Tubing hanger running tool and subsea test tree control system

a technology of test tree and running tool, which is applied in the direction of fluid removal, sealing/packing, and well accessories, etc., can solve the problems of requiring expensive equipment rental, cumbersome process of running sstt, and time-consuming for well operators, so as to reduce the time of rig, reduce the effect of control umbilical, and enhance safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

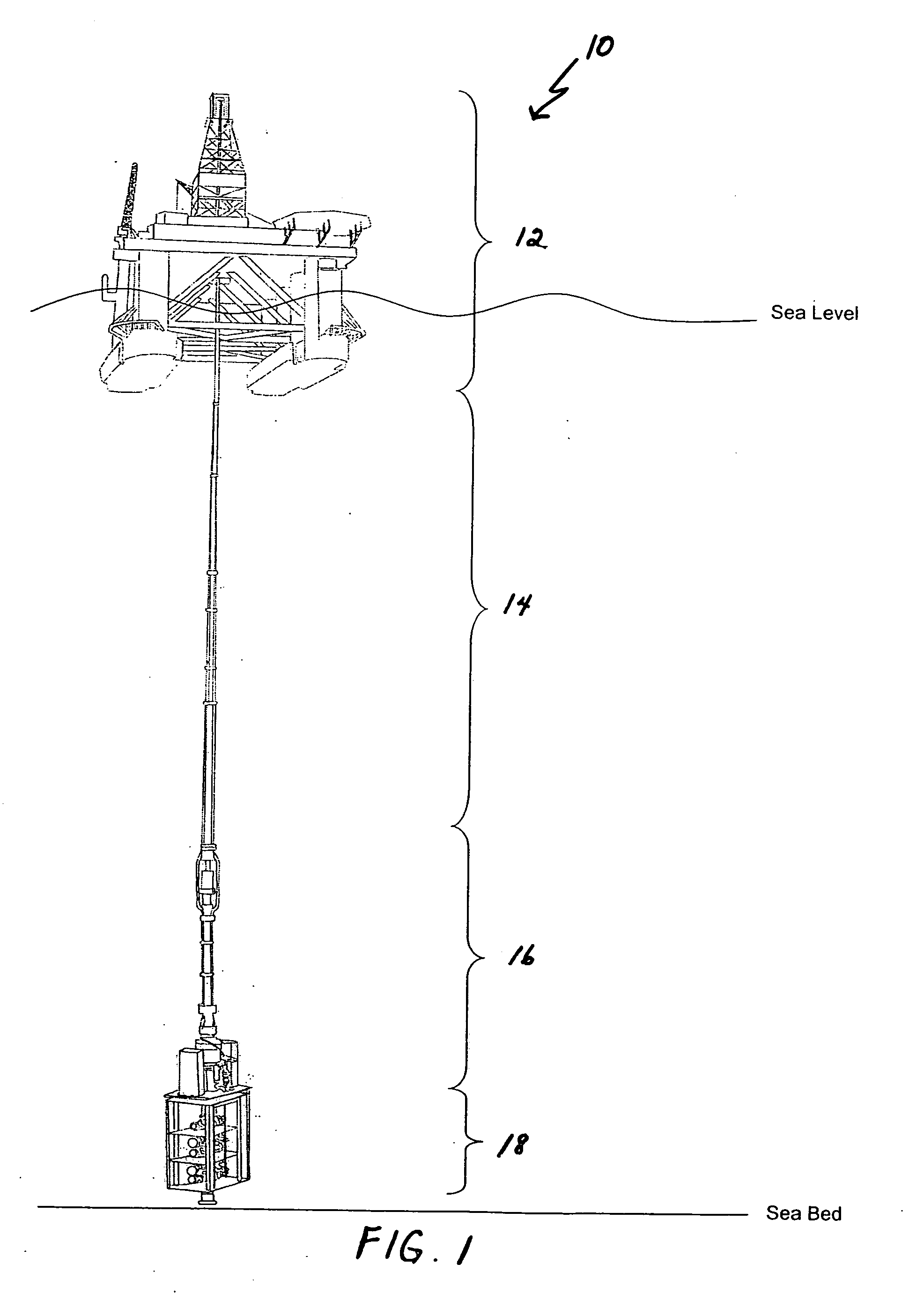

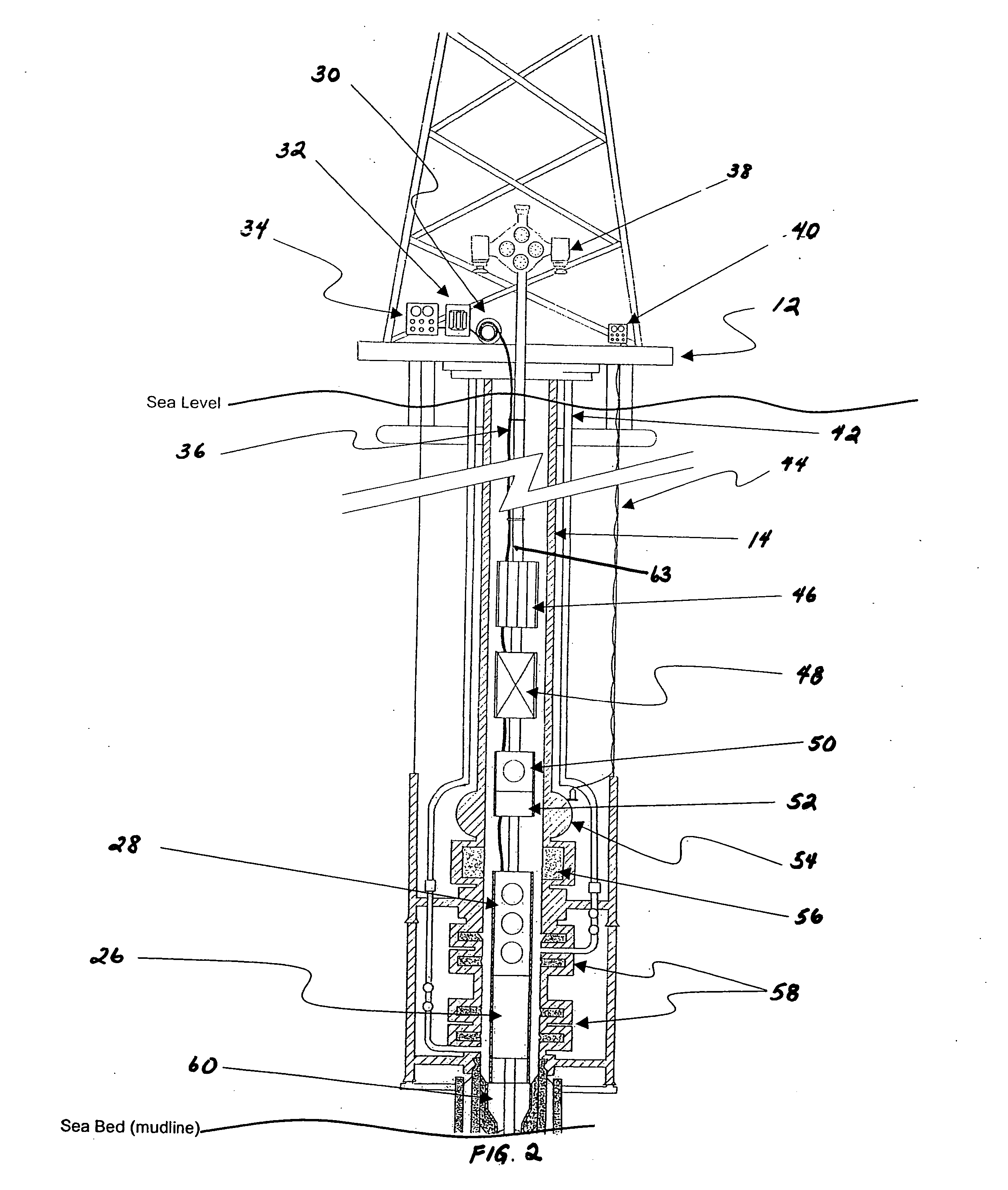

[0020] The features and other details of the invention will now be more particularly described with reference to the accompanying drawings. It will be understood that particular embodiments described herein are shown by way of illustration and not as limitations of the invention. The principal features of this invention can be employed in various embodiments without departing from the scope of the invention.

