Method for mining coal of steeply inclined thin seam

A coal mining method and thin coal seam technology, applied in the field of coal mining, can solve problems such as easy accumulation of gas, easy flaking of coal walls, injuring people, and inconvenient operation of workers, so as to improve coal recovery rate, facilitate gas discharge, and ventilate The simple effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

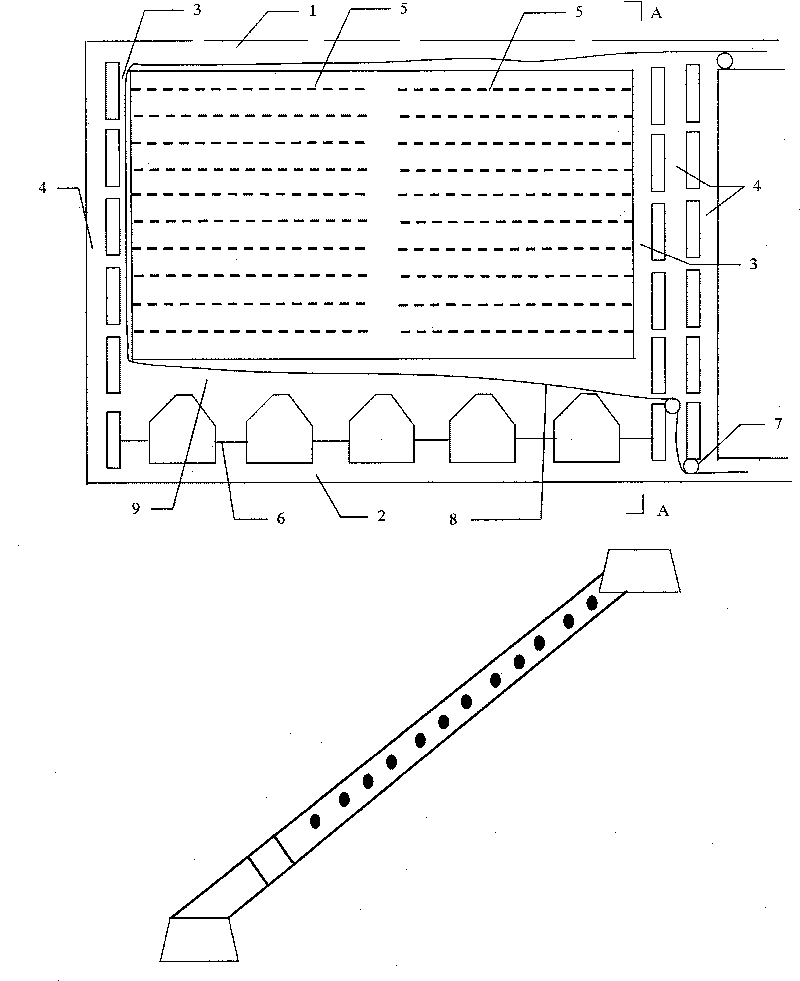

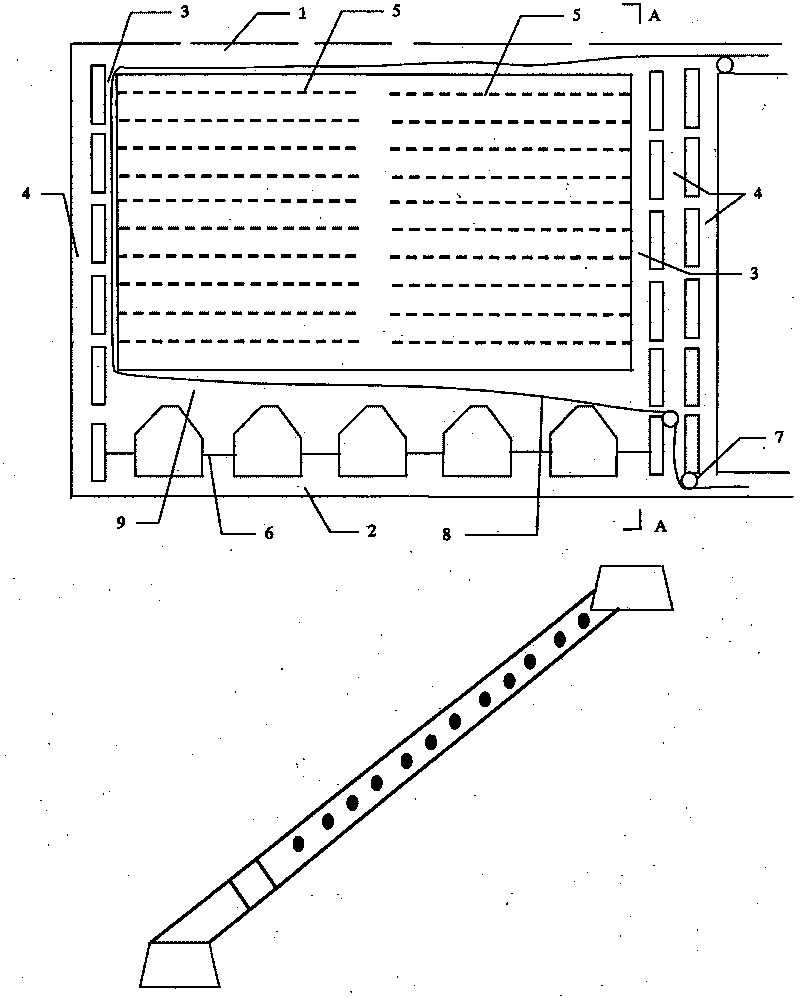

[0011] 1. First, excavate the transportation and return air level road of the mining face. When the transportation and air return roadway is excavated to the vicinity of the cut hole, excavate the drilling inclined alley and the air inlet pedestrian inclined alley from bottom to top (from the transportation alley to the air return alley) until the air return alley. The height of the drilling inclined roadway is the thickness of the coal seam, and the width is 1-2m. At the same time, start to excavate the advanced entryway at the working face at 5-6m above the transport entryway, the height of the advance entryway is excavated along the thickness of the coal seam, and the width is more than 3m. Coal sliding holes are excavated every 5-6m in the advance level roadway to connect with the transport level wayway. After the advance roadway is excavated to an inclined strip, a drilling inclined alley and two inclined pedestrian alleys into the wind and pedestrians are excavated upwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com