Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Safe and quick removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

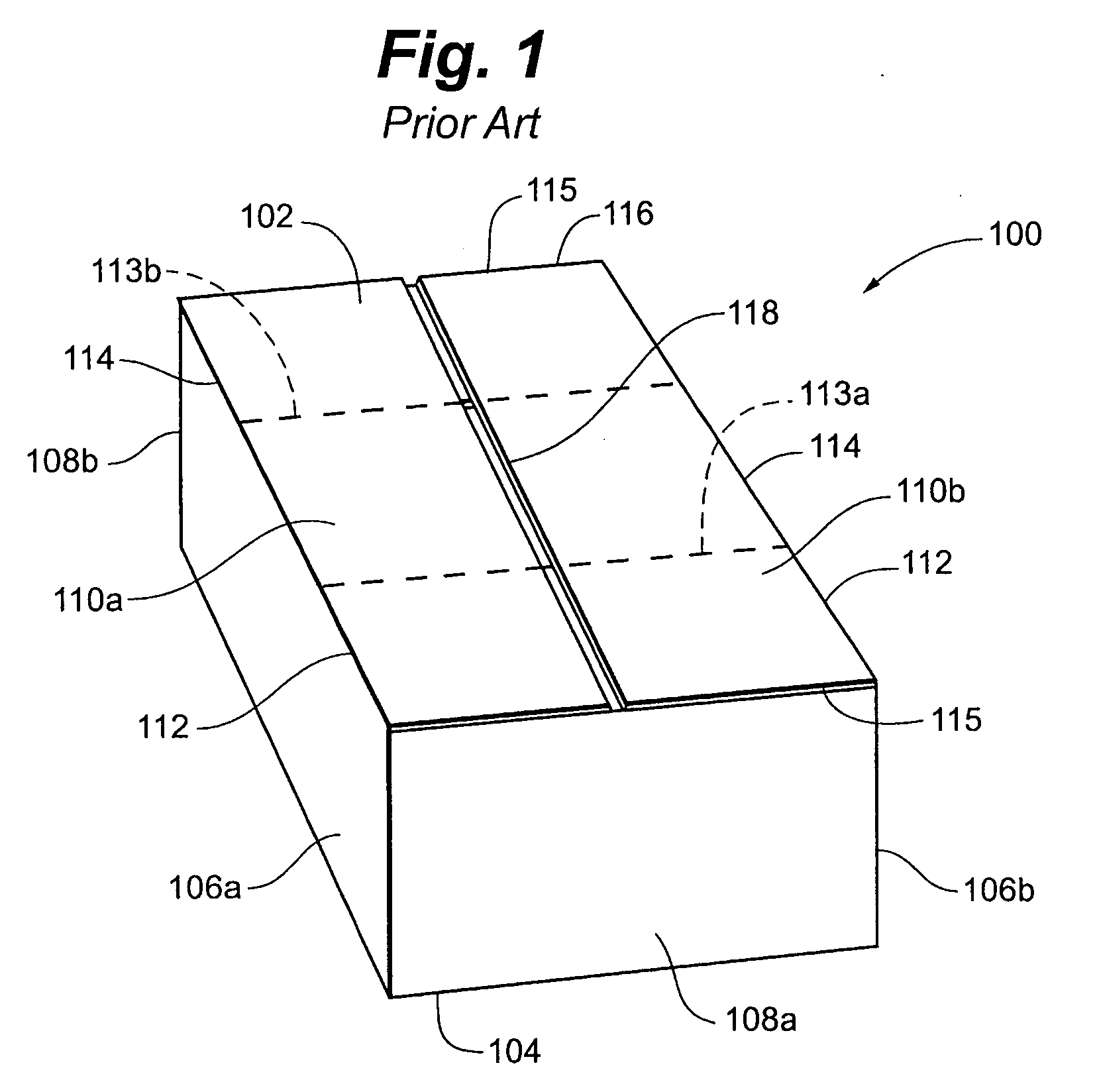

Perforated packaging

Packaging boxes and packaging methods for providing the ability to quickly open tape-sealed packages while eliminating the necessity for cutting tools and potential cutting injuries associated with these cutting tools. Through the inclusion of at least one perforated access panel in at least one end portion of a corrugated packaging box, hand access is provided to an end of the tape allowing the length of tape to be completely removed without the use of any cutting tools. The at least one perforated access panel can include a punch-in section and a tear-away section wherein a tape end is positioned over at least a portion of the punch-in section. The punch-in section can be pushed inwards providing access to the tear-away section. Pulling on the tear-away section results in the tear-away section and correspondingly, the tape being torn from the packaging box.

