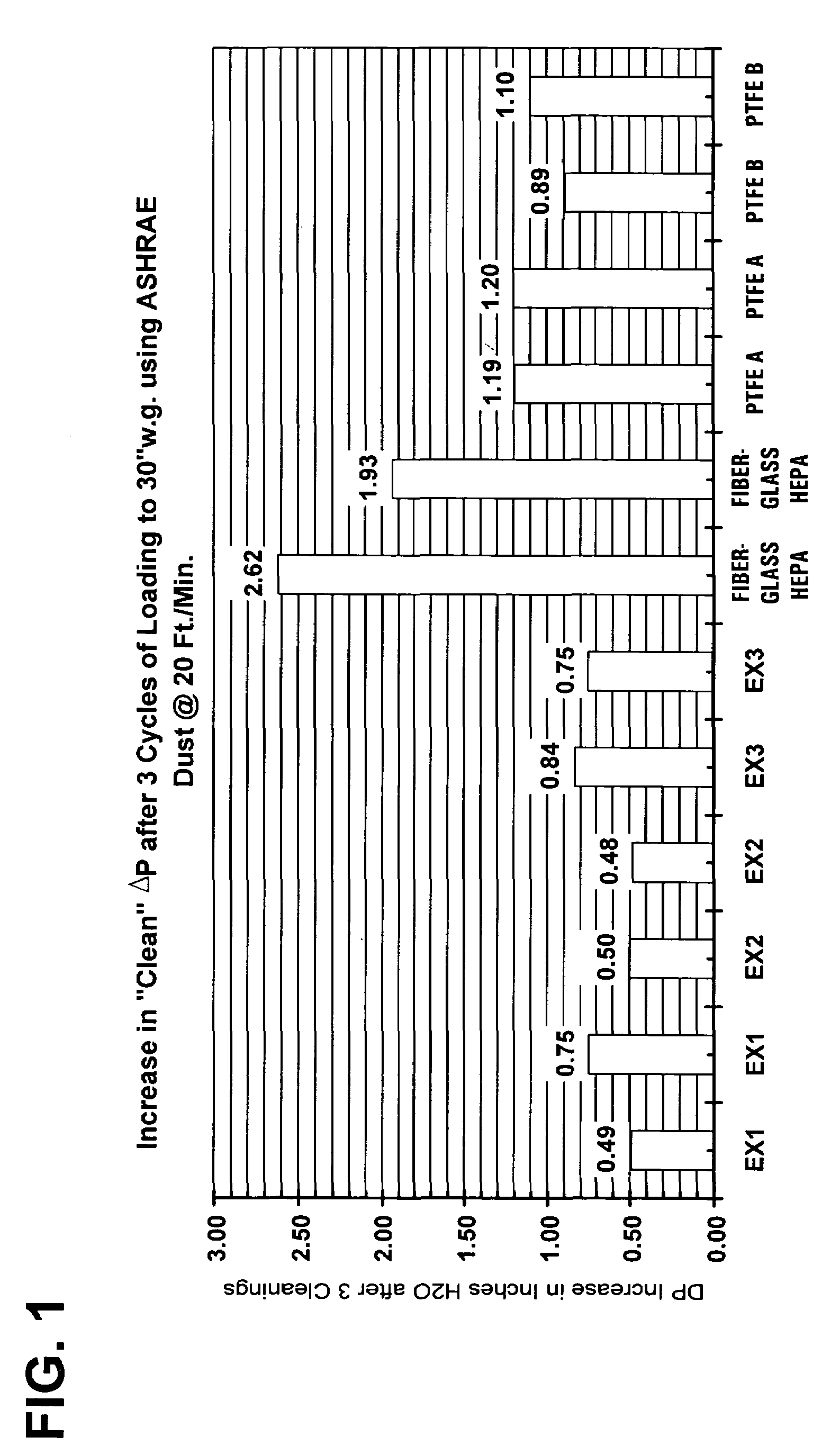

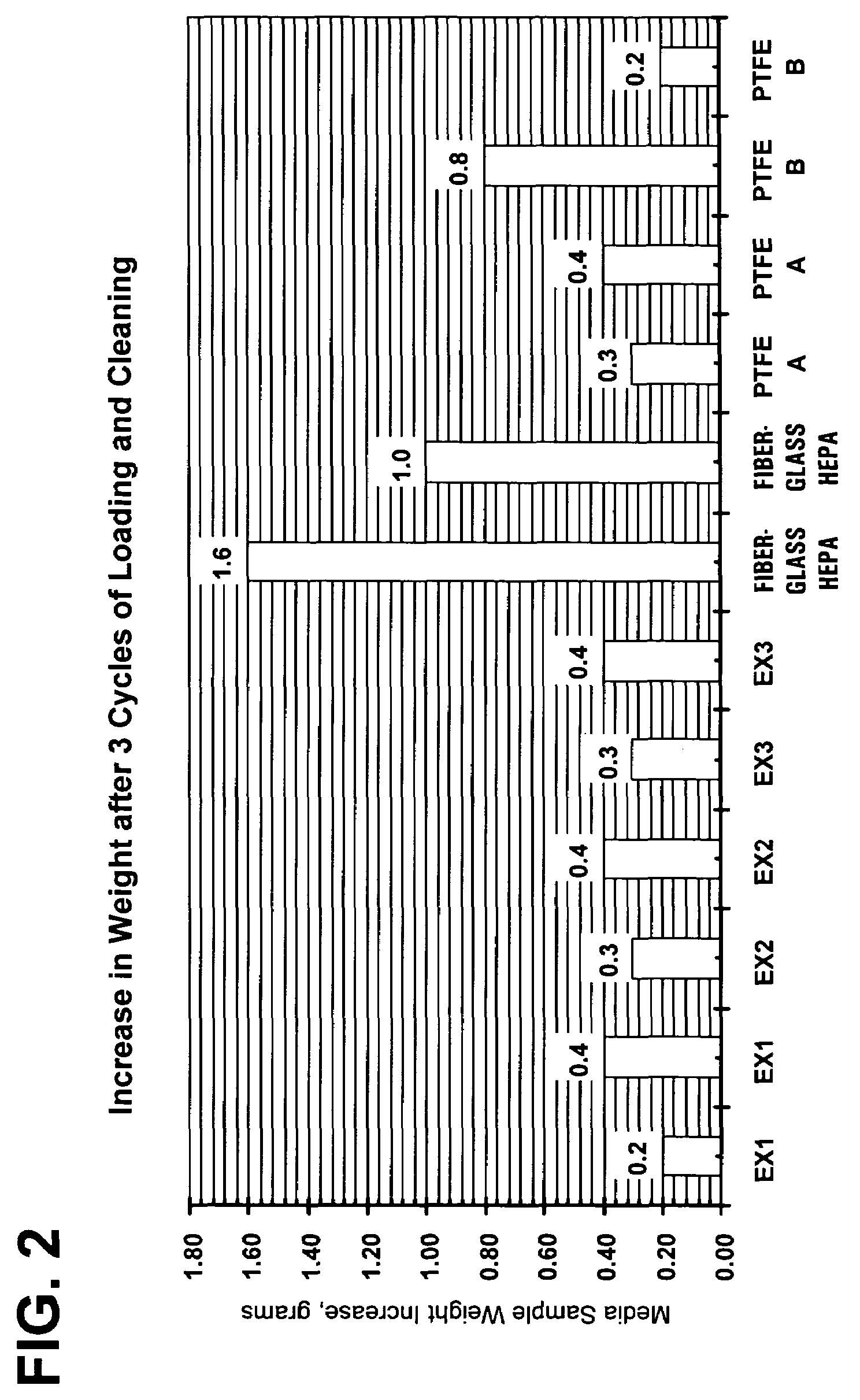

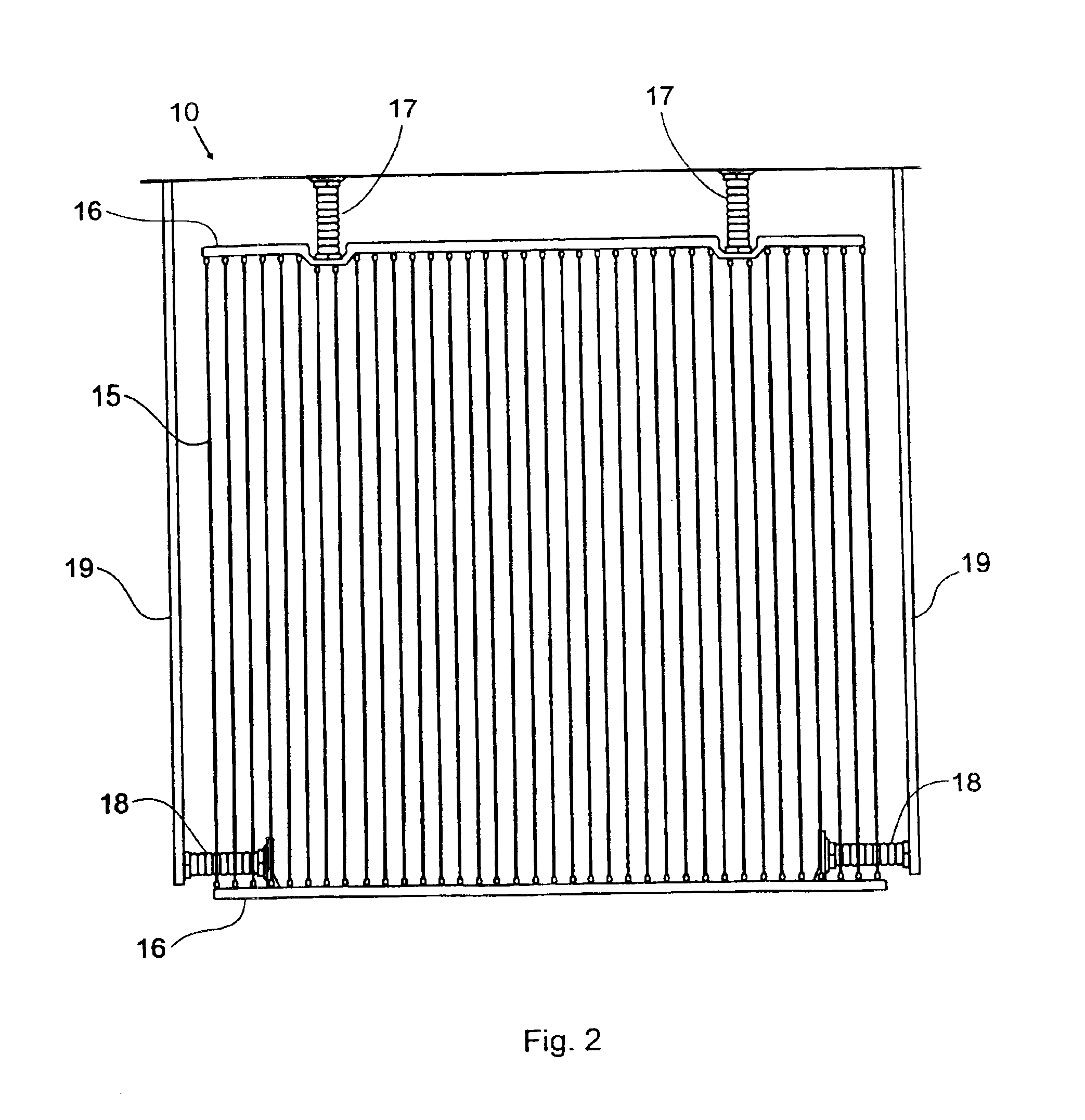

Cleanable high efficiency filter media structure and applications for use

ActiveUS7008465B2Improve filtering effectHigh particle captureCombination devicesAuxillary pretreatmentParticulatesFiber

An improved cartridge, typically in cylindrical or panel form that can be used in a dry or wet / dry vacuum cleaner. The cartridge is cleanable using a stream of service water, or by rapping on a solid object, or by using a compressed gas stream, but can provide exceptional filtering properties even for submicron particulate in the household or industrial environment. The cartridge has a combination of nanofiber filtration layer on a substrate. The nanofiber and substrate are engineered to obtain a maximum efficiency at reasonable pressure drop and permeability. The improved cartridge constitutes at least a substrate material and at least a layer including a non-woven, fine fiber separation layer.

Owner:DONALDSON CO INC

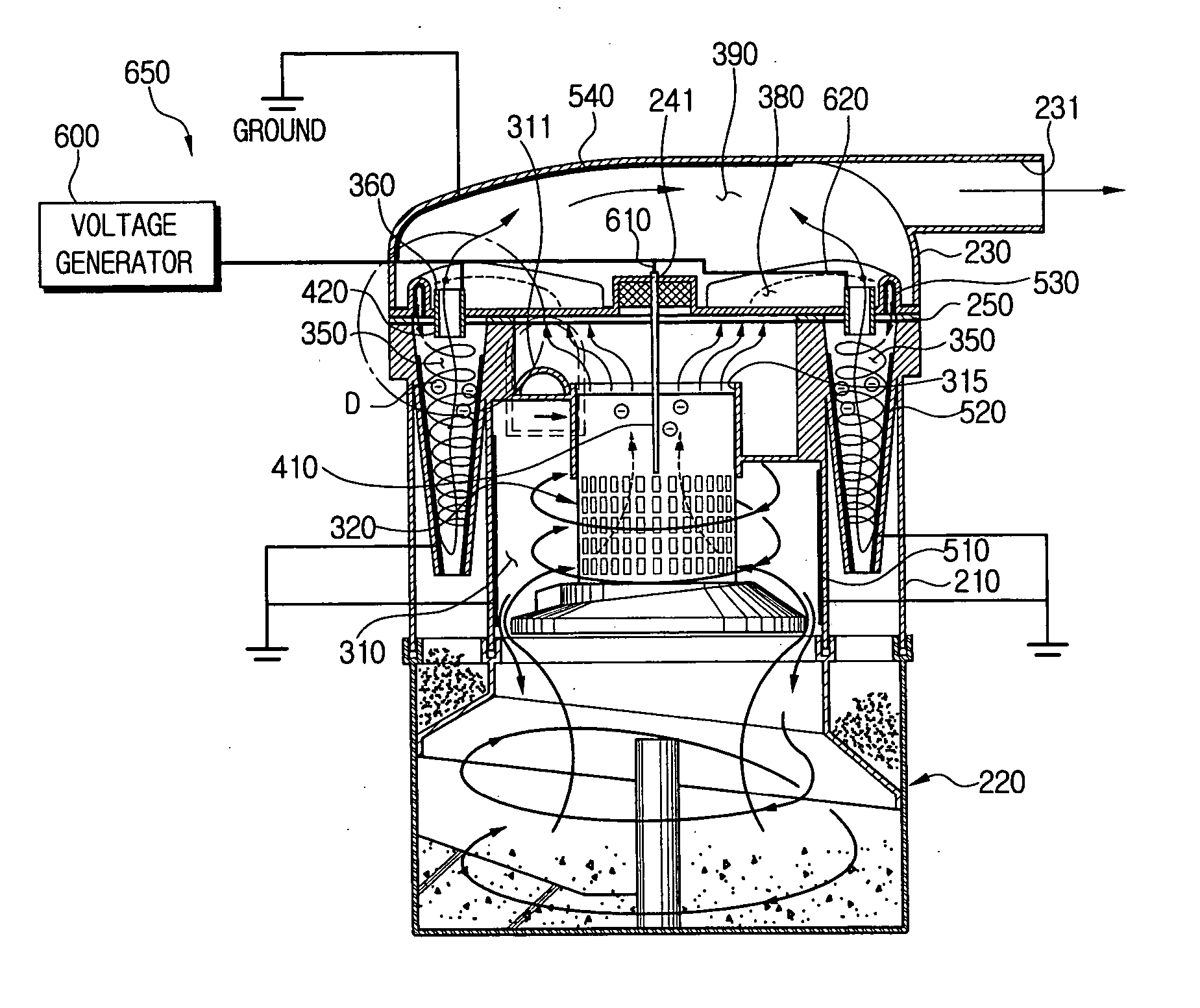

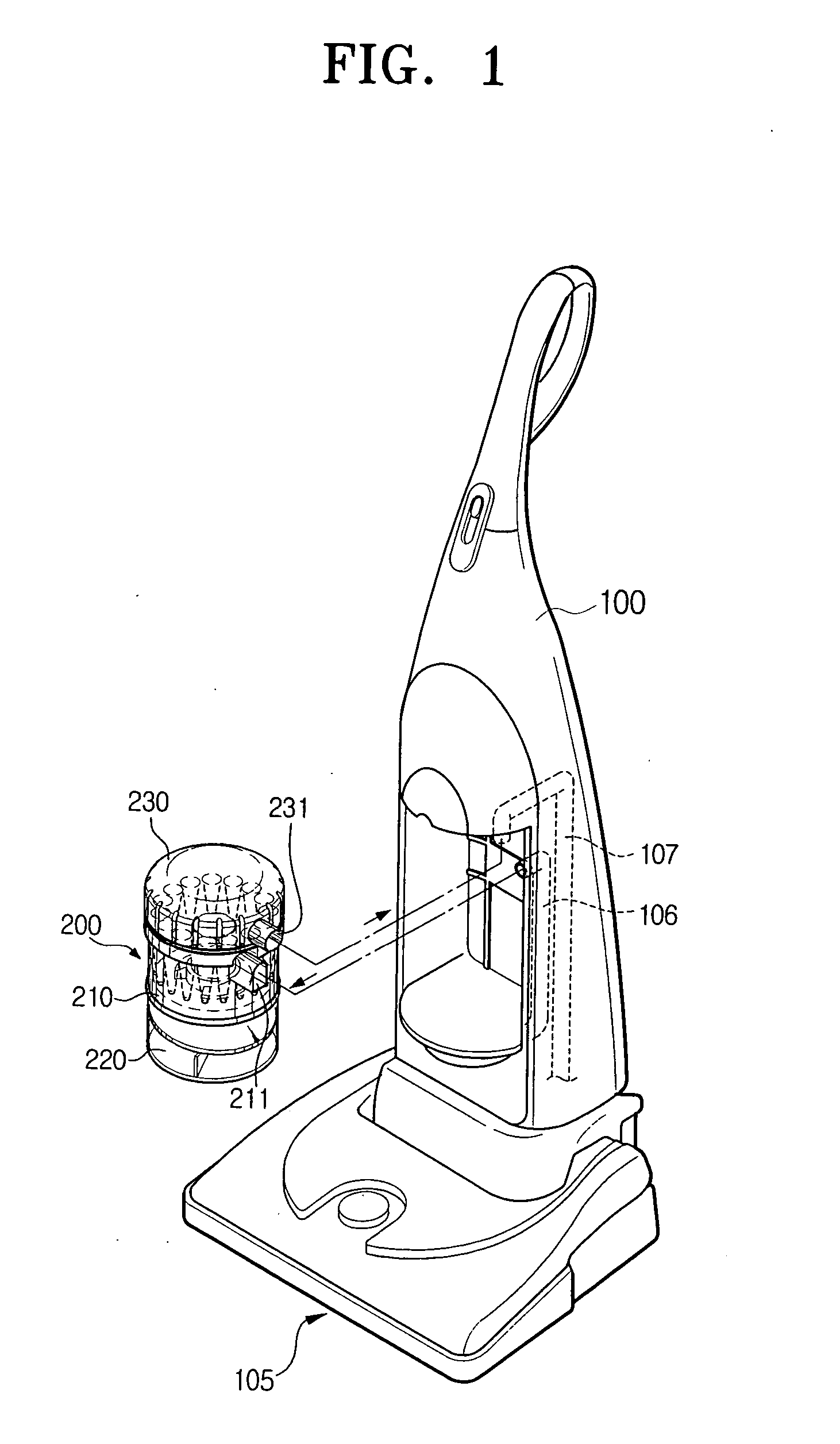

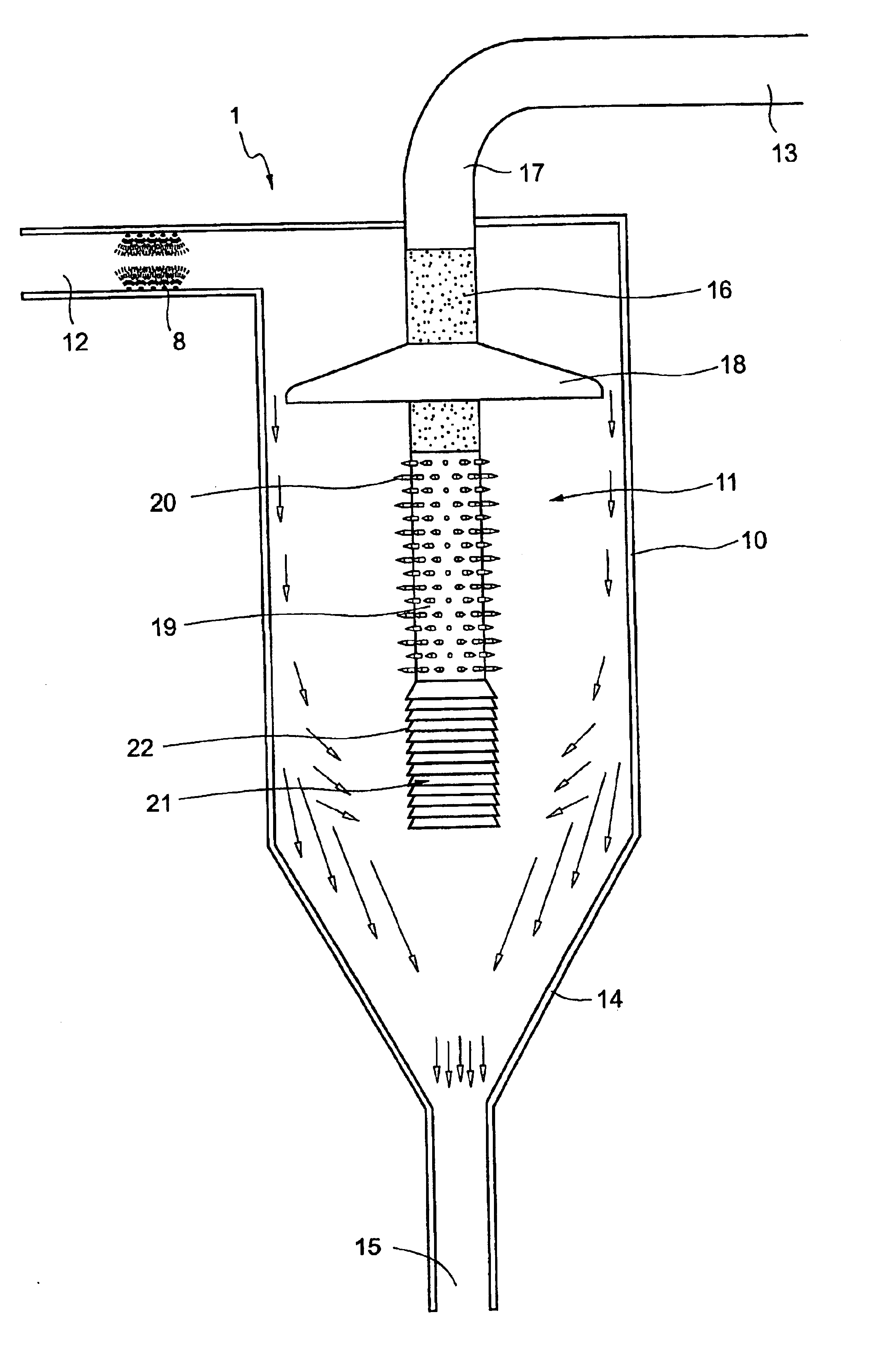

Cyclone dust collecting device for vacuum cleaner

InactiveUS20060278081A1Separation efficiency can be improvedIncreased durabilityCleaning filter meansSuction filtersCorona dischargeConductive materials

A cyclone dust collecting device using a corona discharge is provided. The cyclone dust collecting device includes a cyclone chamber rotating air drawn in from the outside to separate contaminants from the air, a discharge pipe guiding the air separated from the contaminants to the outside of the cyclone chamber and including a discharge electrode part with at least a part made of a conductive material and a power supply unit supplying a power to the discharge electrode part for the discharge electrode part to perform a corona discharge.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

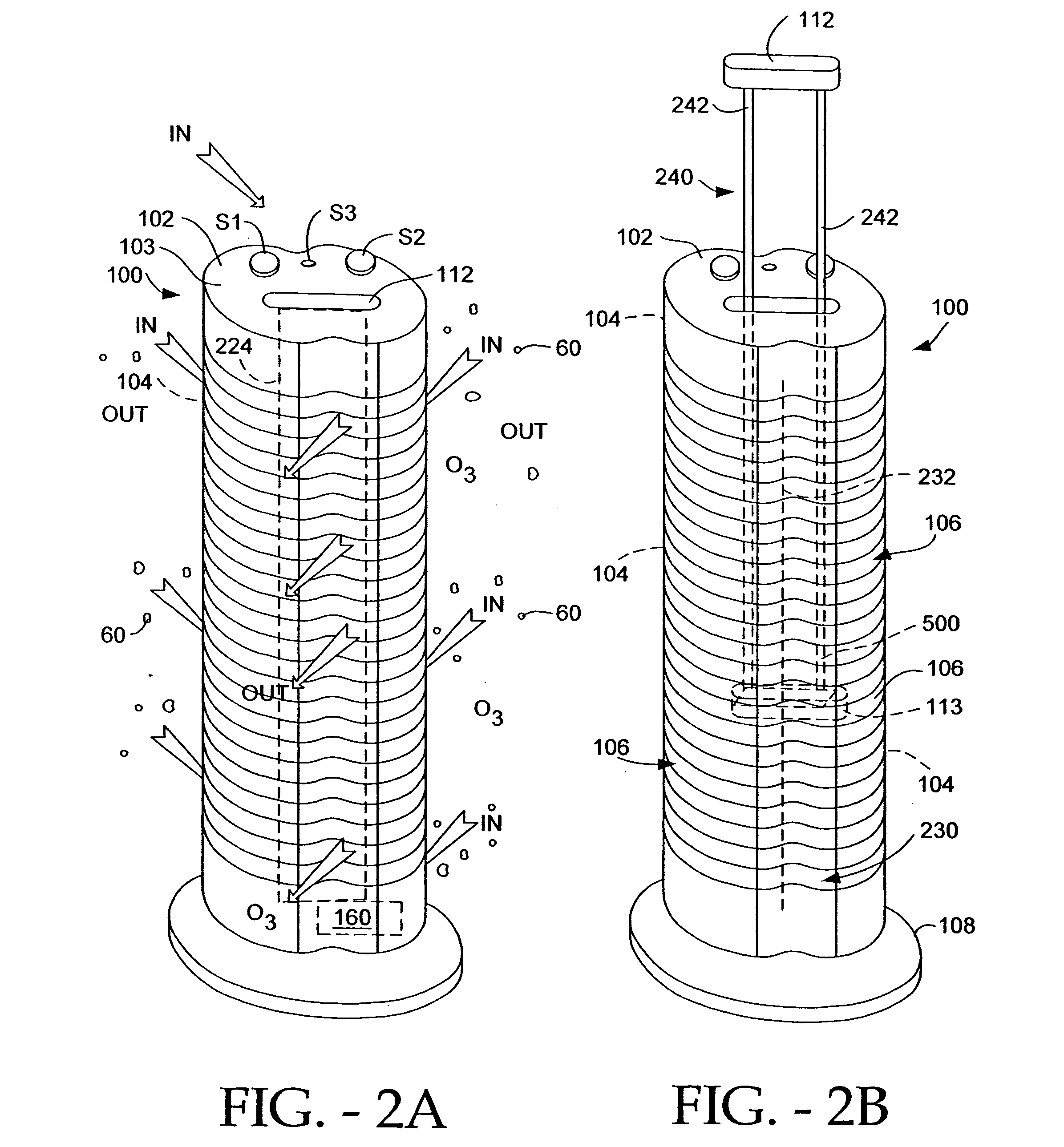

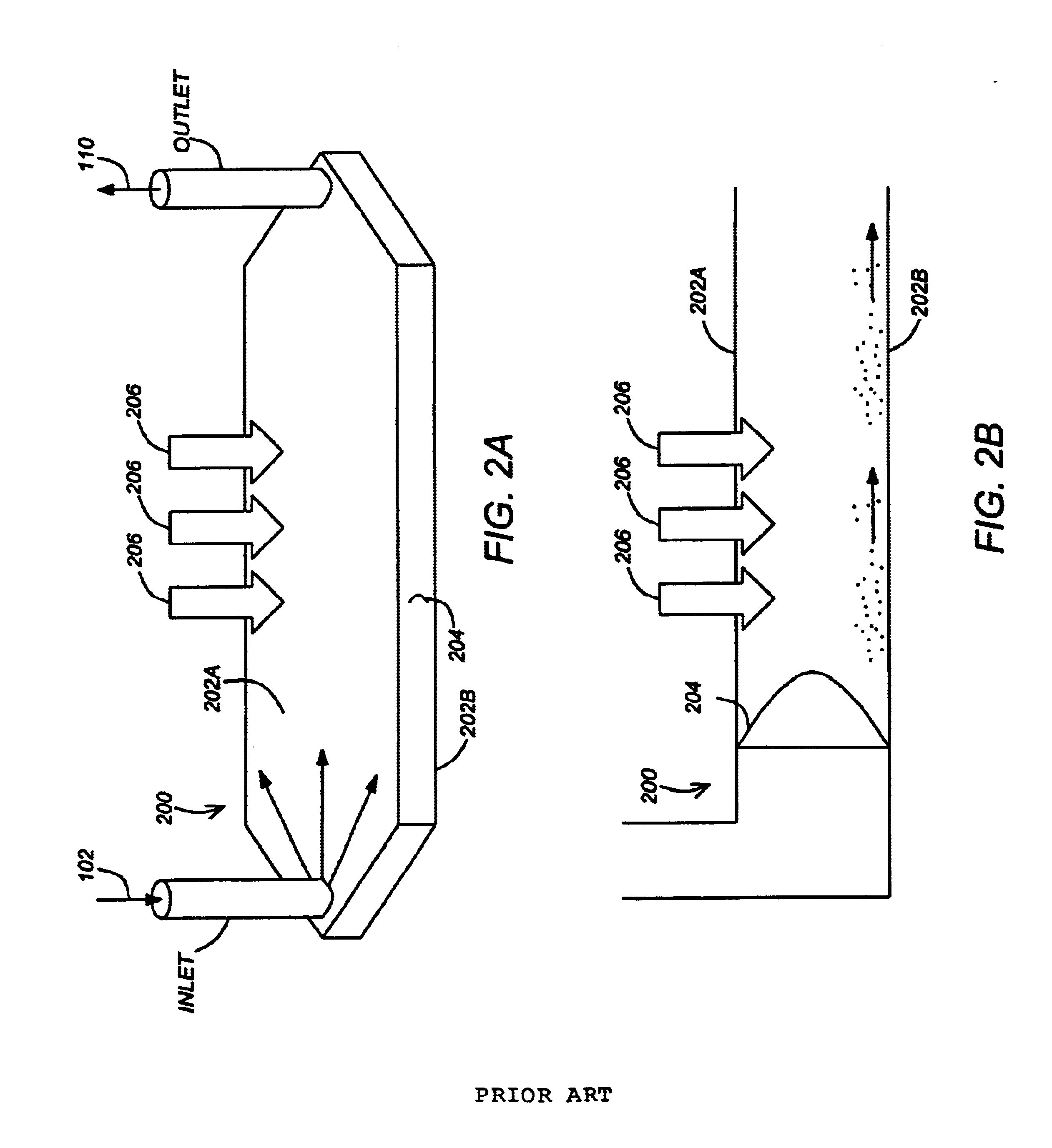

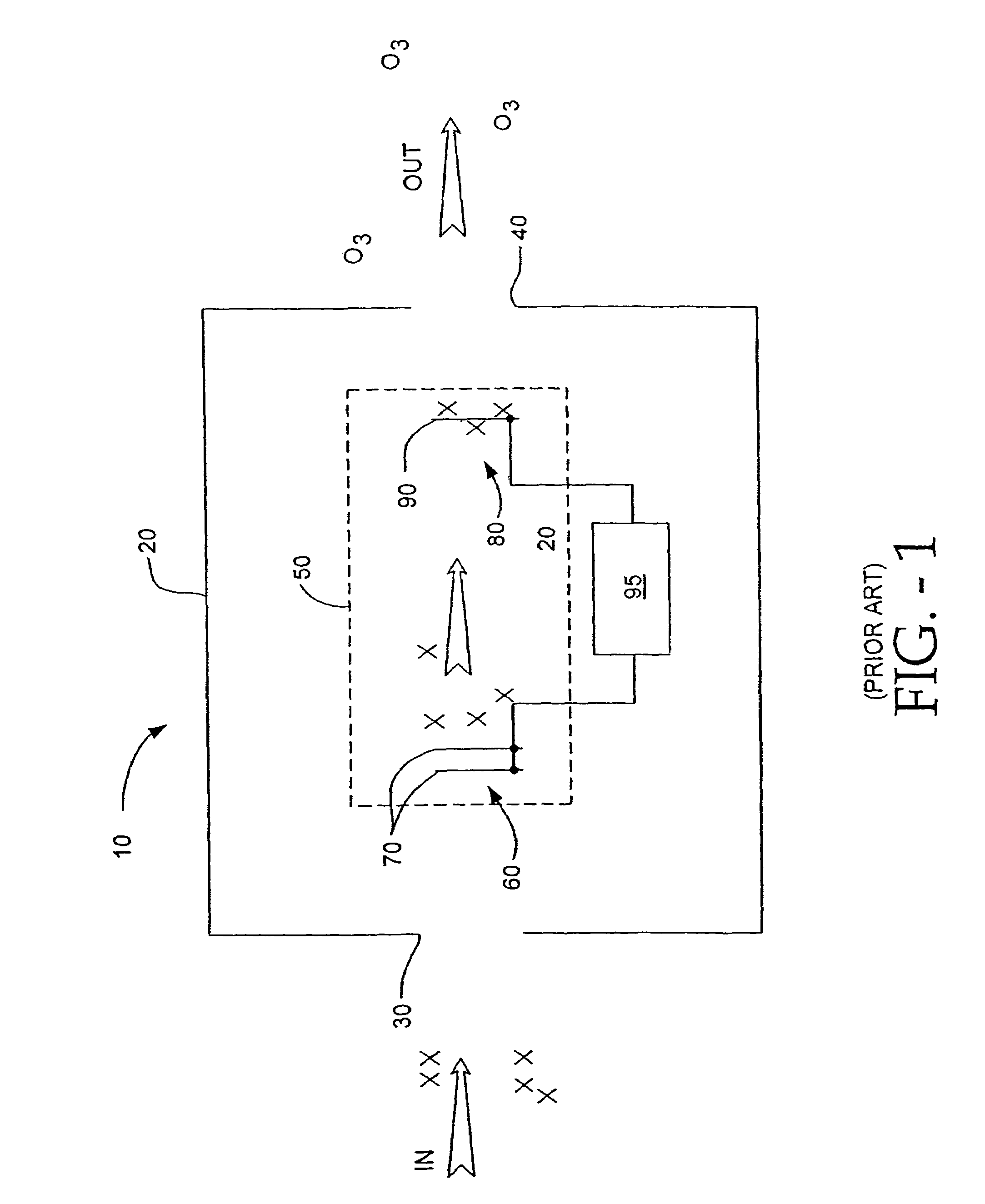

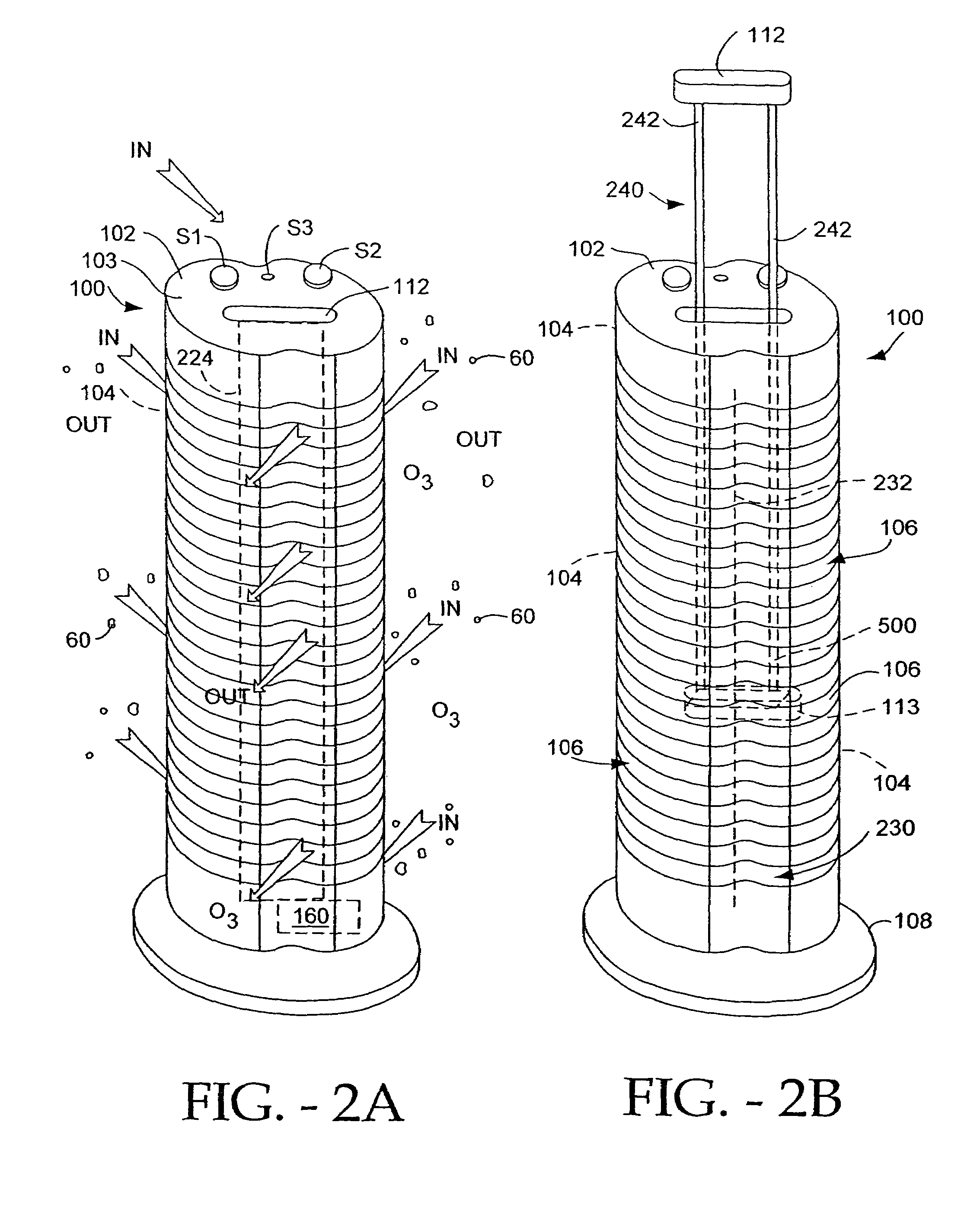

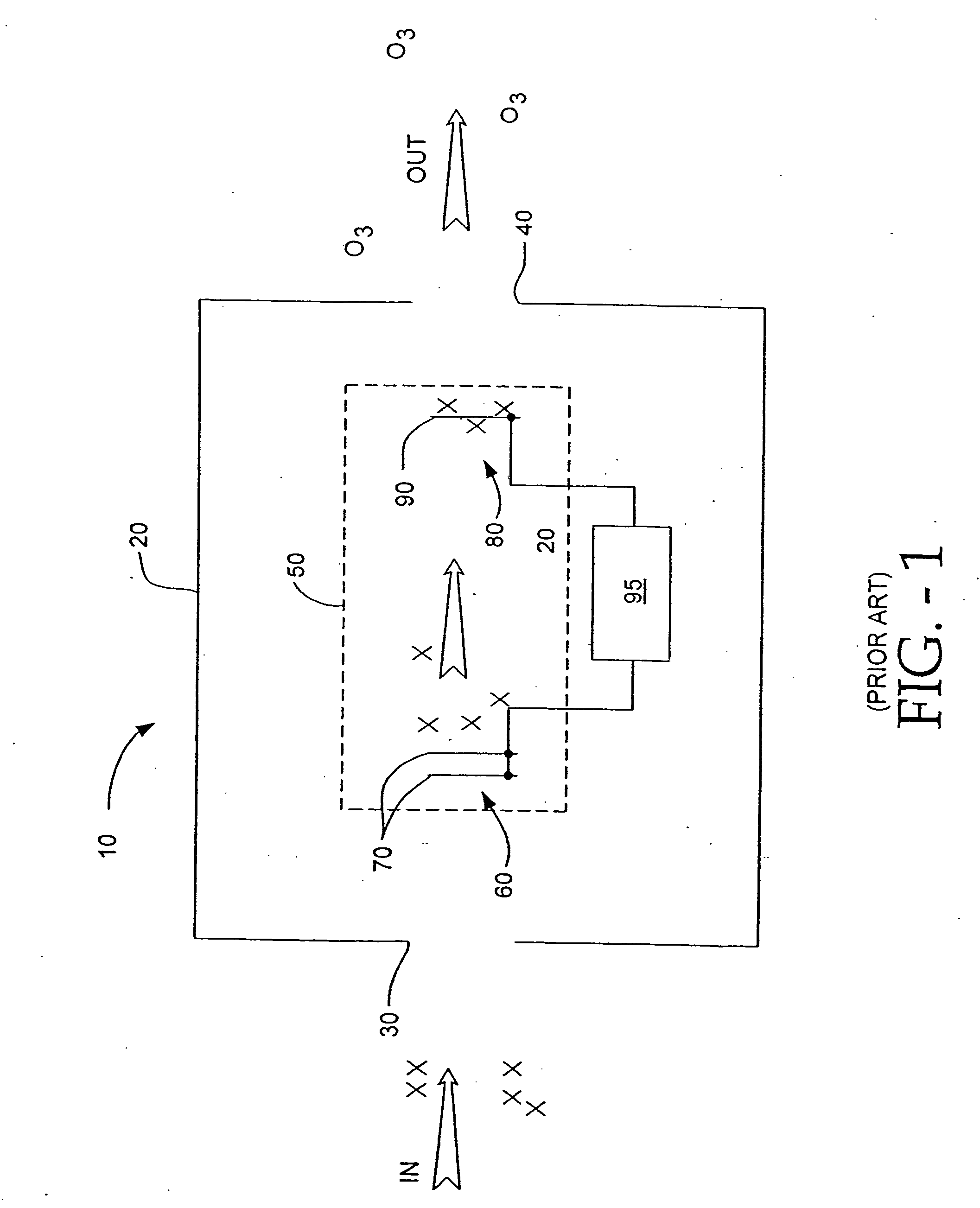

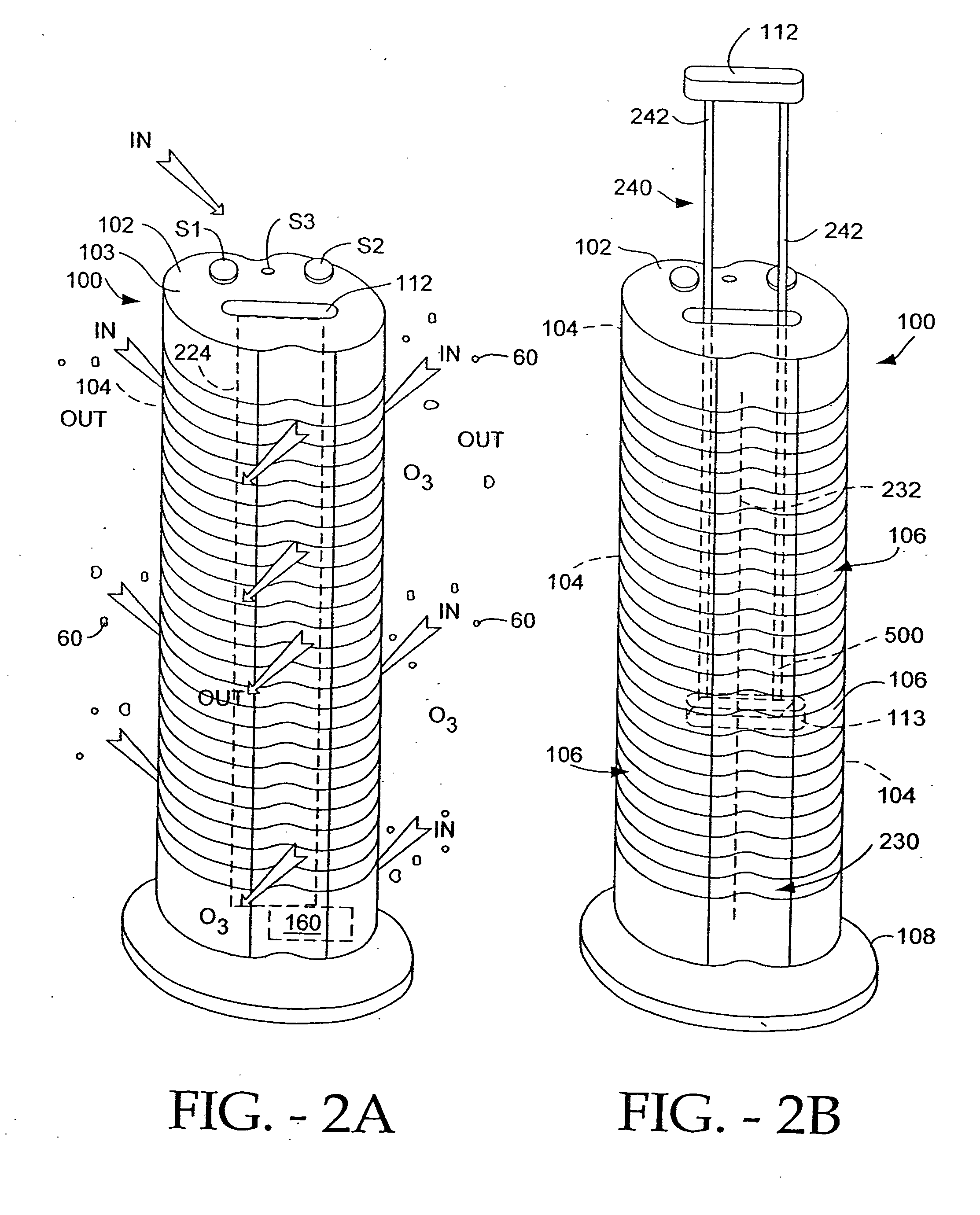

System for purifying and removing contaminants from gaseous fluids

ActiveUS6939397B2Maximizes exposureMinimize timeCombination devicesMechanical apparatusWaste managementRadiation

