Method for exploring and processing interior of boulder hole in front for shield method construction

A processing method, the technology of the shield method, which is applied in the directions of measuring devices, earthwork drilling and mining, and radio wave measurement systems, can solve the problems of inability to realize vertical detection outside the hole, difficulty in realizing full-section detection, and difficulty in measurement and positioning, and achieve Good use effect, convenient realization and reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

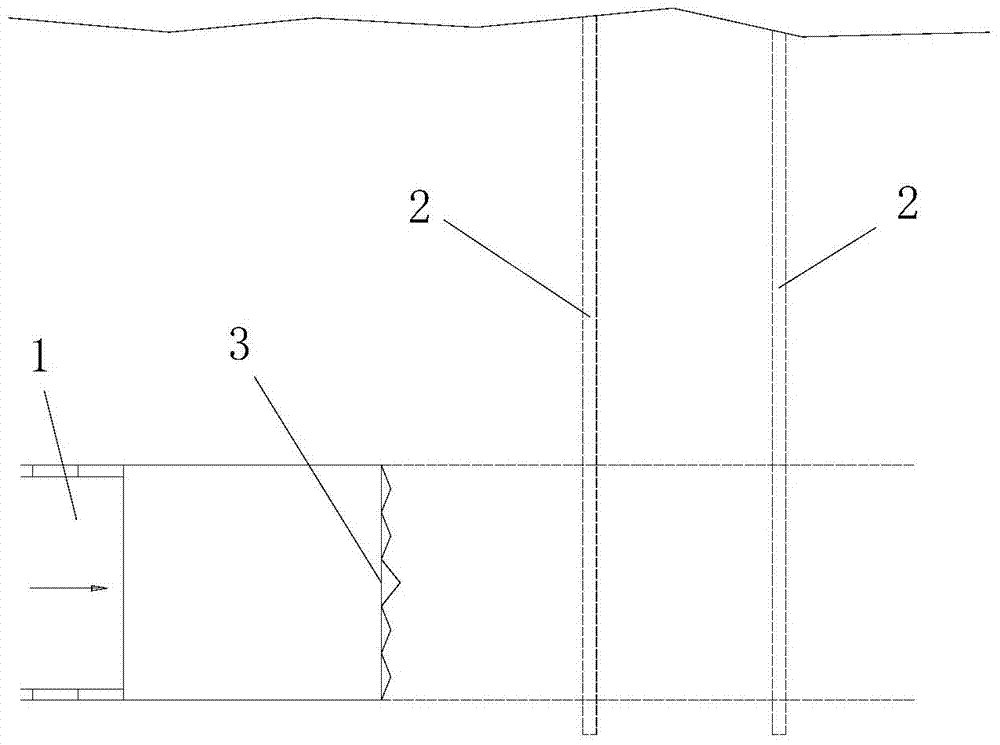

[0044] Such as Figure 4 A method for detecting and processing the lone rock in front of the cave for shield tunneling construction includes the following steps:

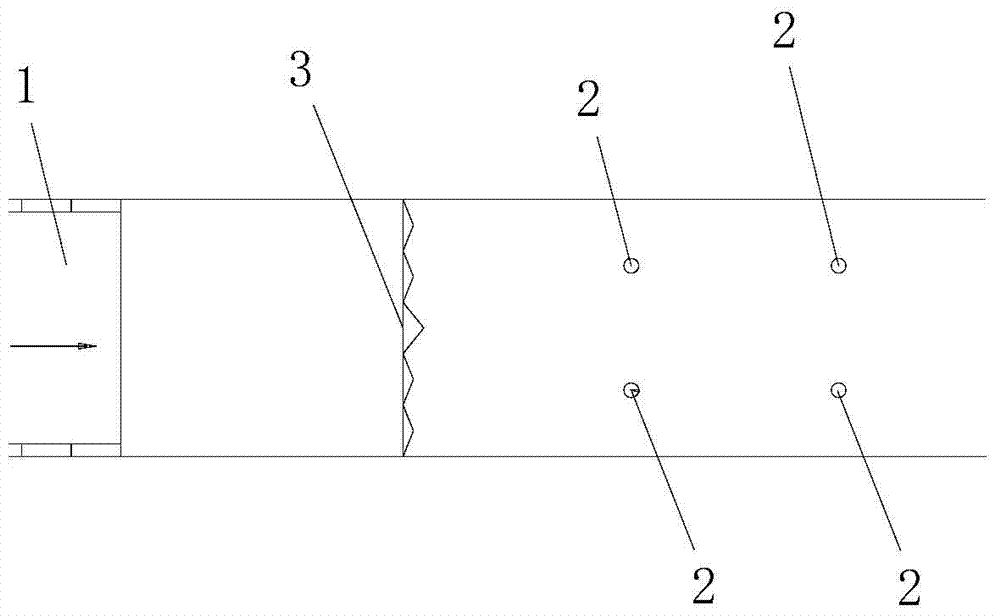

[0045] Step 1. Drilling detection holes in advance: through multiple drilling channels 4 arranged on the cutter head 3 of the shield machine, multiple detection holes 5 are drilled in front of the cutter head 3 of the shield machine from the back to the front. The construction status is detailed. See Figure 5 .

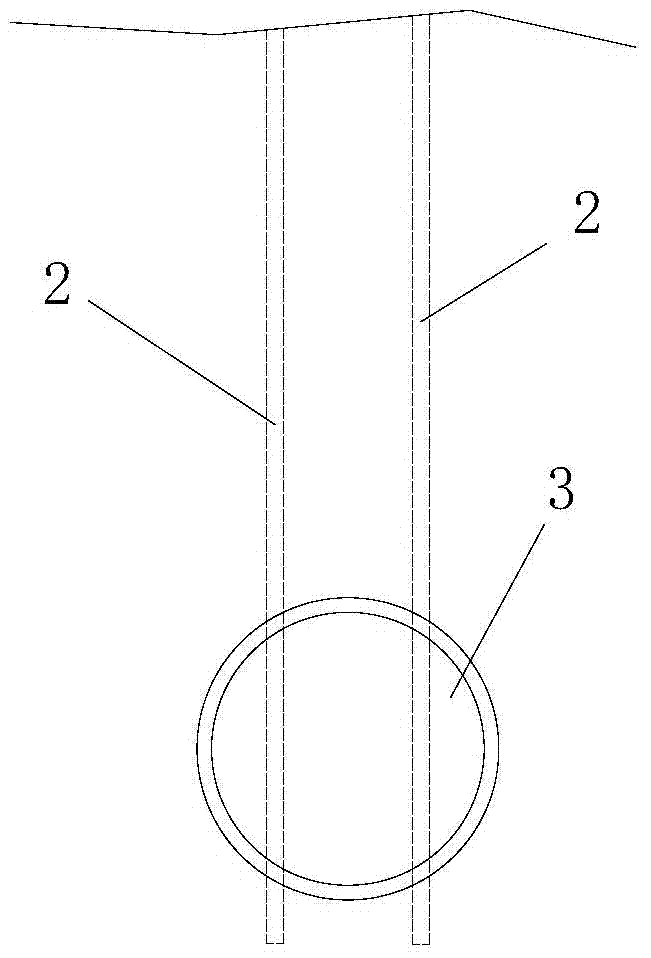

[0046] Such as Figure 6 As shown, a plurality of detection holes 5 are arranged along the axial direction of the shield tunnel 1 to be constructed. The shield machine cutterhead 3 is a circular cutterhead, and a plurality of the drilling passages 4 are circular through holes arranged along the central axis of the circular cutterhead, and a plurality of the detection holes 5 are respectively It is arranged coaxially with the plurality of drilling channels 4 . The plurality of drilling channels 4 inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com