Owner:GENERAL MILLS MARKETING INC

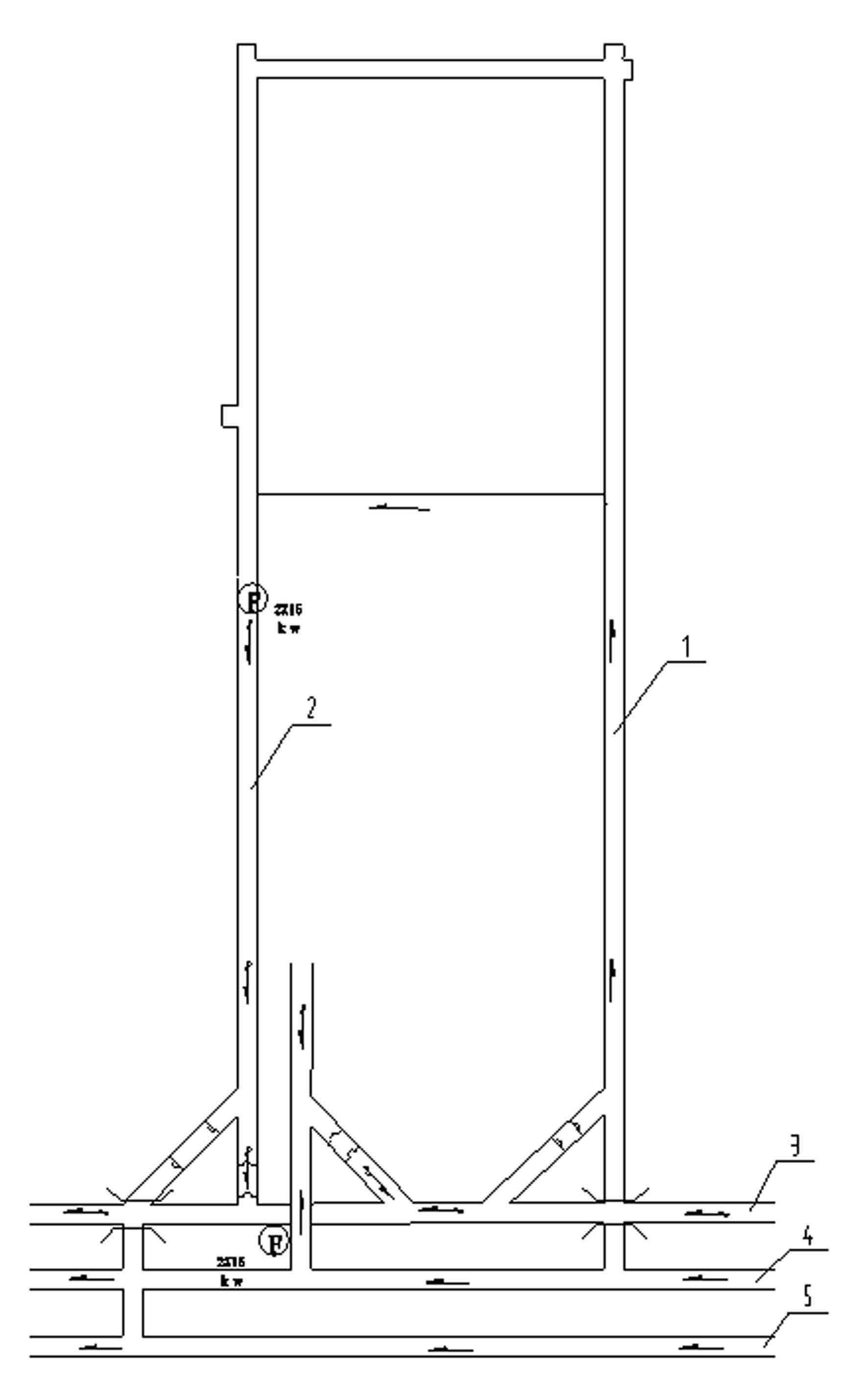

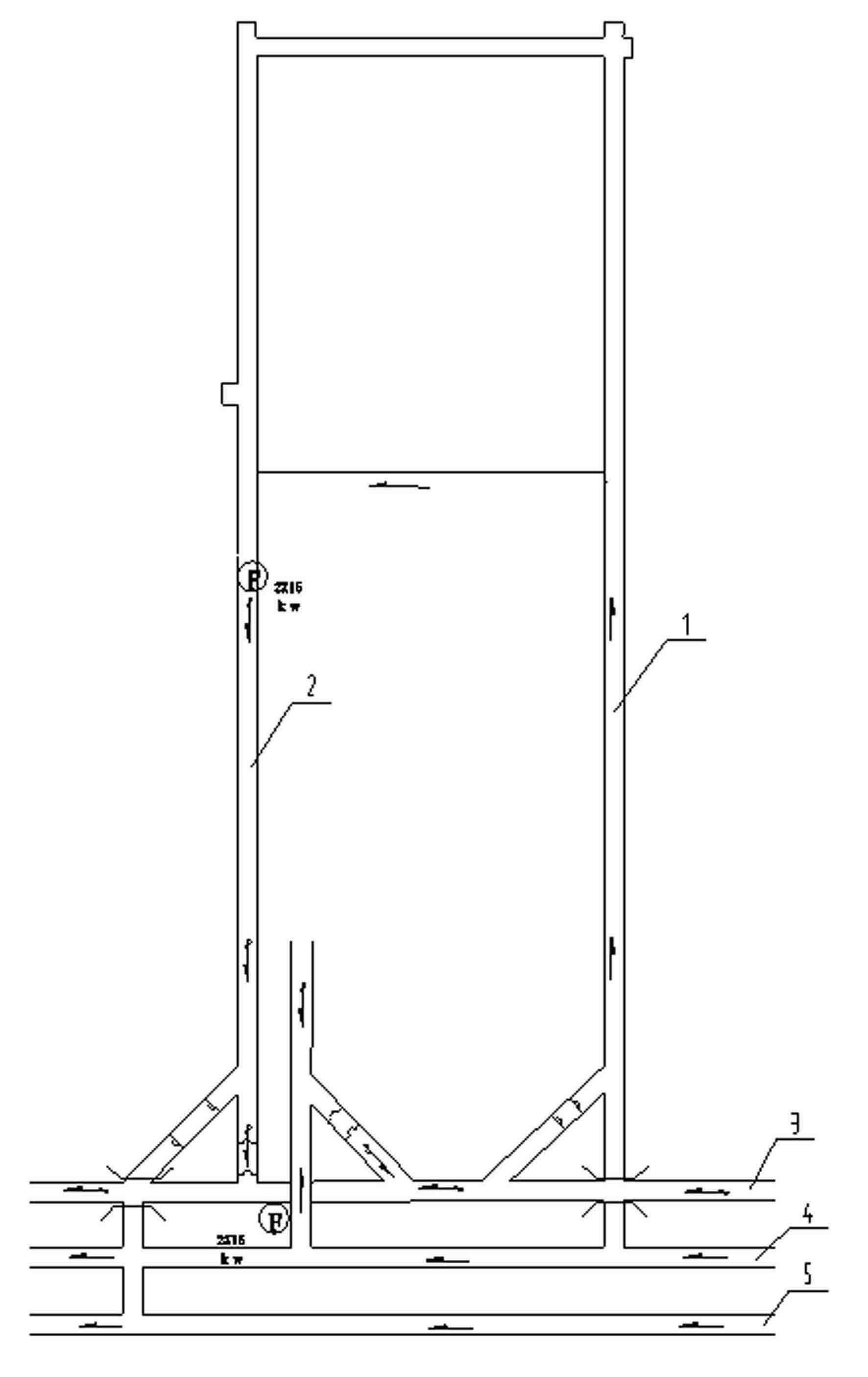

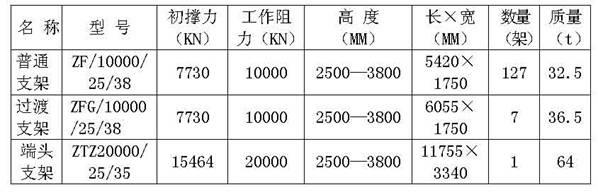

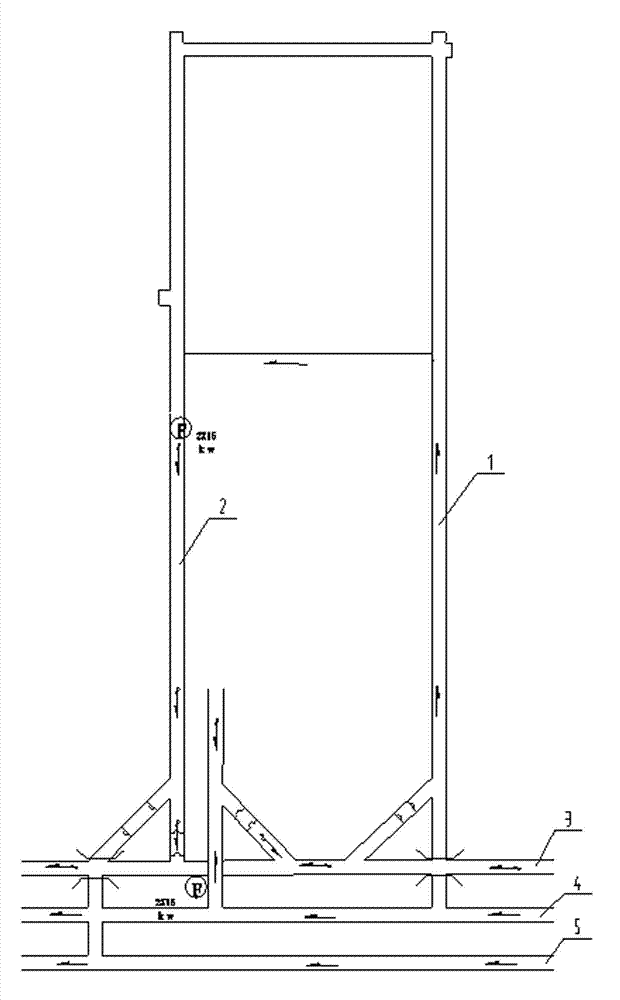

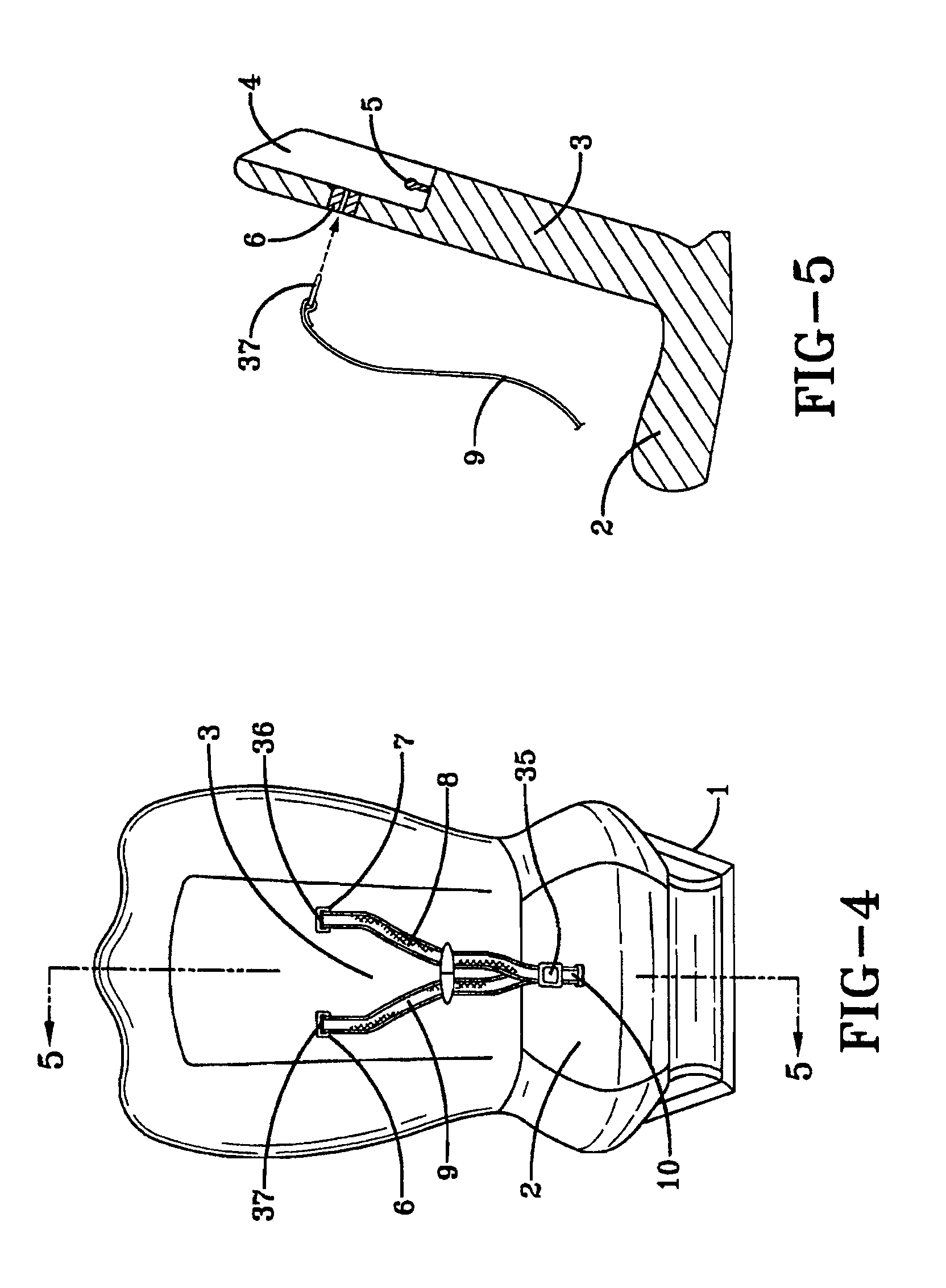

Safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment

ActiveCN102094675AGuarantee support safetySafe and quick removalUnderground transportAnchoring boltsFully developedYard

The invention discloses a safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment. A moving and withdrawing route comprises a moving and withdrawing transport route through an assisted transport gate road, i.e. from a working face to the assisted transport gate road to an assisted transport gate road roundabout channel to an assisted transport tunnel to an auxiliary adit to a stock yard, and a moving and withdrawing transport route through a belt gate road, i.e. from the working face to the belt gate rod to a return airway to the assisted transport tunnel to the stock yard; and a reasonable mining-stopping supporting method and a roof supporting method during the period of moving and withdrawing are simultaneously combined. By virtue of the moving and withdrawing method, maximum effectiveness of labor force and equipment resources are fully developed, long-distance comprehensive transportation of the thick coal seam fully mechanized heavy equipment is realized, and safe and fast moving and withdrawing of facilities in the working surface is ensured.