A system and corresponding methods for purifying and removing contaminants from gaseous fluids includes a housing including an inlet, an outlet, and an elongated UV chamber disposed within the housing. The UV radiation source is disposed longitudinally within the UV chamber. At least one baffle structure is disposed at an upstream location within the housing to restrict flow as well as to generate a turbulent flow of the gaseous fluid within the UV chamber. In addition, a fan is disposed at a selected location within the housing to facilitate a flow of the gaseous fluid through the housing at a selected flow rate. The dimensions of the UV chamber and UV source and the configuration of the baffle structure are selected to increase the exposure time and mixing of fluid flowing through the UV chamber as well as increase the proximity of the flowing fluid to the UV source.

Owner:VYSTAR CORP

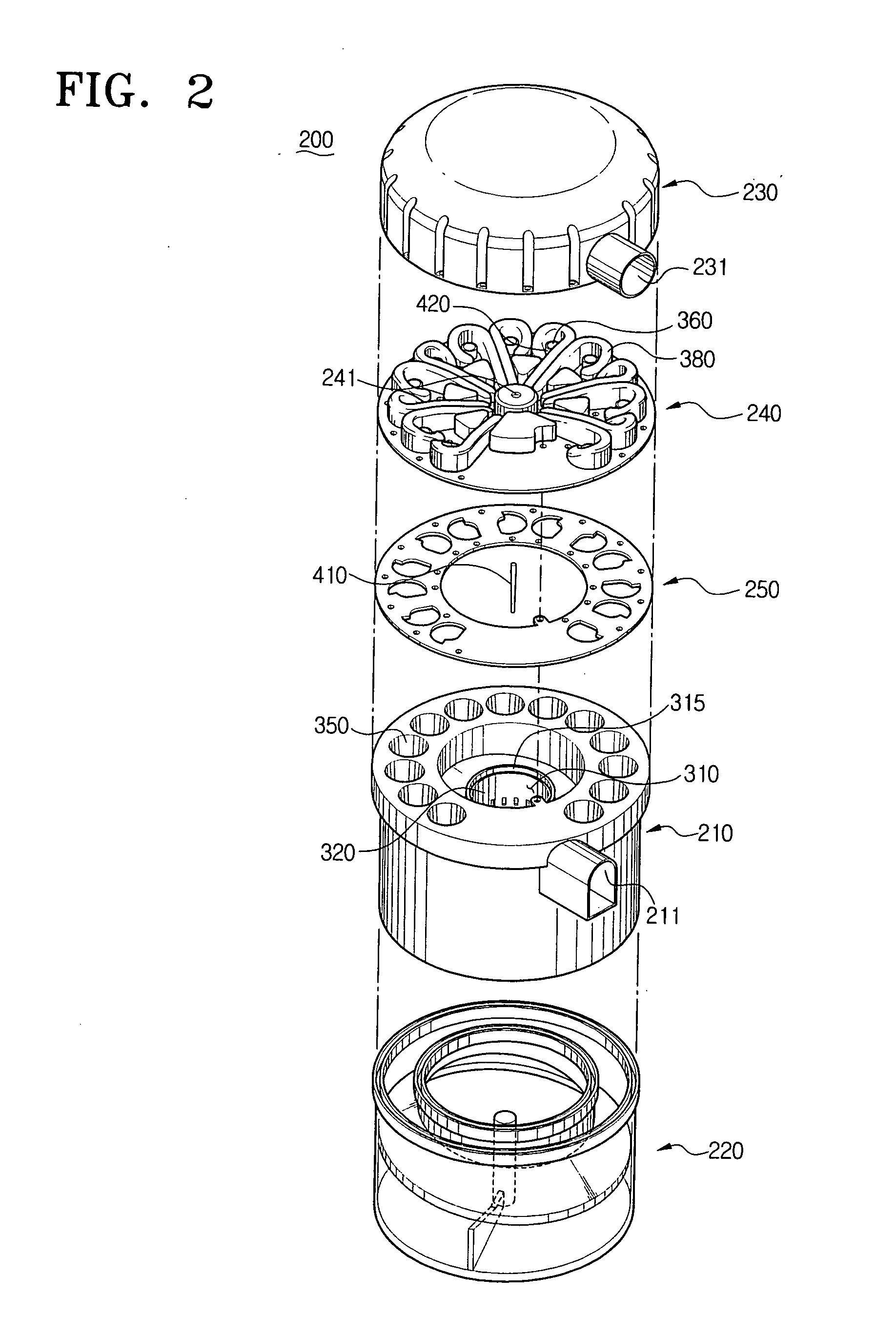

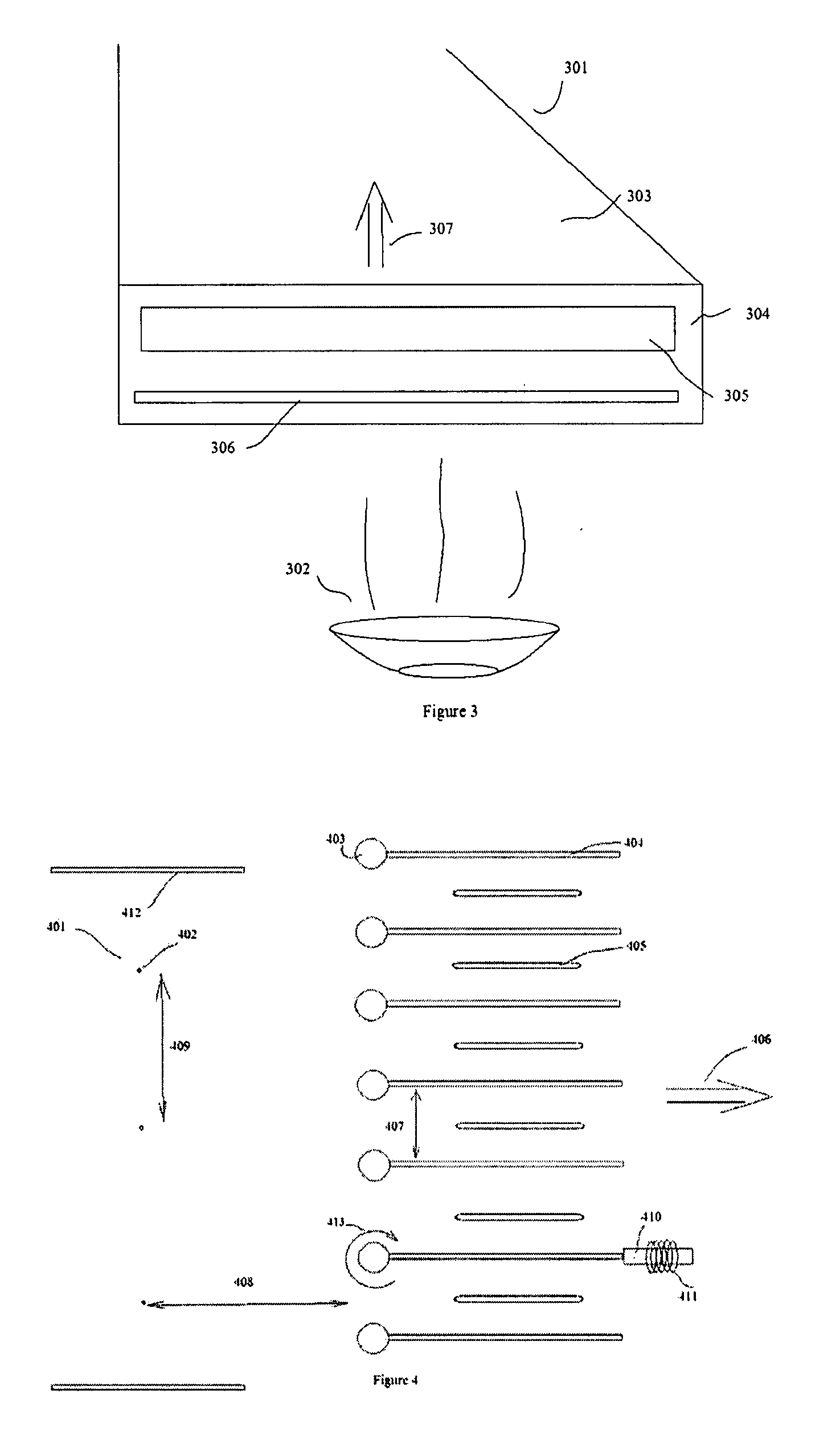

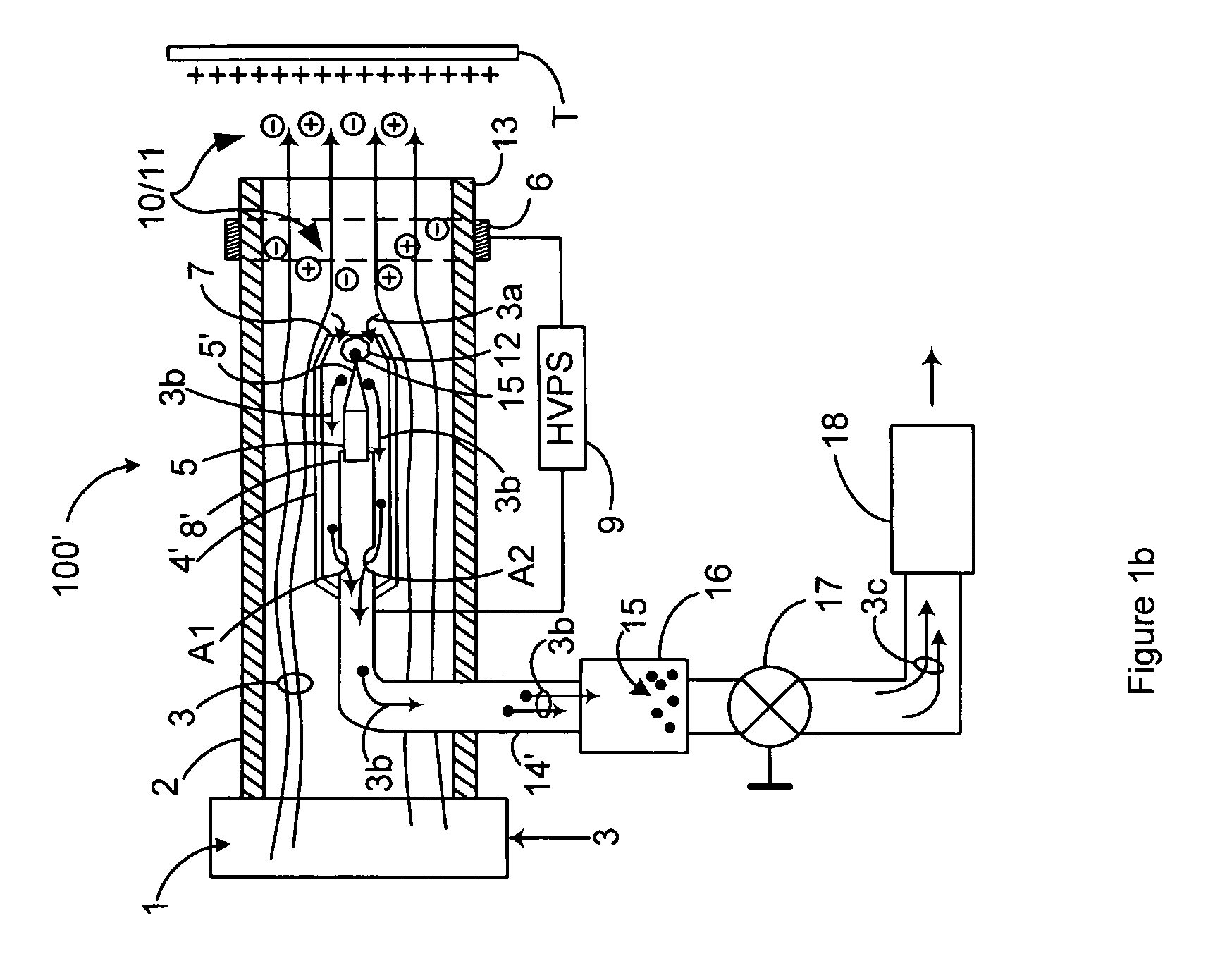

Air conditioner device with trailing electrode

InactiveUS20050000793A1Increase air velocityEasy to collectMechanical apparatusLighting and heating apparatusParticulatesEmissivity

An electro-kinetic air conditioner for removing particulates from the air creates an airflow using no moving parts. The conditioner includes an ion generator that has an electrode assembly including a first array of emitter electrodes, a second array of collector electrodes, and a high voltage generator. Preferably, a third or leading or focus electrode is located upstream of the first array of emitter electrodes, and / or a trailing electrode is located downstream of the second array of collector electrodes. The device can also include an interstitial electrode located between collector electrodes, an enhanced collector electrode with an integrally formed trailing end, and an enhanced emitter electrode with an enhanced length in order to increase emissitivity.

Owner:THE SHARPER IMAGE

System for purifying and removing contaminants from gaseous fluids

ActiveUS20050000365A1Maximizes exposureMinimize timeCombination devicesMechanical apparatusEngineeringWaste management

A system and corresponding methods for purifying and removing contaminants from gaseous fluids includes a housing including an inlet, an outlet, and an elongated UV chamber disposed within the housing. The UV radiation source is disposed longitudinally within the UV chamber. At least one baffle structure is disposed at an upstream location within the housing to restrict flow as well as to generate a turbulent flow of the gaseous fluid within the UV chamber. In addition, a fan is disposed at a selected location within the housing to facilitate a flow of the gaseous fluid through the housing at a selected flow rate. The dimensions of the UV chamber and UV source and the configuration of the baffle structure are selected to increase the exposure time and mixing of fluid flowing through the UV chamber as well as increase the proximity of the flowing fluid to the UV source.

Owner:VYSTAR CORP

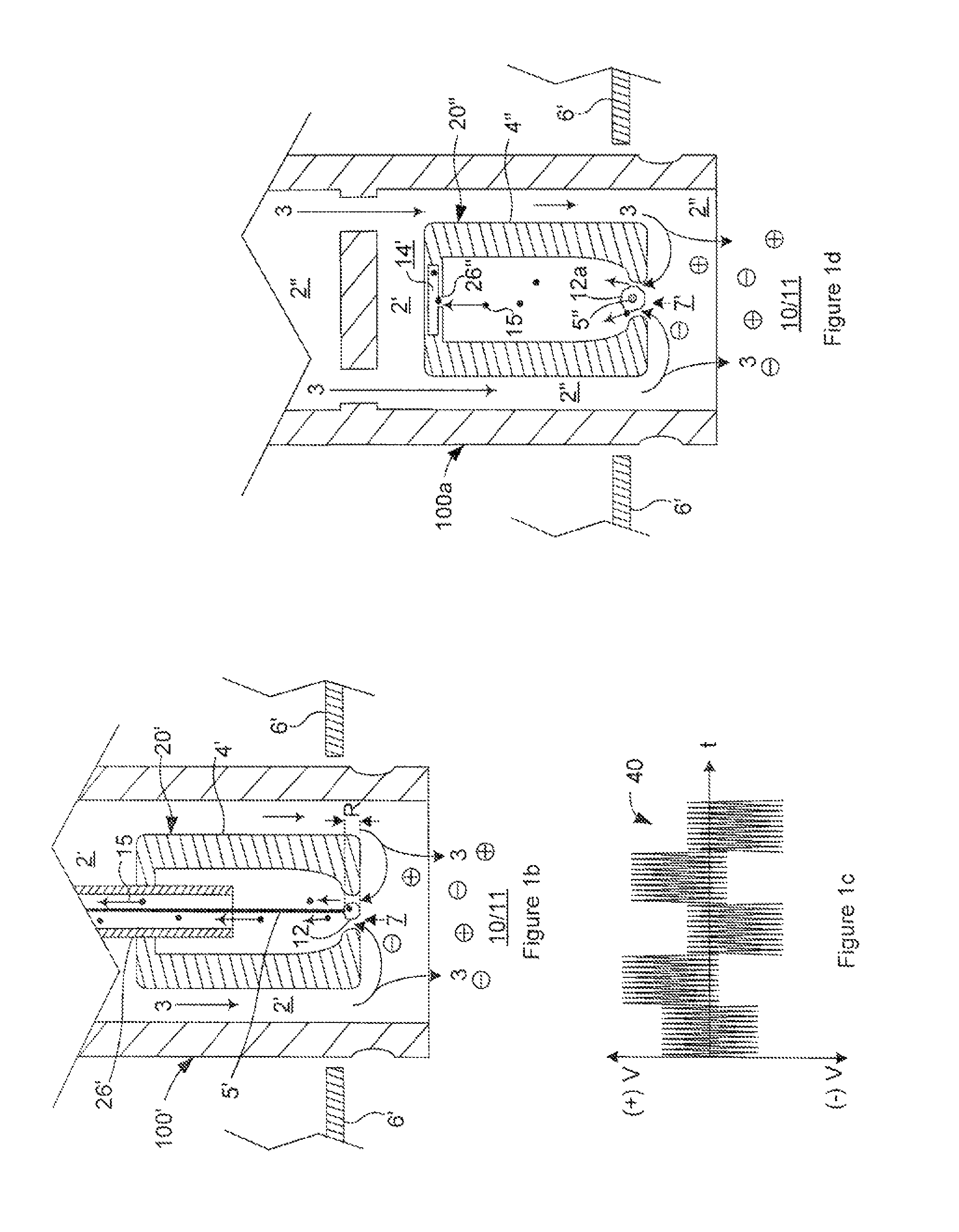

Cross-flow differential migration classifier

ActiveUS6905029B2Increase field strengthReduce flow rateSolvent extractionDialysisPhysicsCross Circulation

A method, system, apparatus, and article of manufacture provide a cross-flow migration classifier capable of separating particles. The classifier provides a channel through which a sample, having one or more particles, passes in a first direction, wherein the channel comprises two or more walls that are permeable to a flow of fluid. A cross-flow enters the channel through one of the permeable walls and exits through another of the permeable walls. An imposed field is applied in a second direction that is counter to the cross-flow and having an orthogonal component to the first direction. The imposed field causes one or more of the particles to migrate at a first velocity opposite and / or equal to a second velocity of the cross-flow. The particles that migrate opposite to the cross-flow are continuously discharged from the cross-flow migration classifier.

Owner:CALIFORNIA INST OF TECH

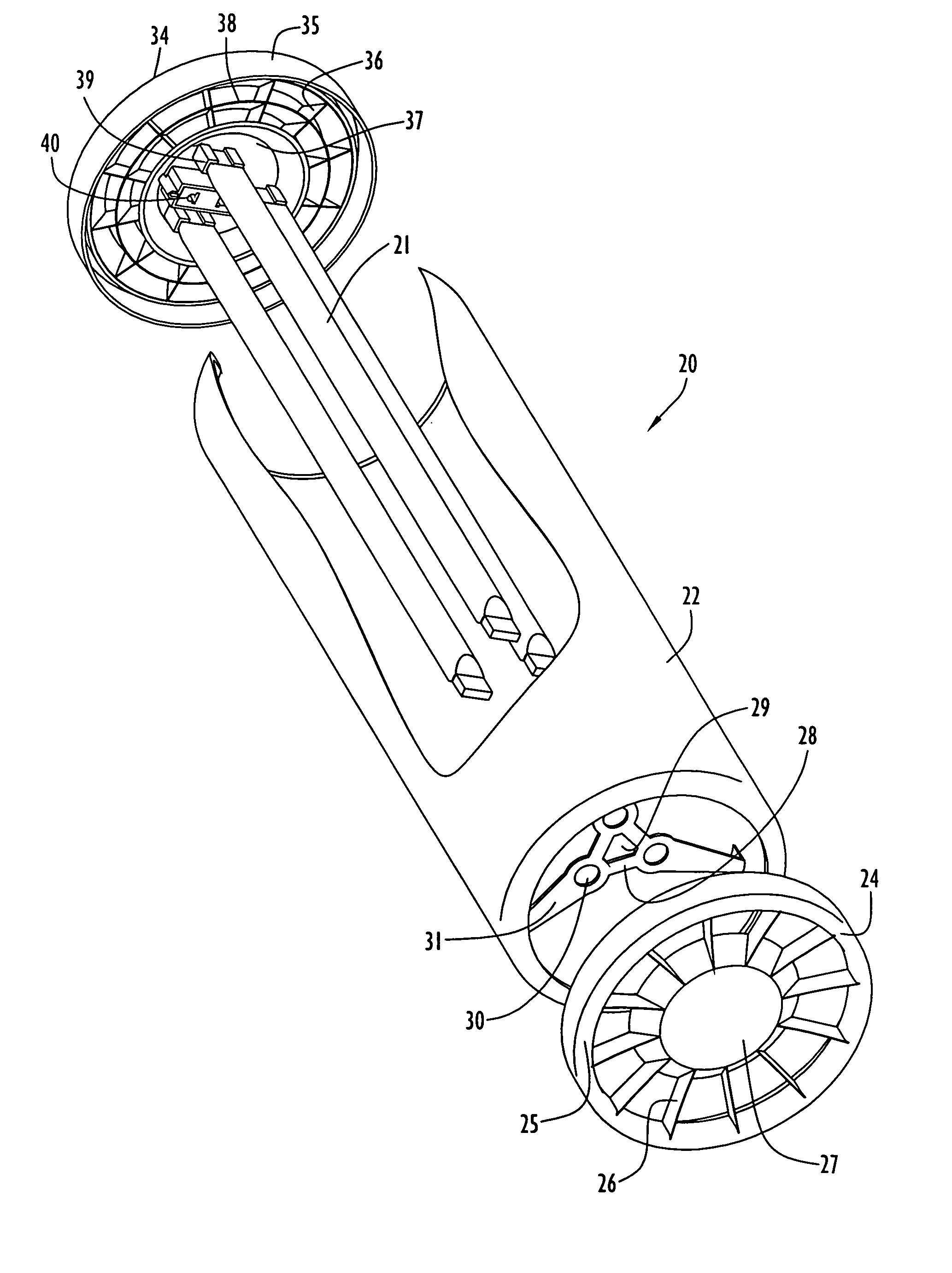

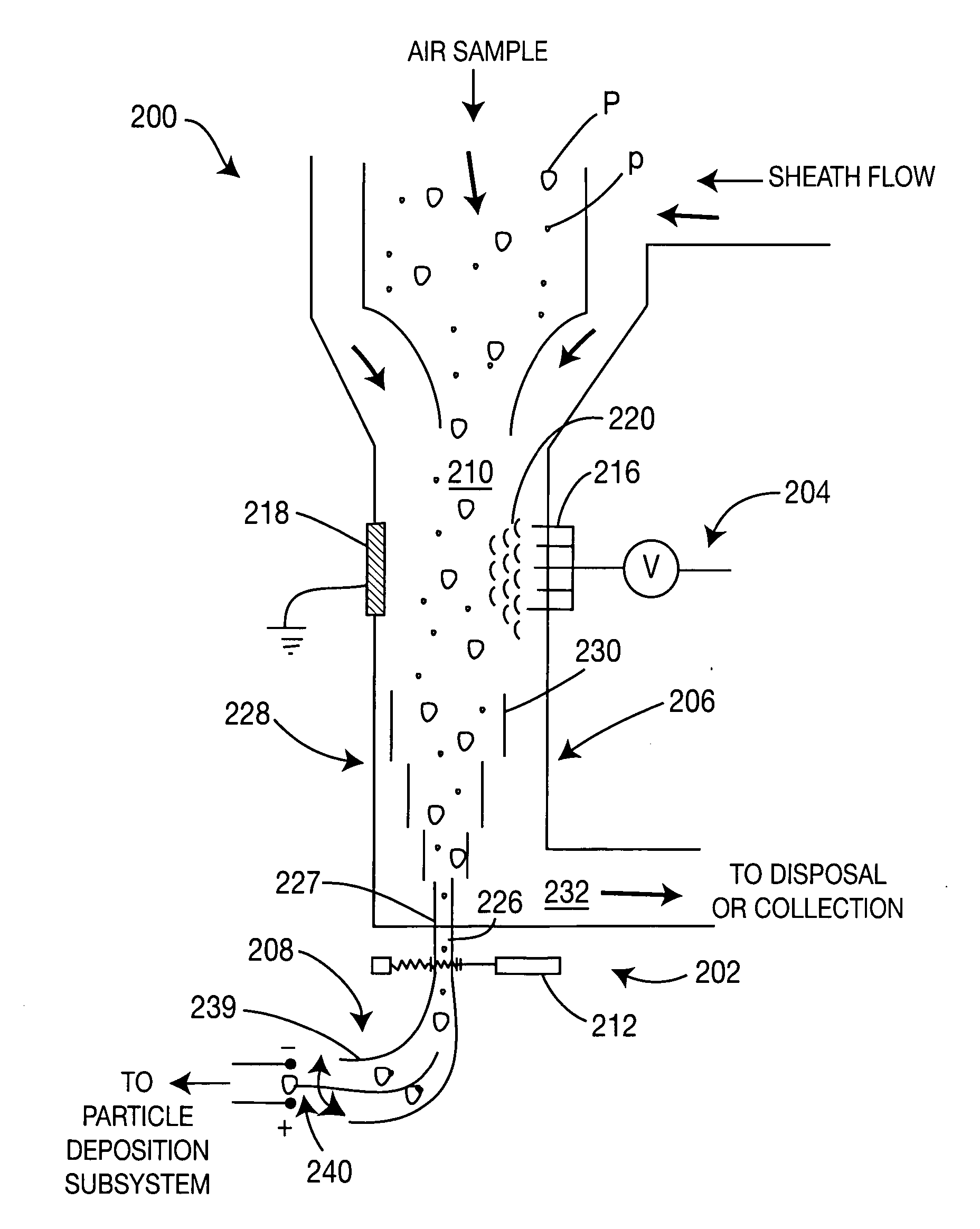

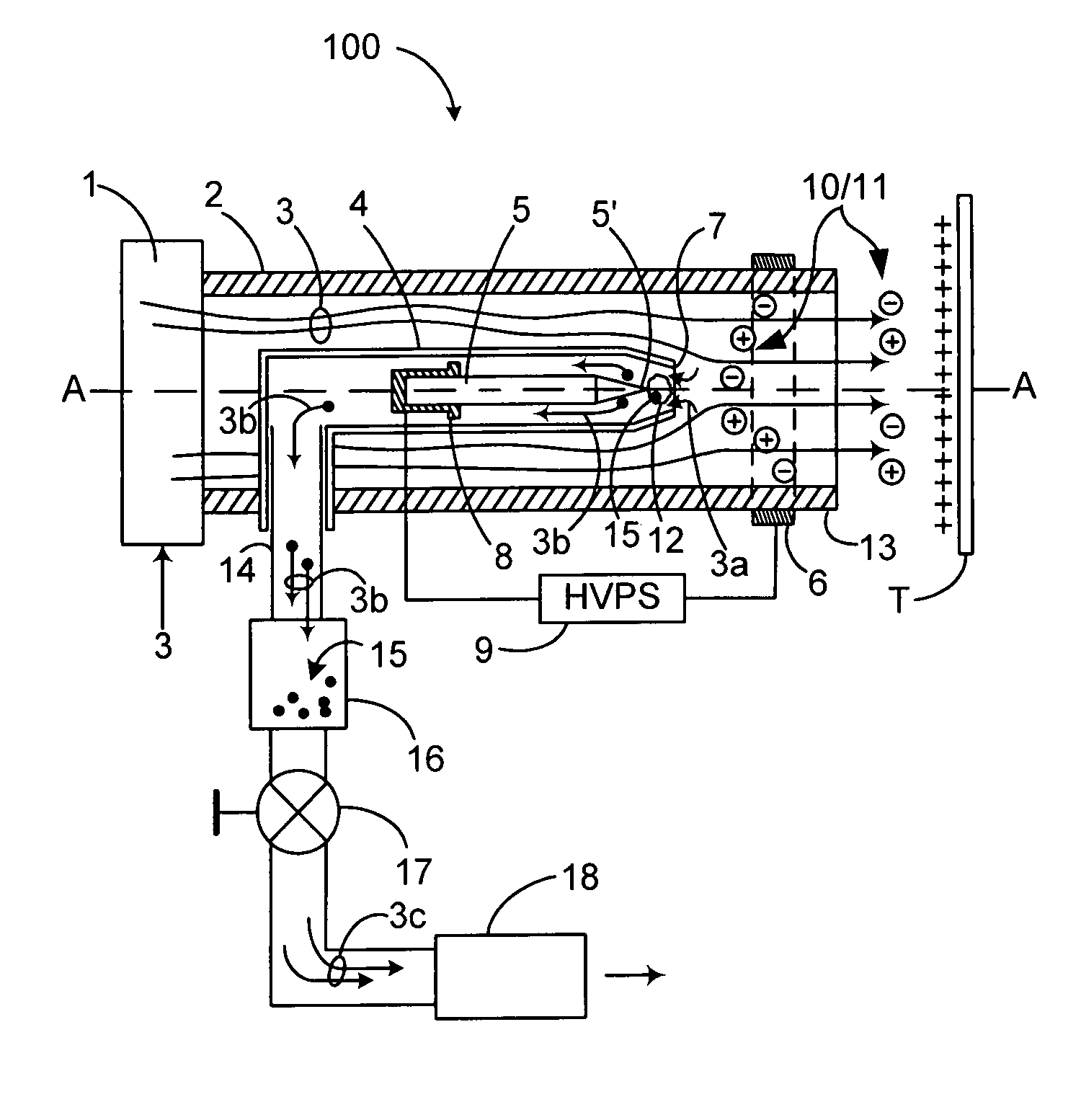

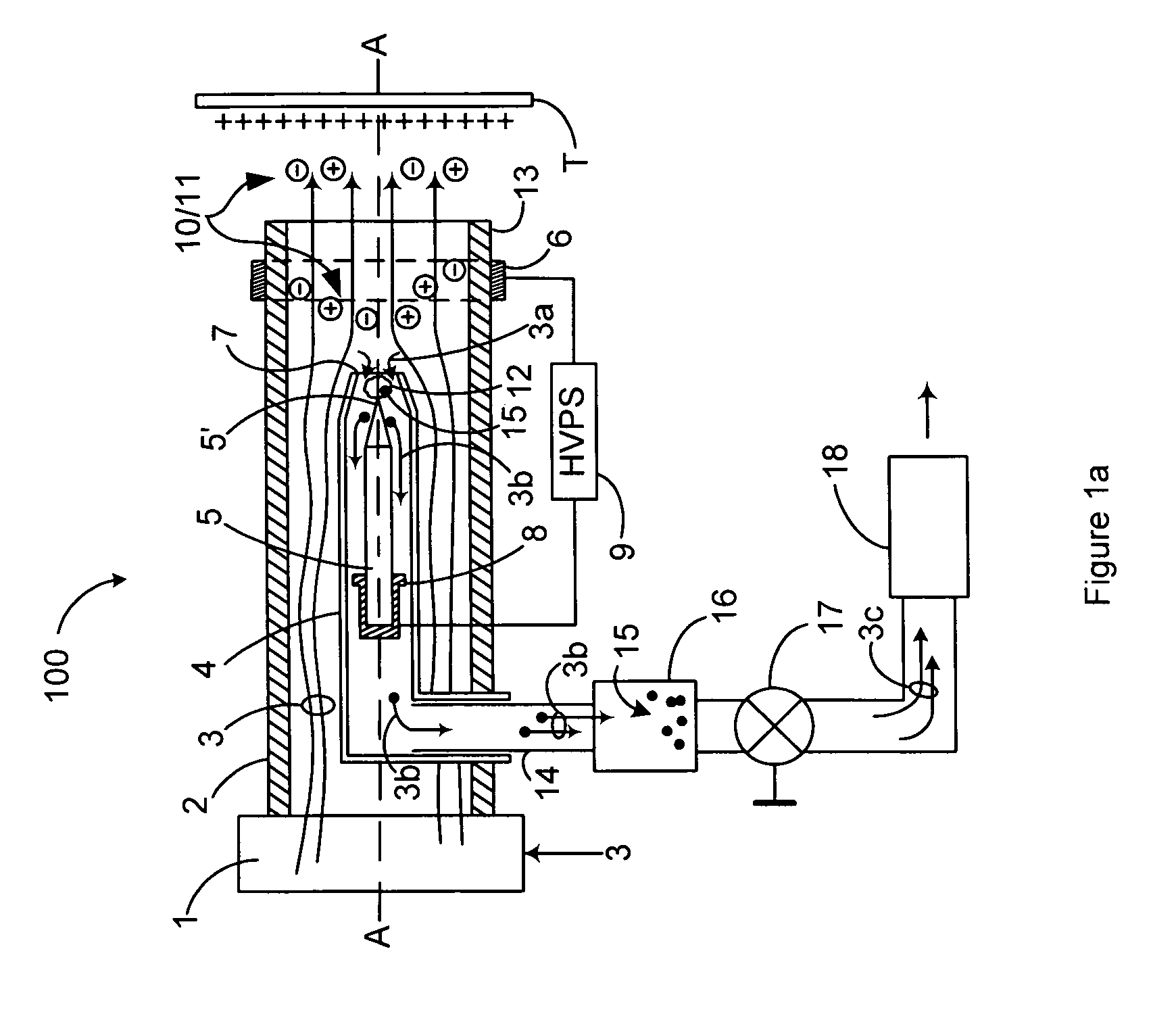

Method and apparatus for airborne particle sorting

InactiveUS20050105079A1Precise particle focusingAccurate focusElectrolysis componentsVolume/mass flow measurementTarget surfaceParticle physics

An apparatus for airborne particle sorting is provided comprising a charging system adapted for applying an electrostatic charge to the particles, such that particles of at least a first group are deflected to a greater extent than particles of a second group are deflected. A focusing system is adapted for electrostatically focusing substantially at least the particles of the first group into a focused stream that is narrower than the input air stream. A deposition system is adapted for substantially depositing the particles of the first group from the focused stream upon a target surface, where the target surface may be transported to an analysis system capable of analyzing the particles deposited thereon.

