Wireless particle collection system

a particle collection and wireless technology, applied in the direction of metal sawing accessories, separation processes, manufacturing tools, etc., can solve the problems of adverse noise, premature failure, and often tedious operation for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

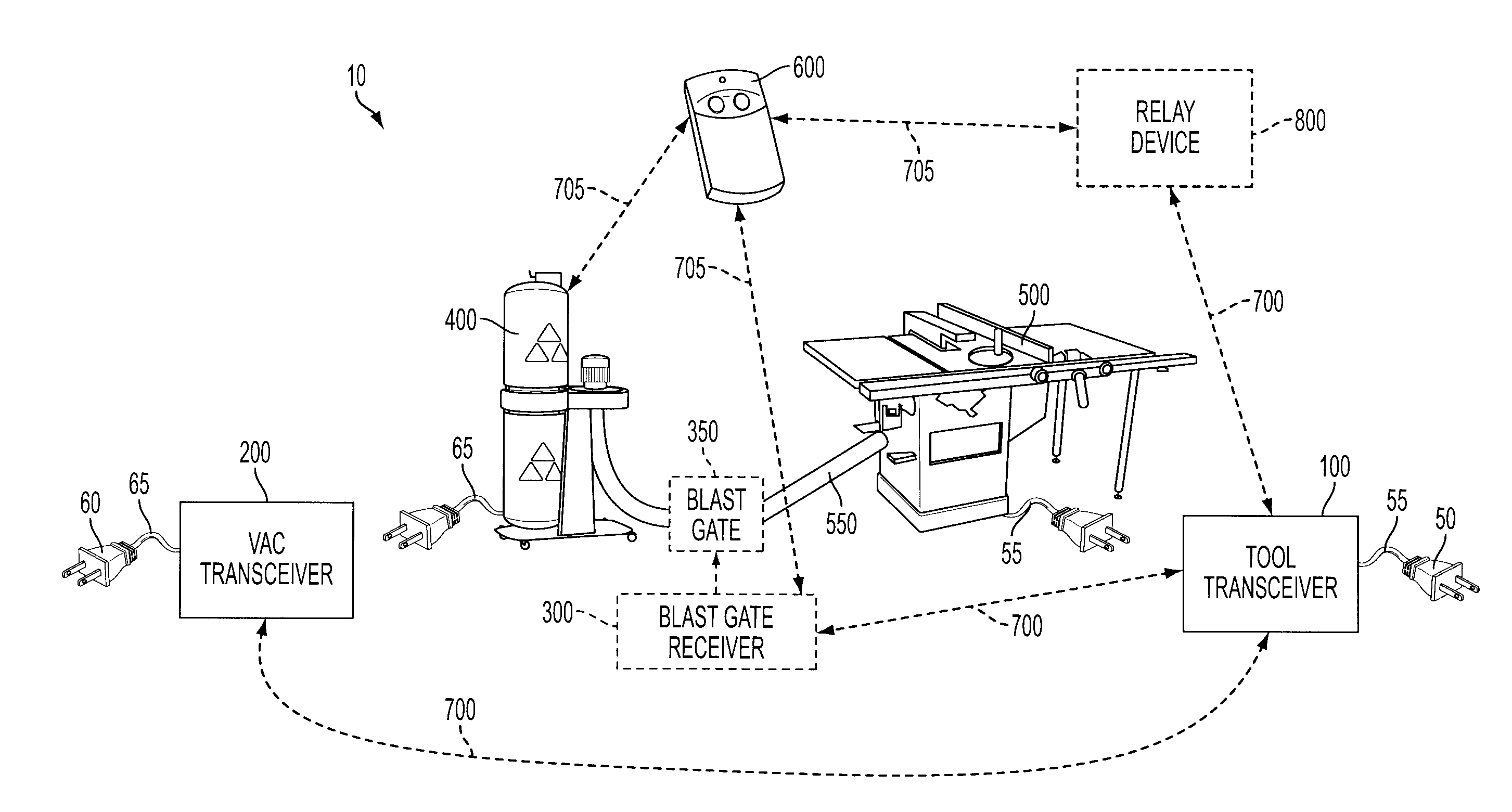

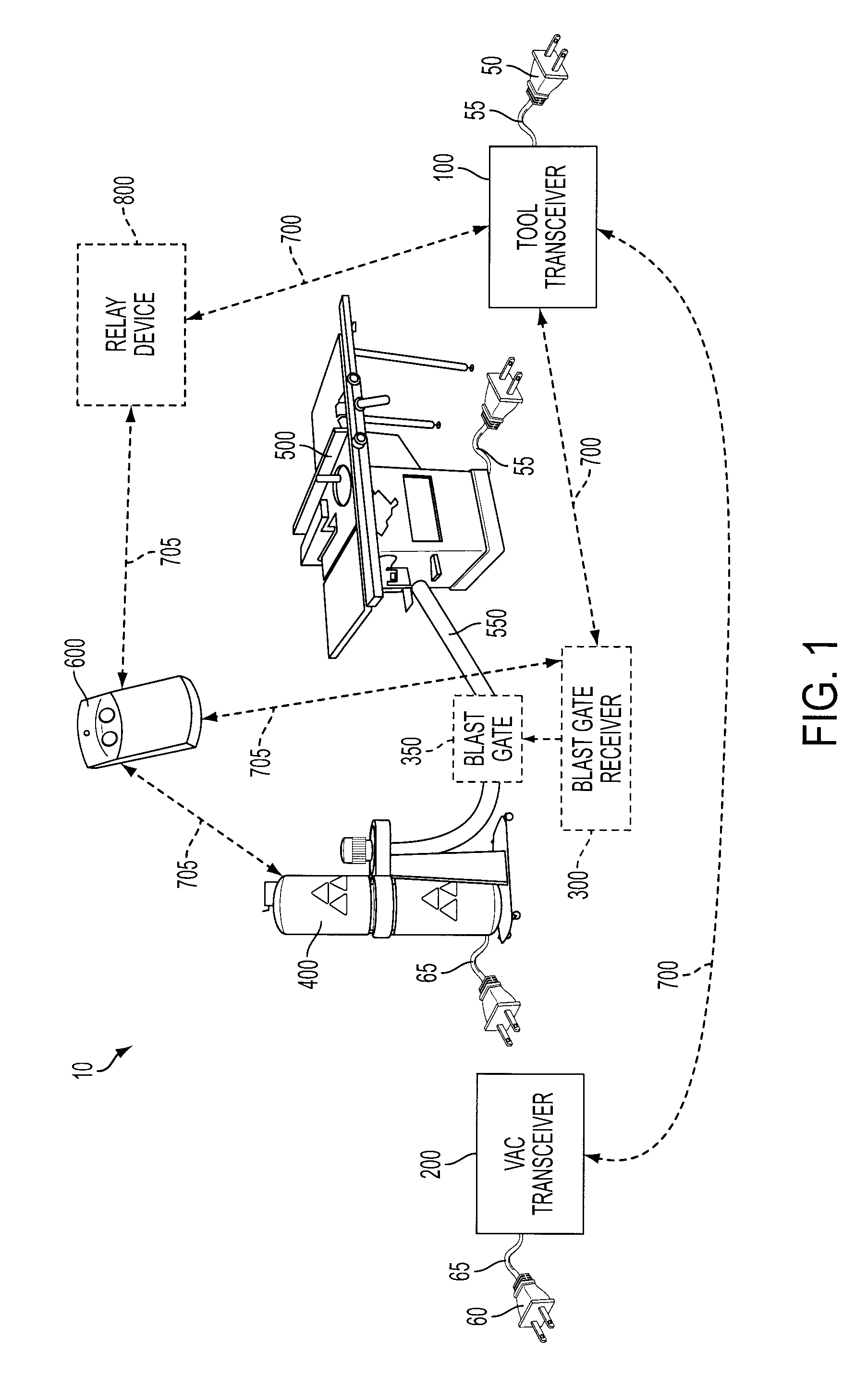

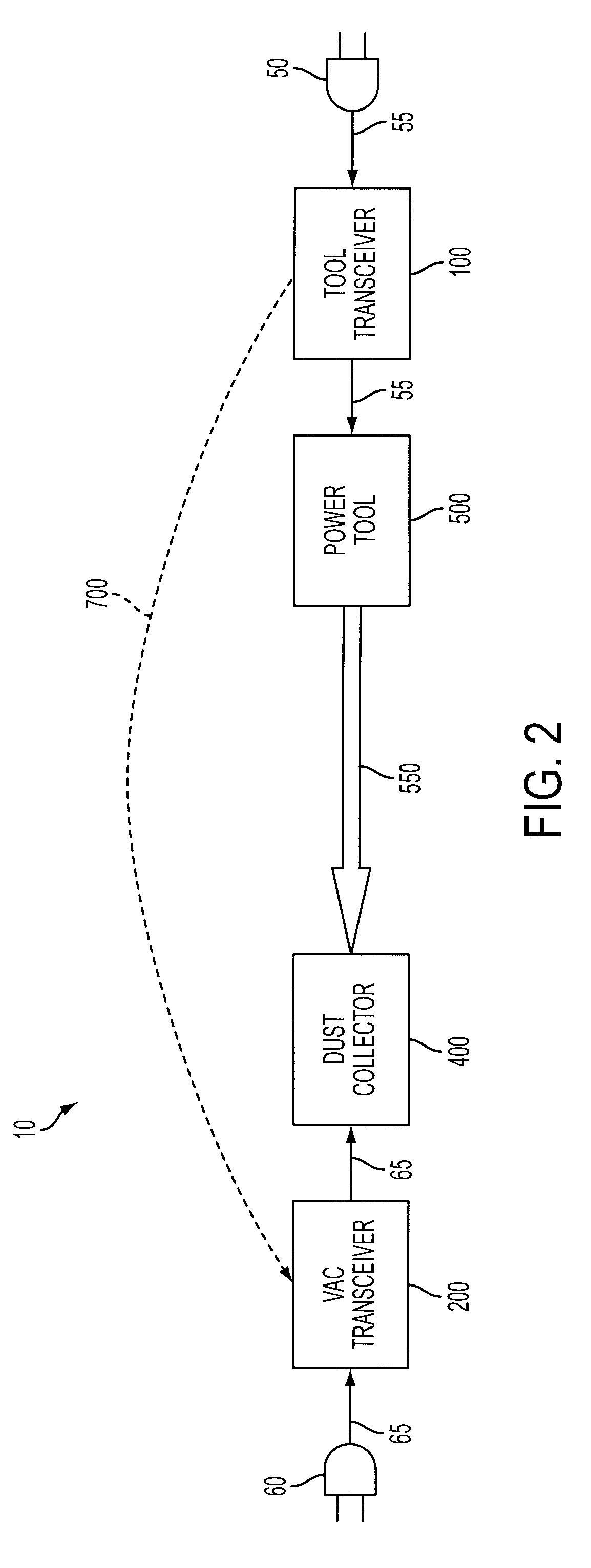

[0023]The example wireless particle collection system described in more detail hereafter senses power tool operation and remotely activates and / or deactivates a dust collector at optimum times. Activation of the dust collector may alternatively be accomplished manually via a key fob that is independent of tool operation.

[0024]The example system can be understood as a network of wireless, independent devices that can communicate with other devices in the network. The devices include a plurality of transceivers, with a given transceiver acting as a primary transmitter and other transceivers acting as receivers (“listening devices”). The primary transmitter, upon a tool activation event, broadcasts a signal that is understood by certain ones of the listening devices. The broadcast signal includes a unique identifier associated with a particular tool and recognized by a group of the receivers so as to associate the primary transmitter with the receivers.

[0025]The transceivers of the sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com