Owner:DATONG COAL MINE GRP

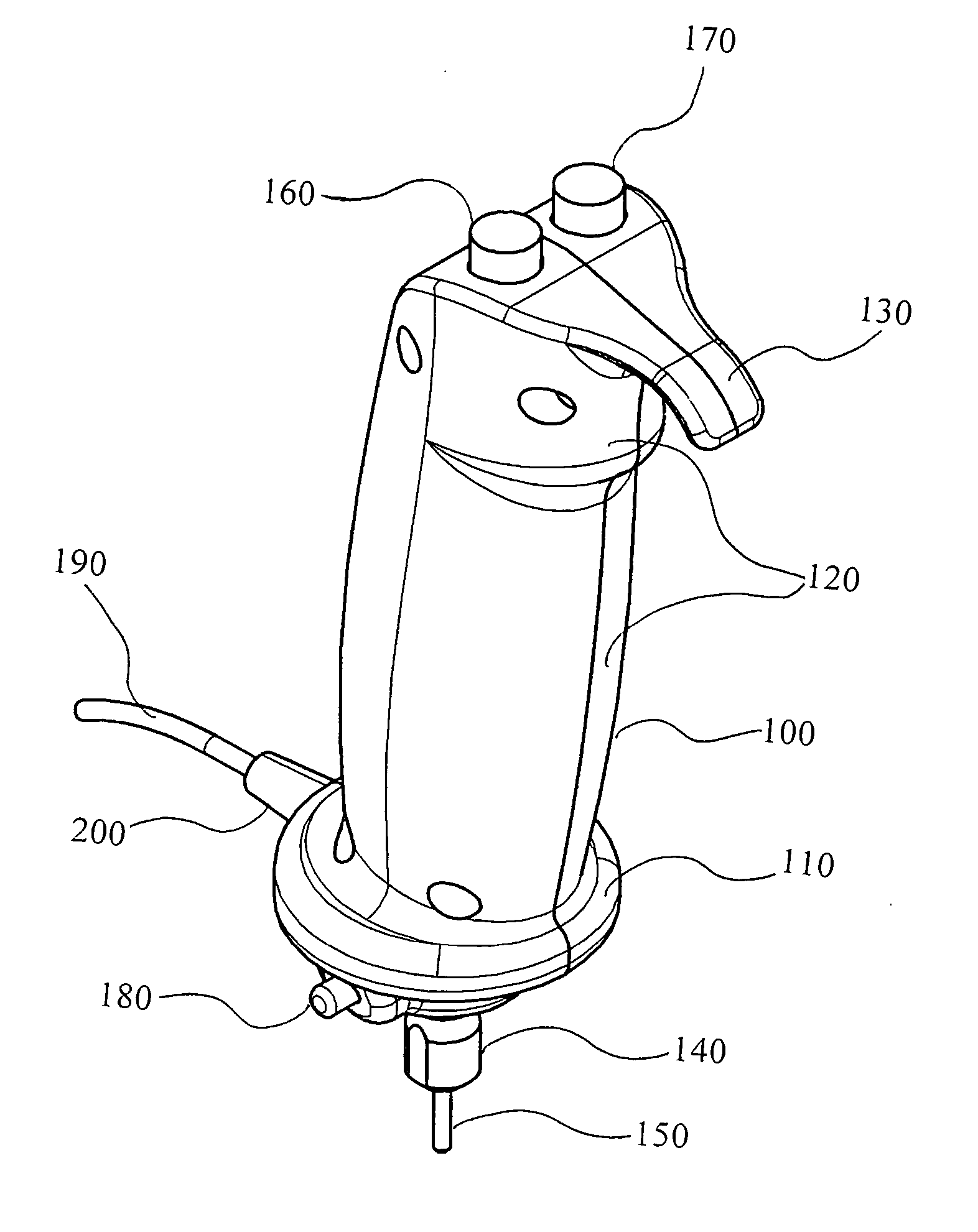

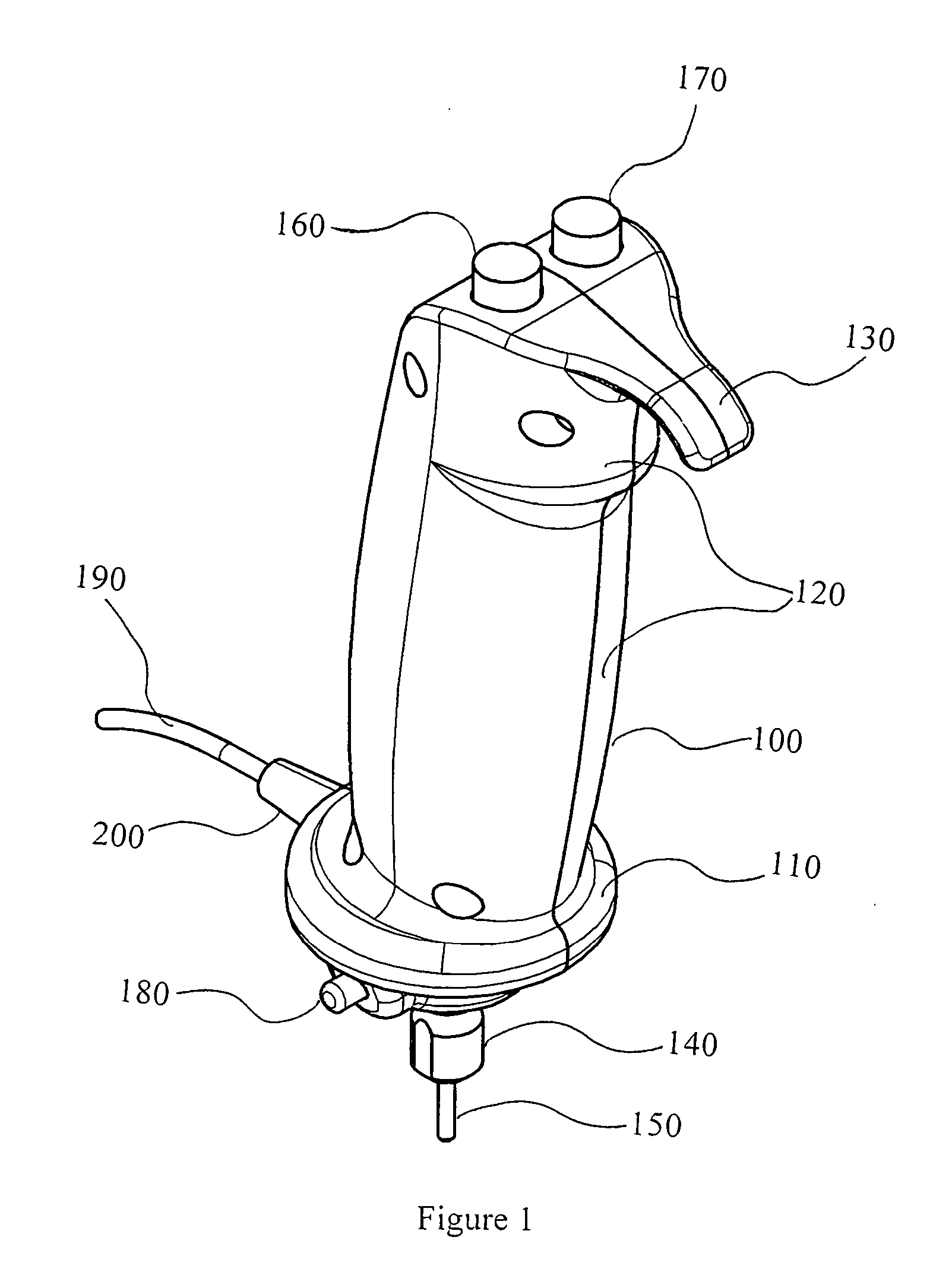

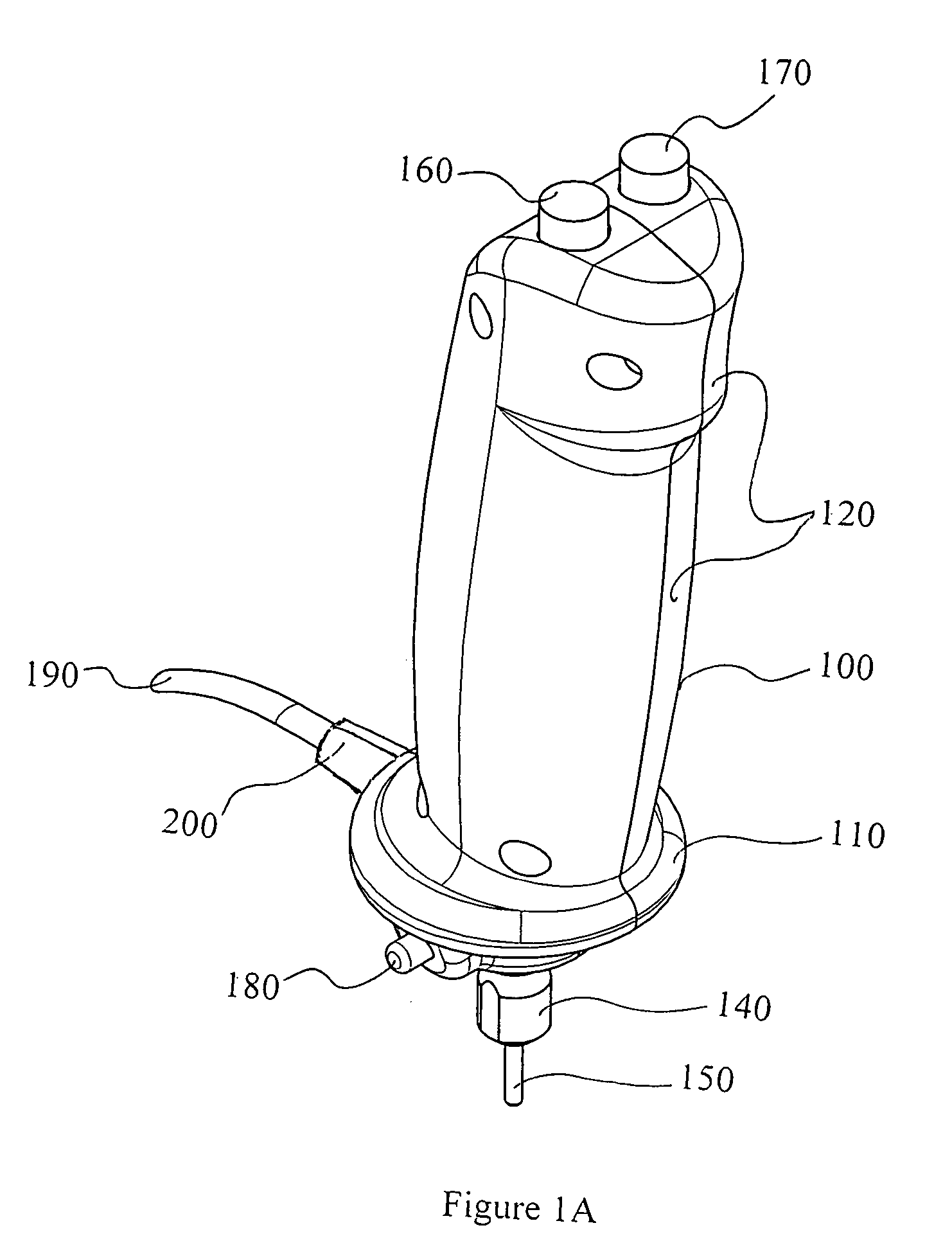