Owner:SARNOFF CORP

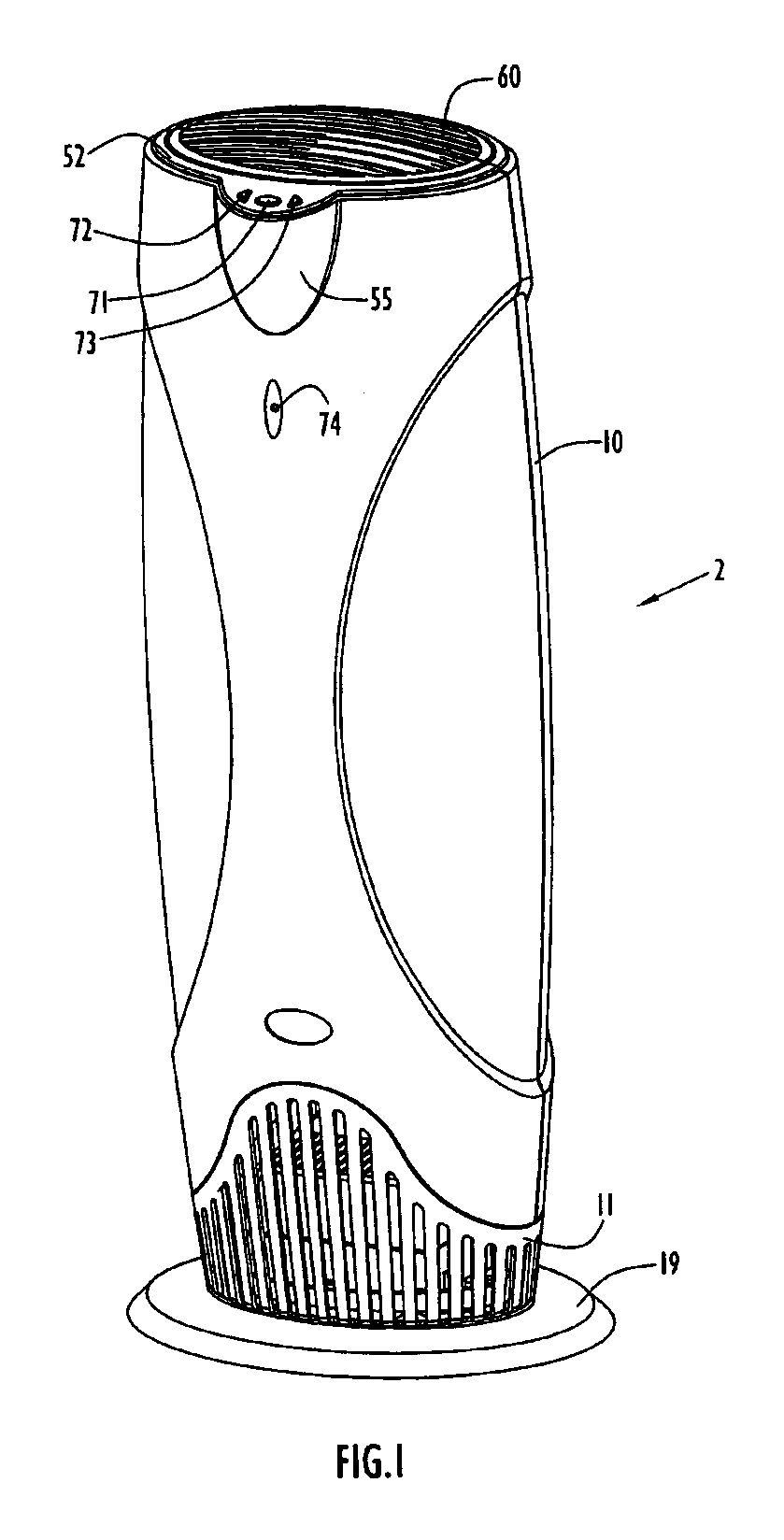

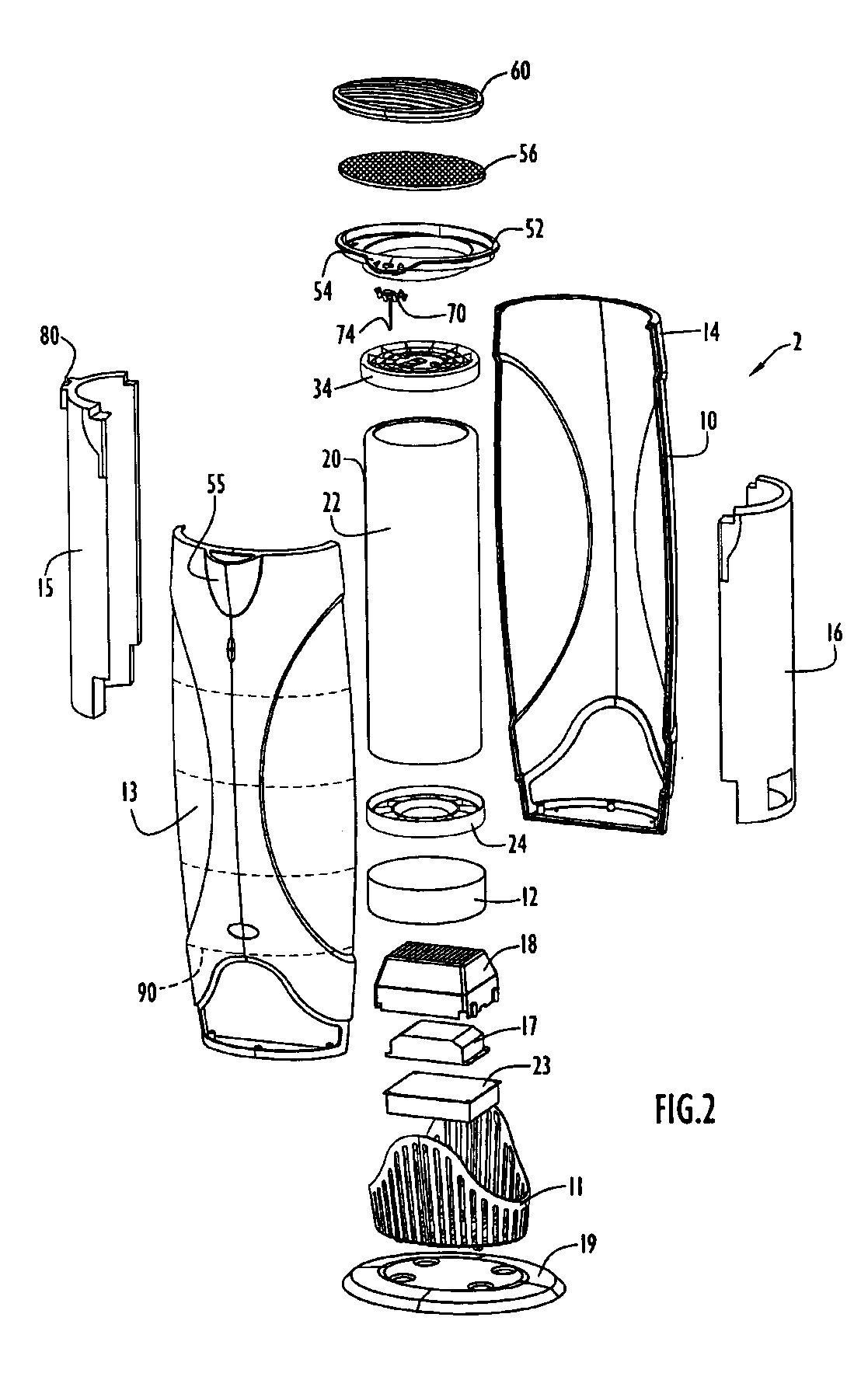

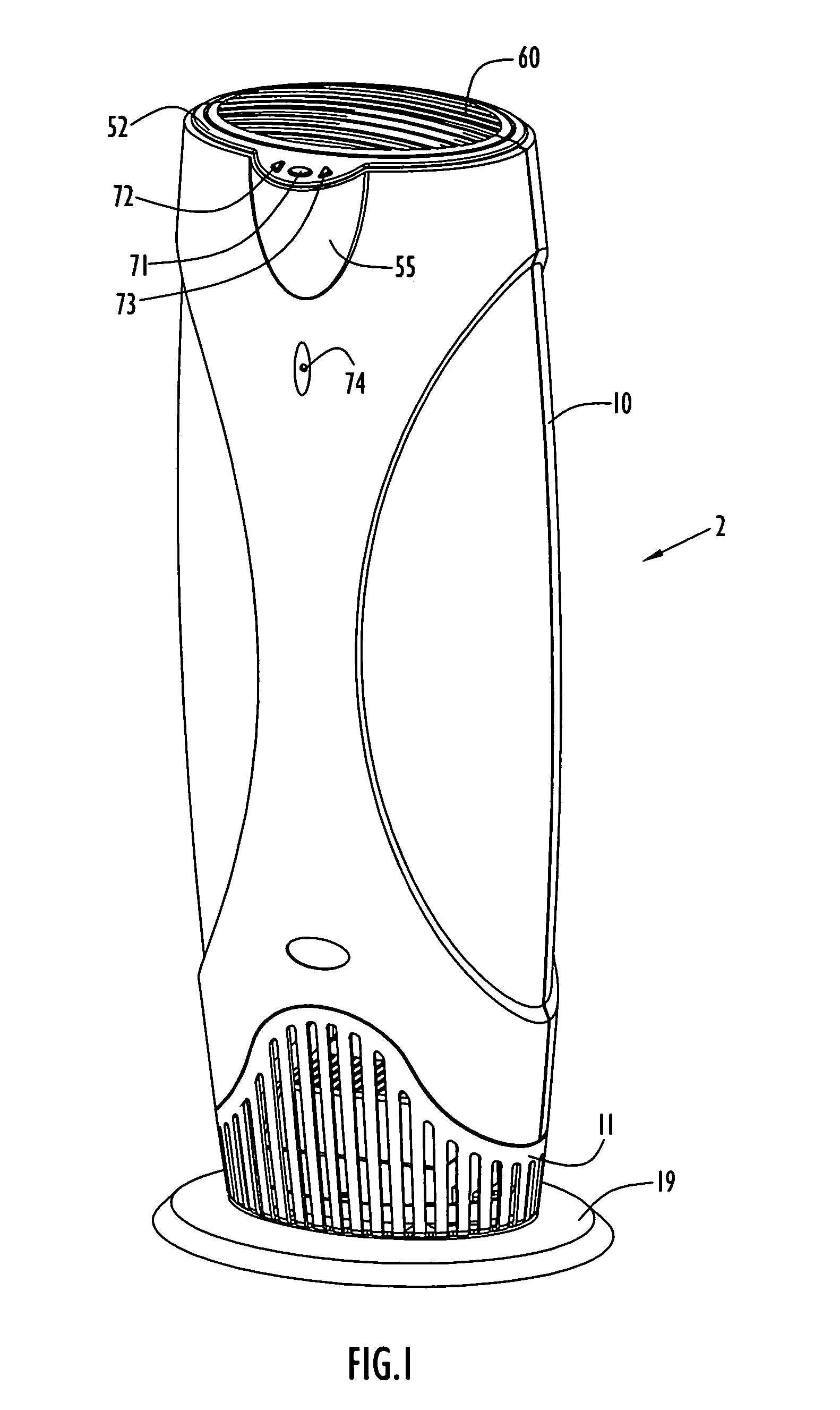

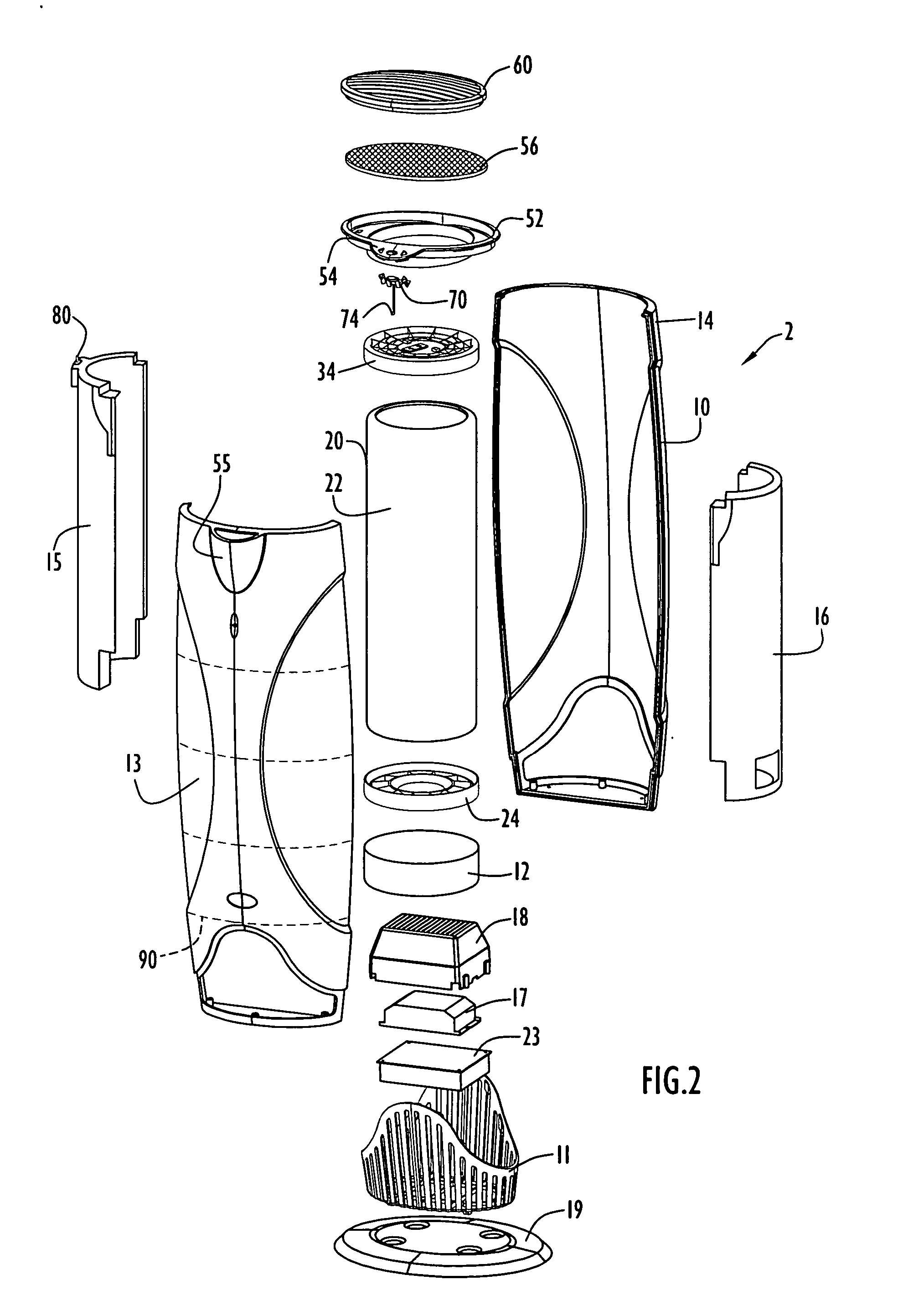

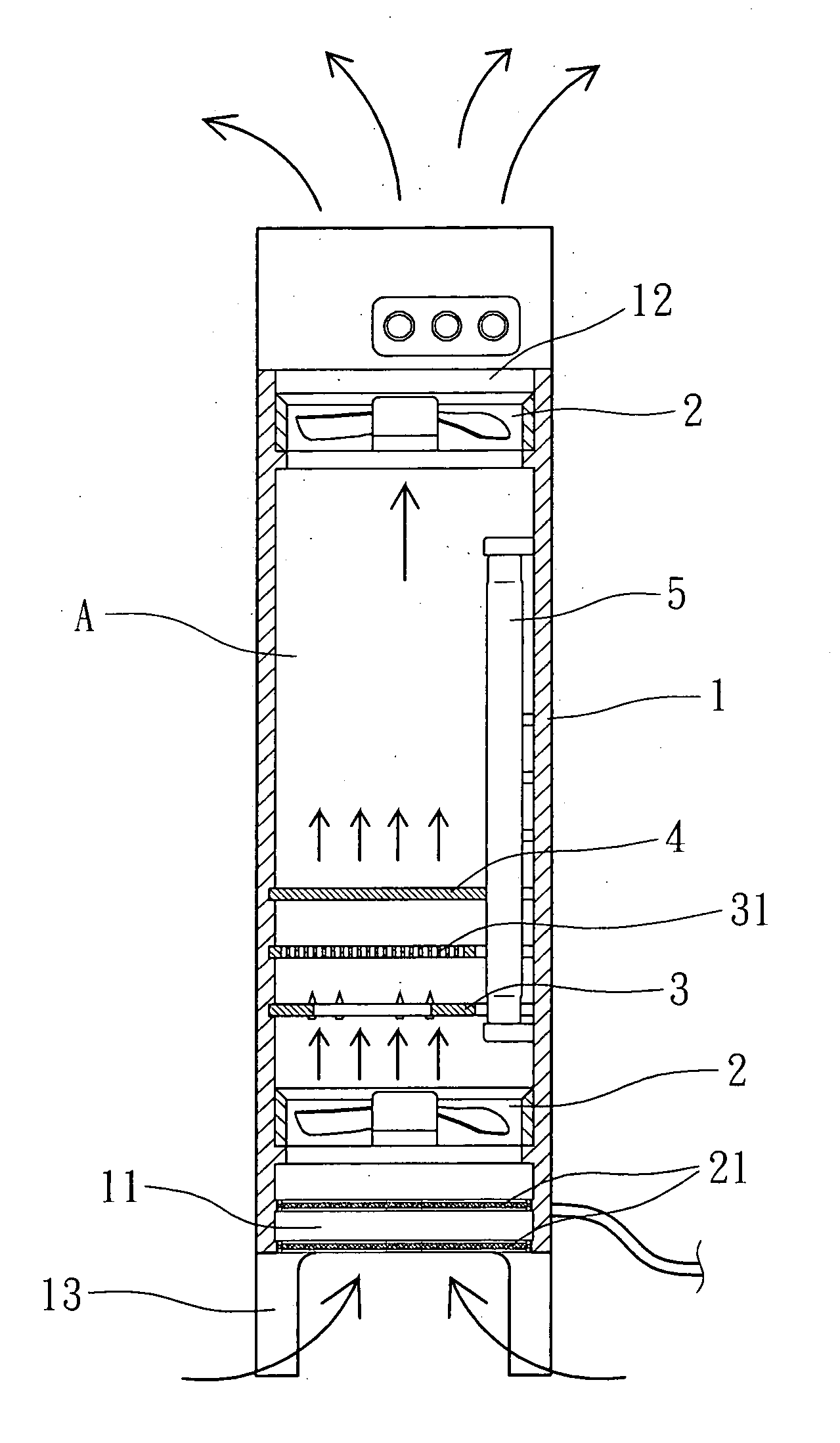

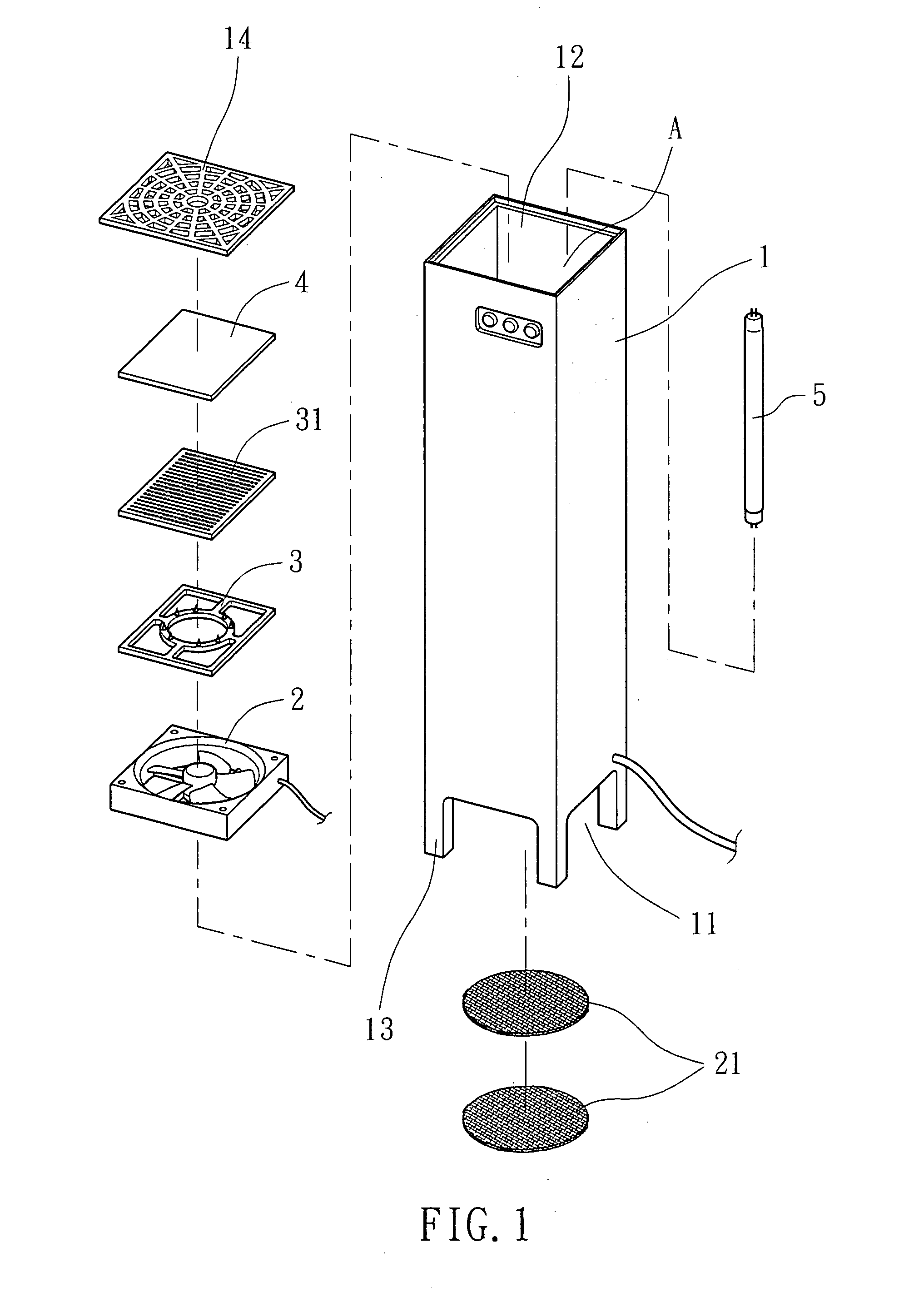

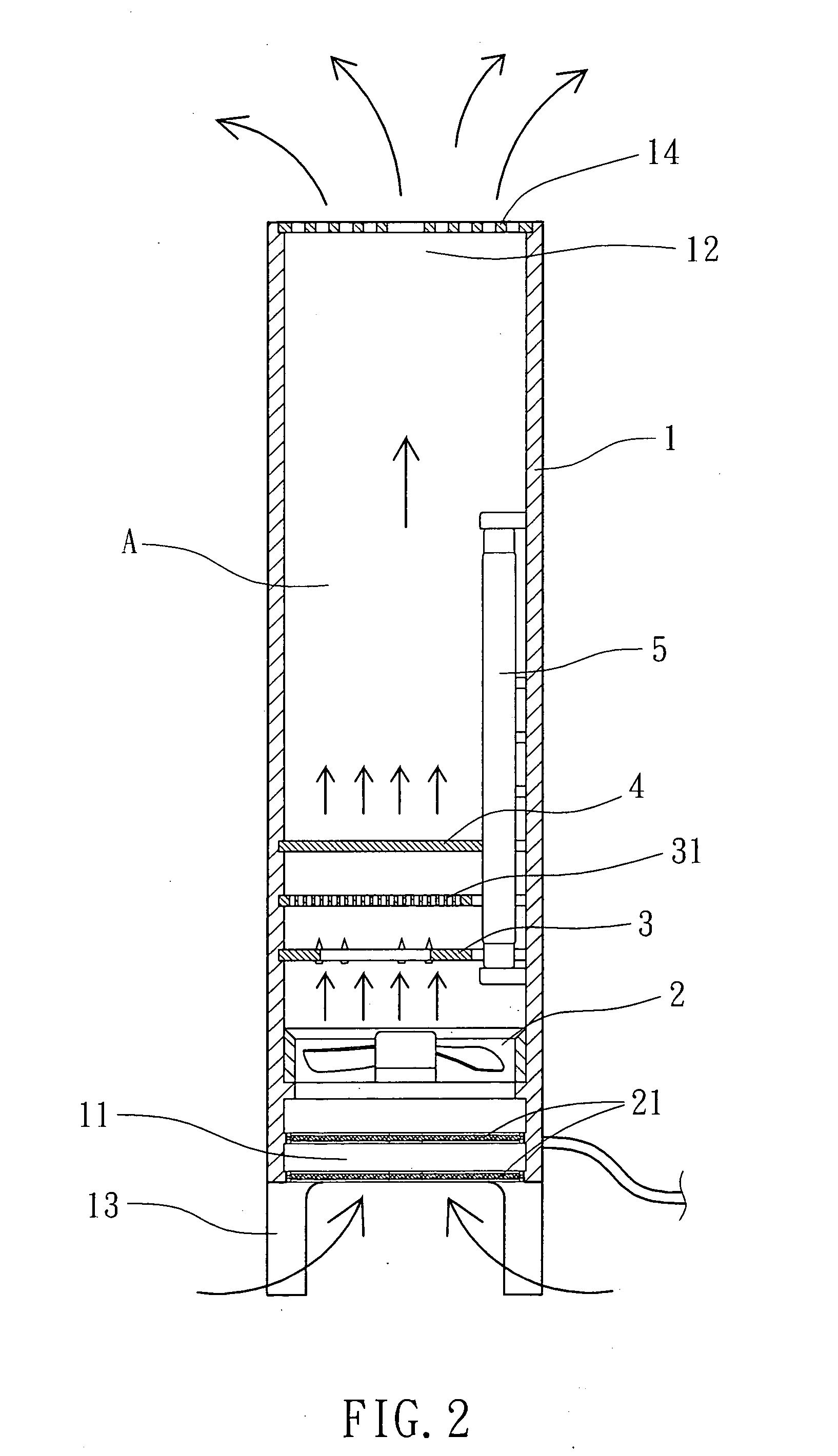

Air purifier

An air purifier includes a vertically disposed housing provided with a wire gauze filter, electric fans and air filter elements. The electric fans draw outside air around the floor vertically into the bottom air intake port toward the top air output port of the housing so that the flow of air, when passed out of the air output port, flows upwards to a certain elevation and is then diffused and lowered in all directions around the housing. By means of the traction of the flow of air, the pressure difference of the convection of air between the low air pressure and the high air pressure at the bottom and top sides of the housing, high concentration of car waste gas, micro dust particles, hair dust, micro fibers and other harmful industrial odors that fall to the floor due to the effect of gravity or floating nearly above the floor are sucked into the inside of the housing by the low air pressure zone at the open bottom side of the housing and then removed by the filter elements.

