Combined type double-shield tunneling machine

A tunnel boring machine and double-shield technology, which is applied in tunnels, tunnel linings, shaft linings, etc., can solve the problems that the anti-twist system cannot be combined to occupy space, the bolter takes up a large space, and the overall length of the roadheader increases. Reduce equipment manufacturing and maintenance costs, save space, and shorten the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with various embodiments and corresponding drawings. Apparently, the described embodiments are some, but not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

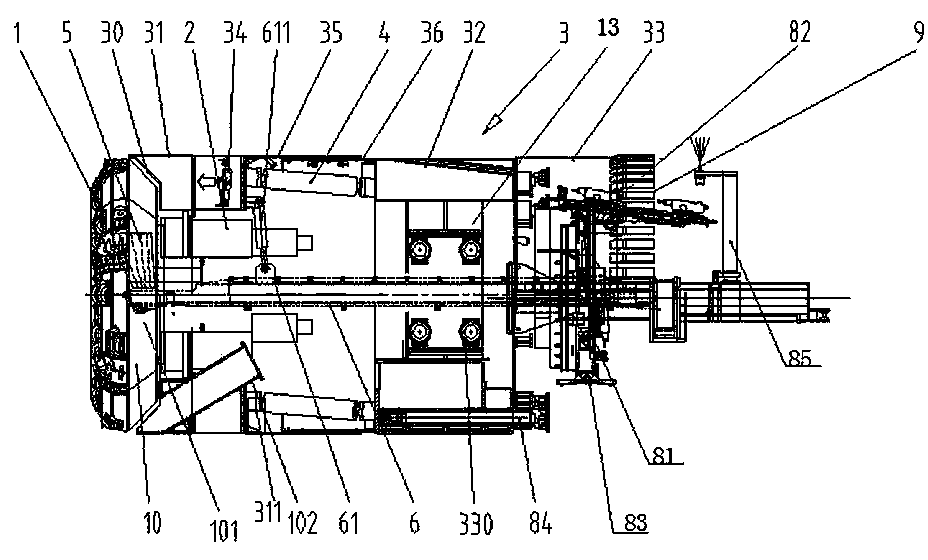

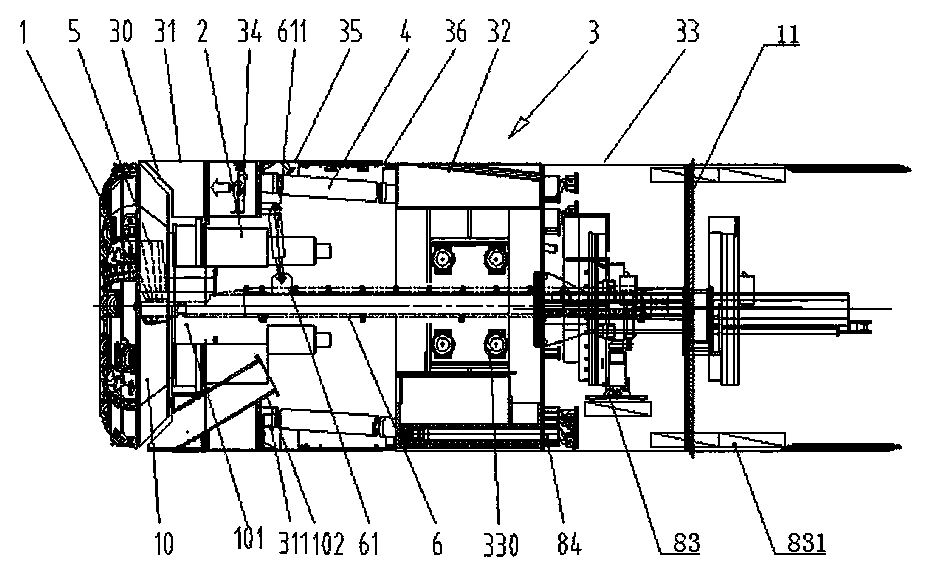

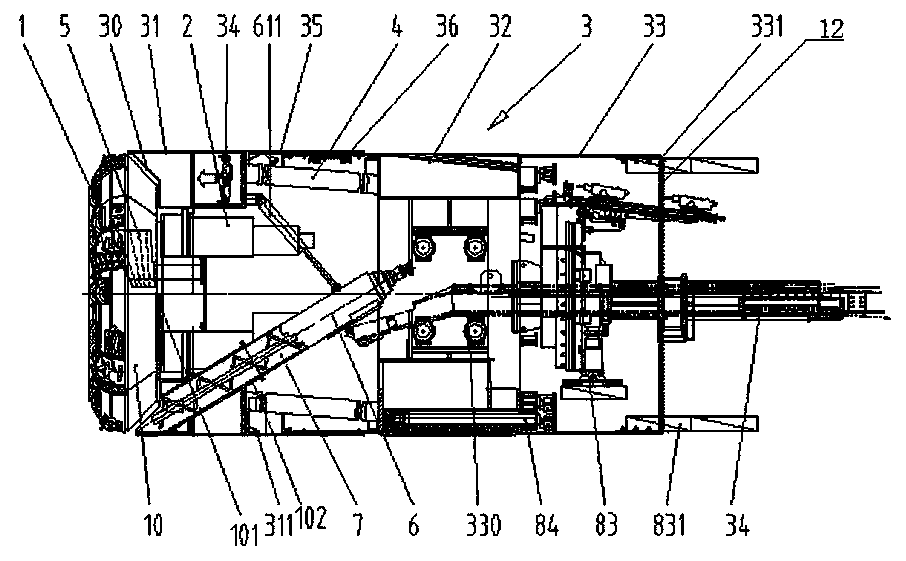

[0028] Such as Figure 1-Figure 7 As shown, the present embodiment is a composite double-shield tunnel boring machine, including a cutter head 1, a main drive 2, a front shield 31, a support shield 32, a tail shield 33, a man compartment 34, an outer telescopic shield 35 and an inner telescopic shield 36. The main drive 2 is set on the front shield 31, the cutter head 1 is connected to the main drive 2, the outer telescopic shie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com