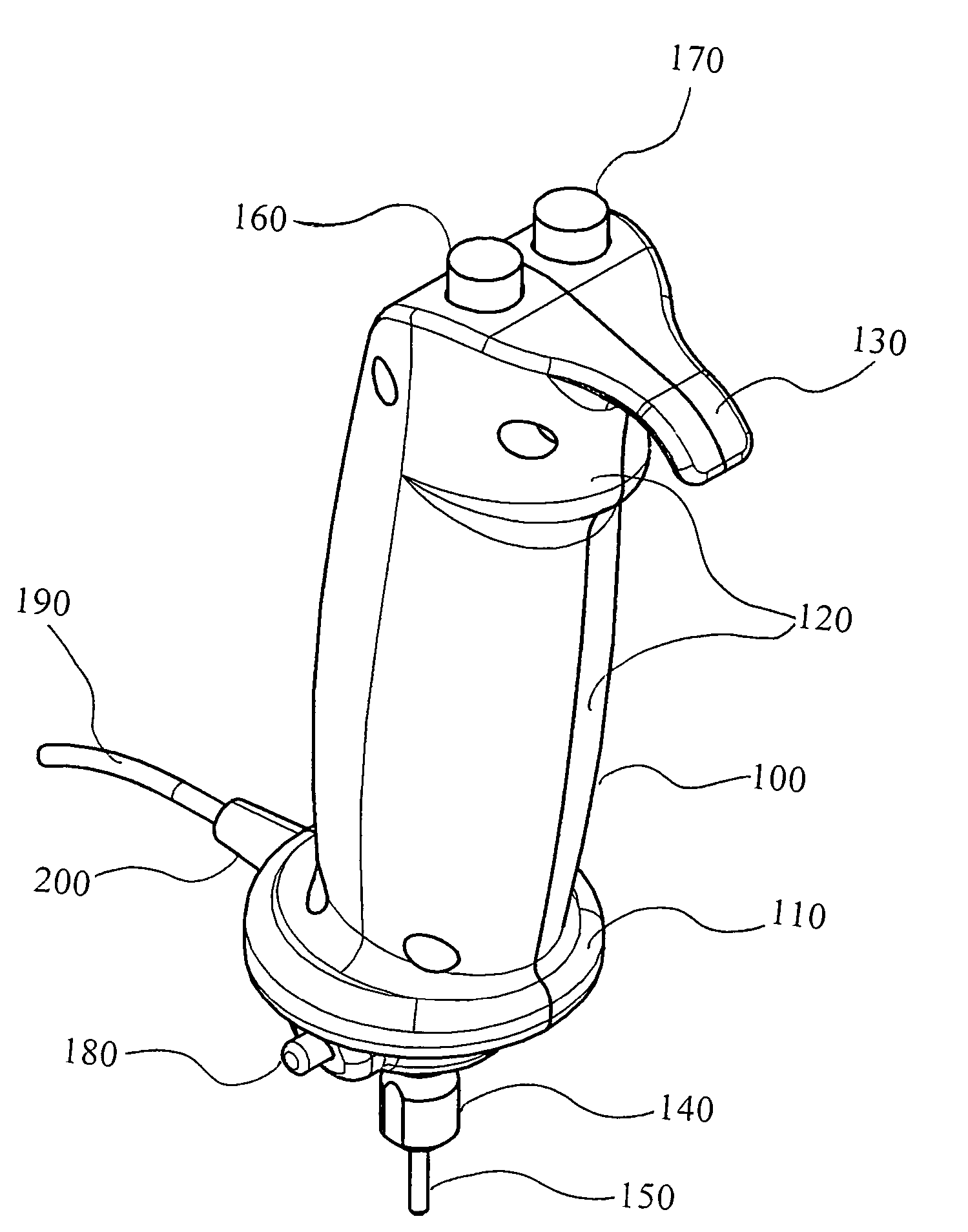

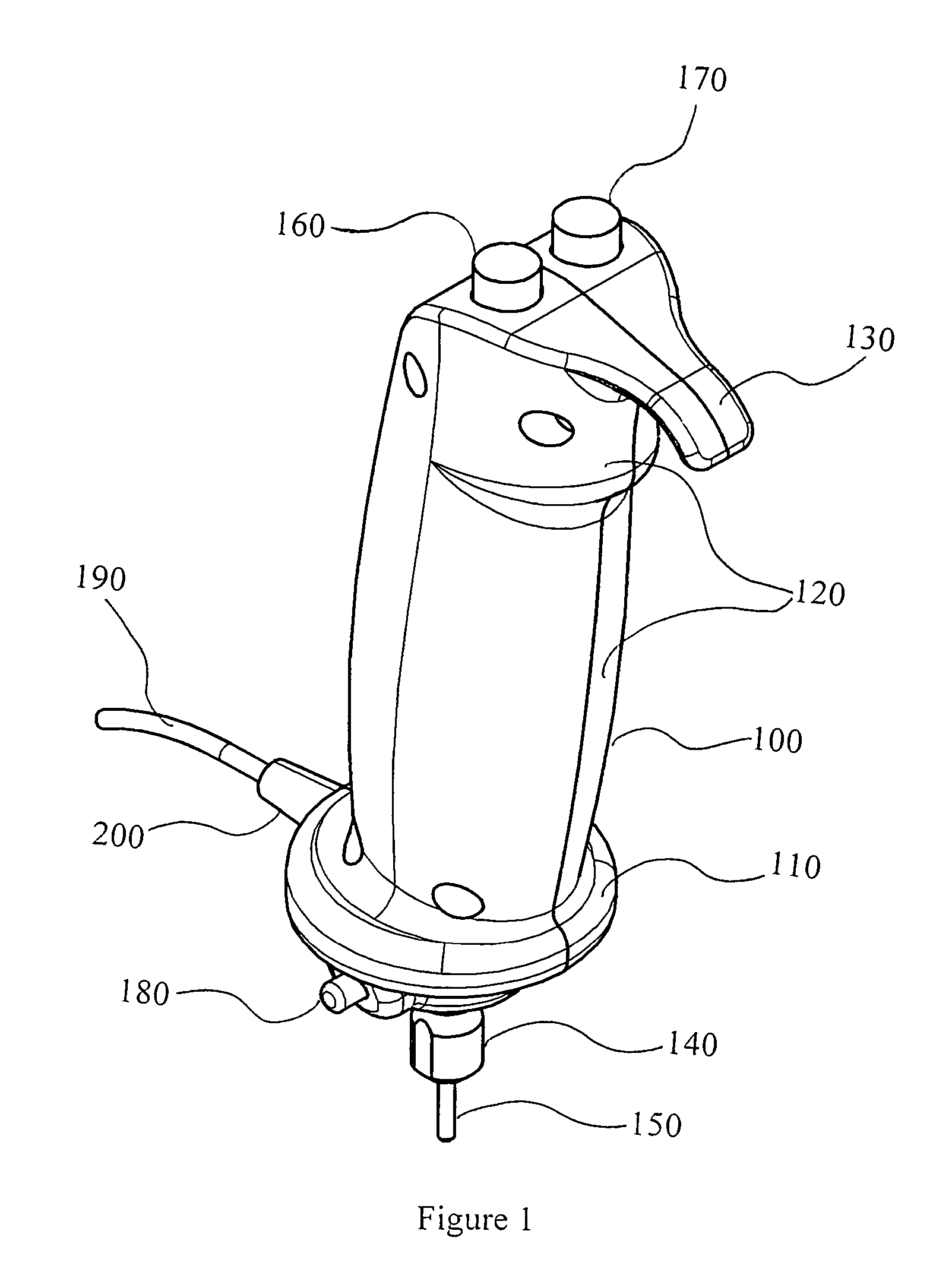

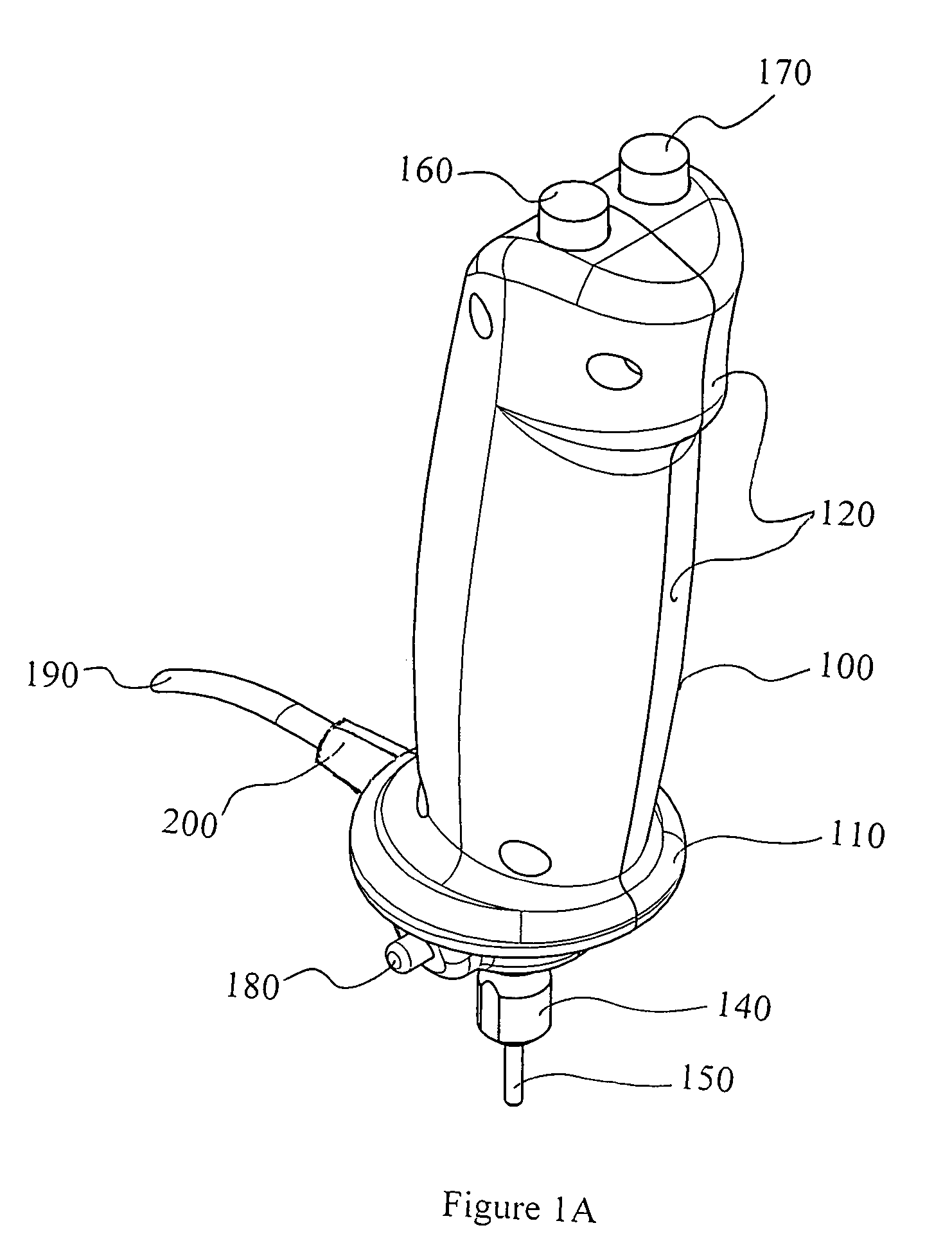

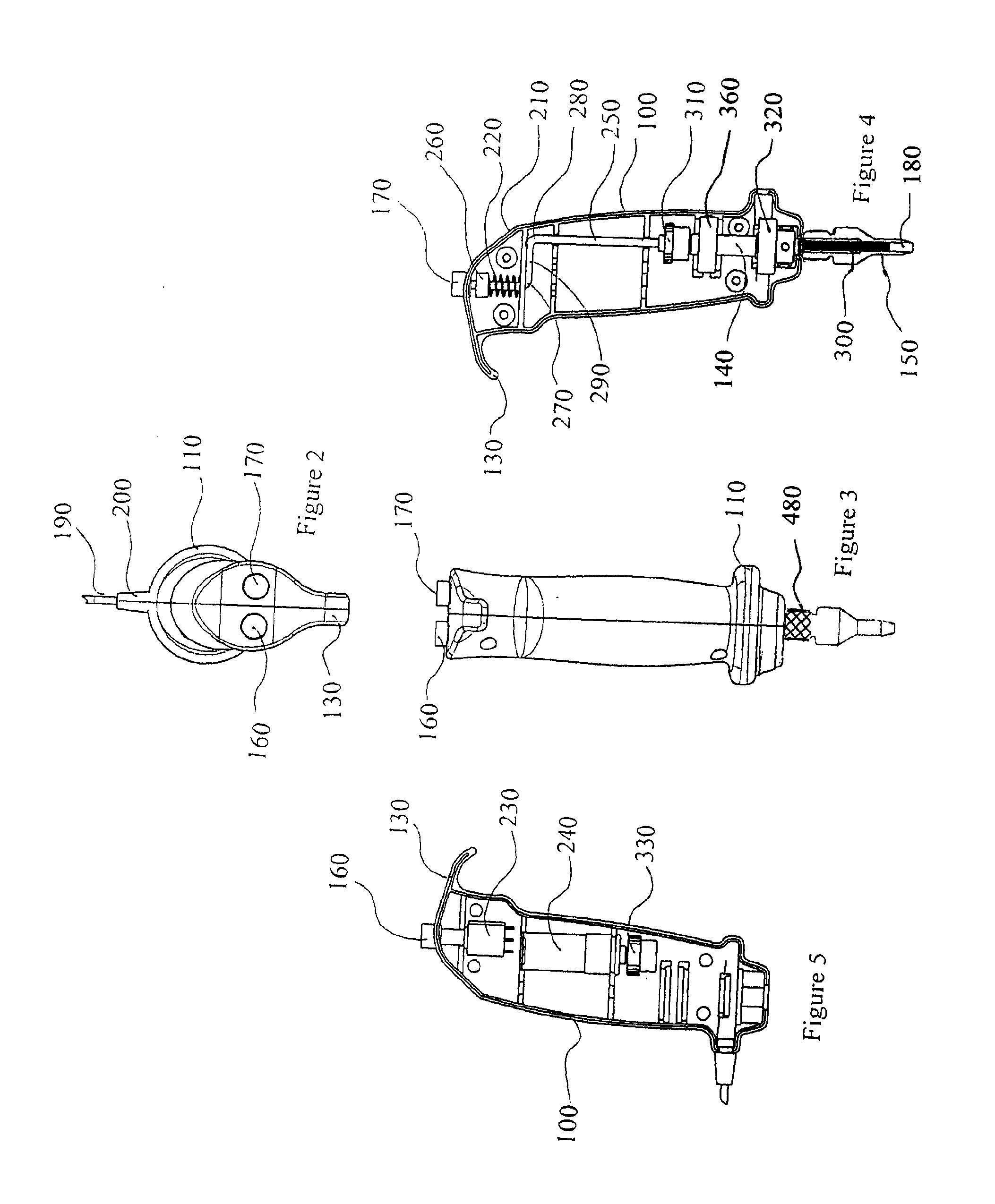