Owner:WU FU CHI

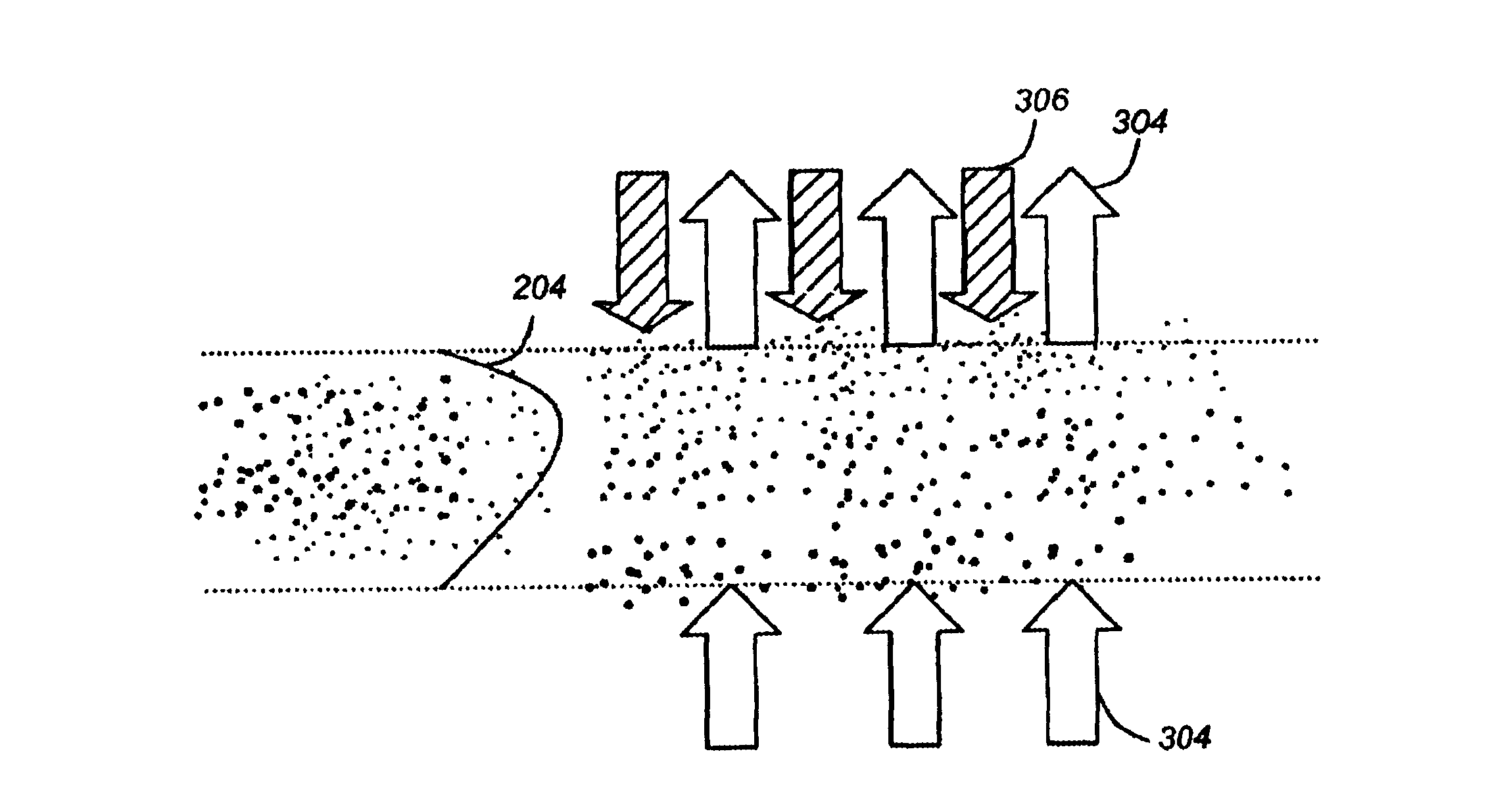

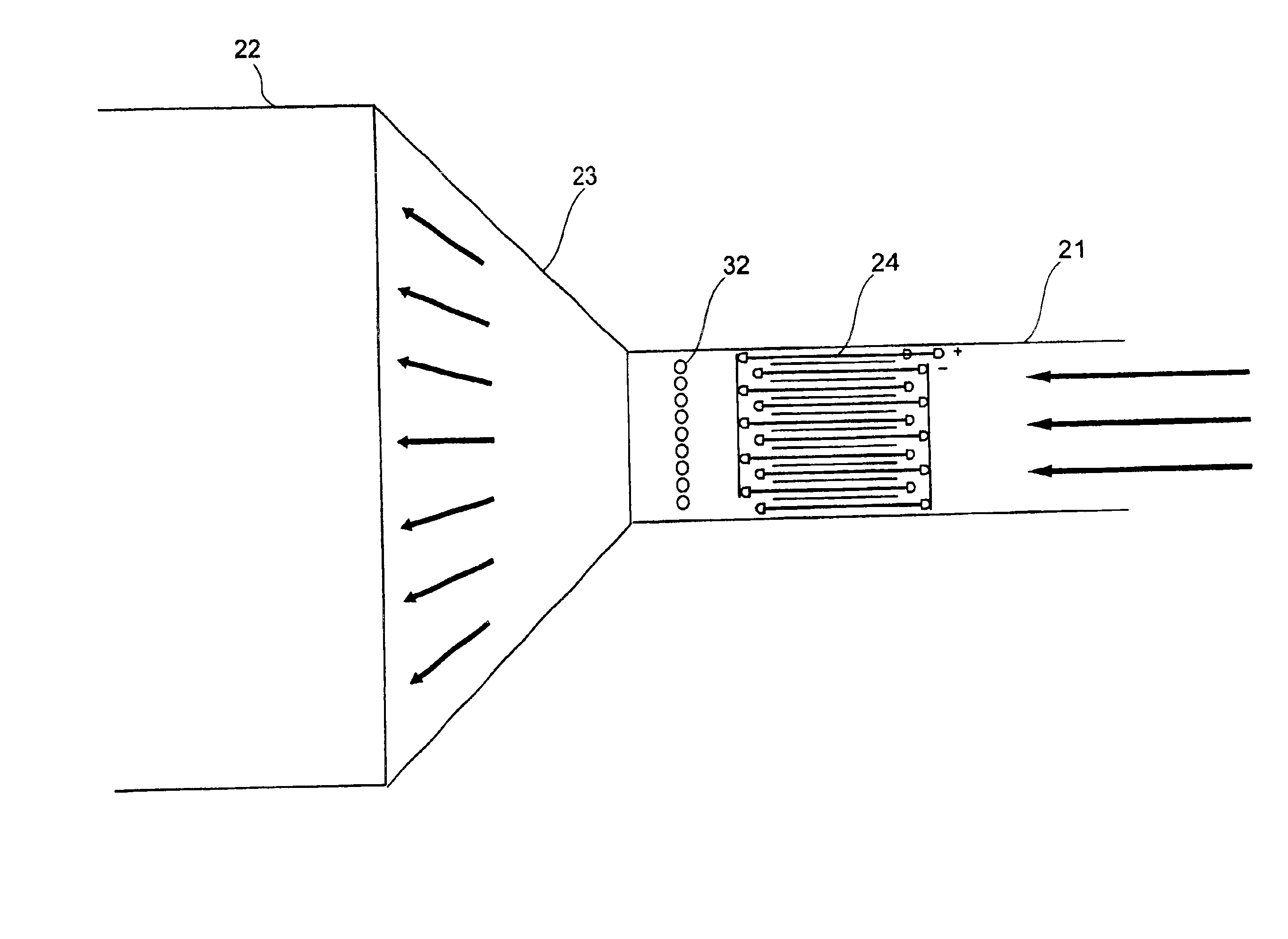

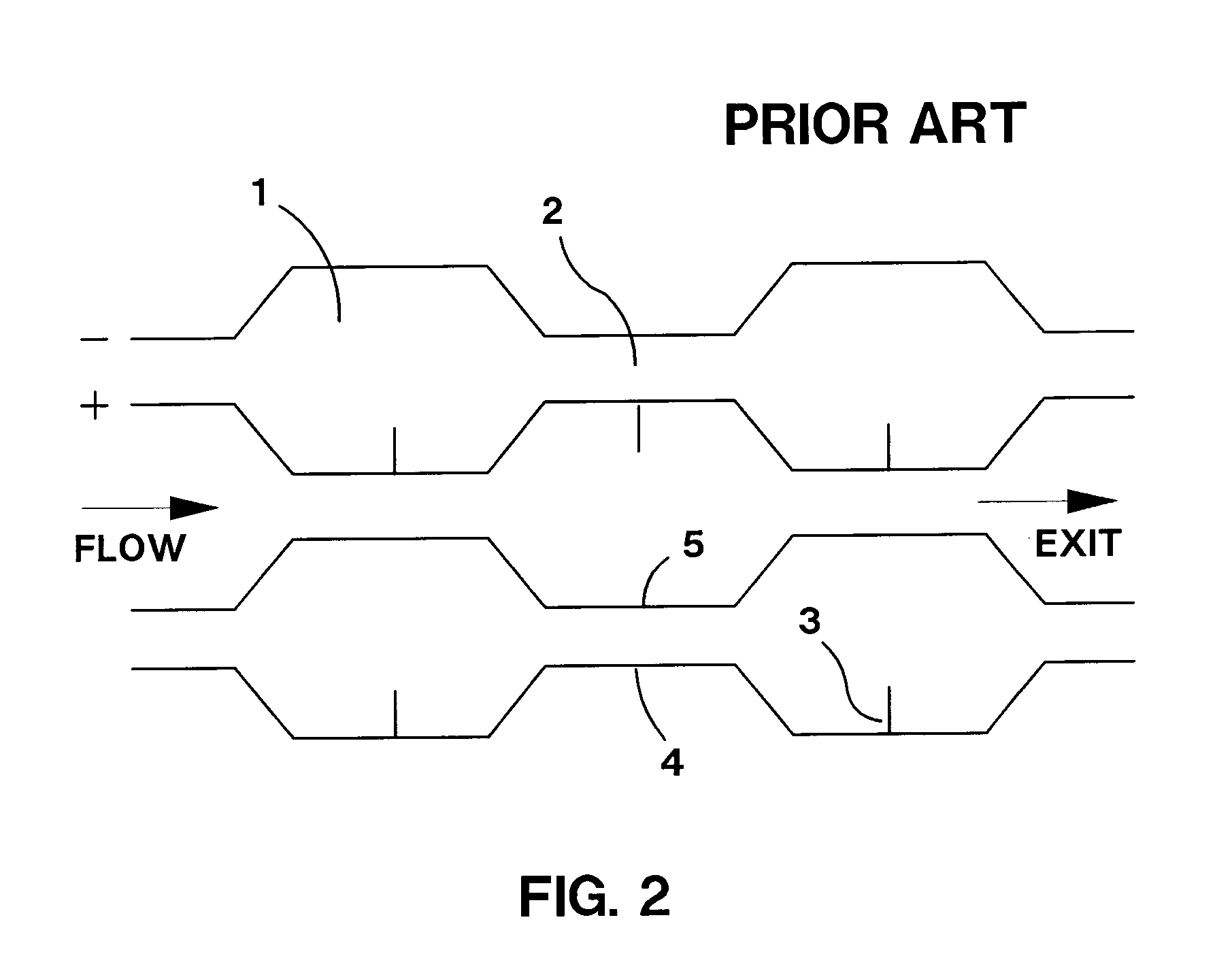

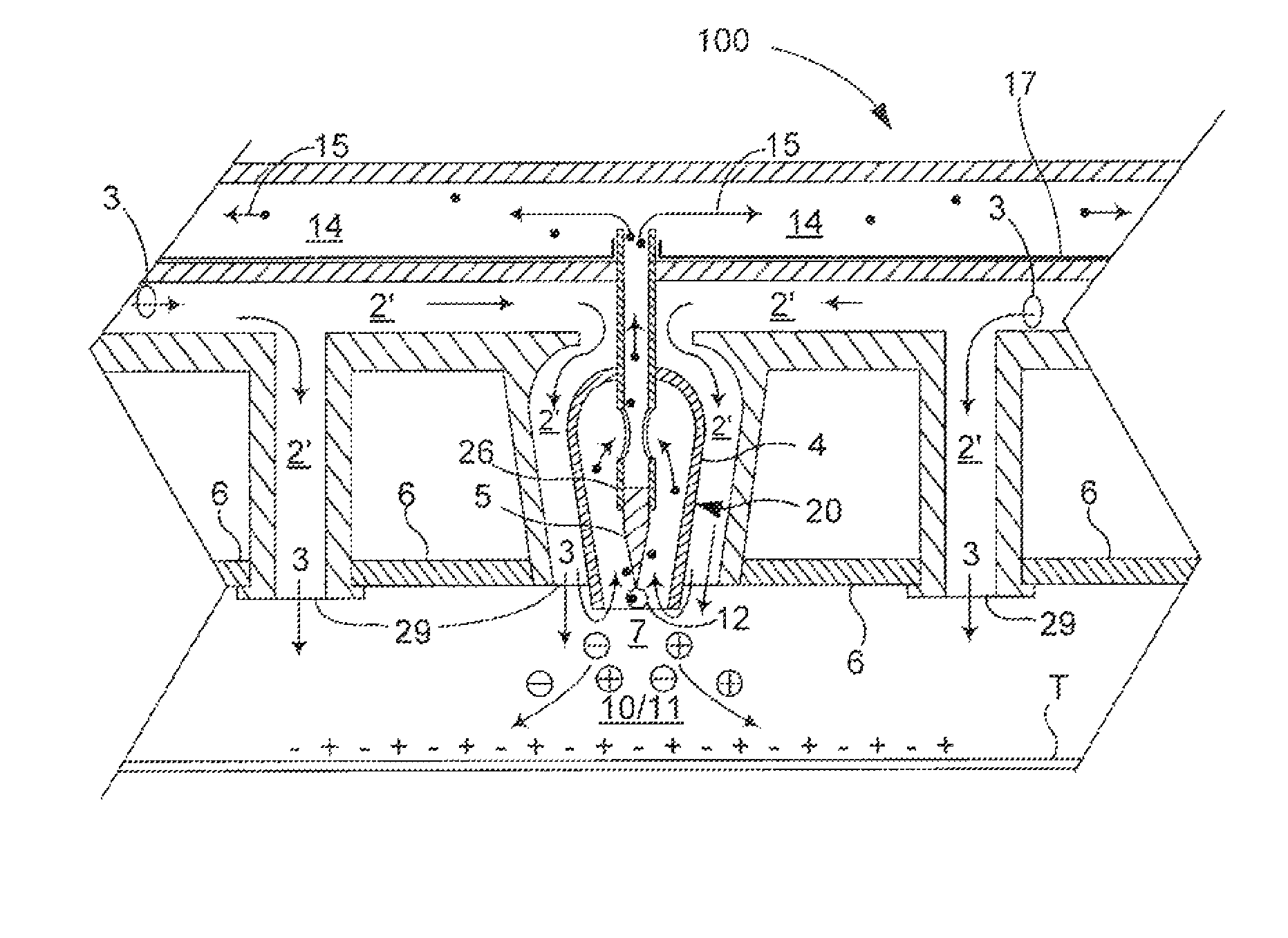

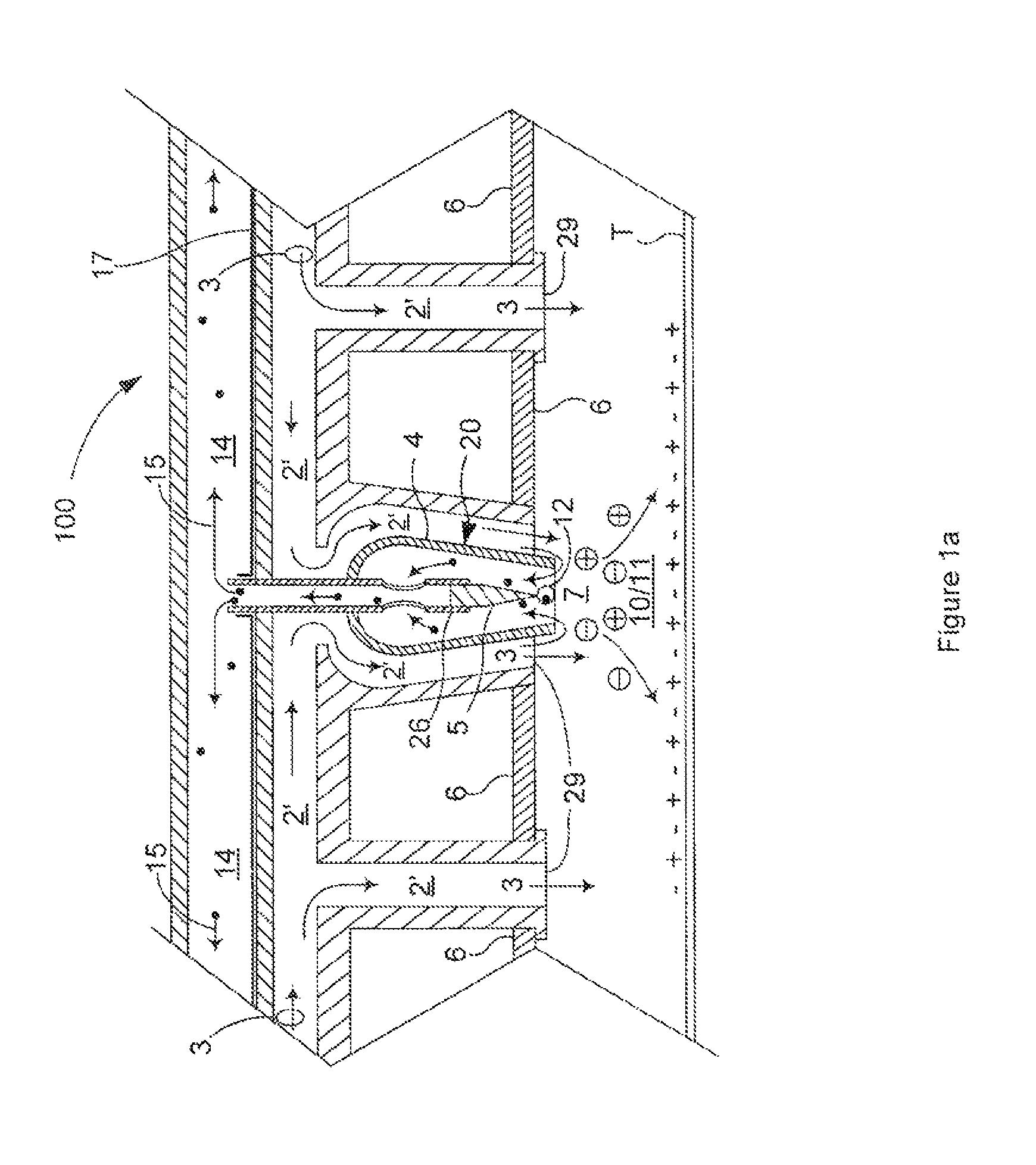

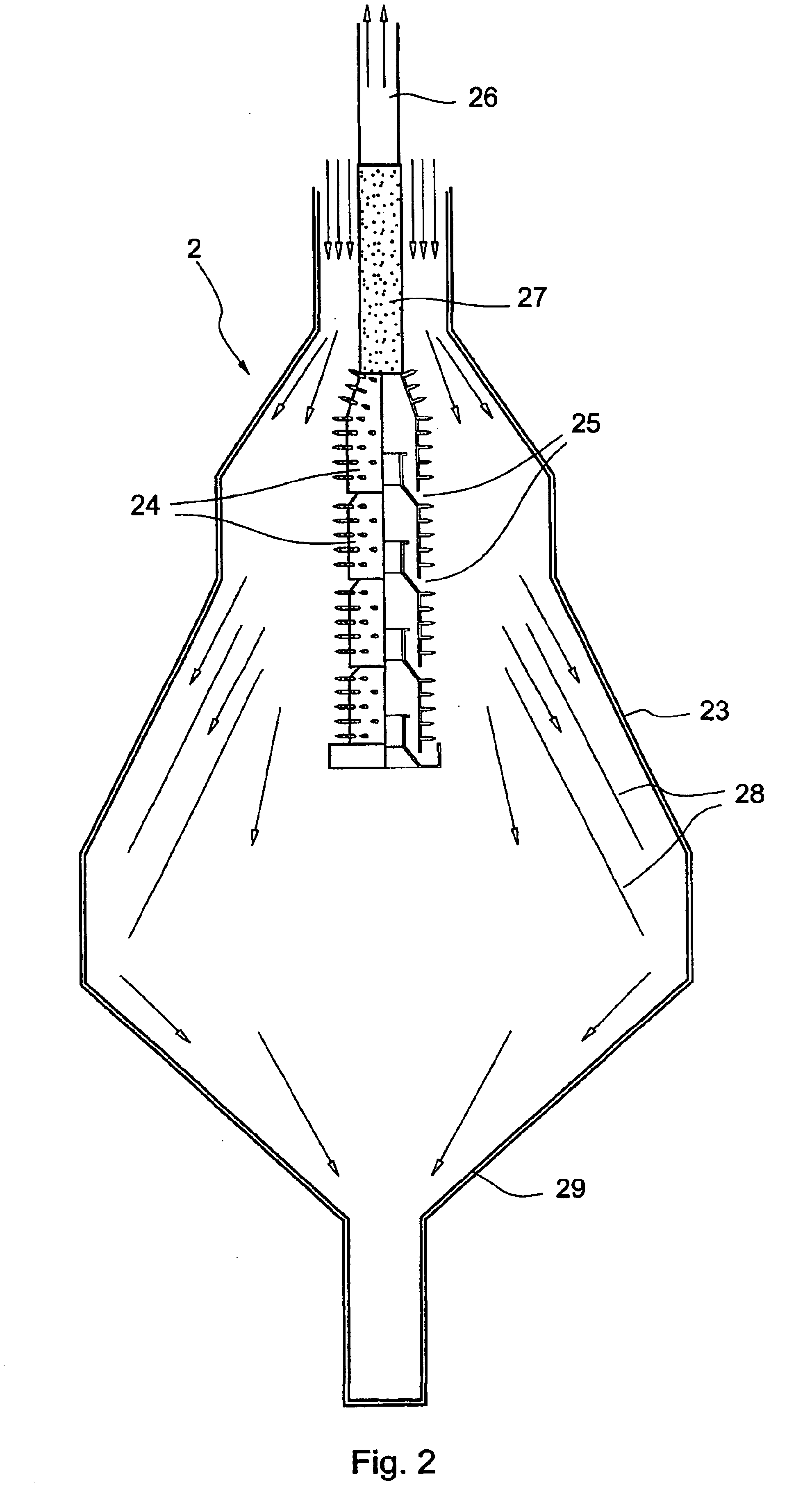

Method and apparatus for particle agglomeration

InactiveUS6872238B1Well mixedImprove adhesionElectrostatic separation housingAuxillary pretreatmentDownstream processingEngineering

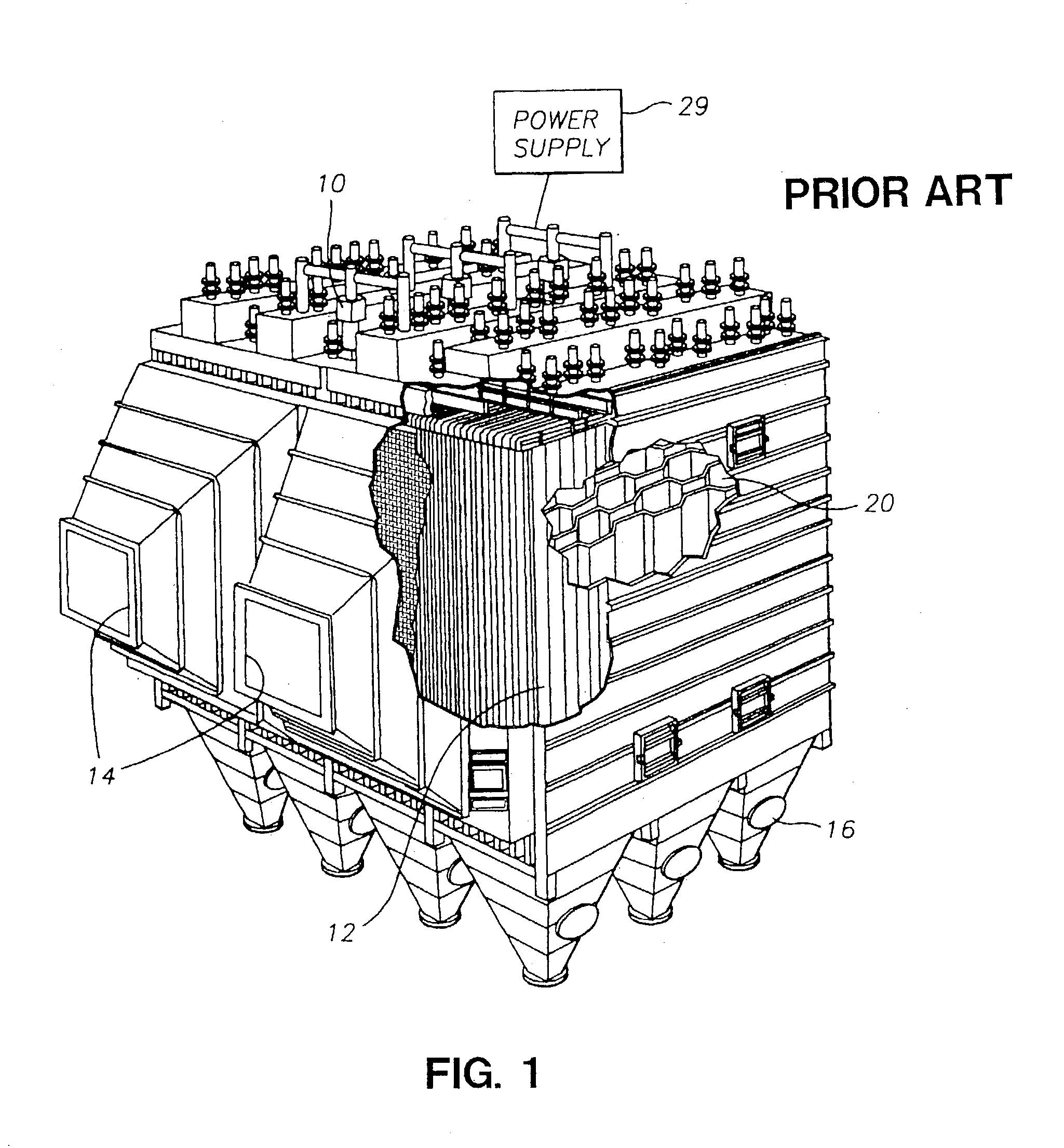

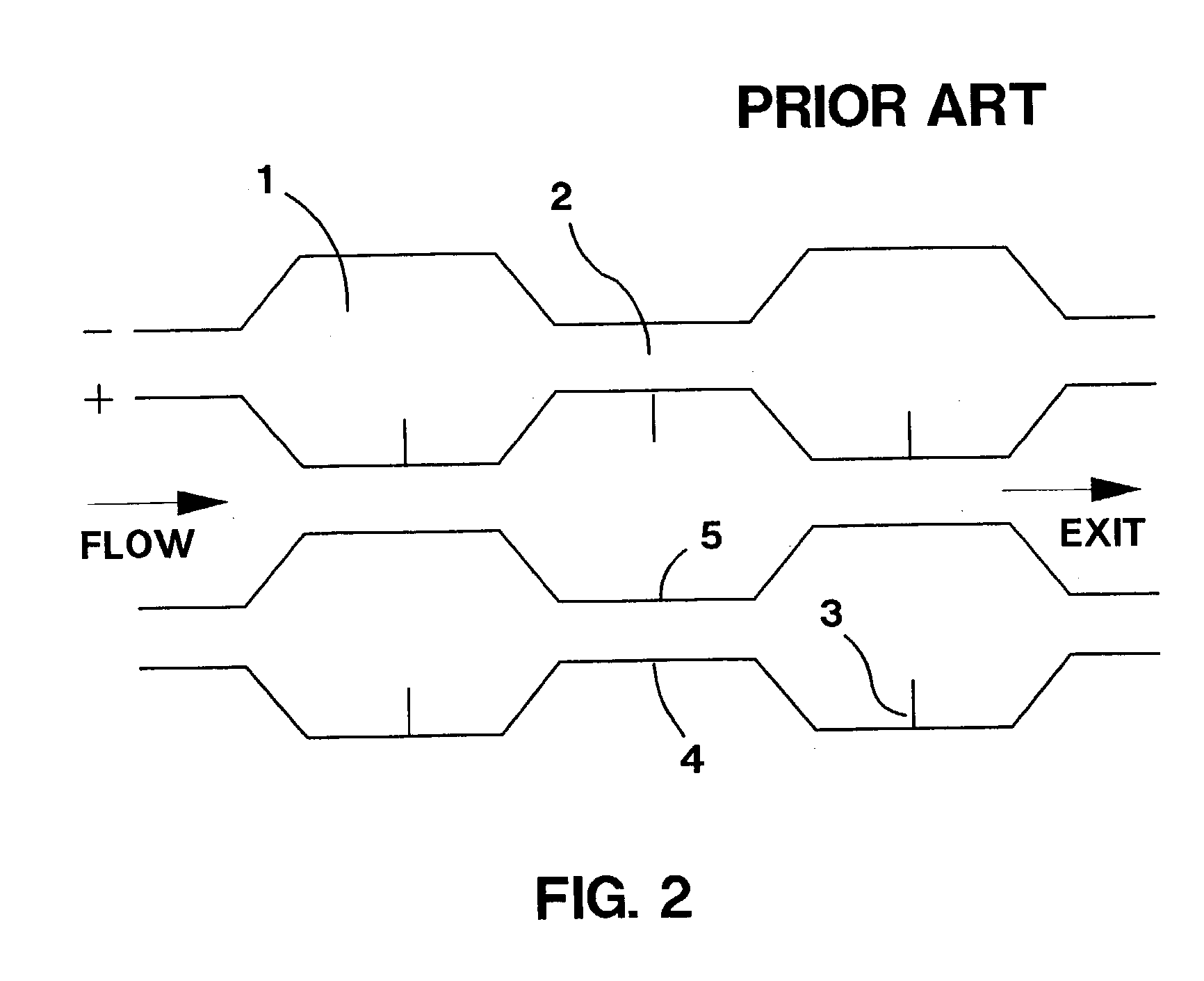

Fine particles of dust and other pollutants in gas streams are agglomerated to form larger particles which are more easily filtered in downstream processing. In one embodiment, particles in successive portions of the gas stream are charged with opposite polarity, and the gas stream is introduced into an Evasé portion (12) to slow it down. Particles of different sizes have differential deceleration and therefore mix generally in the direction of flow, leading to agglomeration of oppositely-charged particles. In another embodiment, a gas stream is divided into substreams in respective parallel passages, and the particles in adjacent passages are charged to opposite polarity. Deflectors at the downstream end of the passages cause substreams of particles of opposite polarity to mix, with resultant agglomeration of oppositely charged particles.

Owner:HANSOM ENVIRONMENTAL PROD

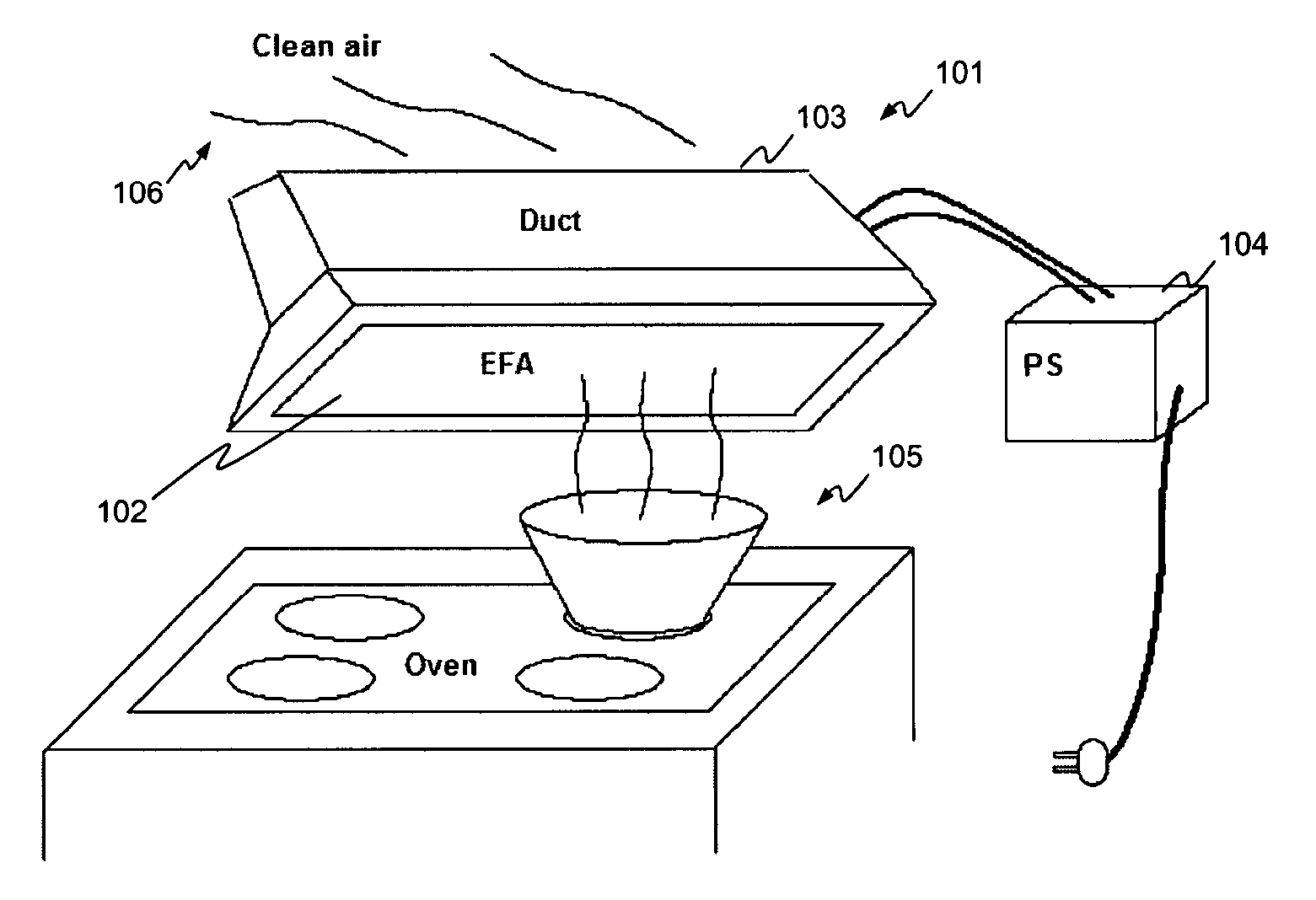

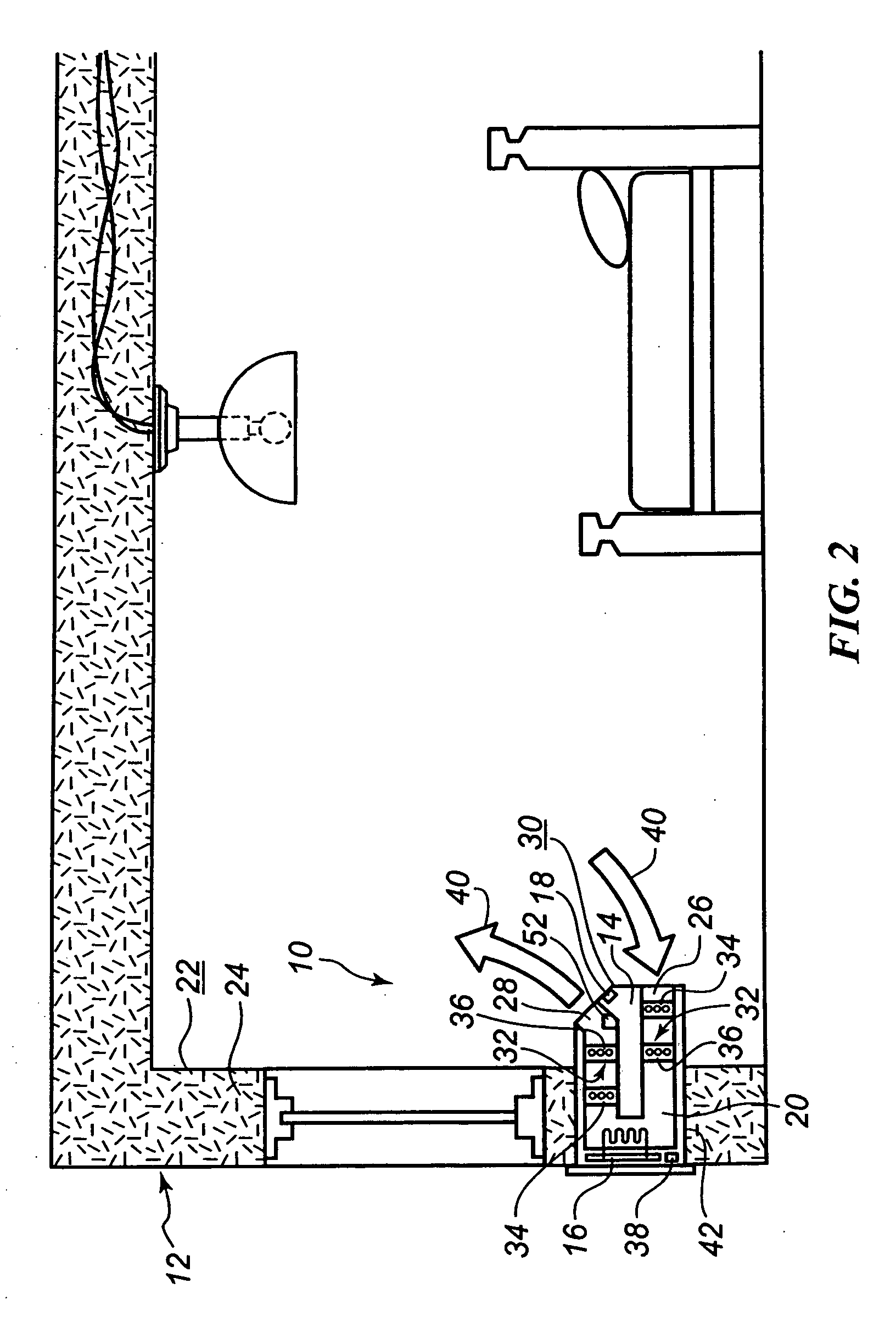

Range hood with electrostatically assisted air flow and filtering

InactiveUS20100089240A1Electricity consumption is minimizedReduce heating powerDomestic stoves or rangesLighting and heating apparatusHazardous substanceControl signal

An improved ventilating range hood includes a sheet metal collecting hood, vented to the outdoors; a variable speed, electronically controllable fan, mounted in such a way as to draw air from a cooking area and out through said vent of said collecting hood; a plurality of air quality sensors capable of detecting both comfort factors and the presence of hazardous substances in the air; an embedded control algorithm which examines the composite output of said discrete air quality sensors, as well as, the trend information and determines from said information an instantaneous ventilation requirement, and a control signal, derived from said algorithm to regulate the fan speed level such that every combination of discrete air quality sensor conditions will have a unique associated fan speed level based on said ventilation requirement. The air quality sensors may include sensors for temperature, humidity, carbon monoxide, smoke, etc.

Owner:KRICHTAFOVITCH IGOR A

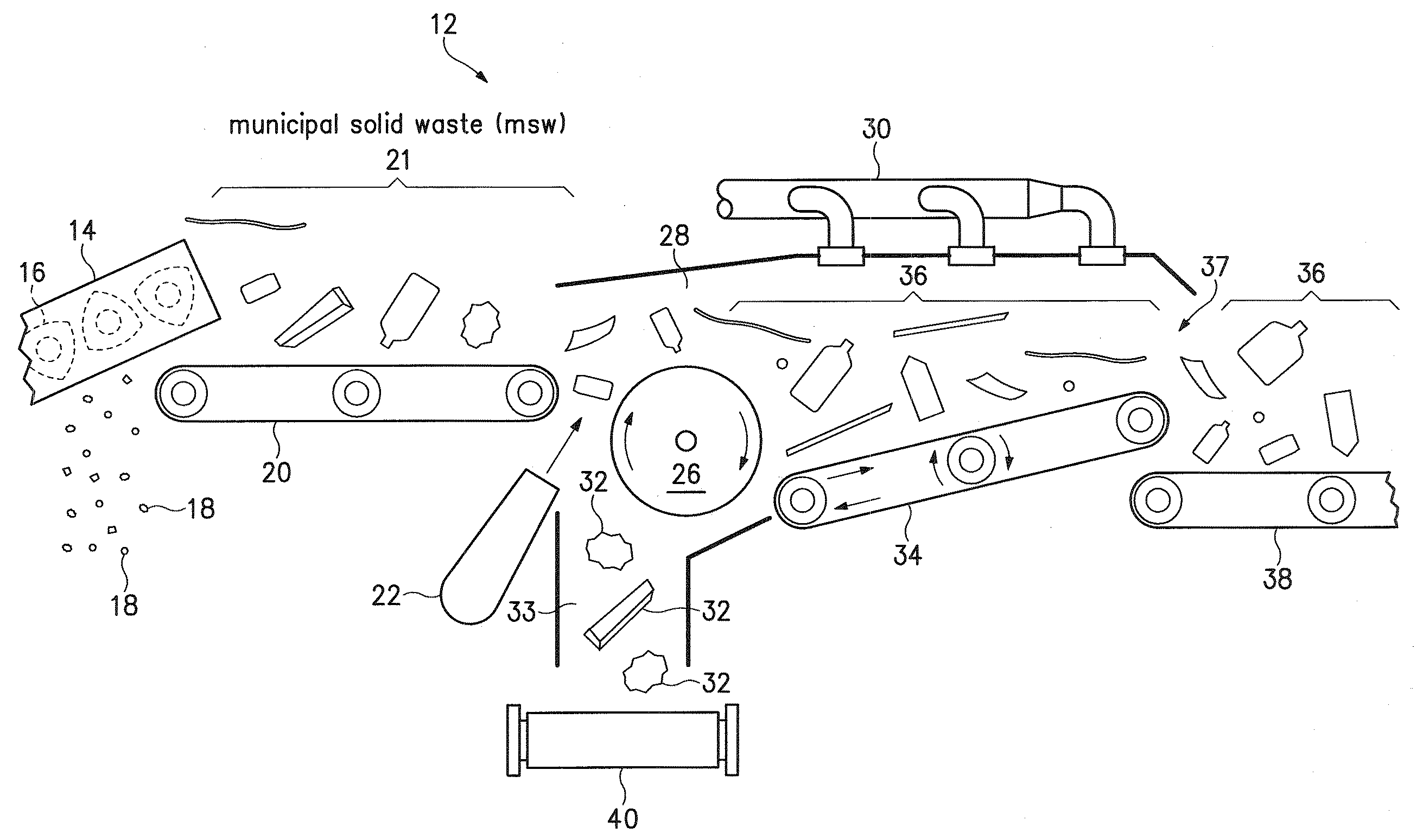

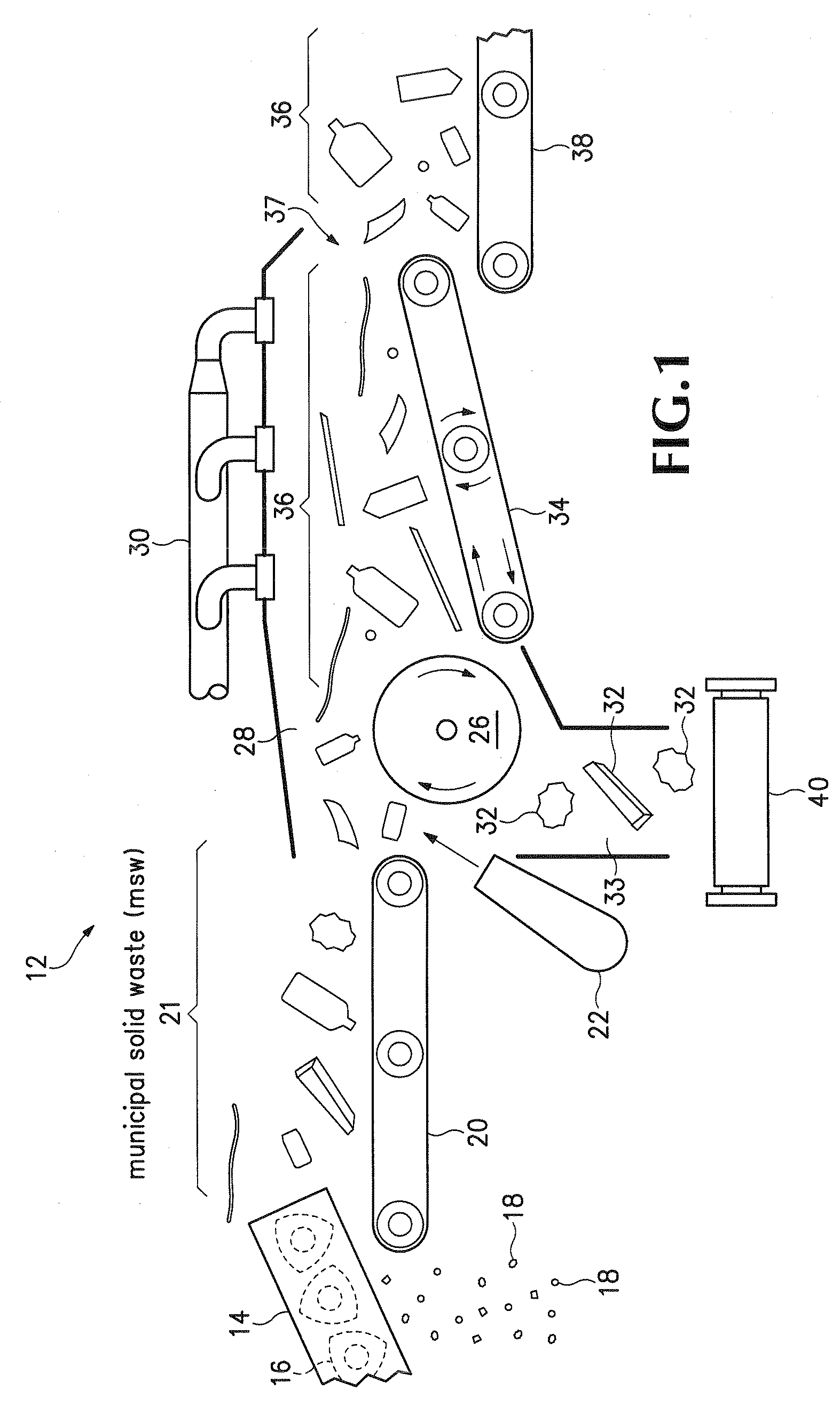

Separation system for recyclable material

A separation system includes an air separator that, in one embodiment, primarily receives Municipal Solid Waste (MSW) containing a mixture of relatively light MSW recyclable materials such as plastic, paper, cardboard, plastic containers, and / or metal containers and relatively heavy MSW such as textiles, food waste, yard debris, etc. The air separator blows the relatively light MSW recyclable materials up though a chamber and onto a first conveyor while the other relatively heavy MSW material drops down a chute onto a second conveyor. A separation screen receives the relatively light MSW recyclable materials from the air separator and separates the relatively flat fiber and plastic film materials from the other paper, plastic and metal containers. In another separation stage, an electrostatic emitter is positioned adjacent to a conveyor for applying an electrostatic charge to the fiber and plastic materials. The electrostatic charge causes at least some of the plastic materials to at least partially cling to the conveyor belt while being carried over an end of the conveyor so that the plastic materials do not drop out as far from the conveyor as the fiber materials.