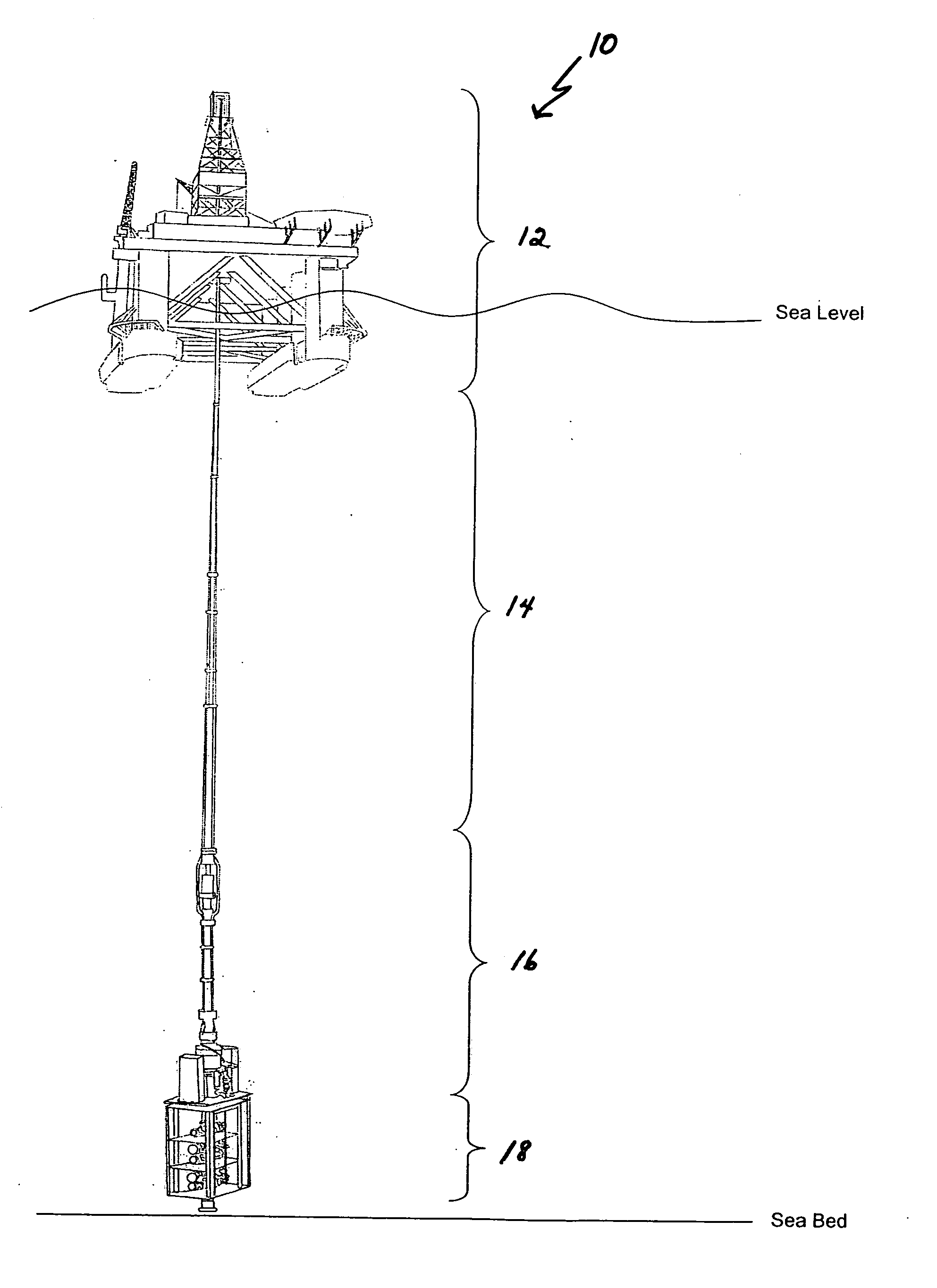

[0021] Embodiments of the invention are related to subsea well technology, and specifically to an improved tubing hanger running tool (THRT) and subsea test tree (SSTT). Embodiments of the invention eliminate a control umbilical and associated hydraulic power pack, as well as associated reel and control panel. Embodiments of the invention use a choke and / or kill line of the blowout preventer system (BOP) to supply hydraulic power. Further, embodiments of the invention use battery powered shuttle valves to direct hydraulic fluid through internal piping and ports to perform many f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com