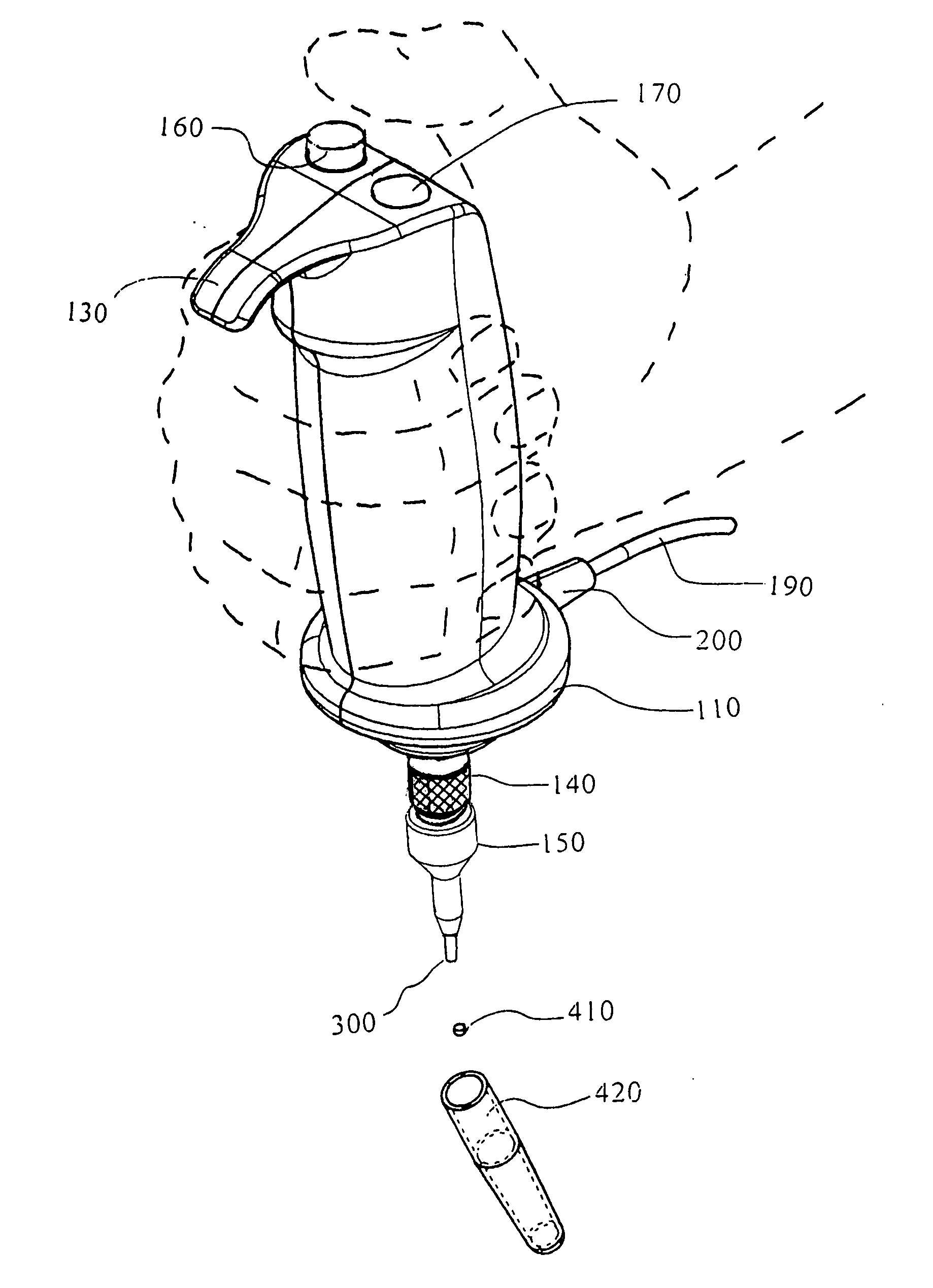

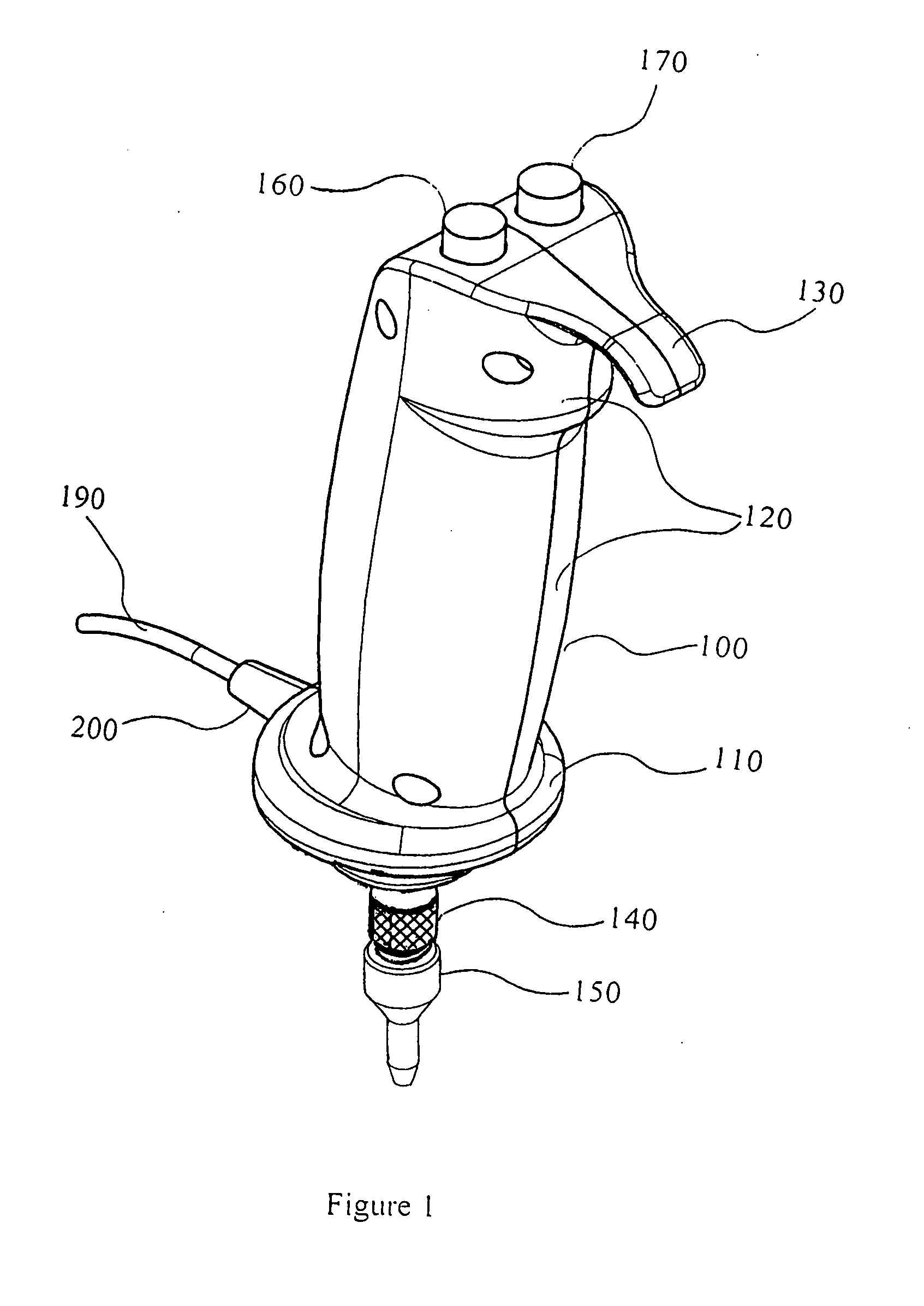

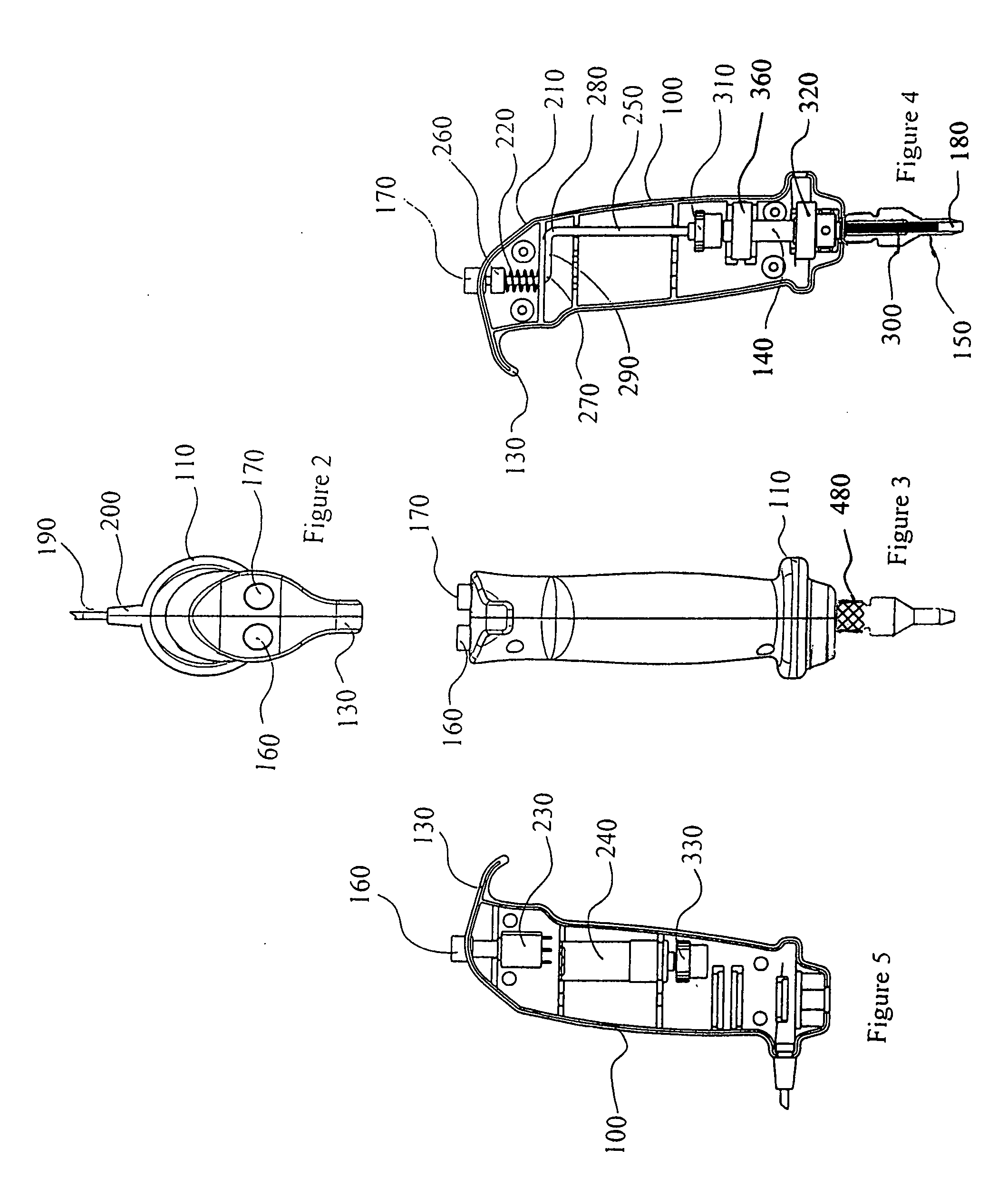

Motor driven sampling apparatus for material collection

InactiveUS20050066751A1Eliminate slippageReduce usageWithdrawing sample devicesMotor driveSource material