Owner:EMERGING ACQUISITIONS

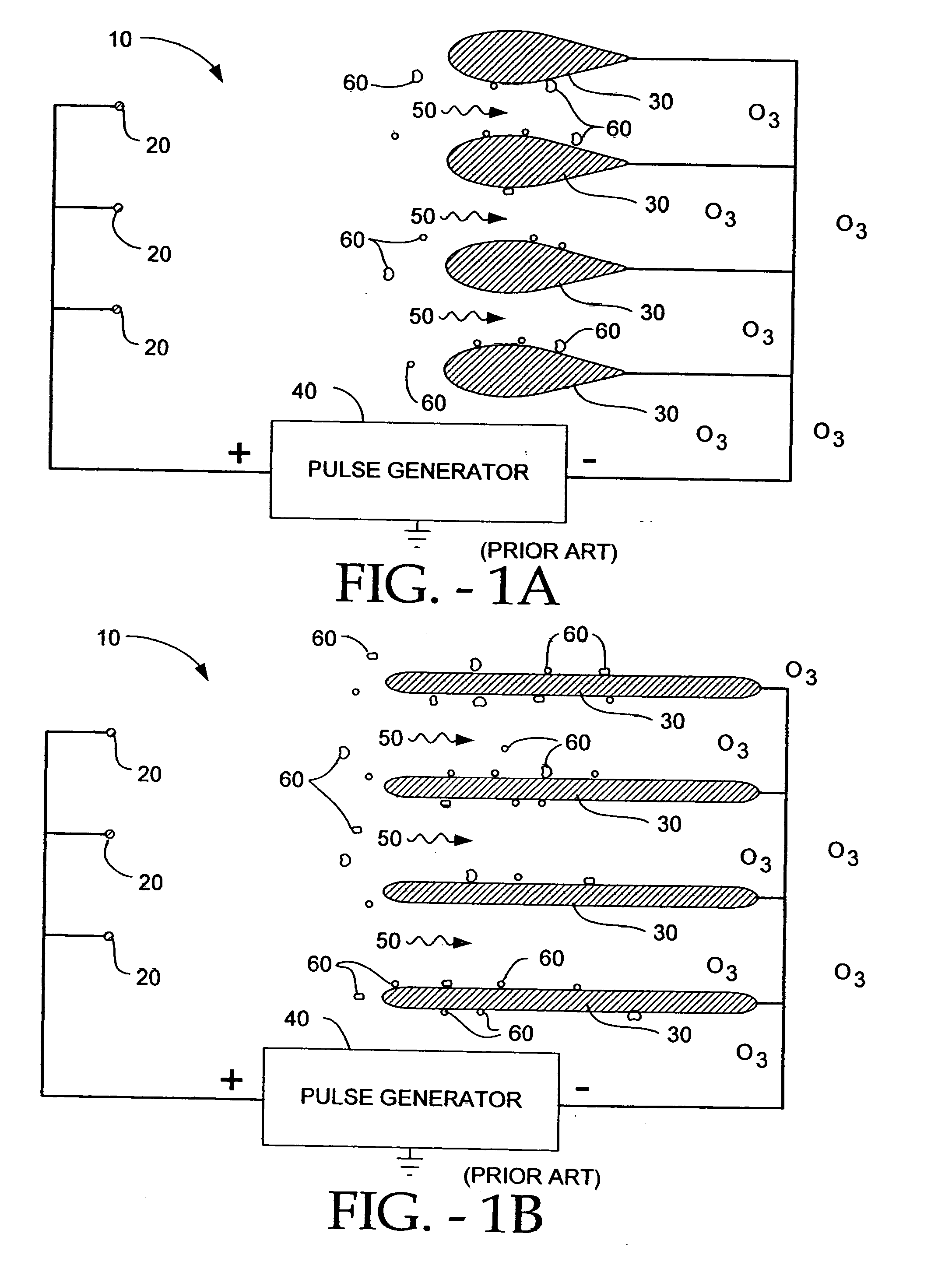

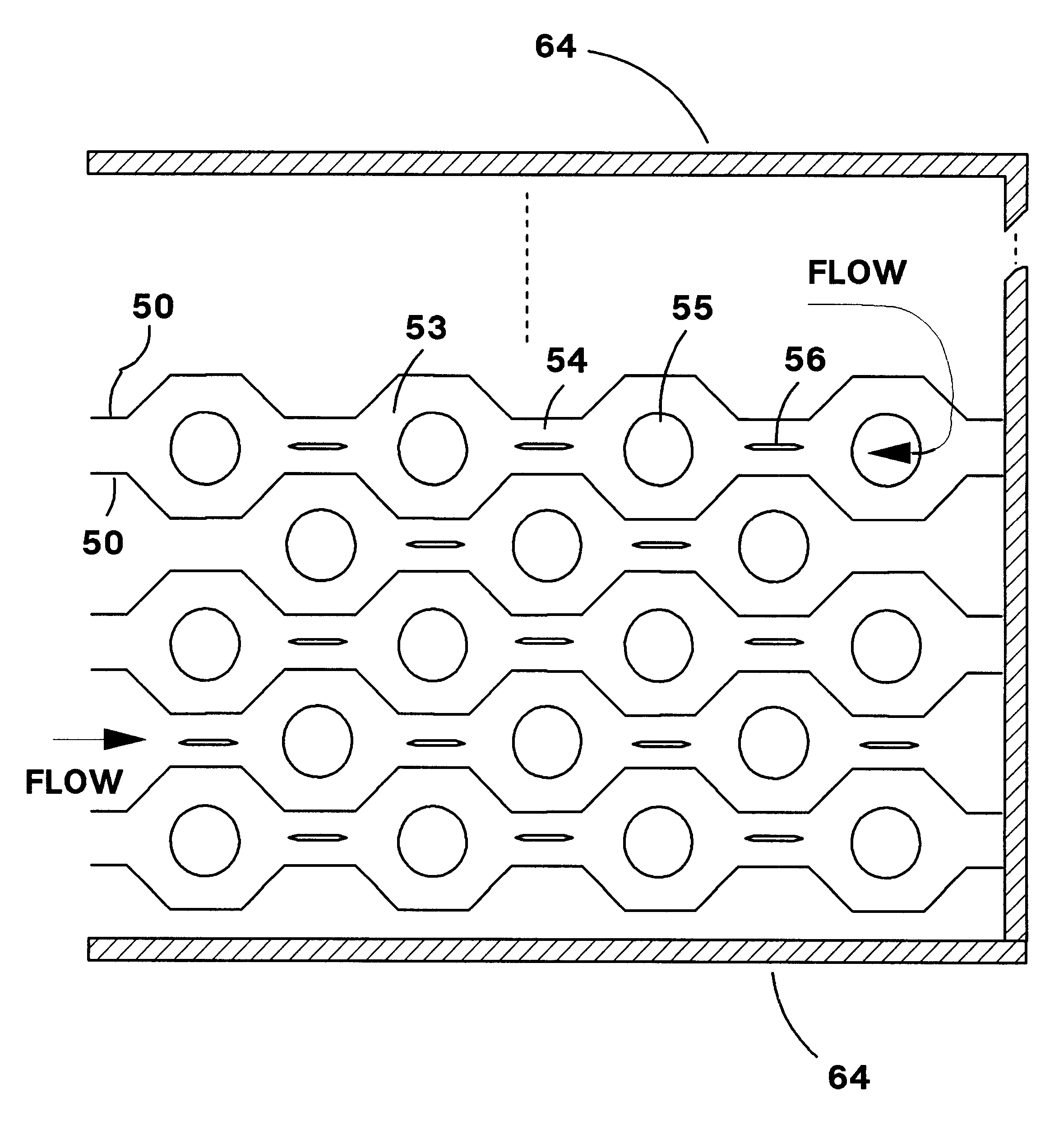

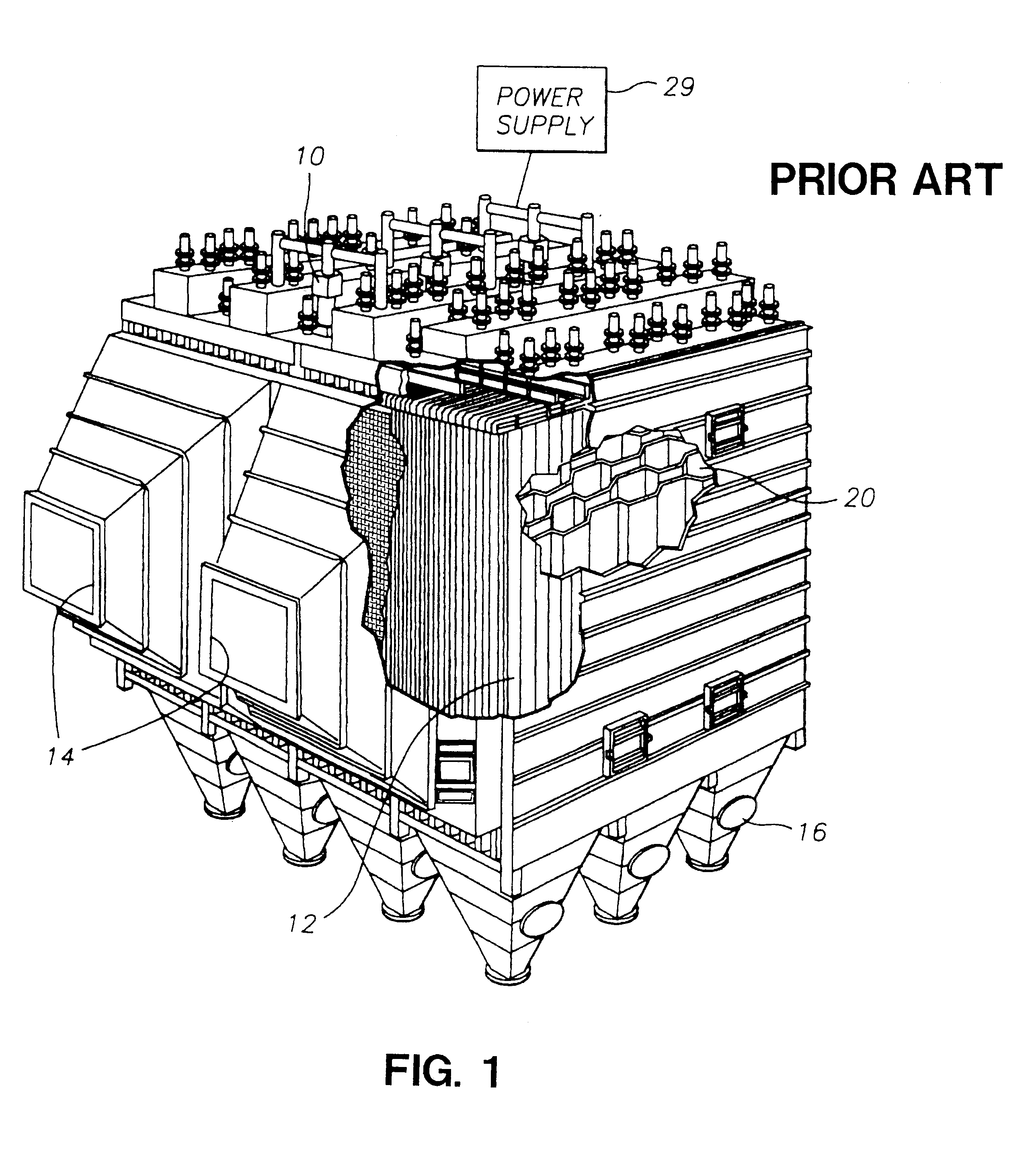

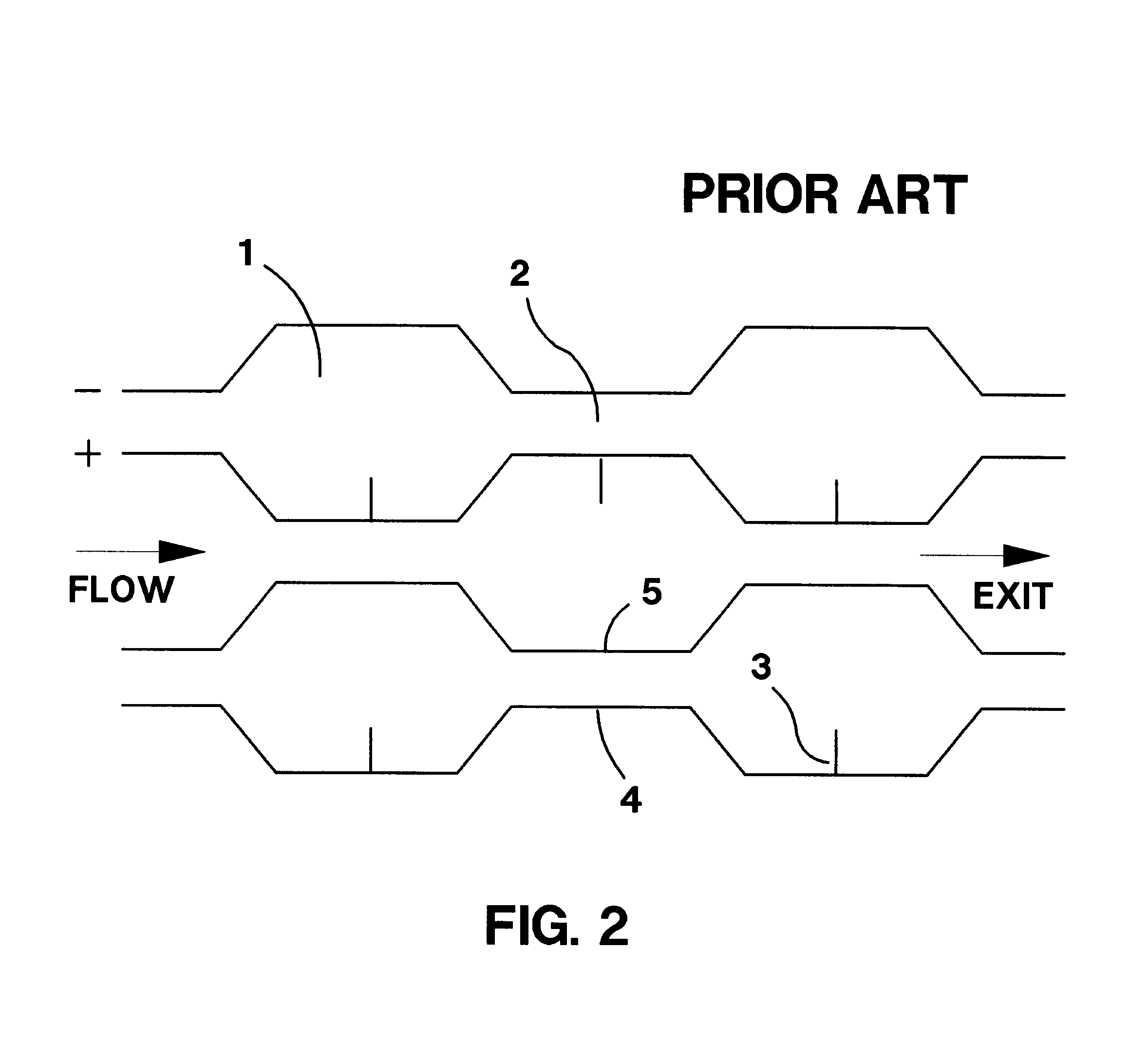

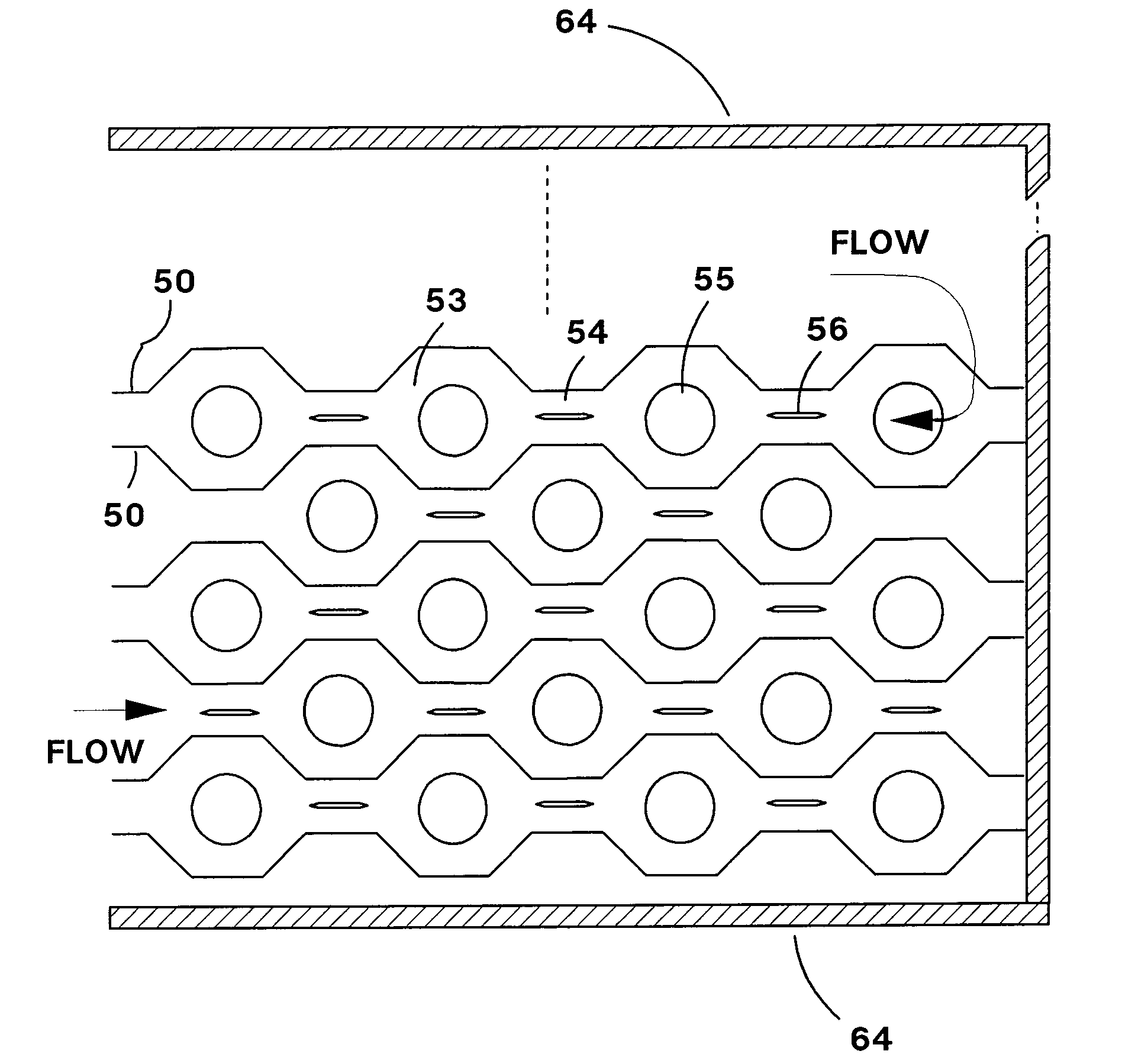

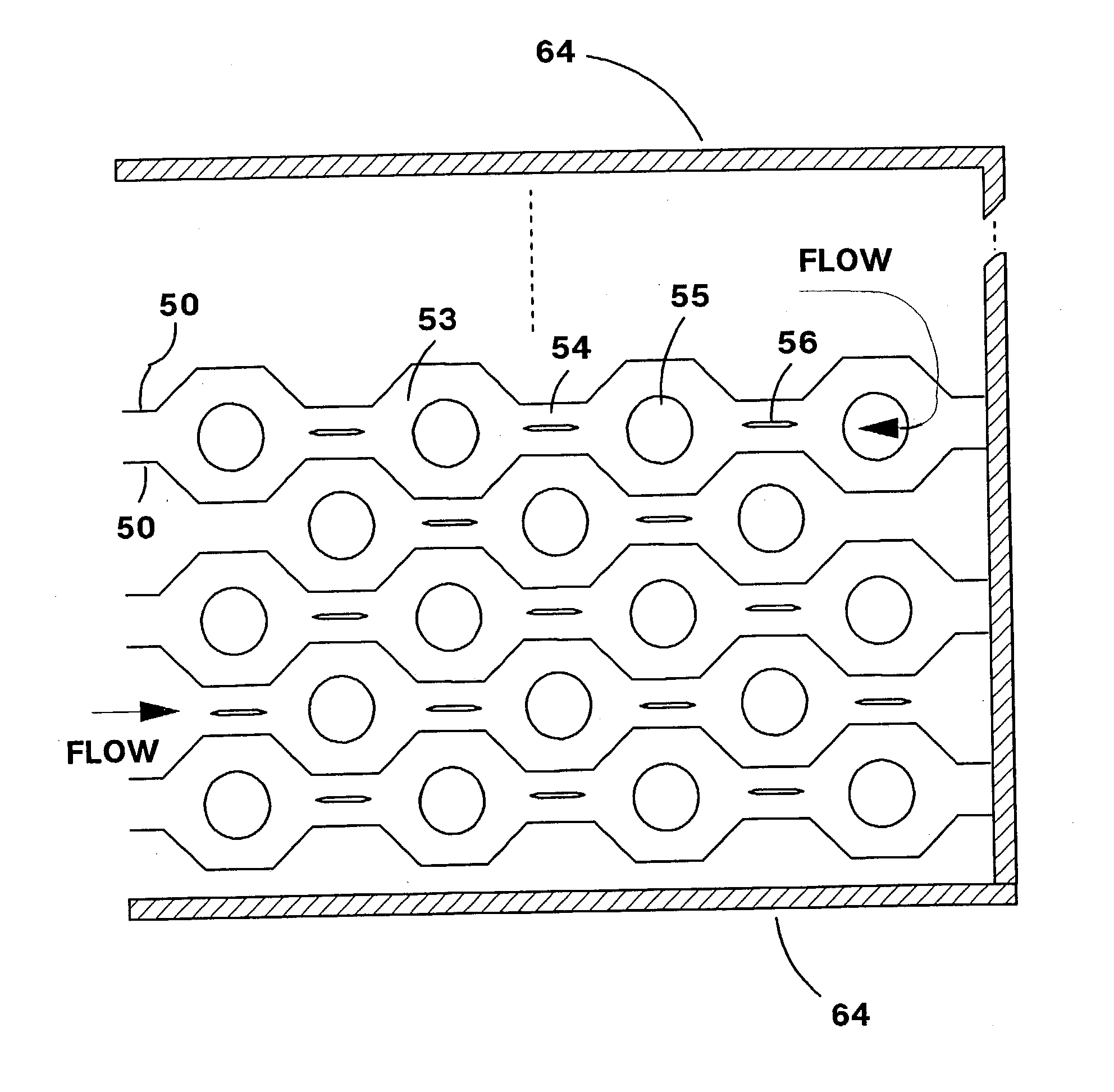

Multi-stage particulate matter collector

InactiveUS6524369B1Improve collection efficiencyIncrease the areaDispersed particle filtrationParticle charging/ionising stationsParticulatesParallel plate

A multi-stage particulate matter collector of the type used to collect particles from waste industrial gas. The collector can contain multiple narrow and wide zones formed by a plurality of parallel corrugated plates. Contained in the narrow zones are elongated electrodes with sharp leading and / or trailing edges. These electrodes provide a non-uniform electric field near their sharp edges leading to corona discharge. The corona discharge causes particulate matter in the gas flow to become charged. The region in narrow zones away from the sharp edges of the electrodes resembles a parallel plate capacitor with relatively uniform electric field. In this region, particles can be collected on the plates and on the electrode. Wide regions can contain barrier filters (bag filters) with conductive surfaces. The electric field is also relatively uniform in this region causing electrostatic collection on the plates and filter surface. Gas exits the array through the sides of the barrier filters which provides additional highly efficient filtering.

Owner:KRIGMONT HENRY V

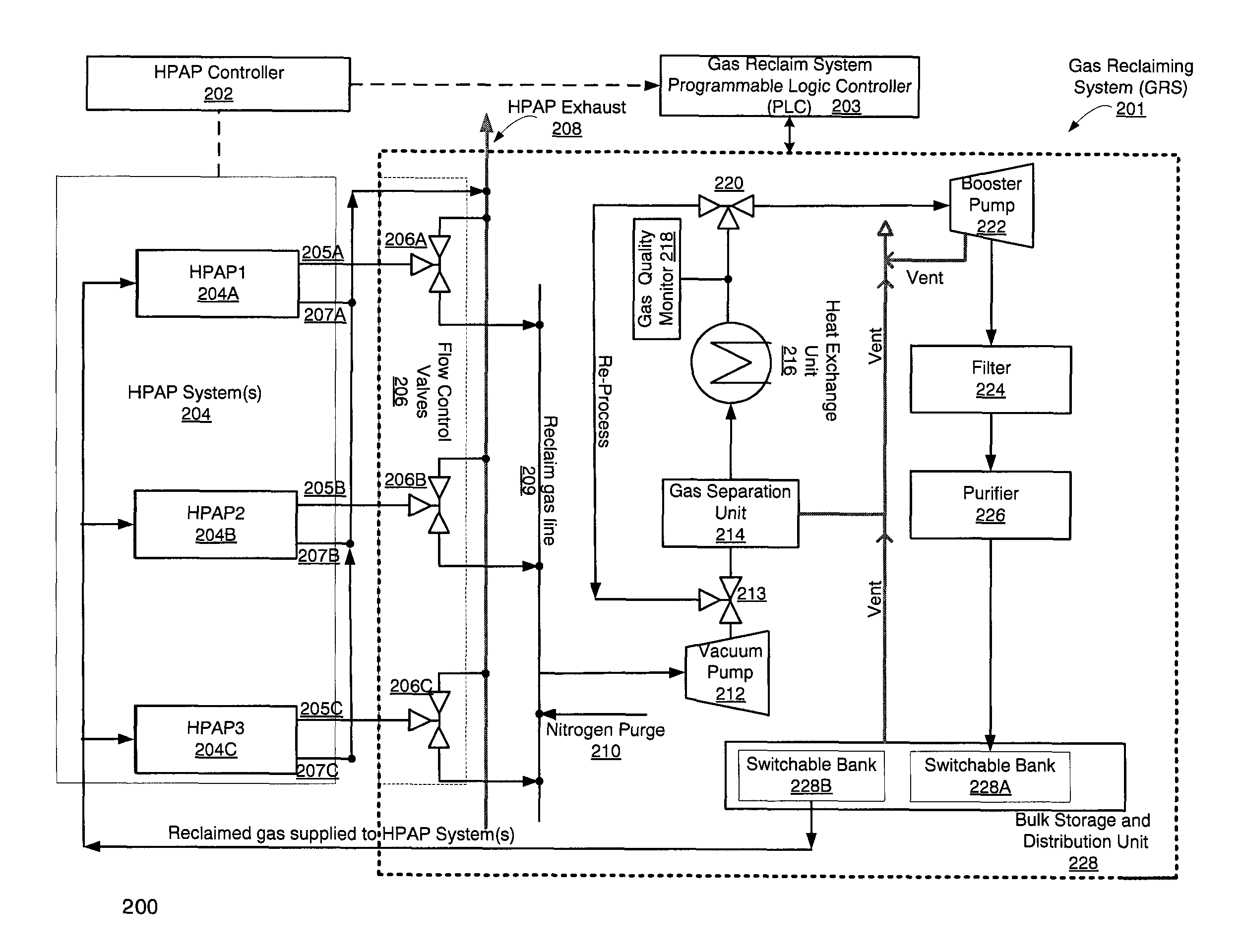

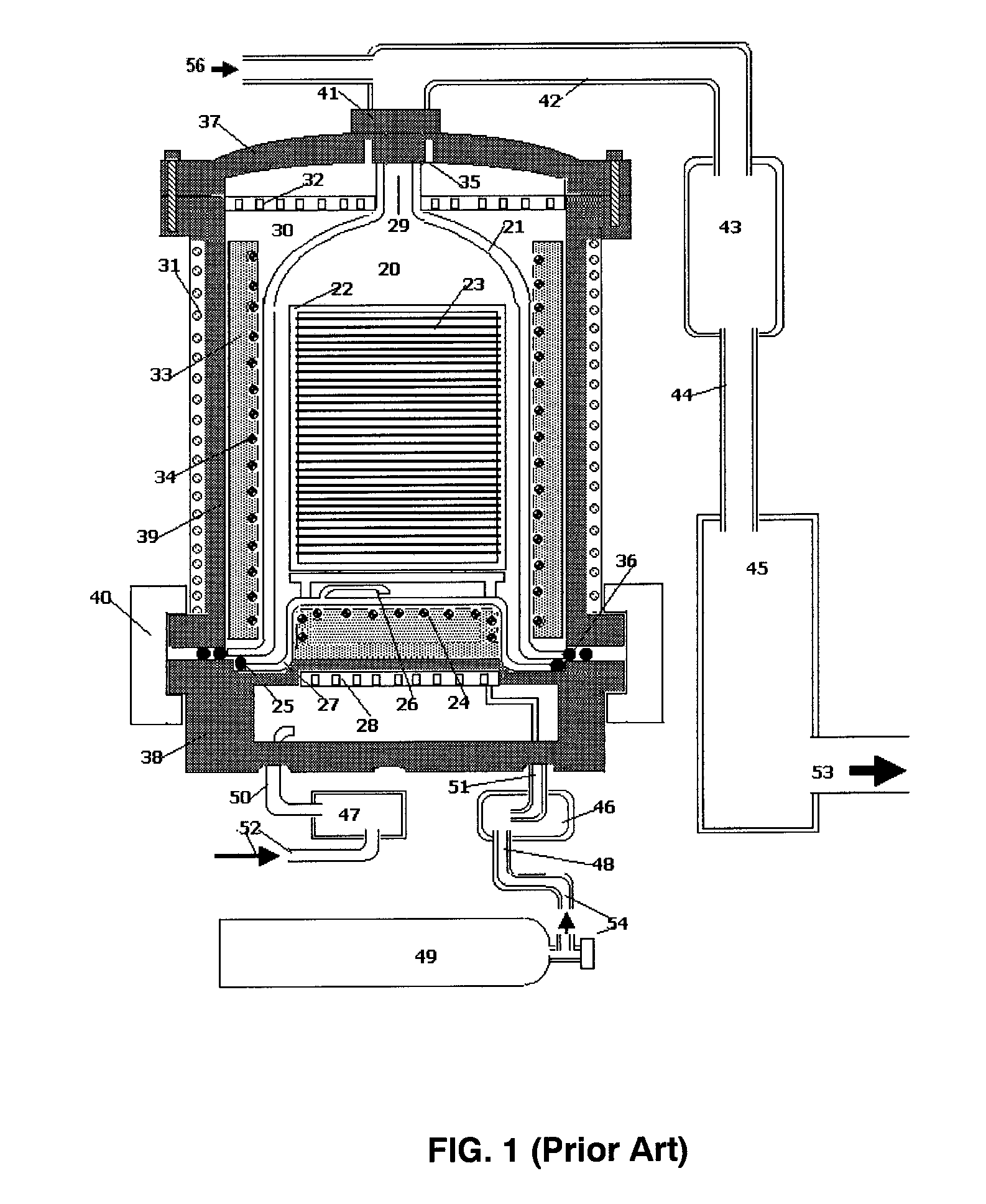

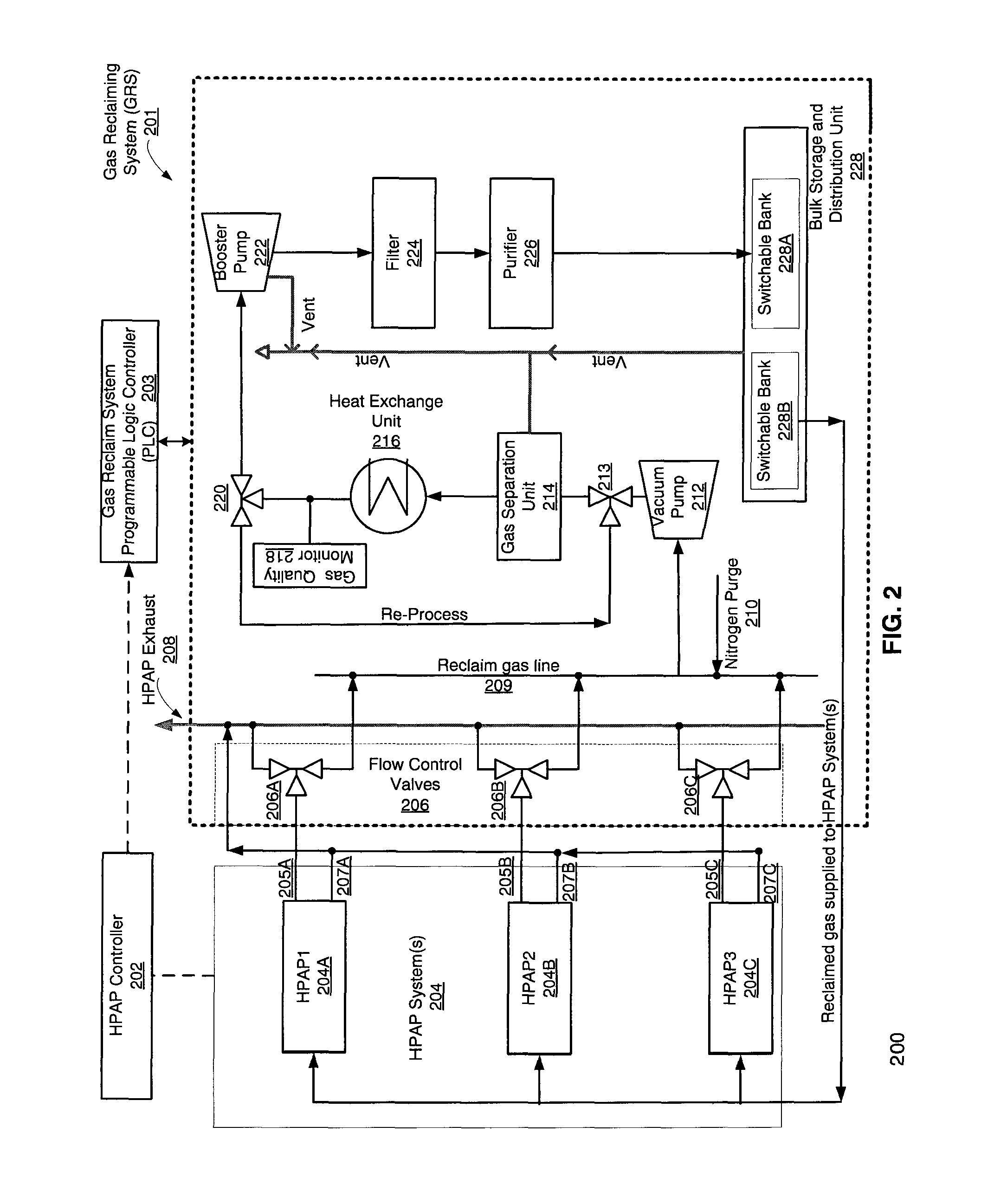

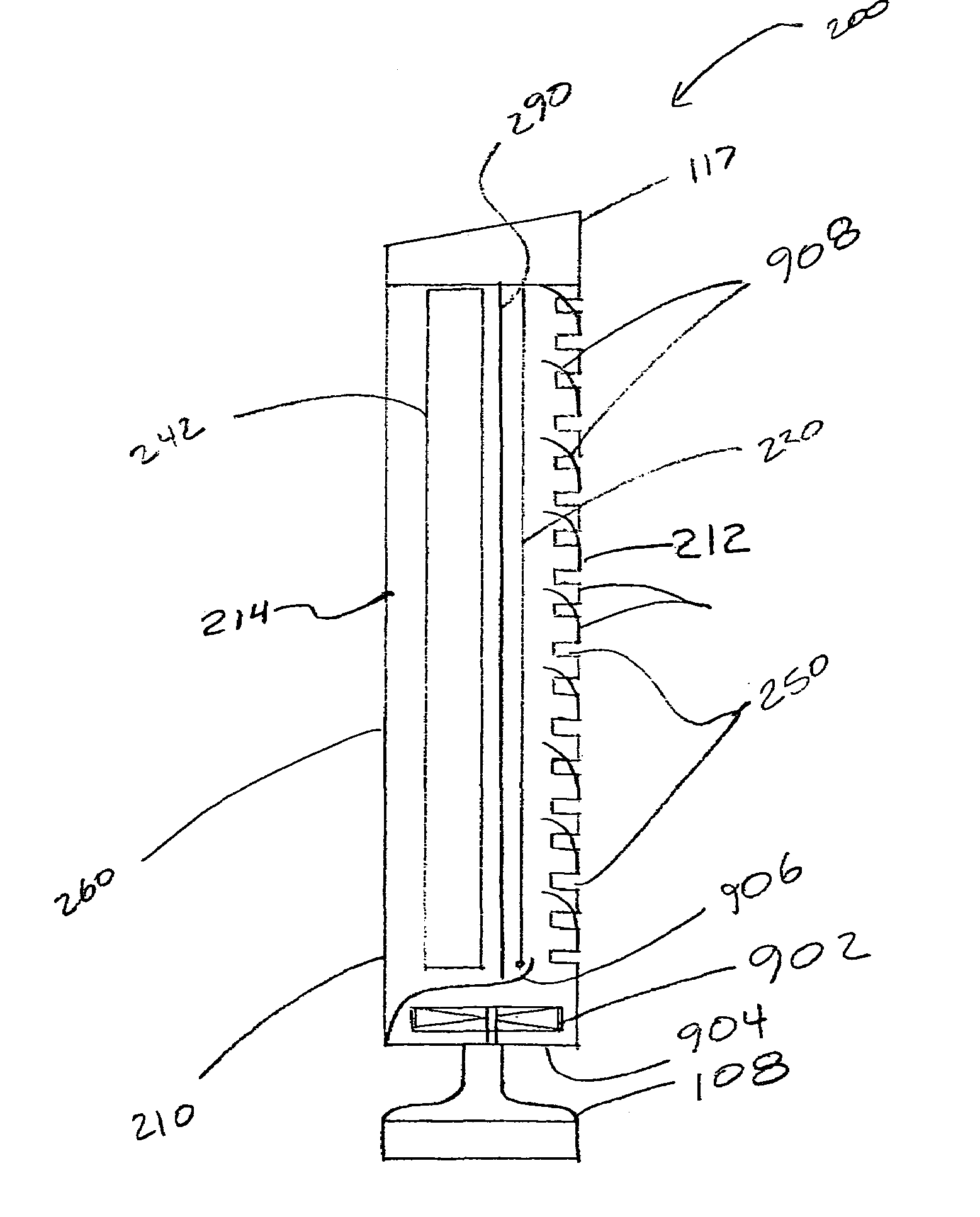

Methods and apparatuses for deuterium recovery

Novel methods, systems, and apparatuses for reclaiming annealing gases from a high pressure annealing processing system are disclosed. According to an embodiment, the exhaust gasses from the high pressure annealing processing system are directed into a gas reclaiming system only when a precious gas, e.g., deuterium is used. The annealing gas is the separated from other gasses used in the high pressure annealing processing system and is then pressurized, filtered, and purified prior to transferring the gas to a bulk storage distribution unit. In one embodiment, the reclaimed gas is then again provided to the high pressure annealing processing system to anneal the wafers.

Owner:HPSP CO LTD

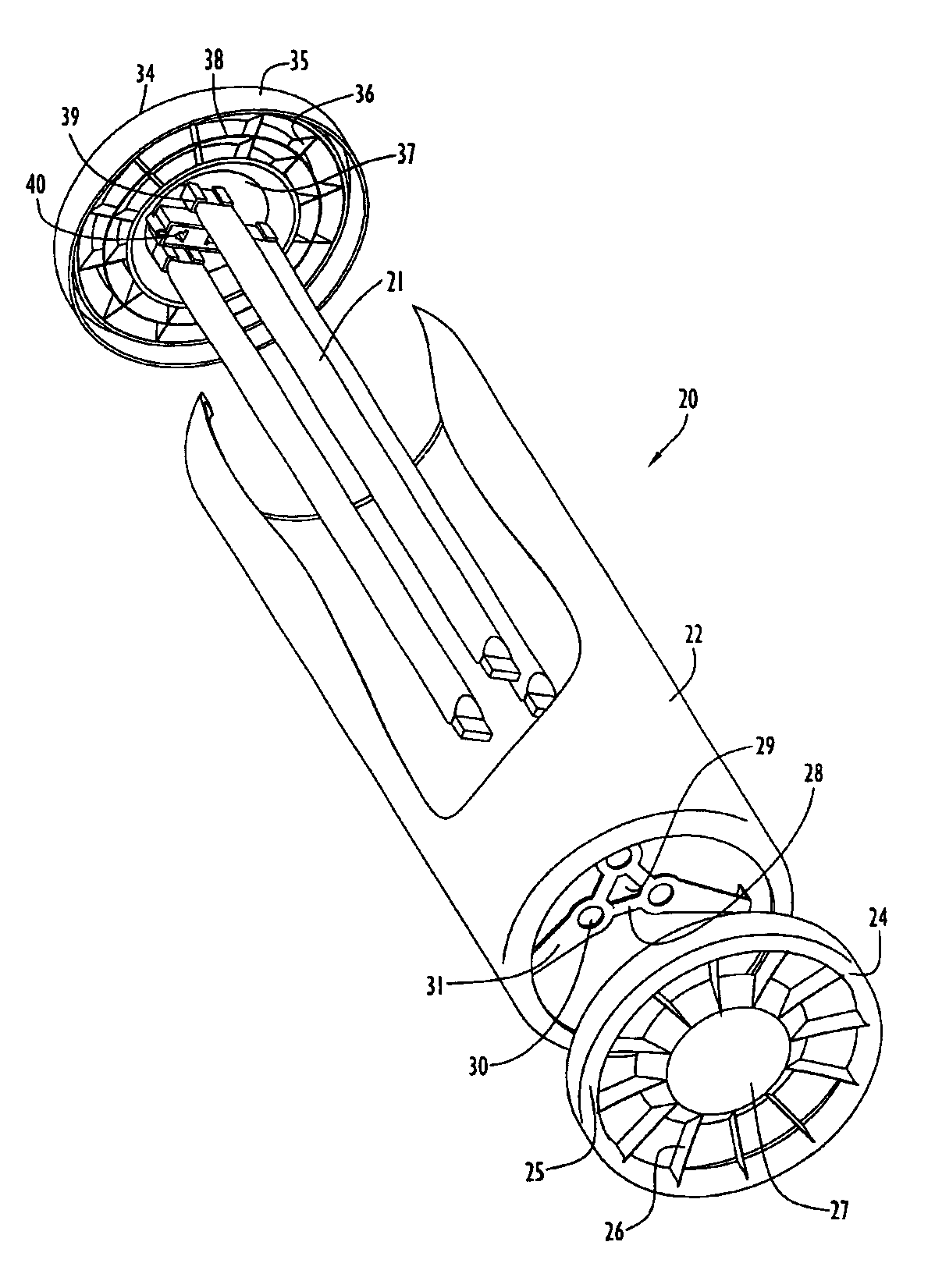

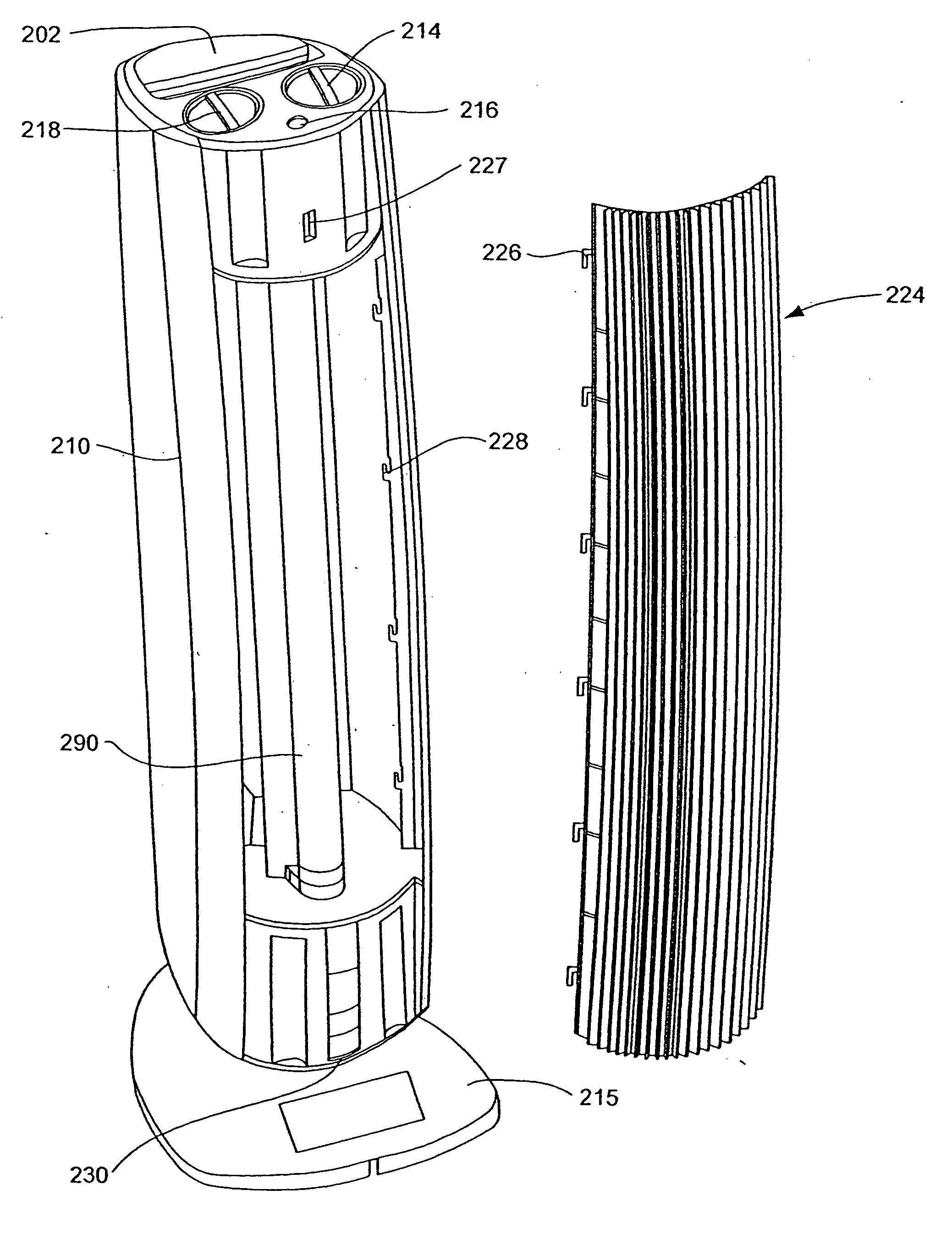

Air treatment apparatus having an electrode extending along an axis which is substantially perpendicular to an air flow path

An air transporter-conditioner device is disclosed that can include an elongated housing having a bottom, a top and an elongated side wall. The housing can have an inlet located adjacent to the bottom and an outlet located adjacent to the elongated side wall, an emitter electrode and a collector electrode and a high voltage generator operably connected to both electrodes. An impeller can be used to draw air into the housing through the inlet and direct the air toward the outlet. The housing can also include a second elongated side wall and a baffle which can include a plurality of deflectors positioned along the second elongated side wall. The baffle can include a plurality of elongated columns of varying lengths and each column can include a deflector. The device can further include a second inlet located adjacent to the elongated side wall and a germicidal lamp located inside the elongated housing.

Owner:SHARPER IMAGE ACQUISITION LLC A DELAWARE LIMITED LIABILITY

Clean corona gas ionization for static charge neutralization

ActiveUS8048200B2Reduce stressEasy to separateElectric discharge tubesElectretsProduct gasIonization

Clean corona gas ionization by separating contaminant byproducts from corona generated ions includes establishing a non-ionized gas stream having a pressure and flowing in a downstream direction, establishing a plasma region of ions and contaminant byproducts in which the pressure is sufficiently lower than the pressure of the non-ionized gas stream to prevent at least a substantial portion of the byproducts from migrating into the non-ionized gas stream, and applying an electric field to the plasma region sufficient to induce at least a substantial portion of the ions to migrate into the non-ionized gas stream.

Owner:ILLINOIS TOOL WORKS INC

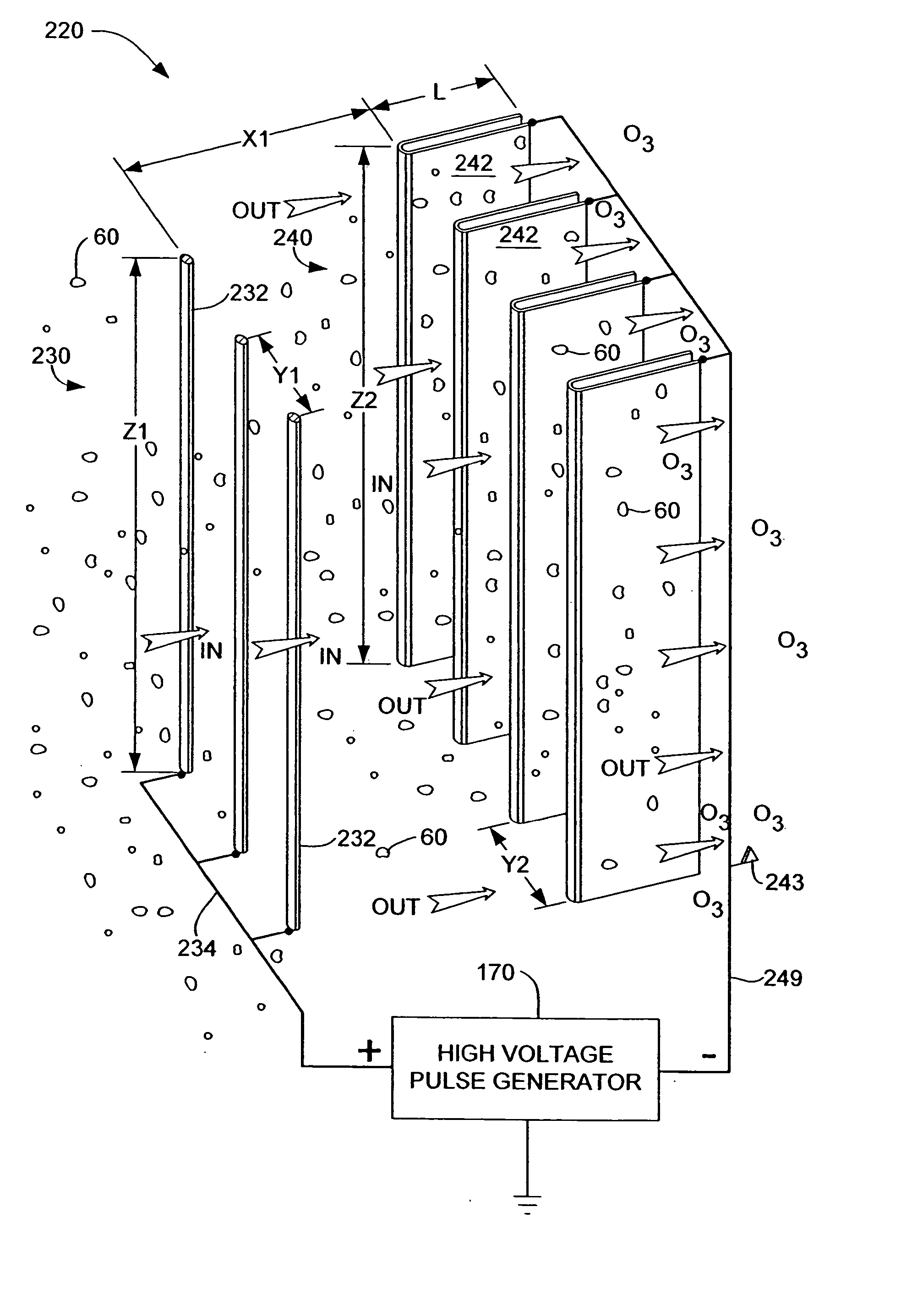

Multi-stage collector and method of operation

InactiveUS6932857B1Improve collection efficiencyIncrease the areaDispersed particle filtrationParticle charging/ionising stationsLeading edgeIndustrial gas

A multi-stage collector of the type used to collect particles from industrial gas. The collector can contain multiple narrow and wide zones formed by a plurality of parallel corrugated plates. Contained in the narrow zones can be elongated electrodes with sharp leading and / or trailing edges. These electrodes can provide a non-uniform electric field near their sharp edges leading to corona discharge. The corona discharge causes particulate matter in the gas flow to become charged. The region in narrow zones away from the sharp edges of the electrodes resembles a parallel plate capacitor with relatively uniform electric field. In this region, particles can be collected on the plates and on the electrode. Wide regions can contain barrier filters (bag filters) with conductive surfaces. The collector can also be used to clean inlet gas in gasification plants and to collect re-usable materials from a gas stream.

Owner:KRIGMONT HENRY

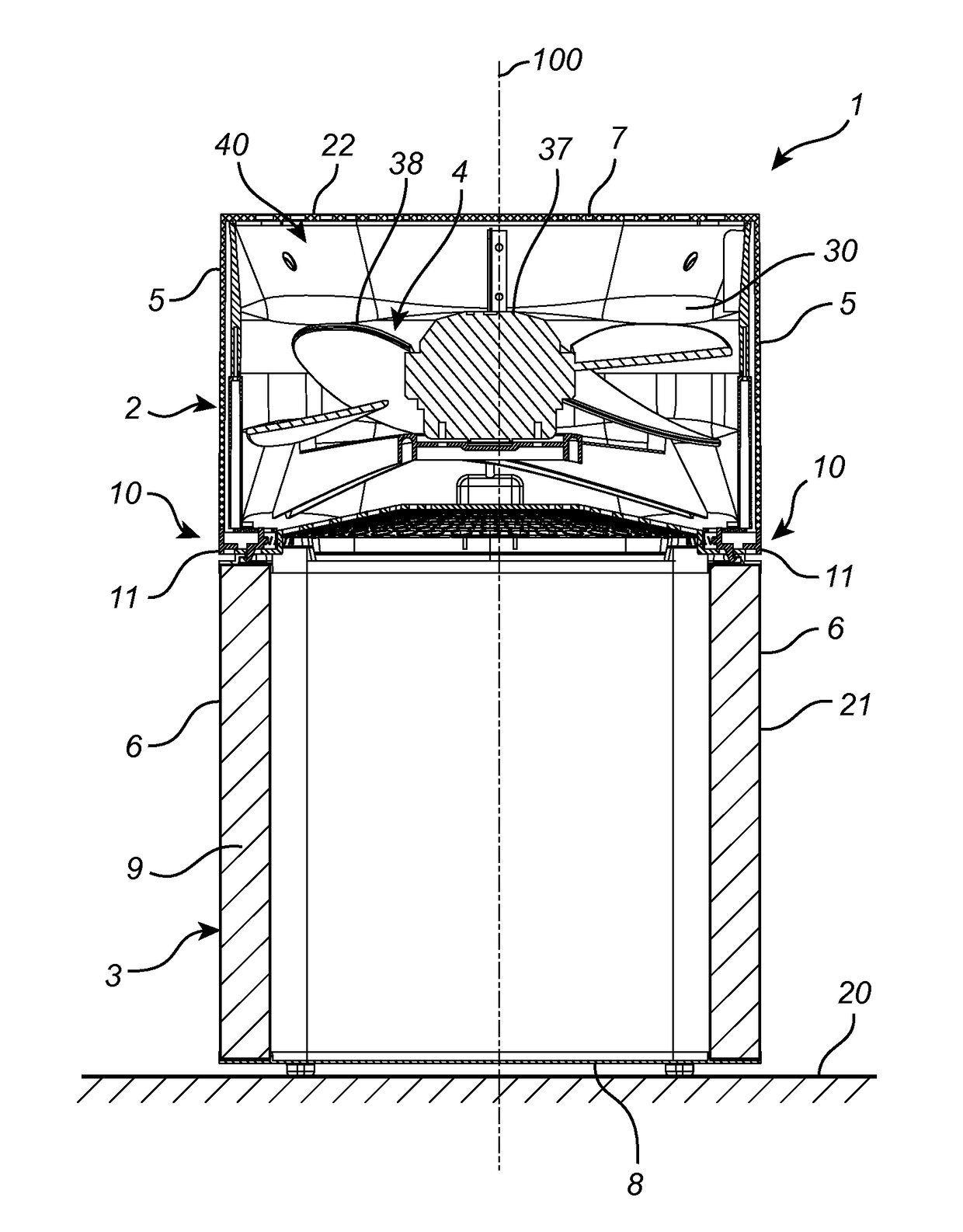

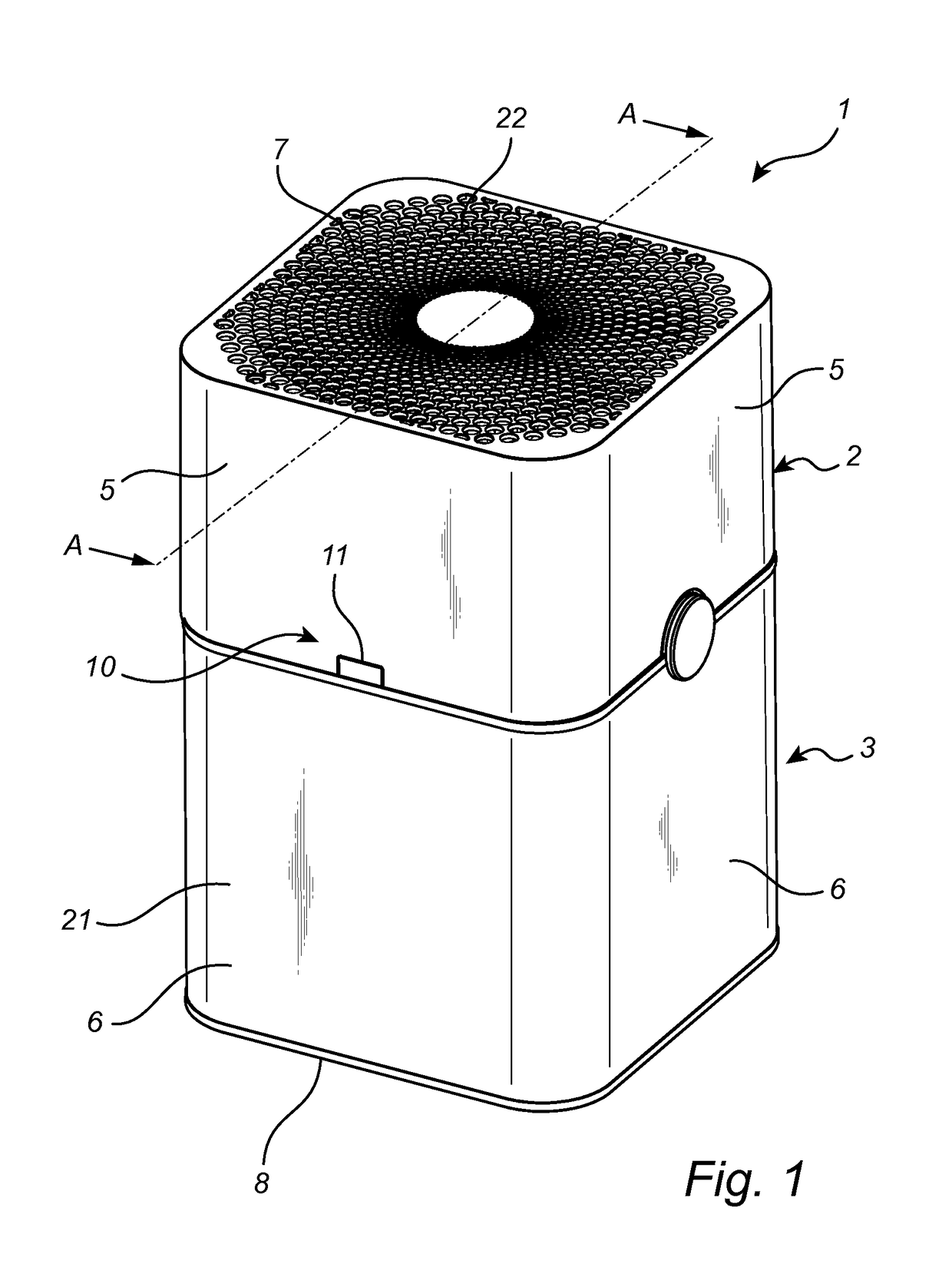

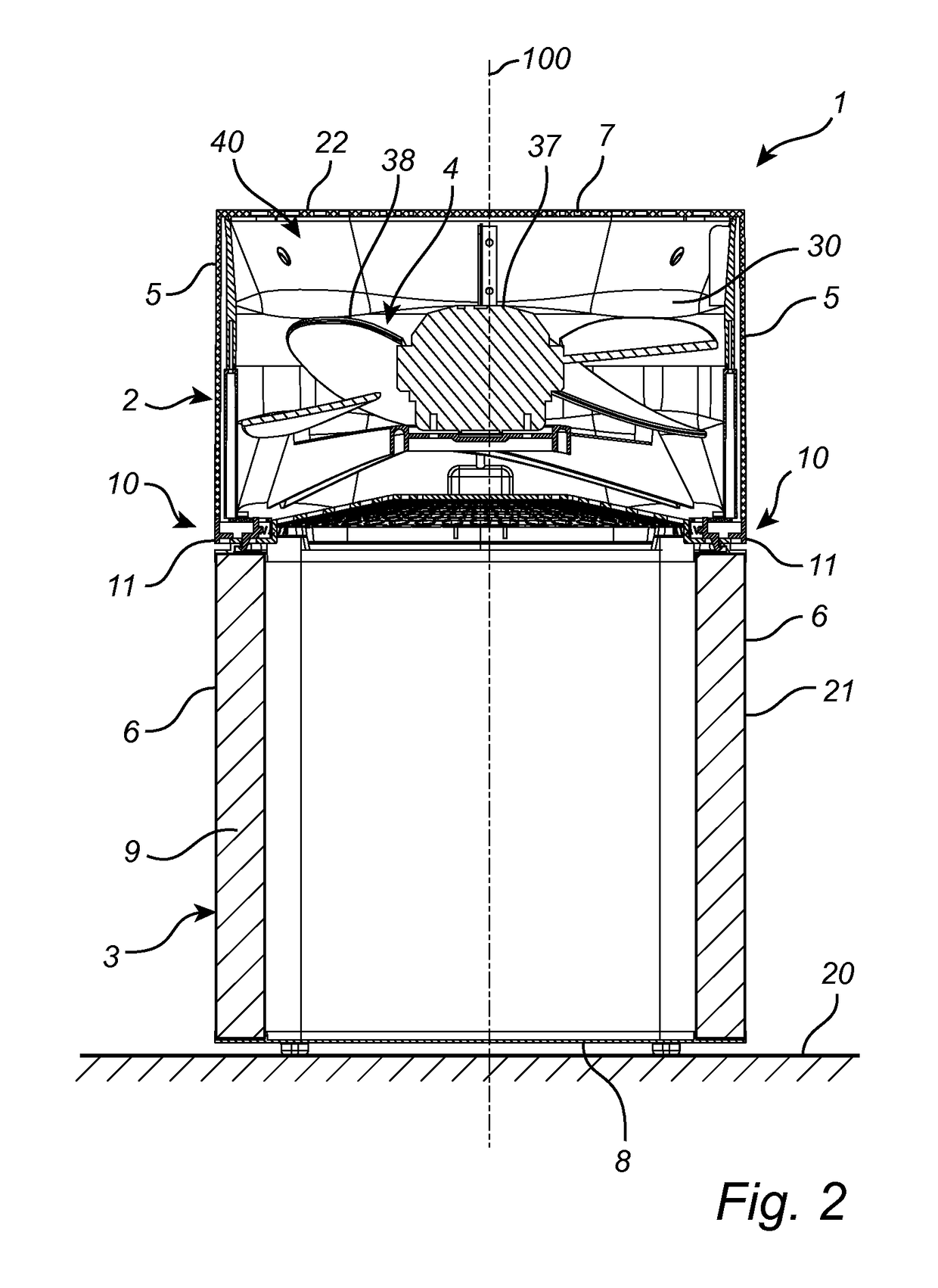

Air filtration device for closed environments

ActiveUS20070283810A1Preserving healthLess frequent maintenanceCombination devicesMechanical apparatusAir filtrationEngineering

An air filtration device for suppressing biological pollutants for closed environments, comprising at least one enclosure with at least one air inlet, at which at least one perforated conducting grille is located, that has a preset negative electrical potential adapted to emit electrons when air flows, so as to give negative electric charge to particles to which microorganisms adhere, at least one air passage duct being formed between at least one plate having predefined positive potential for collecting negatively charged particles to which microorganisms adhere, at least one deflector plate having a negative potential adapted to divert the particles to which microorganisms adhere, an electrical field being generated between the collector plate and the deflector plate, facing each other, the field to divert and precipitate the particles to which the microorganisms adhere onto the collector plate, and an inactivator for inactivation of the microorganisms provided and at least one filtered air outlet.

Owner:DAITECH SA

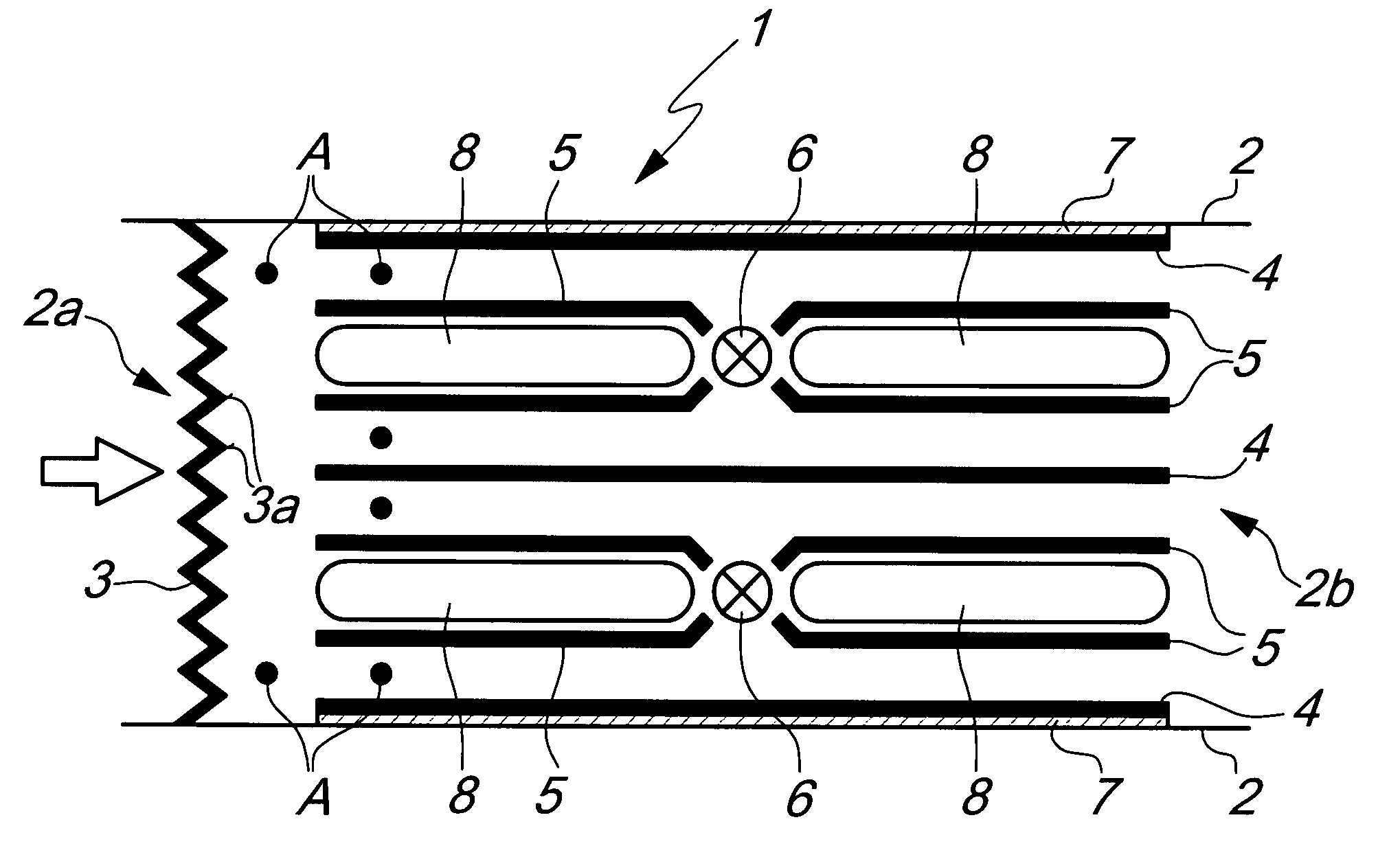

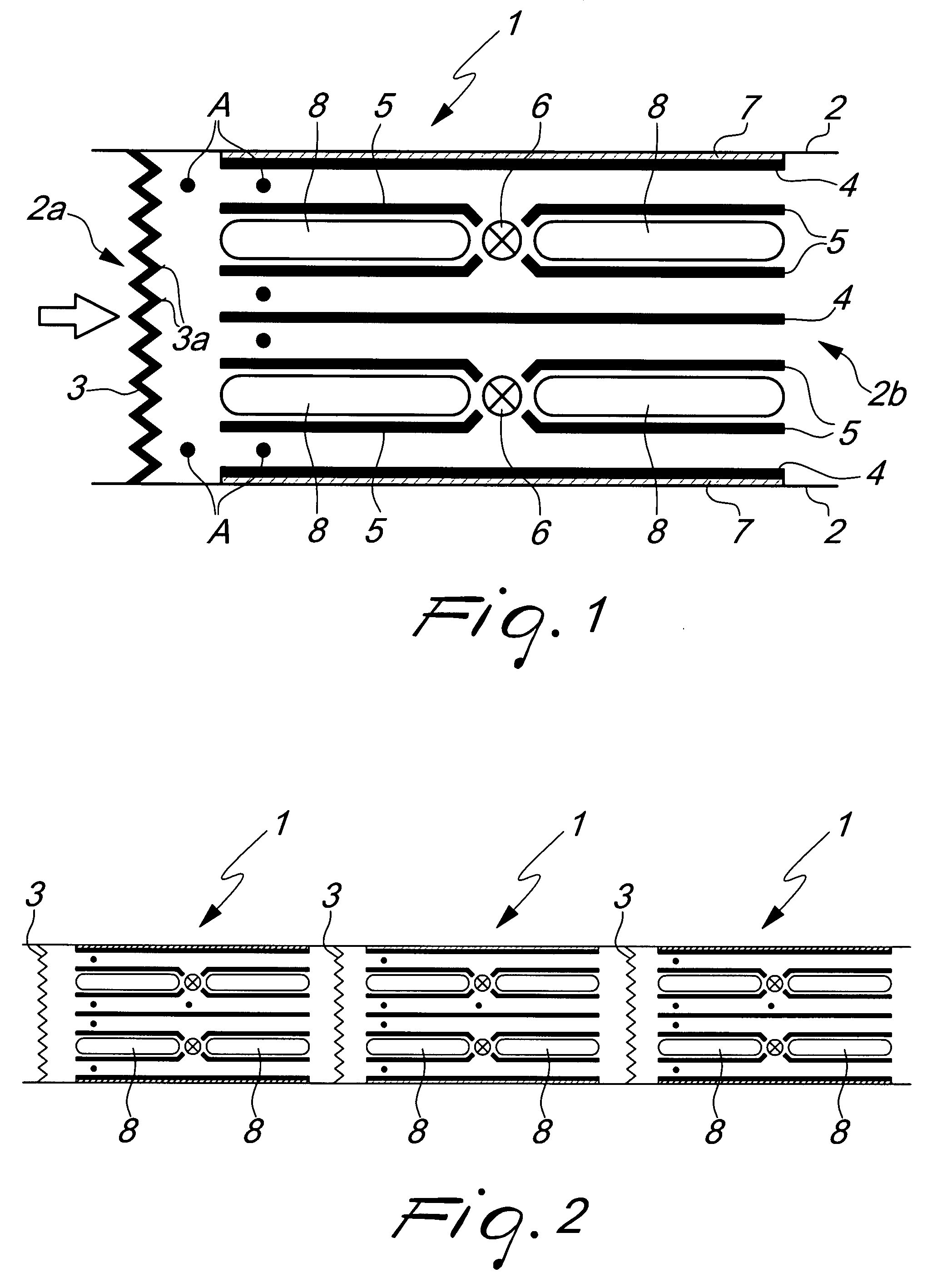

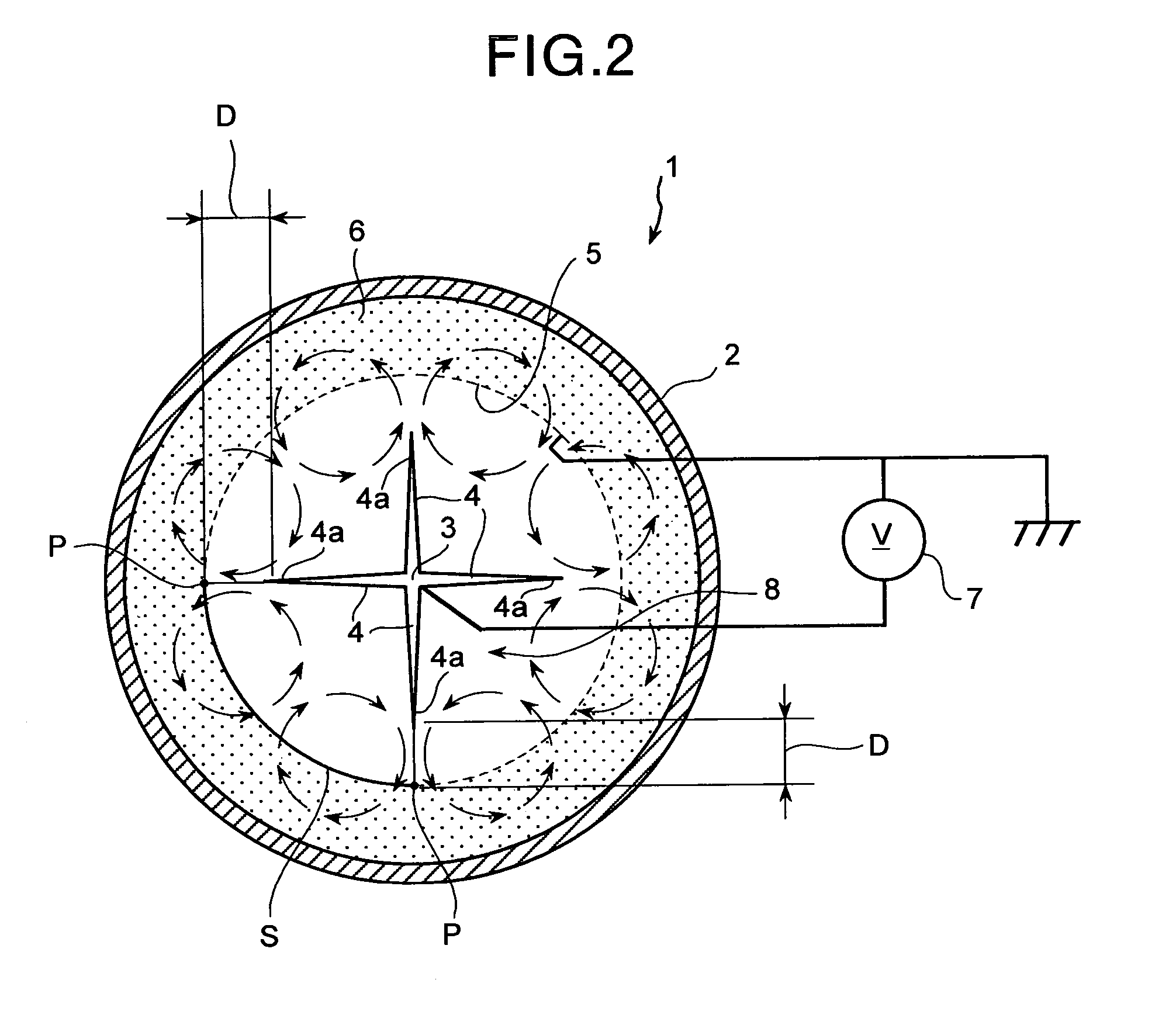

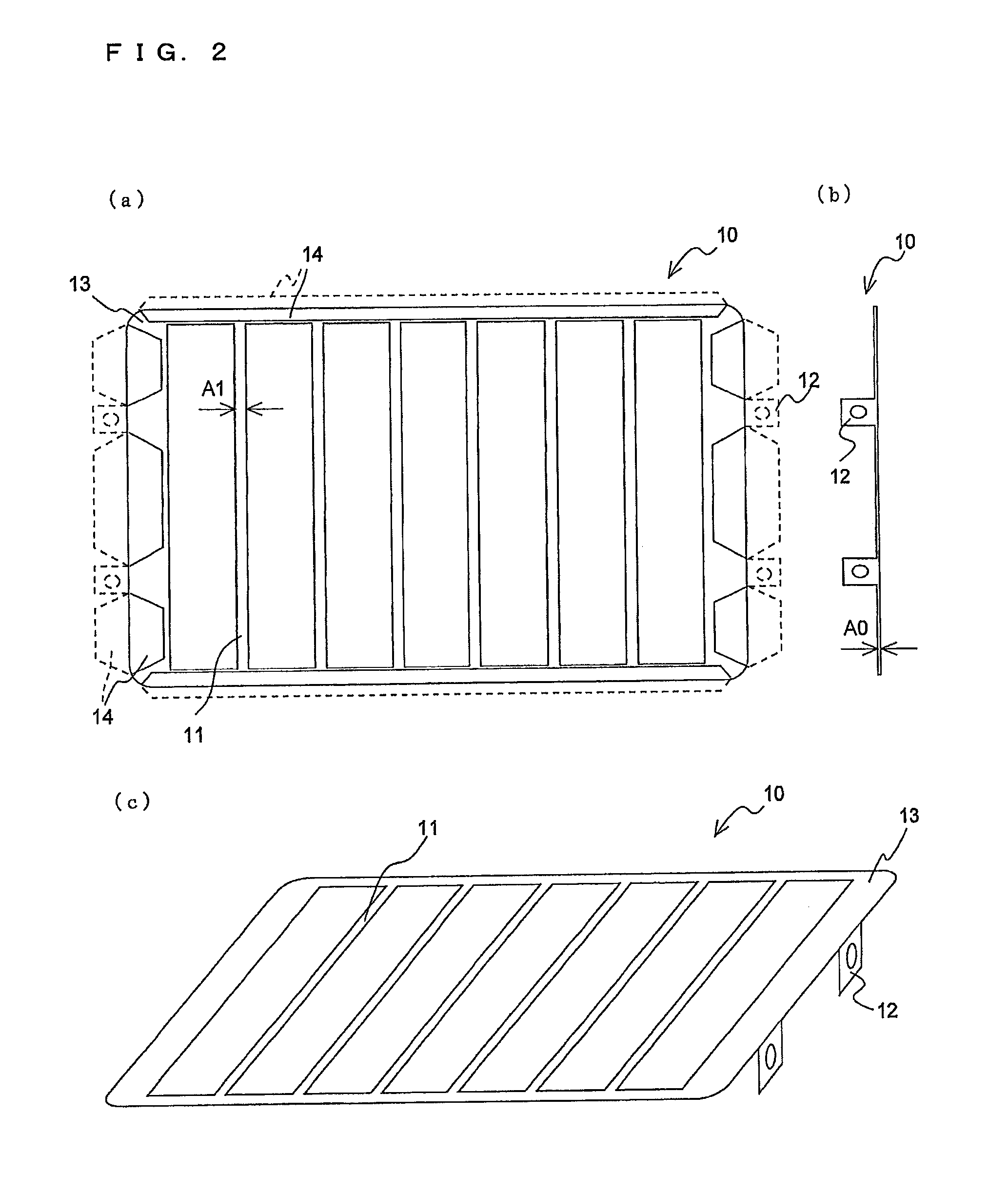

Dust collector

ActiveUS7316735B2Efficiently collecting the particulate matter containedVapor flow controlGas separationEngineeringAperture ratio

An apparatus, which collects particulate matter contained in a gas flowing through a flow path formed in a cylindrical shape having an outer surface and an inner surface, includes: an outer shell that forms the outer surface of the flow path; a ground electrode that forms the inner surface of the flow path; a filter layer that is arranged between the outer shell and the ground electrode; and a discharge electrode that generates, when a voltage is applied, an ion wind inducing a secondary flow toward the ground electrode in a direction transverse to the flow path. The secondary flow passes through the ground electrode and the filter layer having a predetermined aperture ratio.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

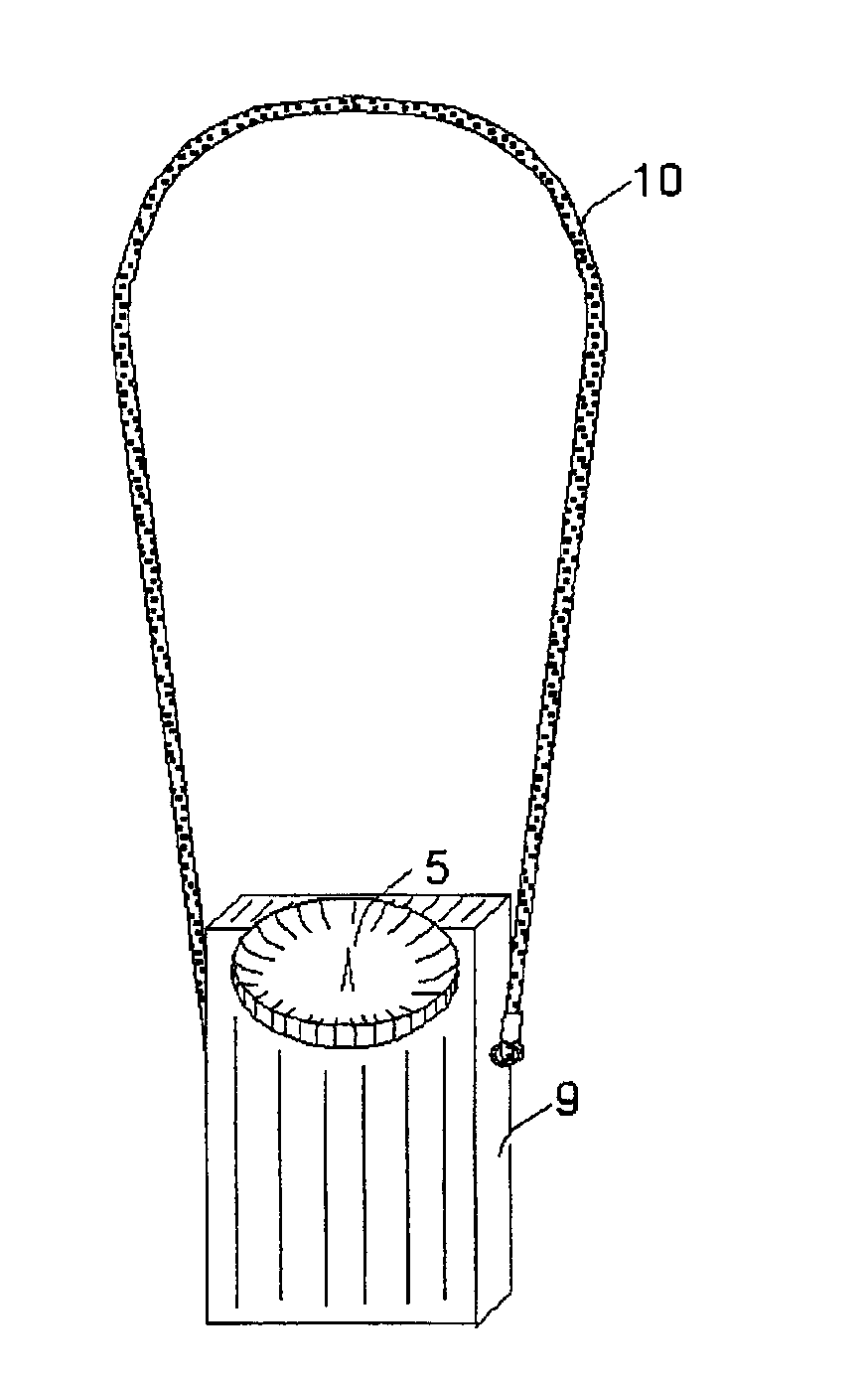

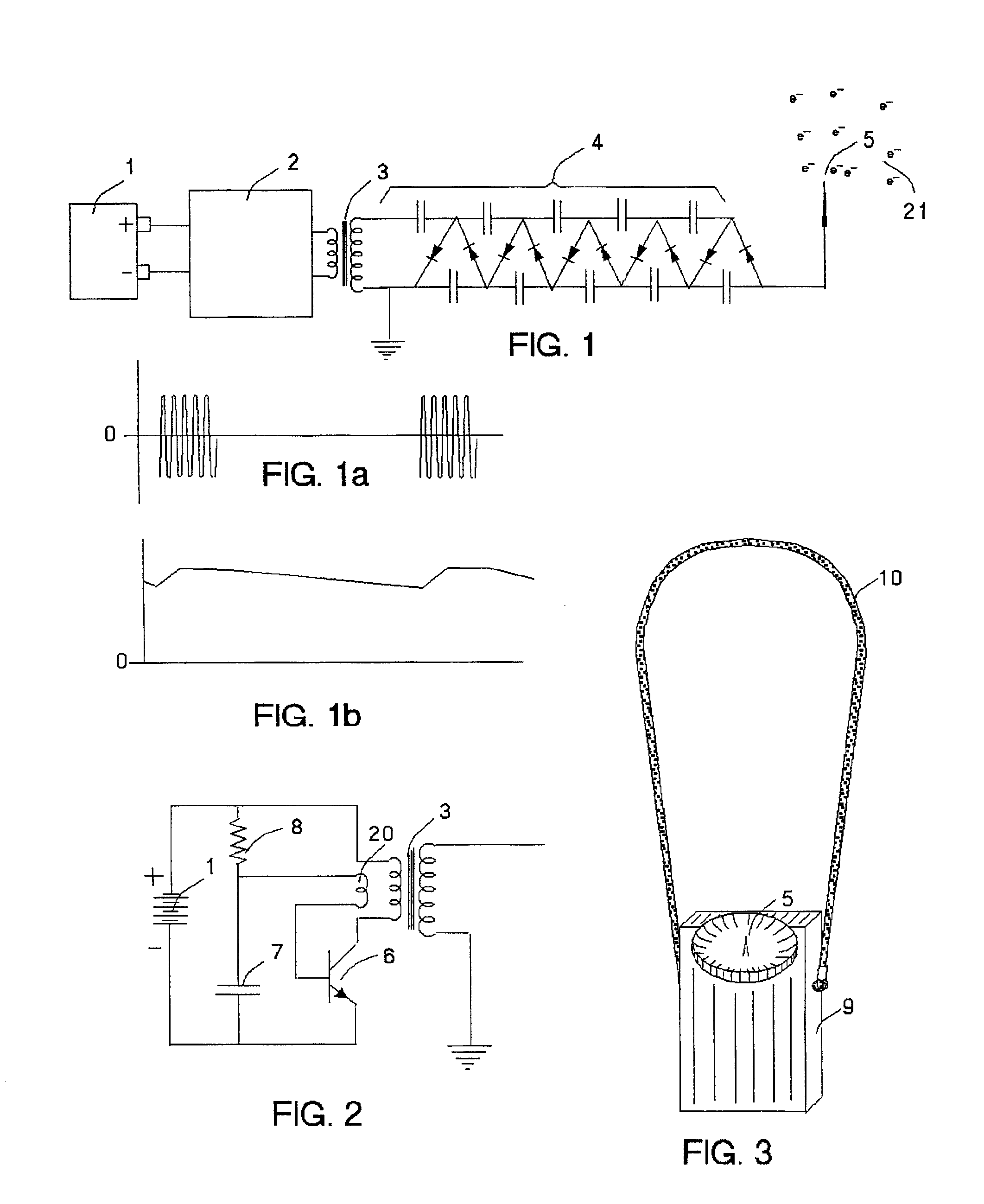

Portable ion generator and dust collector

InactiveUS6919053B2Large conductingConveniently providedMechanical apparatusElectrical apparatusElectrical batteryEngineering

This invention relates to a portable, battery-operated ion generator featuring an electronic high voltage system which uses extremely low battery power. The ion generator can be made in the form of a pendant using a standard 9-volt alkaline battery, which can last for several months of continuous operation. The ion generator can also serve as a dust collector for air purification. In particular, the dust collecting electrode is removable for ease of cleaning.