An apparatus to excise a sample of material and temporarily store sample has a hollow clamshell casing with a blended grip under which is a tubular sample sleeve extends downwards from the base of the grip. Within the casing an electric motor is housed which drives, via juxtaposed spur gears, the sample sleeve in a rotational manner. The end of the sample sleeve, distal from the clamshell casing, forms a cutting edge circumscribing a circular region. An ejection rod slides reciprocally within the sample sleeve between a stowed position and an expulsion position. When the ejection rod moves from the stowed position to the expulsion position it will extend past the cutting edge and expel any material sample contained within the sample sleeve. A user cuts a sample from a source material resting on a pliable substrate, using the cutting edge of the sample sleeve when the ejection rod is in the stowed position. A sample is cut when the cutting blade contacts the source material while gentle downward pressure is applied. The thumb activates the electric drive which rotates the cutting sleeve. Once the source material has been cut it is simultaneously extracted and lodged within the tubular sample sleeve. The extracted sample remains lodged in the hollow of the sample sleeve until the user extends the ejection rod through the sample sleeve to the expulsion position to eject the sample of source material. The automatic return of the eject rod is comprised of a compression spring that biases the ejection shaft which holds the ejection rod in the retracted and stowed positions.

Owner:GE HEALTHCARE BIO SCI CORP

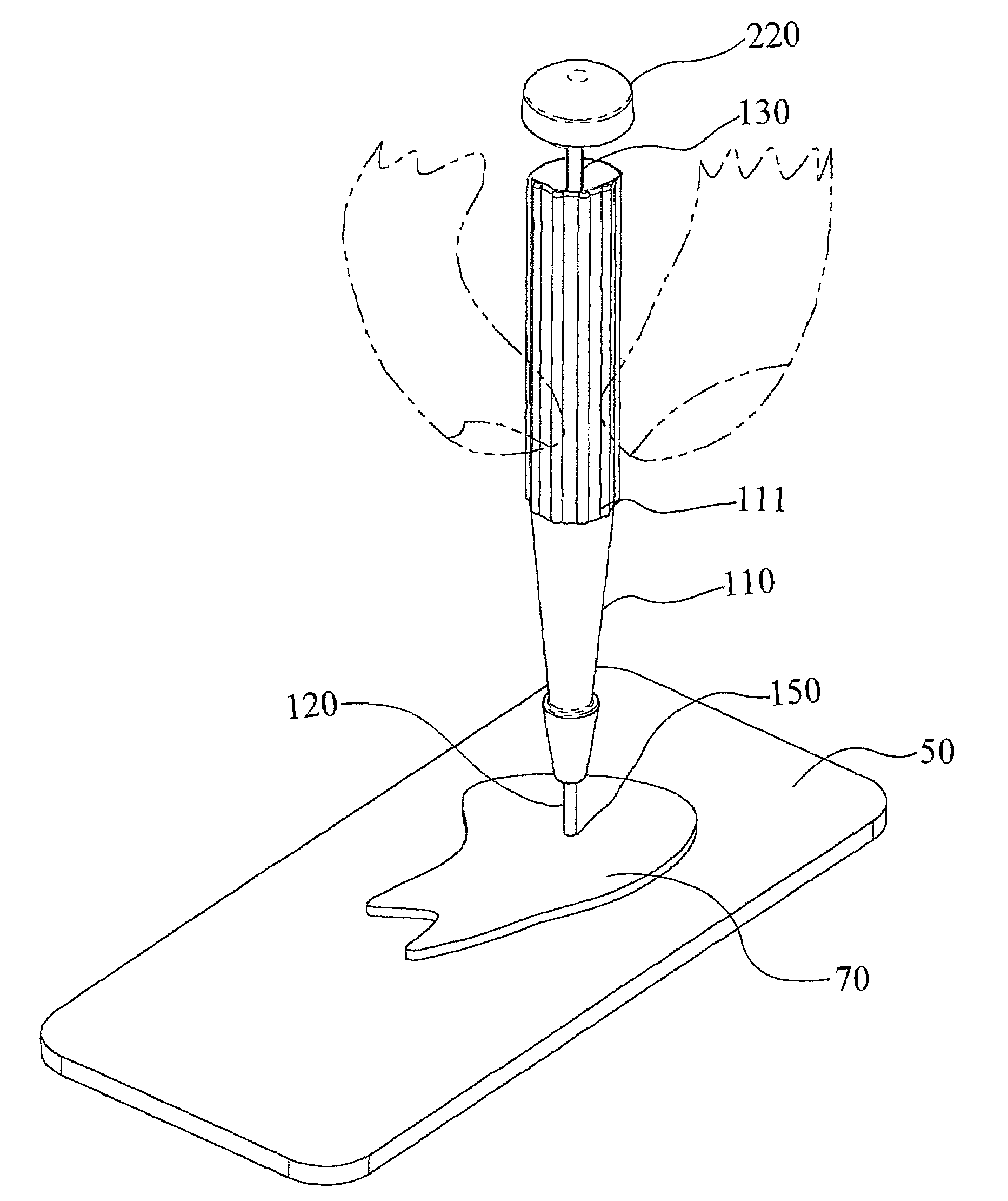

Sampling apparatus for material collection

ActiveUS7093508B2Reduce the possibilityReduce the amount requiredWithdrawing sample devicesBiological testingSource materialBiomedical engineering

An apparatus to collect a sample of material has a handle with a tubular sample sleeve extending from an end of the handle. The end of the sleeve distal from the handle forms a cutting edge circumscribing a circular sampling region. A plunger slides reciprocally within the tubular sample sleeve between a retracted position and an expulsion position. A user cuts a sample from a source material by engaging contact between the cutting edge of the tubular sample sleeve and the source material. The sample cut from the source is lodged within the tubular sample sleeve. Actuation of the plunger from the retracted position toward the expulsion position displacing the sample from the sleeve.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