Owner:HEADWATERS RES & DEV CANADA

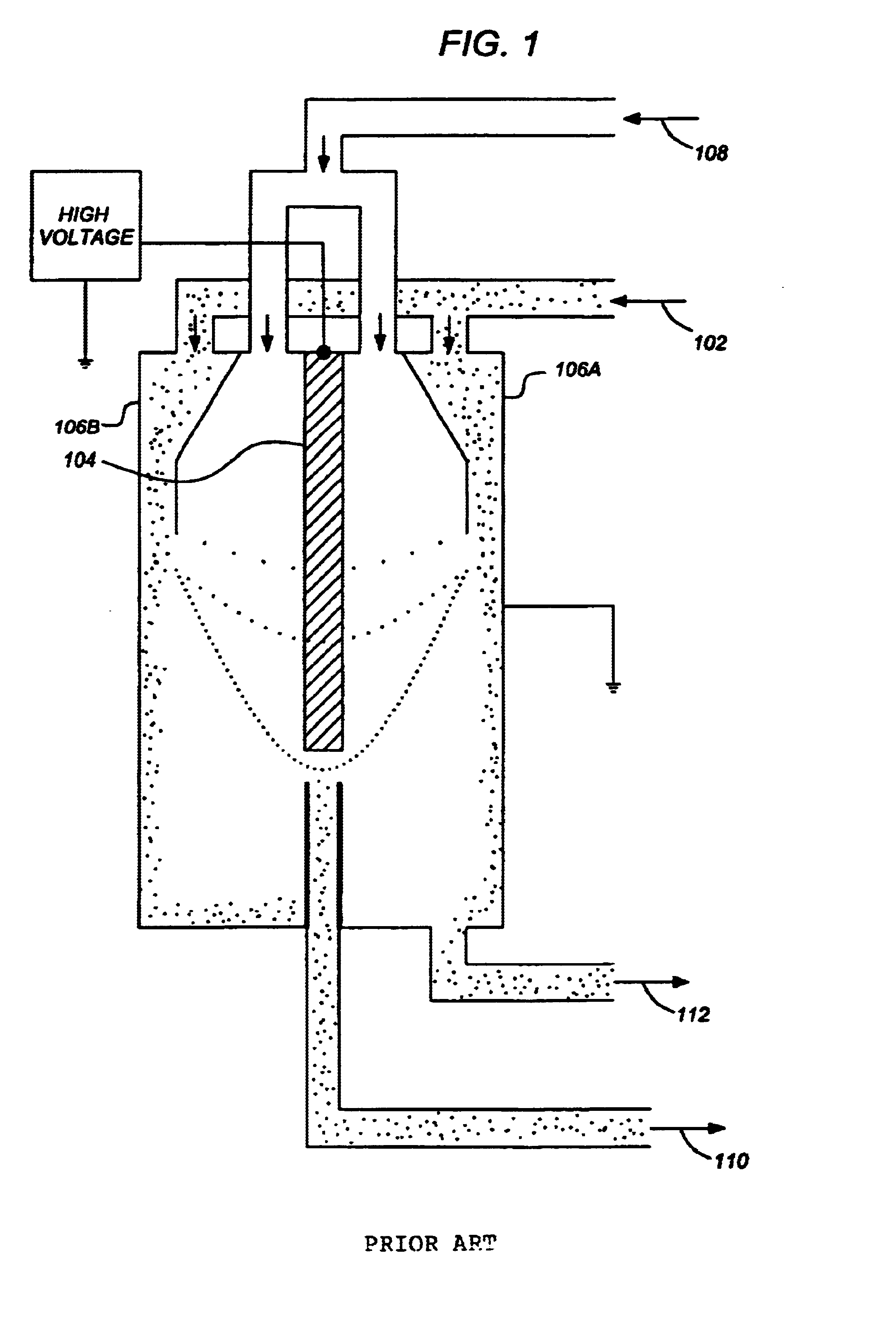

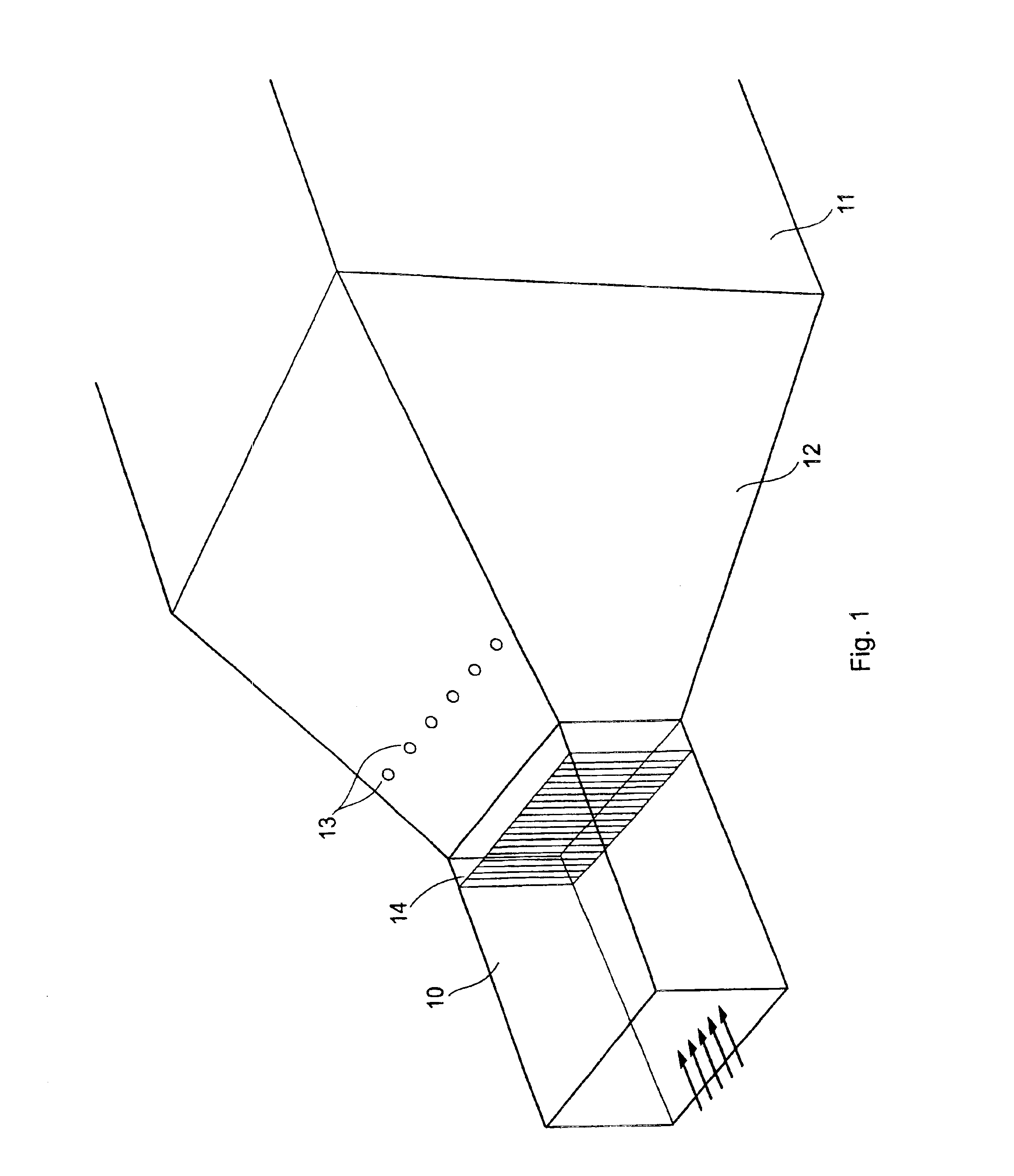

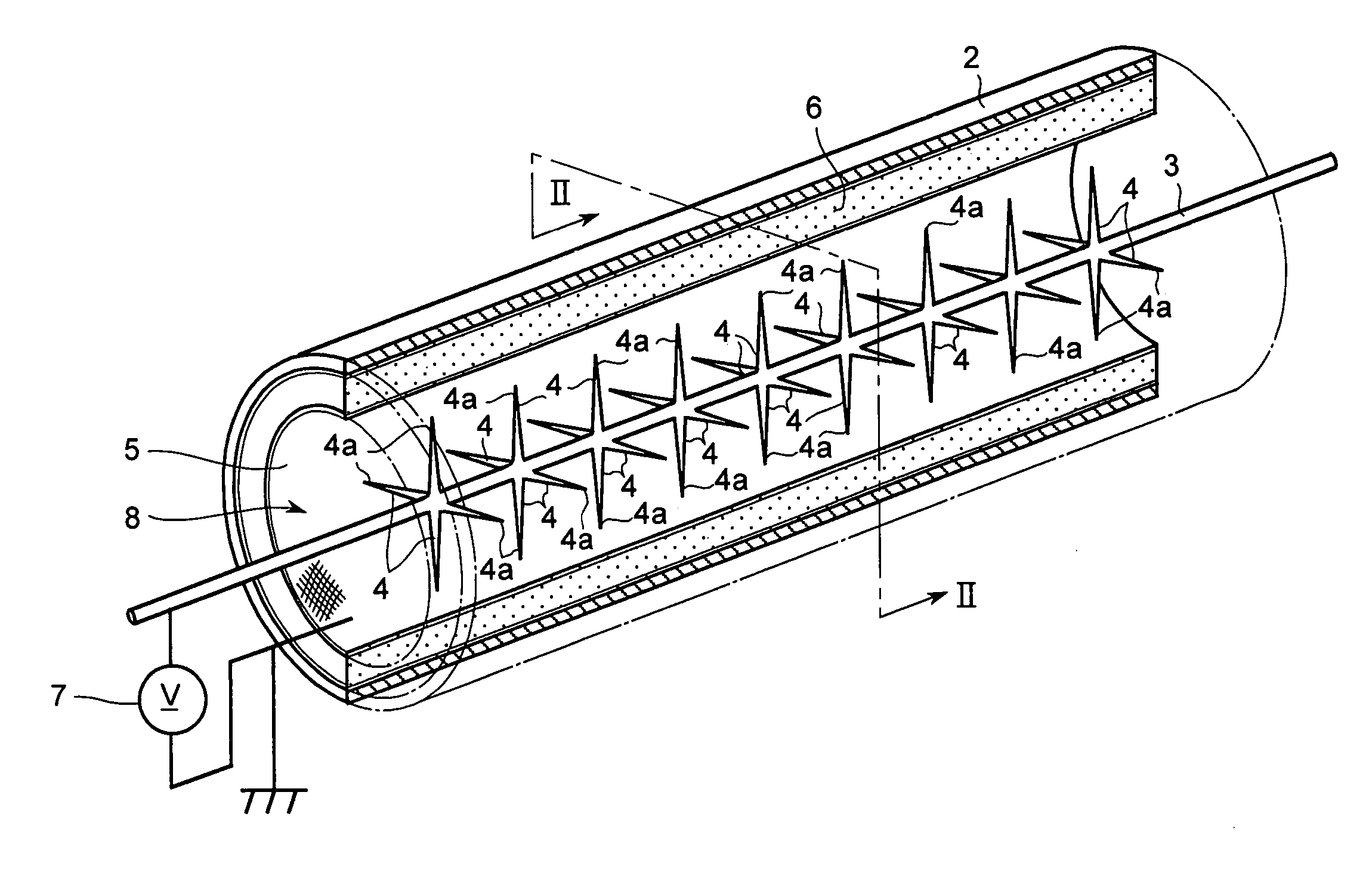

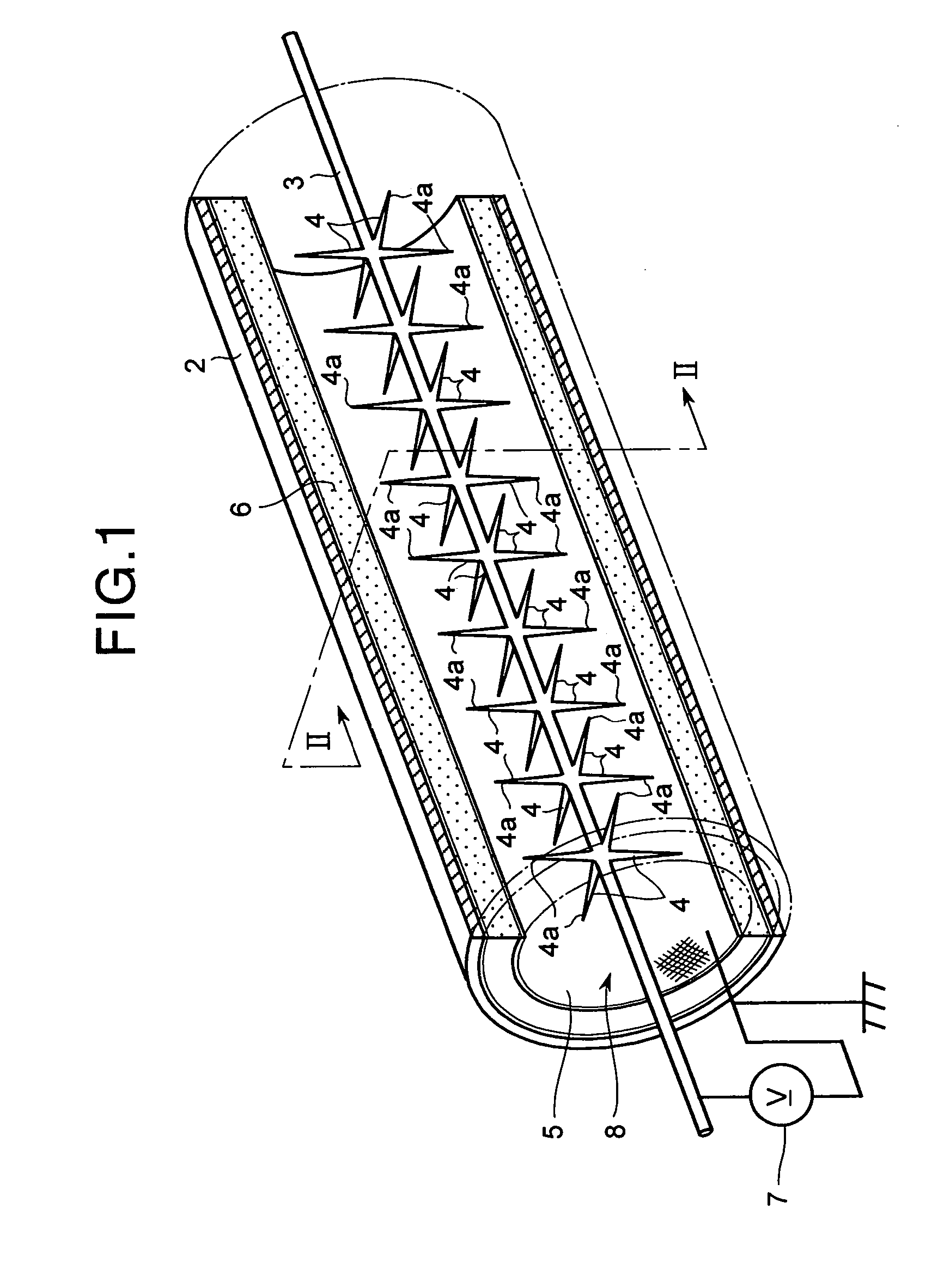

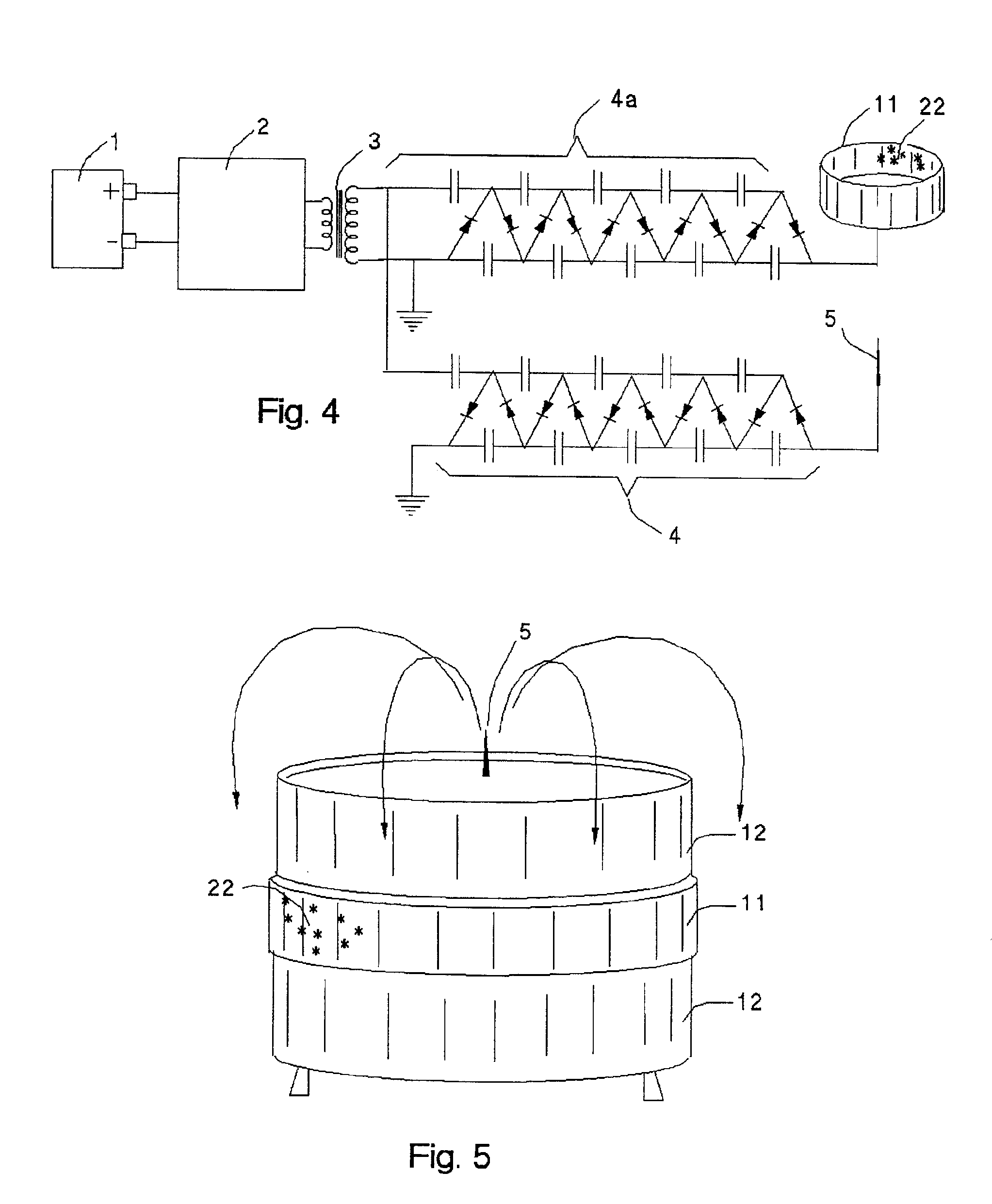

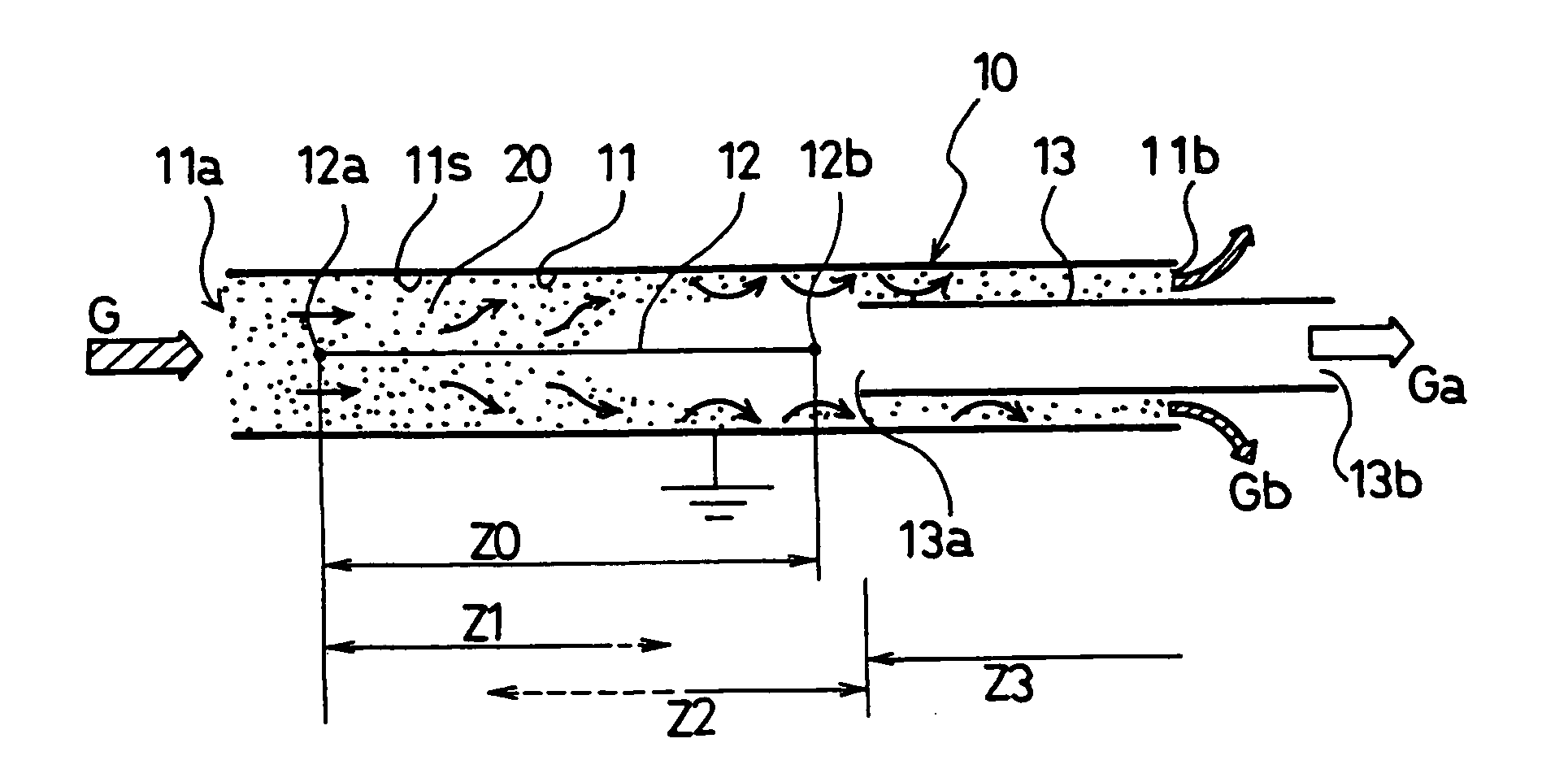

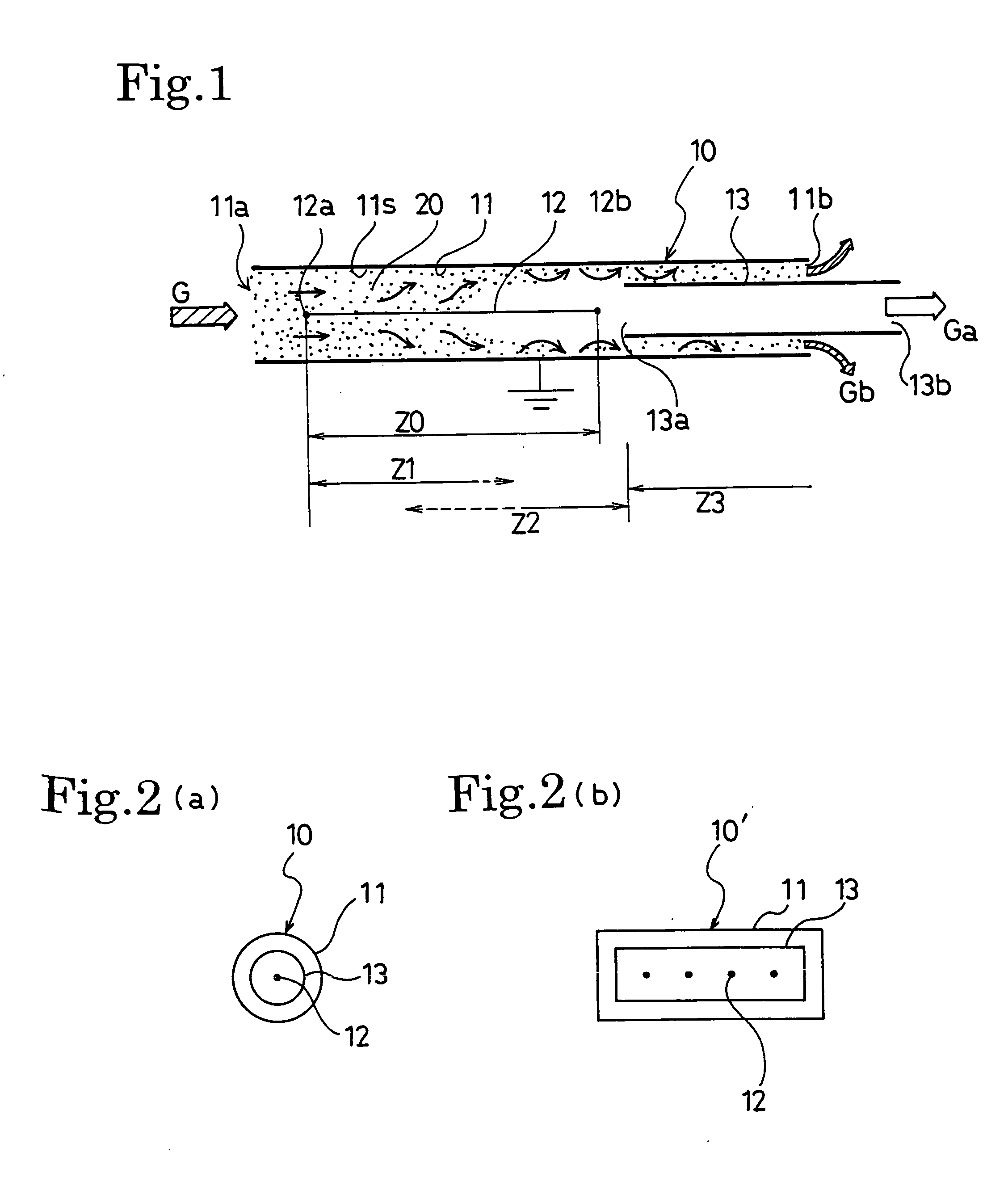

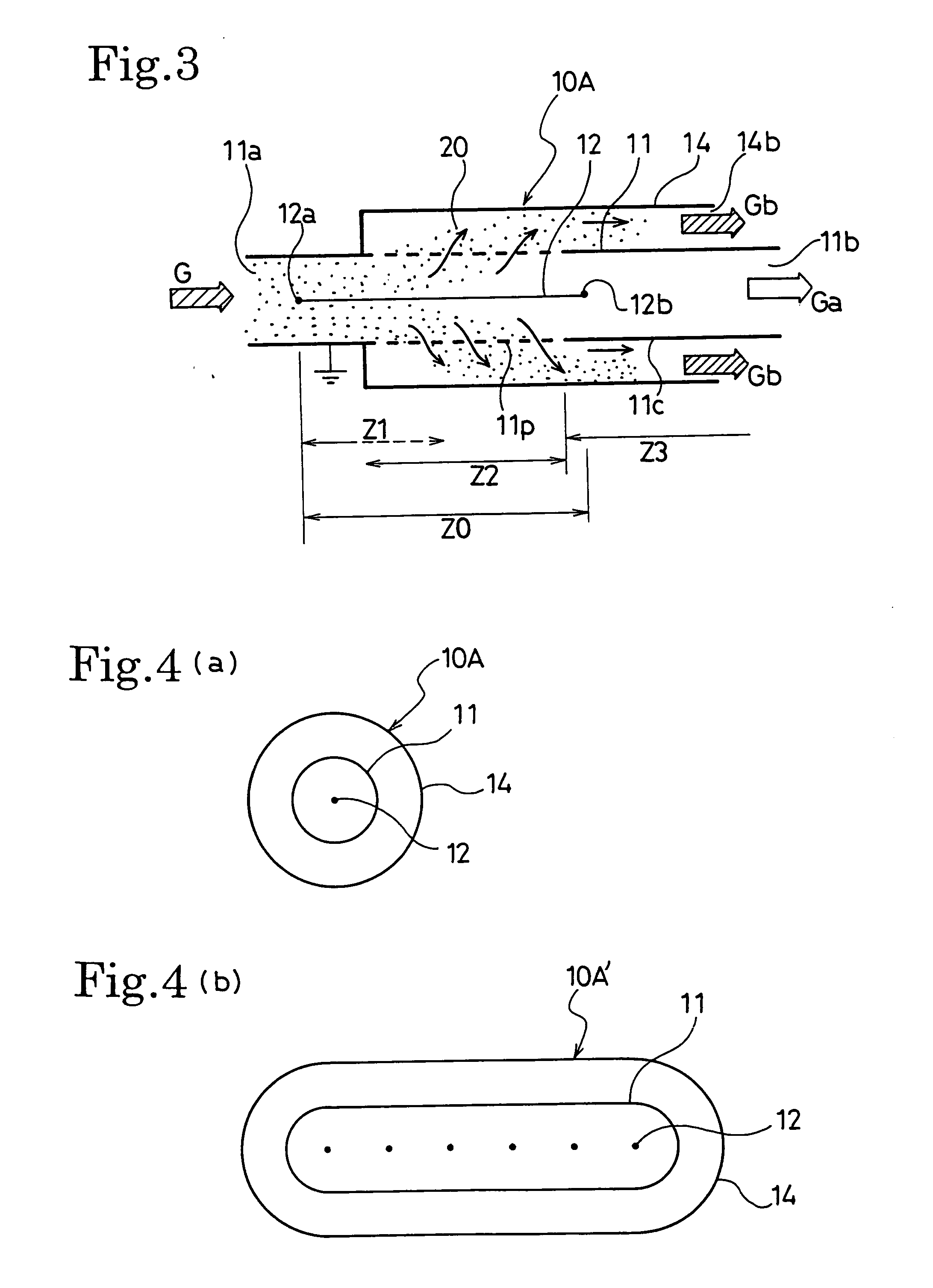

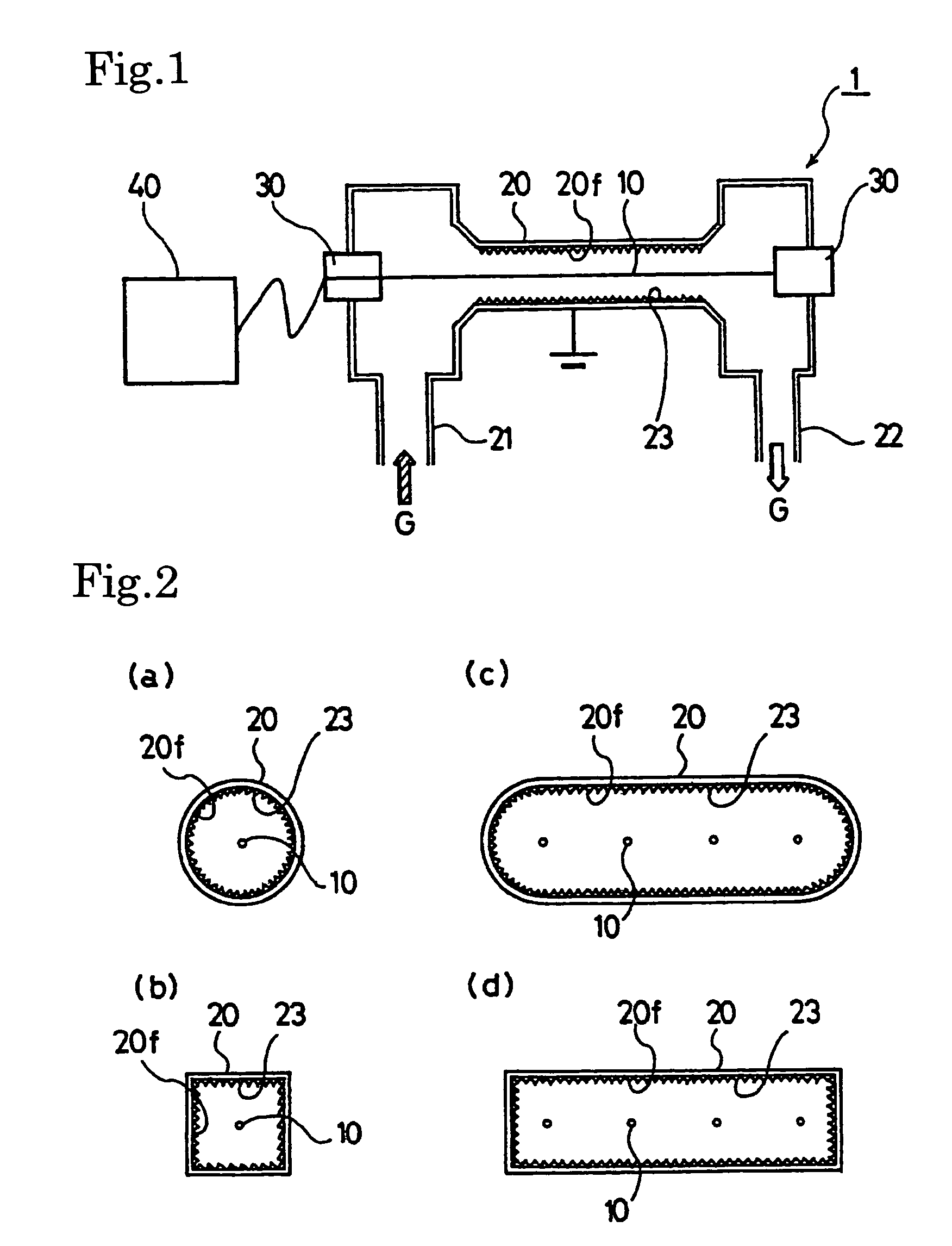

Exhaust gas processing method and exhaust gas processing system

InactiveUS20070000236A1Easy to condenseLower resistanceAuxillary pretreatmentInternal combustion piston enginesHigh concentrationParticulates

An exhaust gas processing method and an exhaust gas processing system for controlling the spatial density distribution of particulate matter in exhaust gas by utilizing corona discharge in exhaust gas containing floating particulate matter such as diesel engine exhaust gas to form a relatively particulate matter-rich area and a relatively particulate matter-lean area, and diving exhaust gas particulates to the former and the latter. An exhaust gas processing system (10) provided with a high-voltage electrode (12) and a low-voltage electrode (11), wherein exhaust gas G is allowed to flow between the facing high-voltage electrode (12) and low-voltage electrode (11), and a high voltage is applied to between the counter electrodes to generate corona discharge in the exhaust gas G, whereby floating particulate matter (20) in the exhaust gas G is charged, the spatial density distribution of the floating particulate matter in the exhaust gas is controlled by an electrostatic force between the counter electrodes, and the exhaust gas G is divided into a high-concentration exhaust gas Gb in the vicinity of the low-voltage electrode where a particulate matter concentration is relatively high and a low-concentration exhaust gas Ga in the vicinity of the high-voltage electrode where a particulate matter concentration is relatively low.

Owner:NISSIN ELECTRIC CO LTD +2

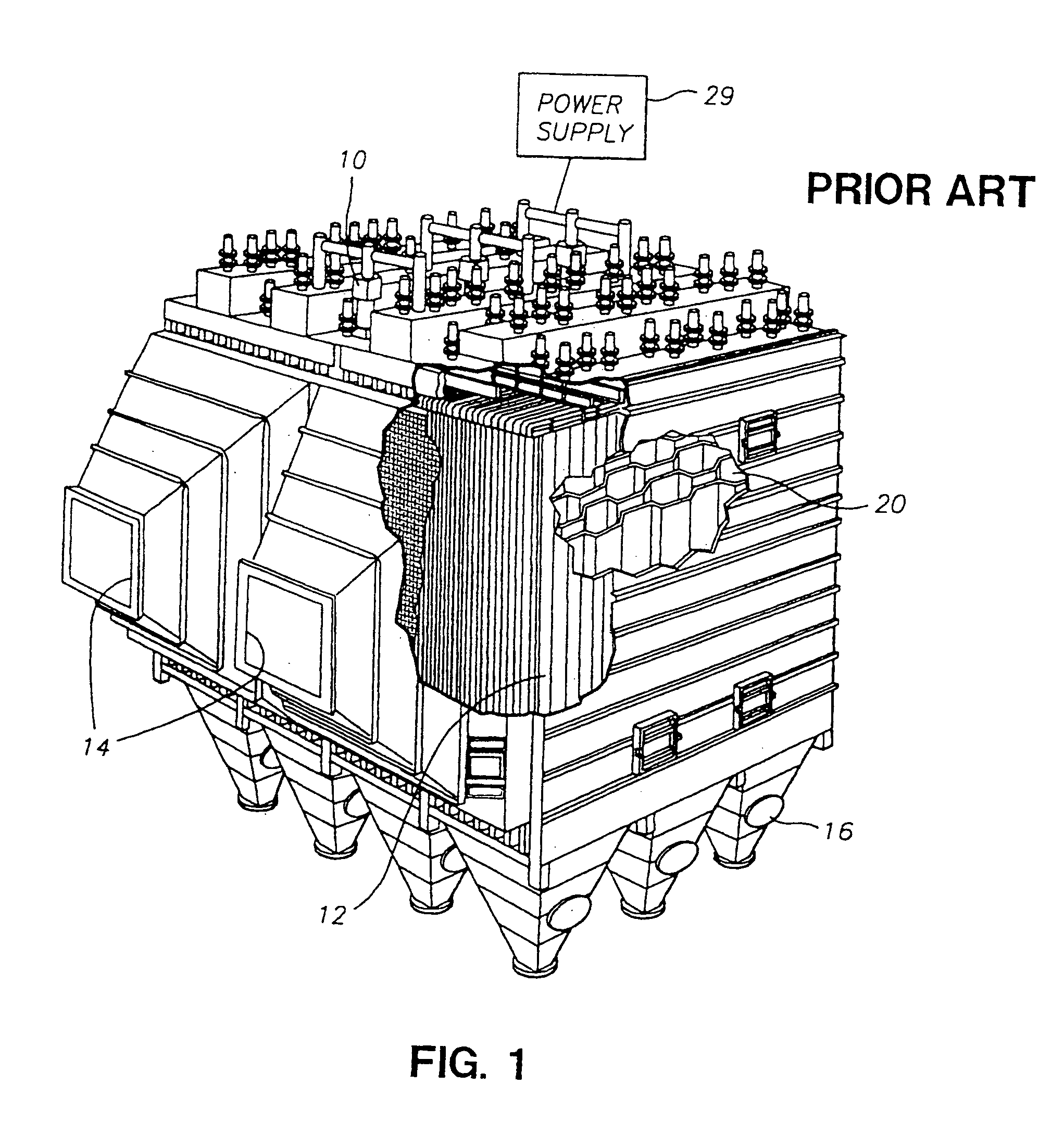

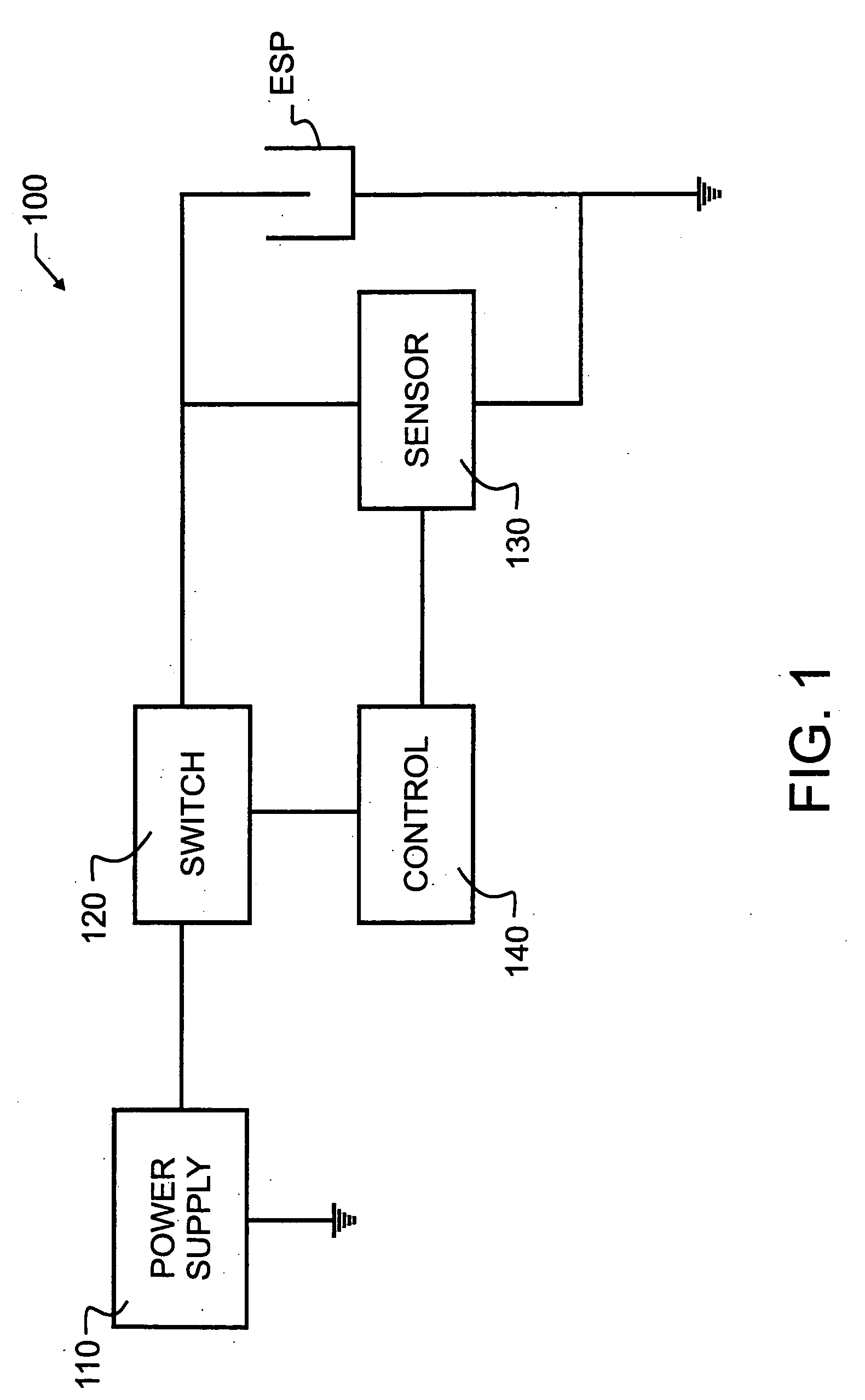

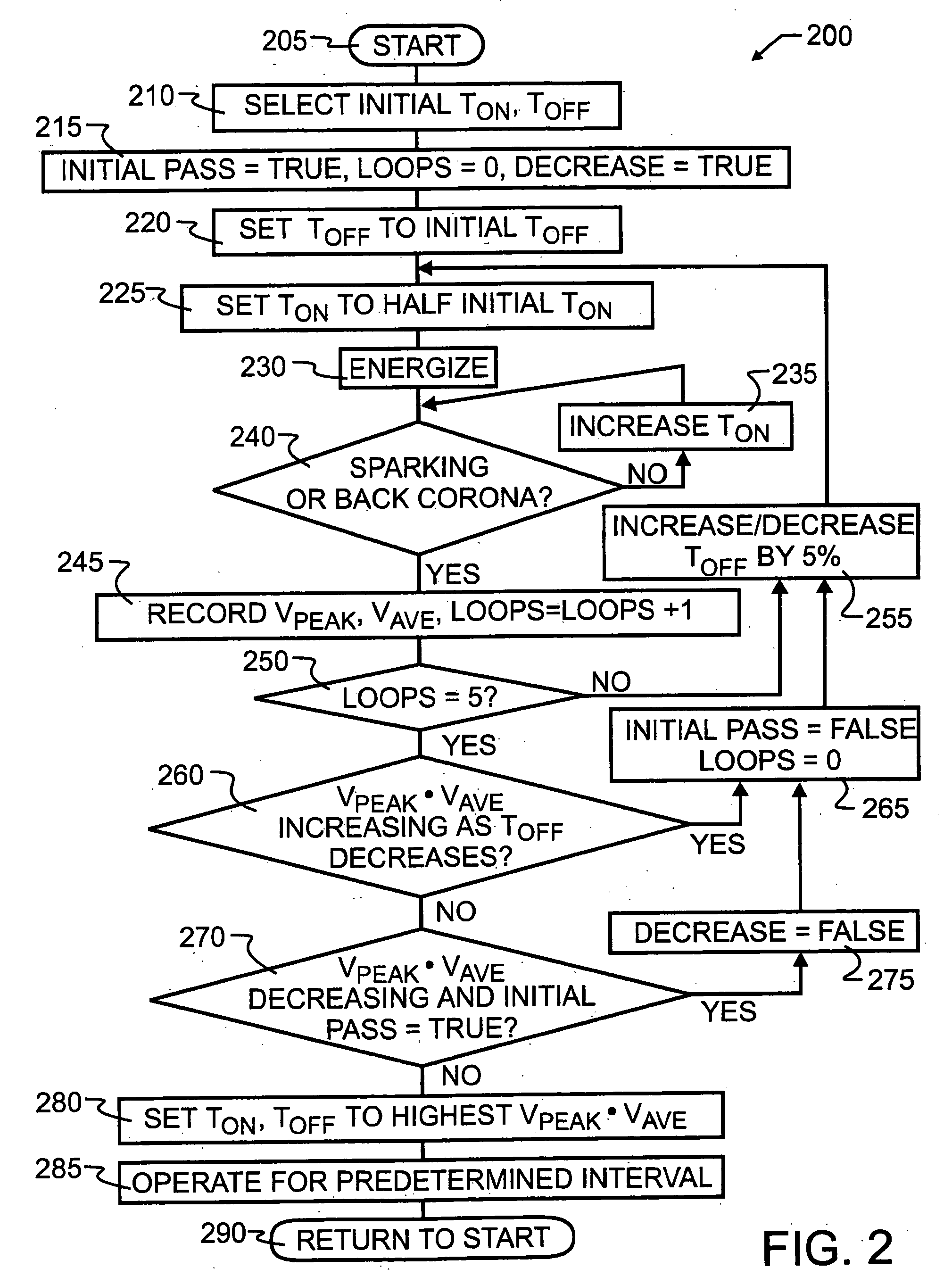

ESP performance optimization control

InactiveUS20050178265A1Improve operational efficiencySuitable for collectionPower supply linesExternal electric electrostatic seperatorOperational systemHigh peak

A gas separation apparatus which uses electrostatic precipitators and a DC power supply is controlled to optimally remove moderate to high resistivity ash. The DC power supply is pulse width modulated to maximize the product of the peak electric field and the average electric field. The method used to optimize operation includes selecting initial on and off times for the power supply, operating the power supply using the initial off and on times, and progressively decreasing the off time. A determination is made whether the off time may be further decreased. Ultimately, the on and off time intervals that produce the highest peak and average voltage are determined, and the system is operated using these parameters. A procedure may be periodically repeated to monitor the process and detect if there has been a change in the system that would require new time intervals. The novel separation apparatus and control method offer particular synergy when applied to the effluent stream from a coal-fired electric power plant or other similar gas streams.

Owner:ELECTRIC POWER RES INST INC

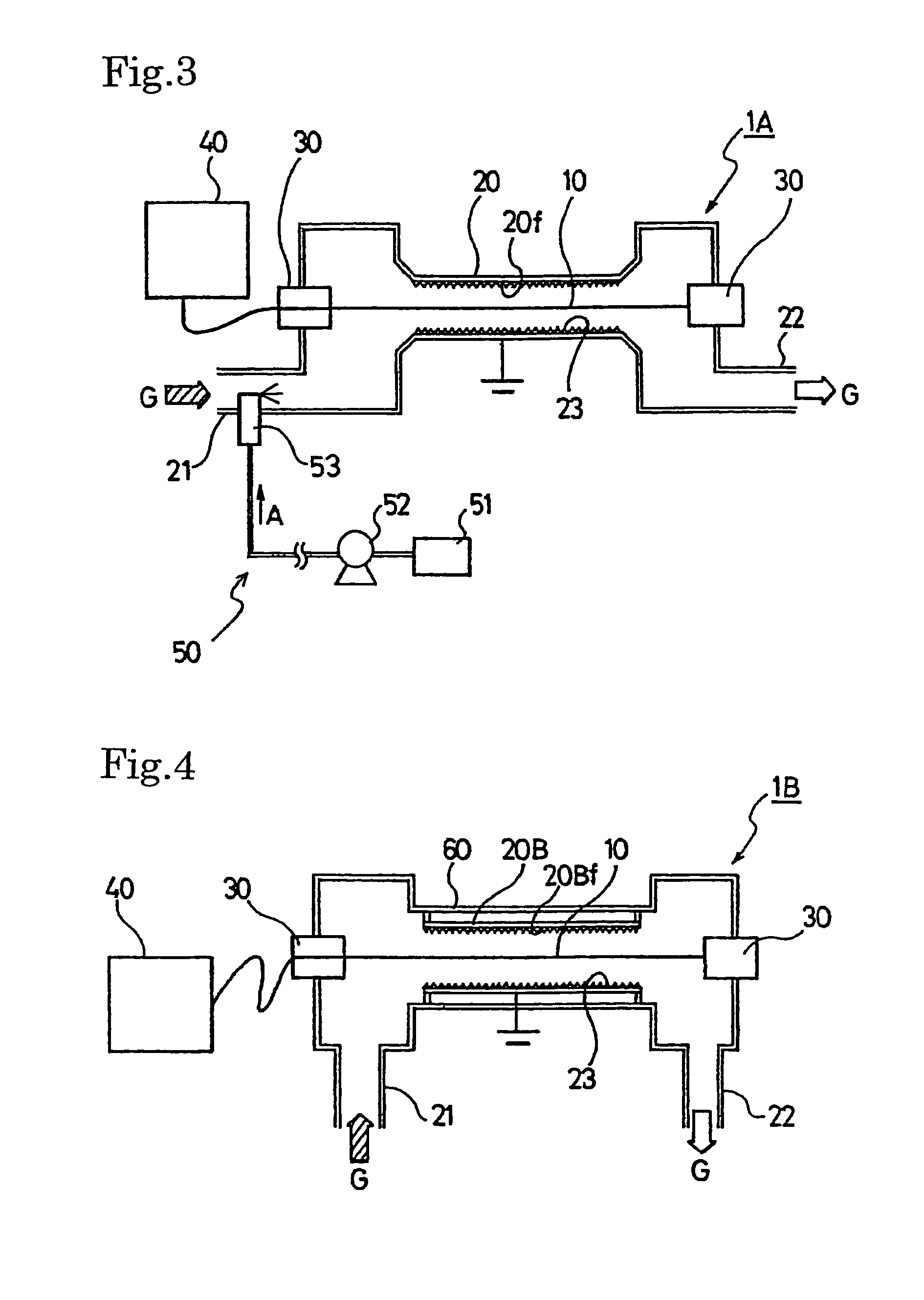

Gas treatment device

InactiveUS7758675B2Improve performanceLess pressure lossGas treatmentInternal combustion piston enginesGas passingCorona discharge

Owner:AKIRA MIZUNO +1

Electro-kinetic air transporter conditioner device with enhanced anti-microorganism capability and variable fan assist

An air transporter-conditioner device comprising: an elongated housing having a bottom, a top and an elongated side wall, the housing having an inlet located adjacent to the bottom and an outlet located adjacent to the elongated side wall; an emitter electrode and a collector electrode; a high voltage generator operably connected to both electrodes; an impeller to draw air into the housing through the inlet and direct the air along the elongated housing; and a baffle to direct air from the fan toward the outlet. The housing includes a second elongated side wall and the baffle includes a plurality of deflectors positioned along the second elongated side wall. The baffle includes a plurality of elongated columns of varying lengths, wherein each column includes a deflector. The device further comprises a second inlet located adjacent to the elongated side wall and a germicidal lamp located inside the elongated housing.

Owner:SHARPER IMAGE ACQUISITION LLC A DELAWARE LIMITED LIABILITY

Separating contaminants from gas ions in corona discharge ionizing bars

ActiveUS8038775B2Prevent and decrease fuzz ballProlong maintenance-free timeElectretsMagnetic separationCorona dischargeIonization

Owner:ILLINOIS TOOL WORKS INC

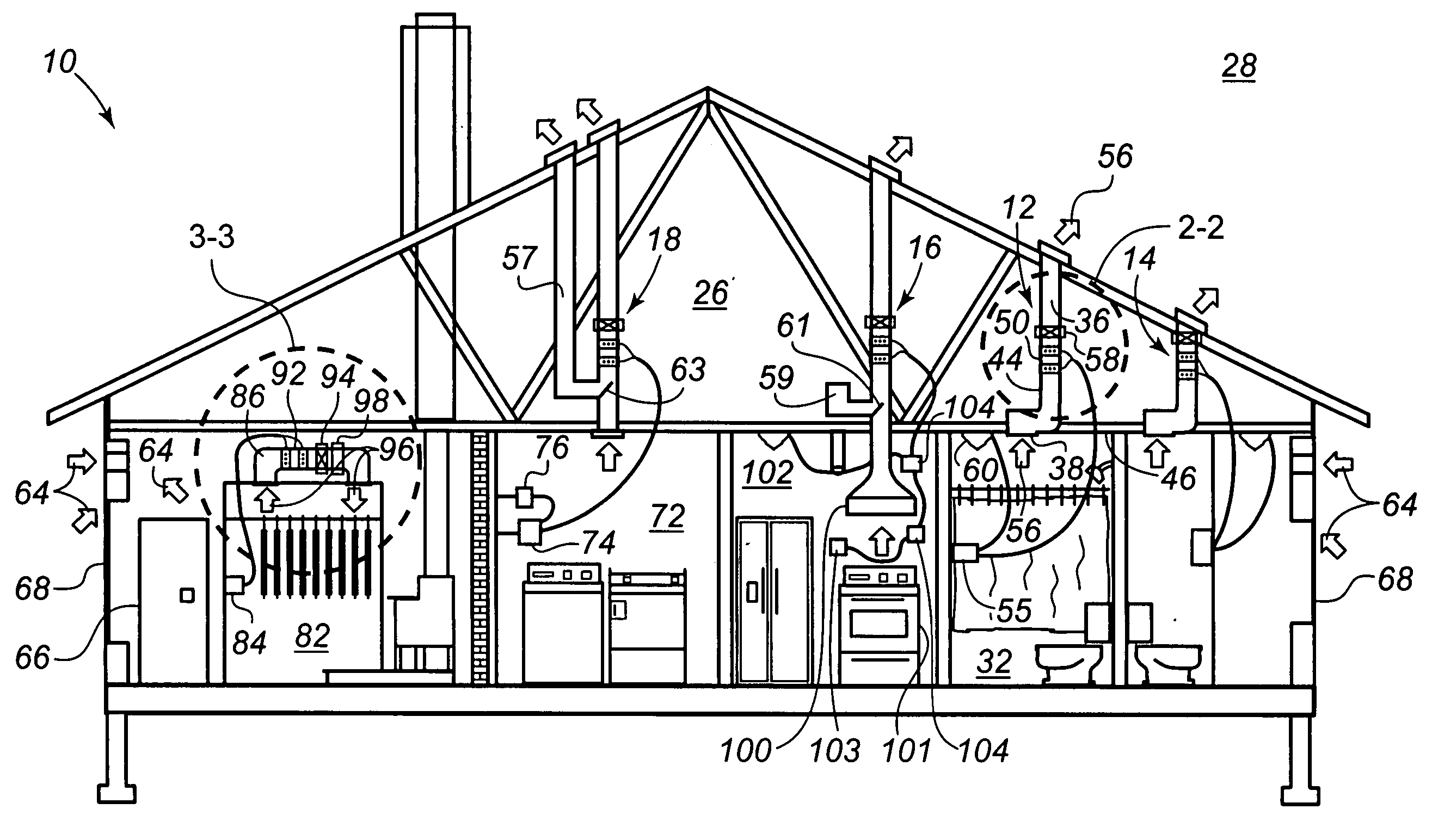

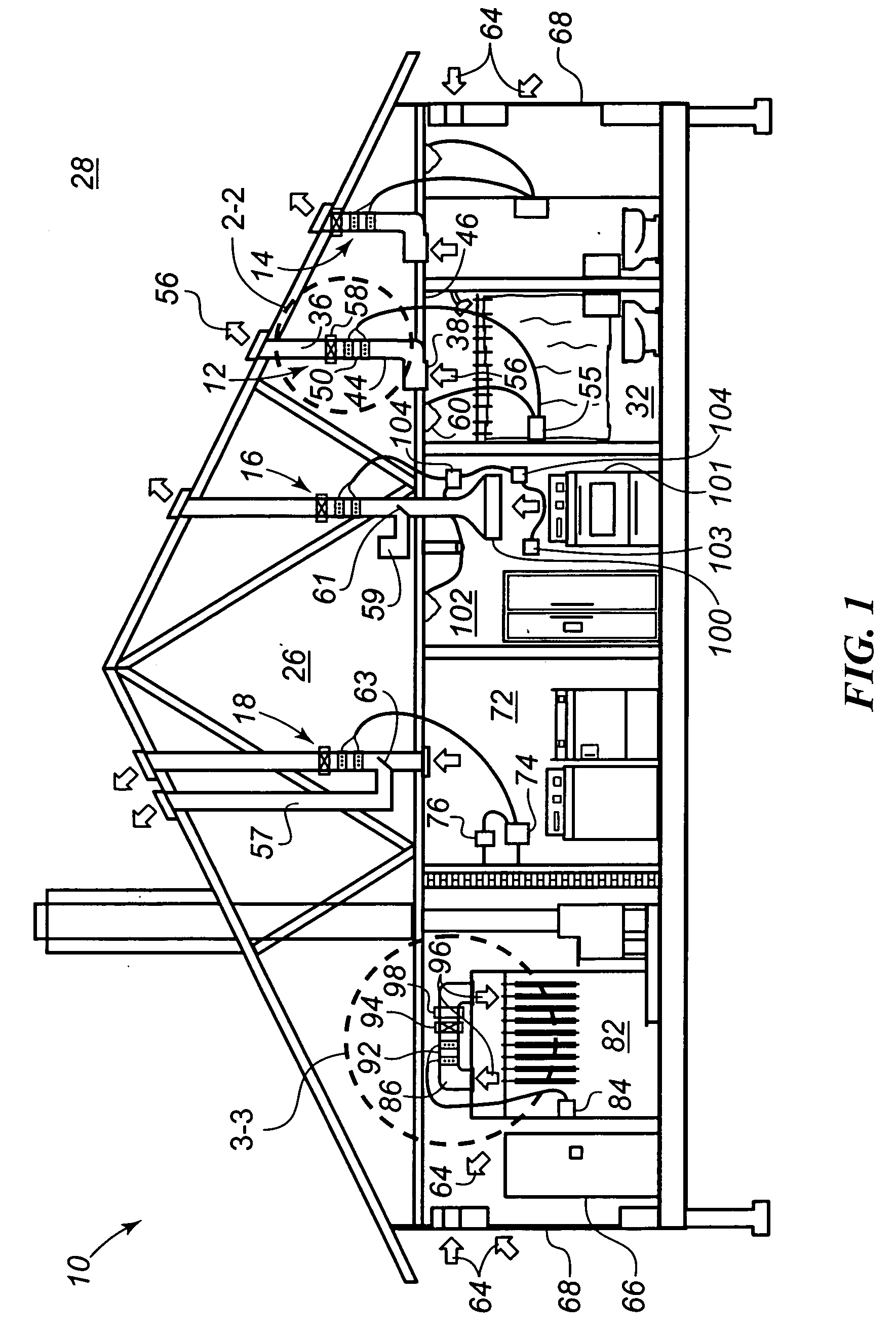

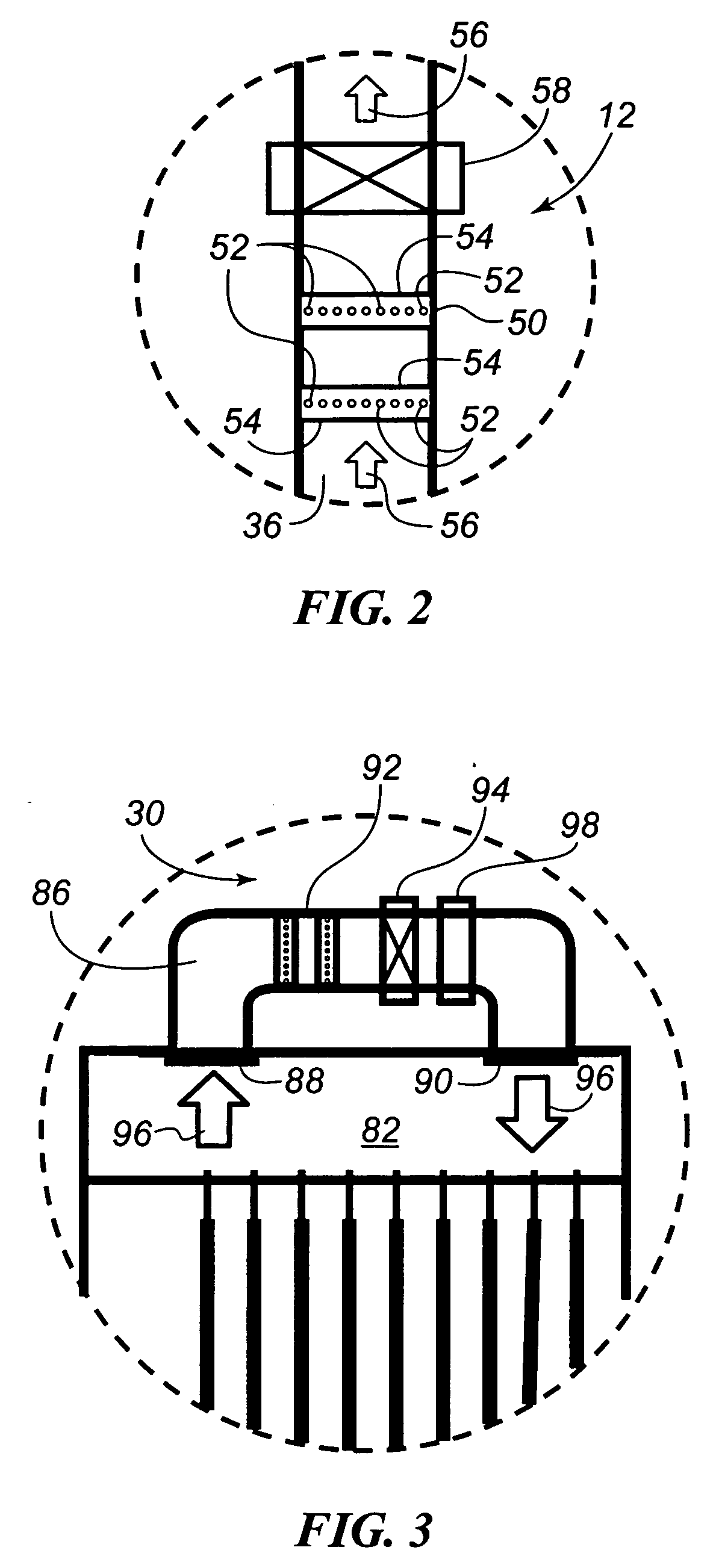

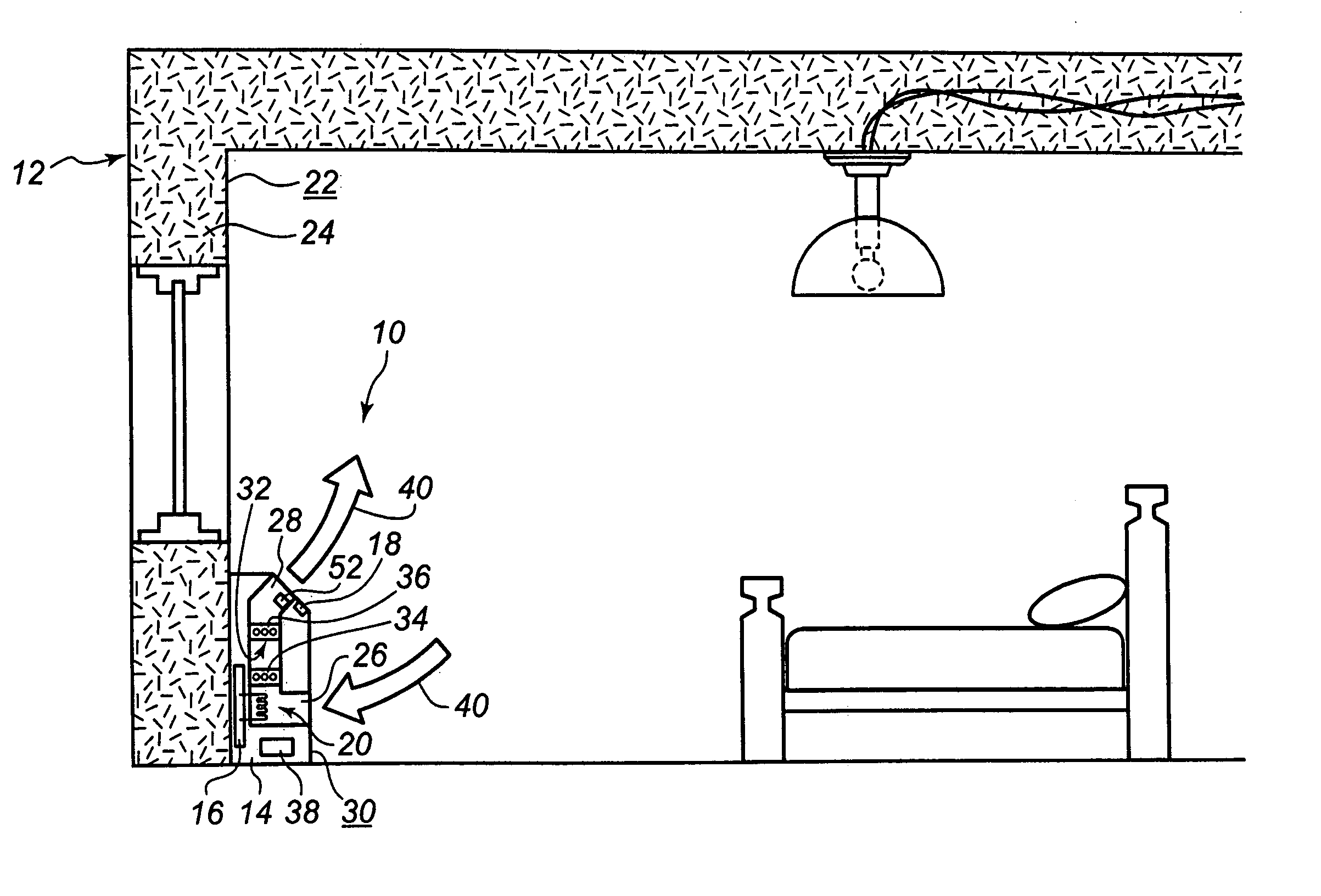

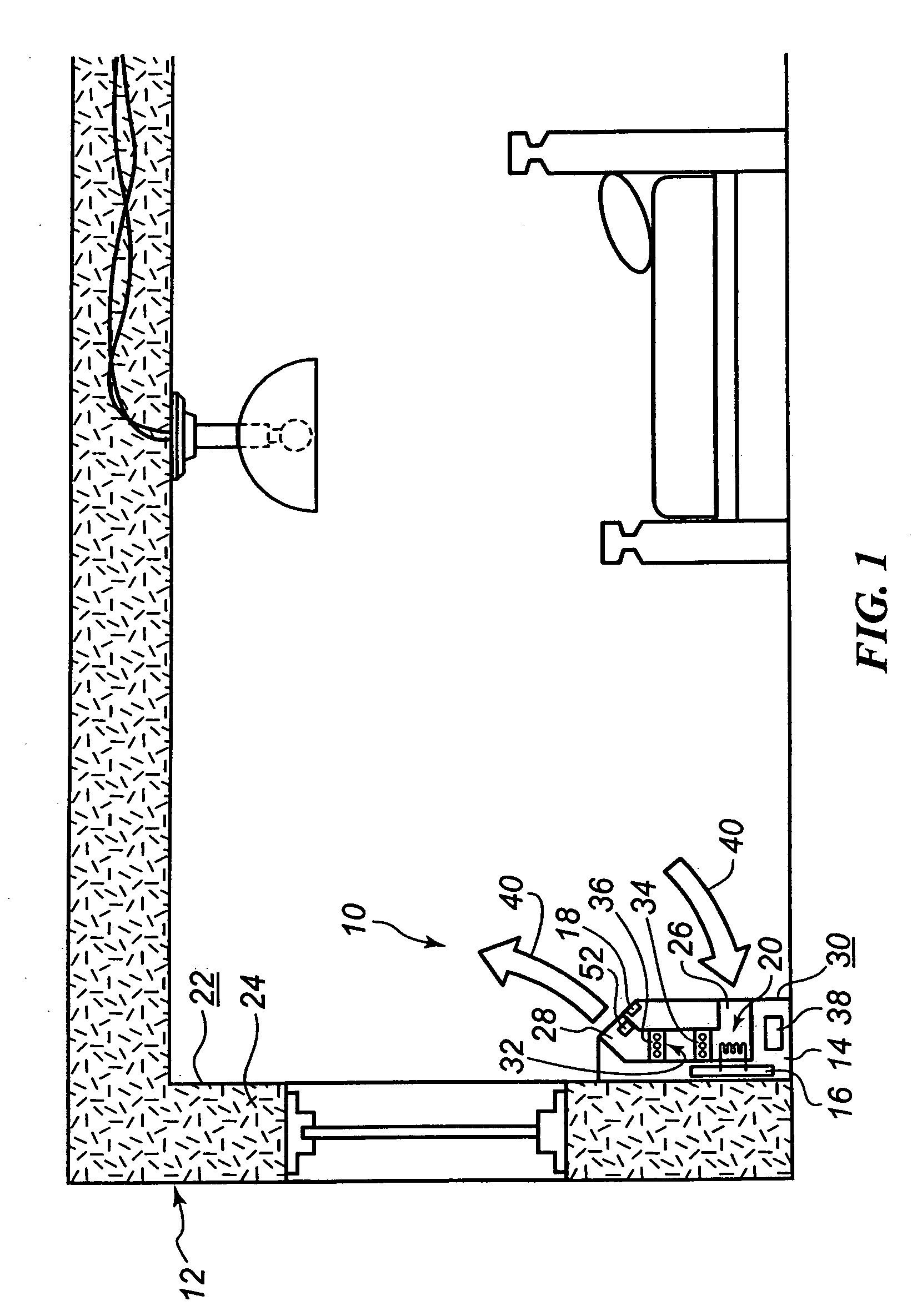

Spot ventilators and method for spot ventilating bathrooms, kitchens and closets

InactiveUS20060112828A1Improve responsivenessEasy to operateCombination devicesAuxillary pretreatmentCorona dischargeEngineering

A spot ventilator and method for spot ventilating a localized environment of a building is provided. The spot ventilator comprises a passage and at least one corona discharge apparatus. The passage extending between an inlet positioned in the localized environment and an outlet. The at least one corona discharge apparatus positioned in relation to the passage such that a fluid from the localized environment is drawn into the passage through the inlet and is expelled through the outlet. The method of ventilating a localized environment of a building includes the steps of sensing a first change in the localized environment, energizing a corona discharge apparatus to produce an electric wind, drawing air from the localized environment into a passage via the electric wind and expelling the air from the passage through the outlet.

Owner:RANCO OF DELAWARE

Electrostatic filter

An electrostatic filter (1) has a chamber (11) into which a gas stream is introduced. An ioniser (19) in the form of an electrode array (20) is located in the chamber (11) and creates an ionising zone through which the gas stream passes. A charged outlet (21) is located downstream from the ioniser (19). As the gas stream passes through the ionising zone, the unwanted particles therein are charged and urged away from the outlet (21) by the ioniser (19). Charged particles approaching the outlet (21) are also electrostatically repelled therefrom, permitting “clean” gas to be extracted through the outlet.

Owner:HANSOM ENVIRONMENTAL PROD

Corona-discharge air mover and purifier for packaged terminal and room air conditioners

InactiveUS20060112708A1Without usingMechanical apparatusDomestic cooling apparatusElectricityCorona discharge

An air conditioning device for heating and / or an environment is provided. The air conditioning device includes a heat exchanging apparatus, a passage, and a corona discharge apparatus. The passage is in thermal communication the heat exchanging apparatus and extends between an inlet and an outlet. The corona discharge apparatus is disposed within the passage to draw a fluid from the environment into the passage through the inlet, move the fluid through the passage to permit the heat exchanger to remove or heat the fluid, and expel the fluid through the outlet into the environment. As such, the environment is cooled or heated. Embodiments of the present invention include package terminal air conditioners (PTACs), room air conditioners (RACs), and mini-split heating and cooling systems.

Owner:RANCO OF DELAWARE

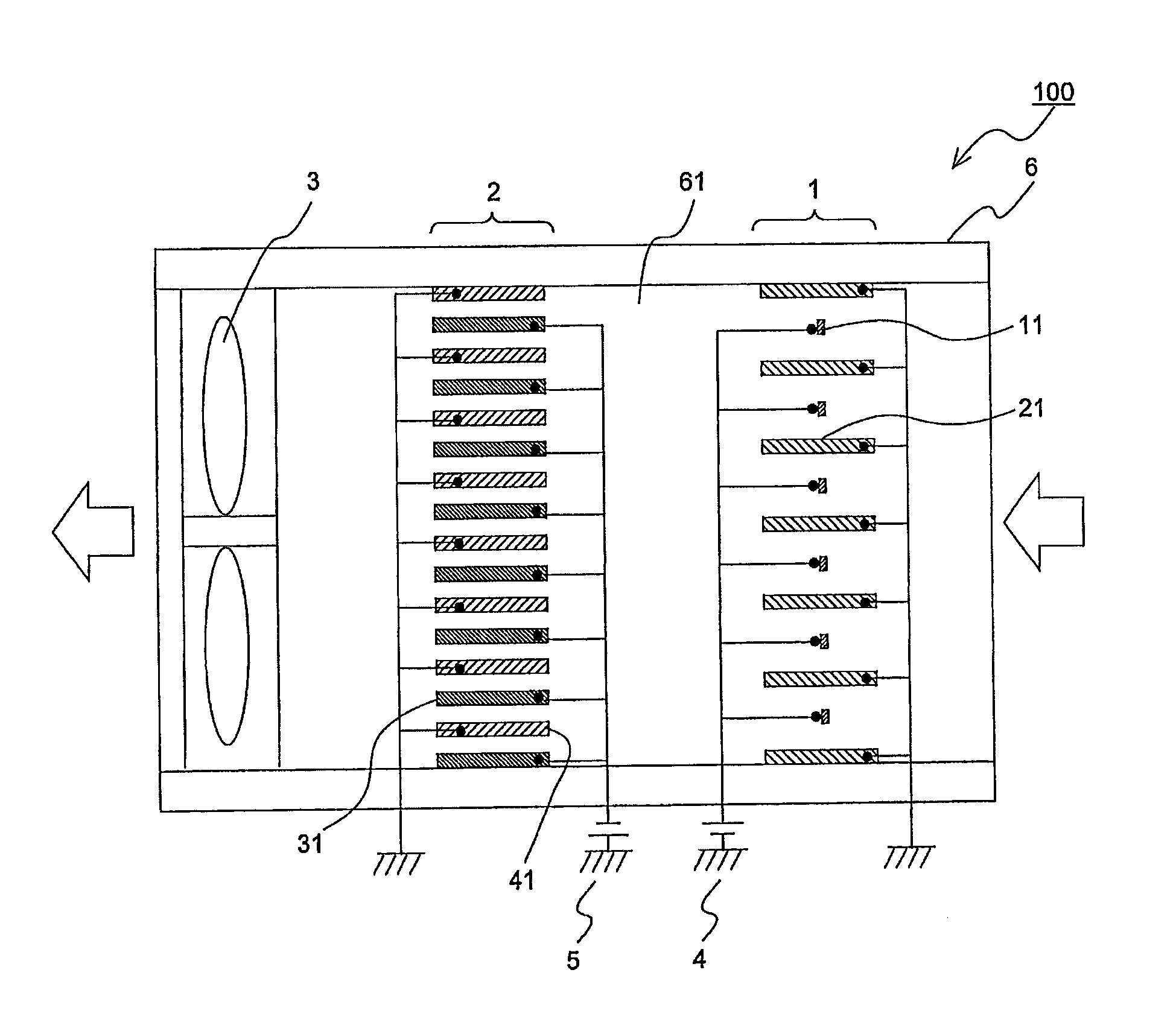

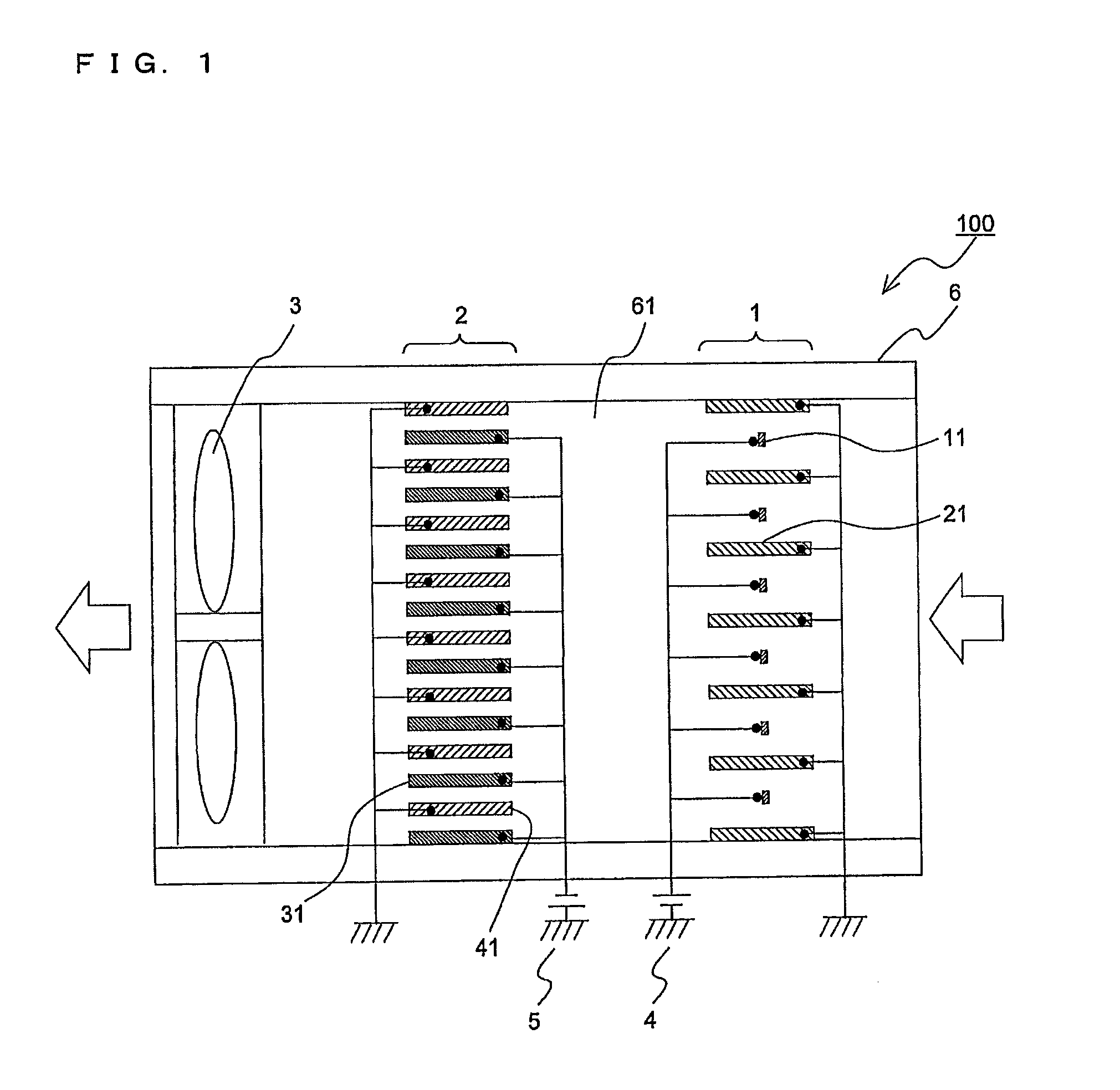

Corona discharge device and air-conditioning apparatus

ActiveUS9457118B2Improve charge efficiencyEasy to assembleMechanical apparatusLighting and heating apparatusCorona dischargeEngineering

A corona discharge device includes a charging-section high-voltage electrode unit including a plurality of charging-section high-voltage electrodes, and a charging-section ground electrode unit includes a plurality of charging-section ground electrodes formed by flat plates. The plurality of charging-section high-voltage electrodes are arranged at intervals in a direction intersecting an airflow in an air path, and are connected to one another at at least one longitudinal end by a conductive frame portion. The plurality of charging-section ground electrodes are disposed between the charging-section high-voltage electrodes in an orientation such that flat surfaces thereof are substantially parallel to the airflow in the air path, and are connected at at least one longitudinal end by a conductive frame portion. The plurality of charging-section high-voltage electrodes and the plurality of charging-section ground electrodes are alternately stacked in the direction intersecting the airflow in the air path to be spaced apart from each other.

Owner:MITSUBISHI ELECTRIC CORP

Air purifier device with ionizing means

ActiveUS9694369B2Reduce weightImprove the preparation effectElectrode carrying meansMechanical apparatusAir purifiersAir cleaning

Owner:BLUEAIR

Multi-stage collector

InactiveUS20030177901A1Improve collection efficiencyIncrease the areaParticle charging/ionising stationsExternal electric electrostatic seperatorIndustrial gasLeading edge

A multi-stage collector of the type used to collect particles from industrial gas. The collector can contain multiple narrow and wide zones formed by a plurality of parallel corrugated plates. Contained in the narrow zones can be elongated electrodes with sharp leading and / or trailing edges. These electrodes can provide a non-uniform electric field near their sharp edges leading to corona discharge. The corona discharge causes particulate matter in the gas flow to become charged. The region in narrow zones away from the sharp edges of the electrodes resembles a parallel plate capacitor with relatively uniform electric field. In this region, particles can be collected on the plates and on the electrode. Wide regions can contain barrier filters (bag filters) with conductive surfaces. The collector can also be used to clean inlet gas in gasification plants and to collect re-usable materials from a gas stream.

Owner:KRIGMONT HENRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com