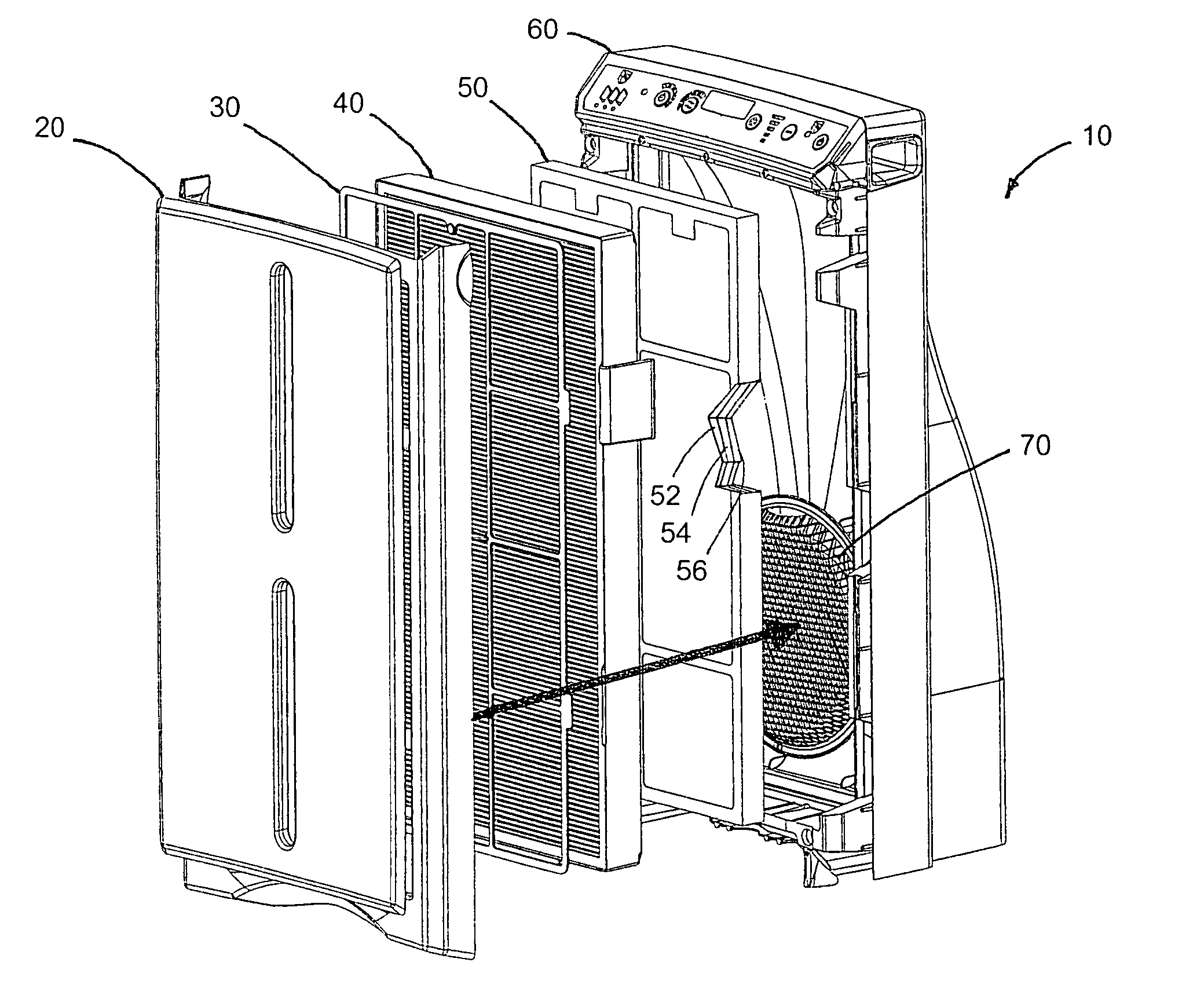

Air treatment filter and related method

ActiveUS7316732B2Lower Level RequirementsEasy to oxidizeGas treatmentDispersed particle filtrationO-Phosphoric AcidActivated carbon filtration

Owner:ACCESS BUSINESS GRP INT LLC

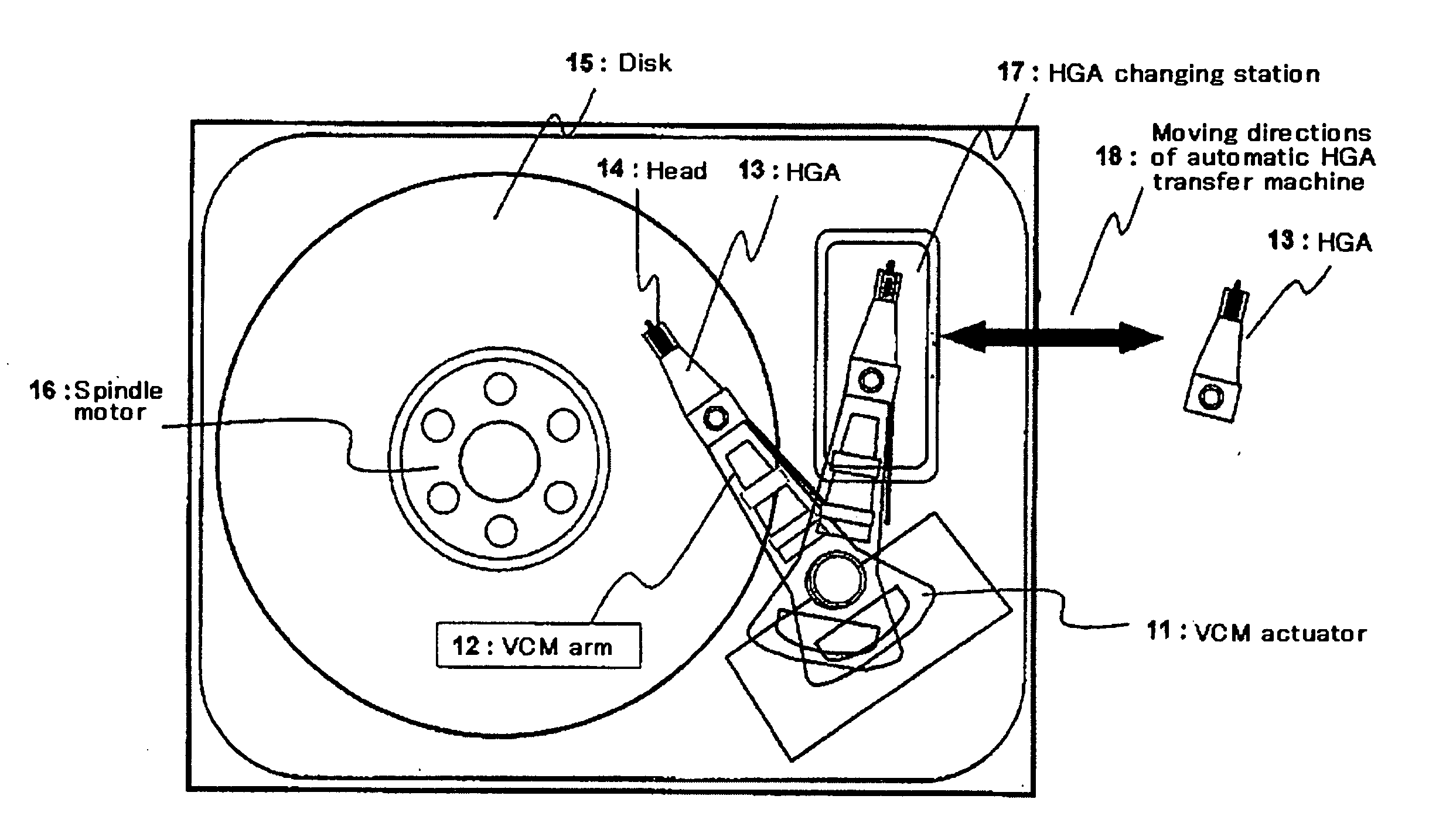

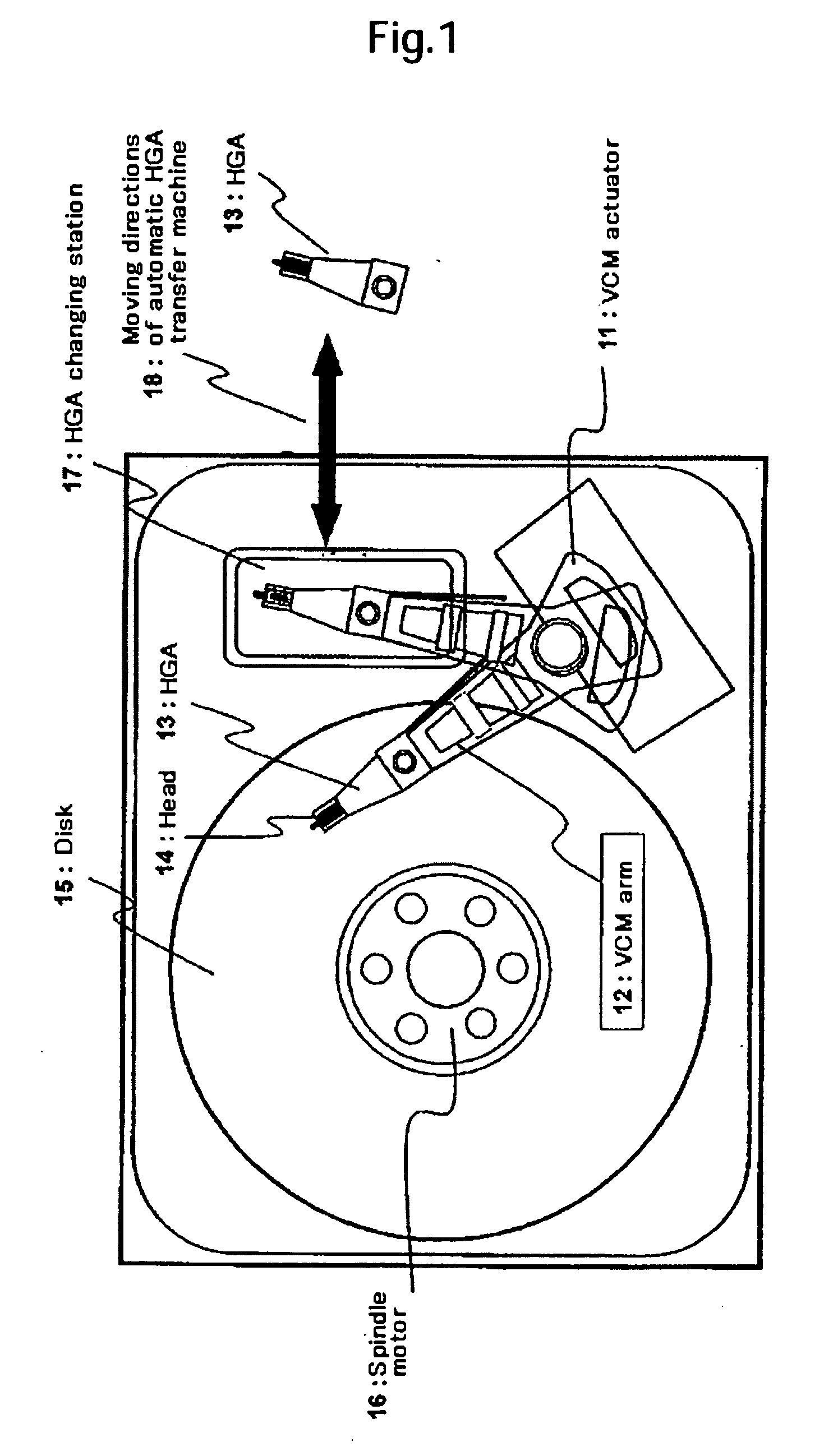

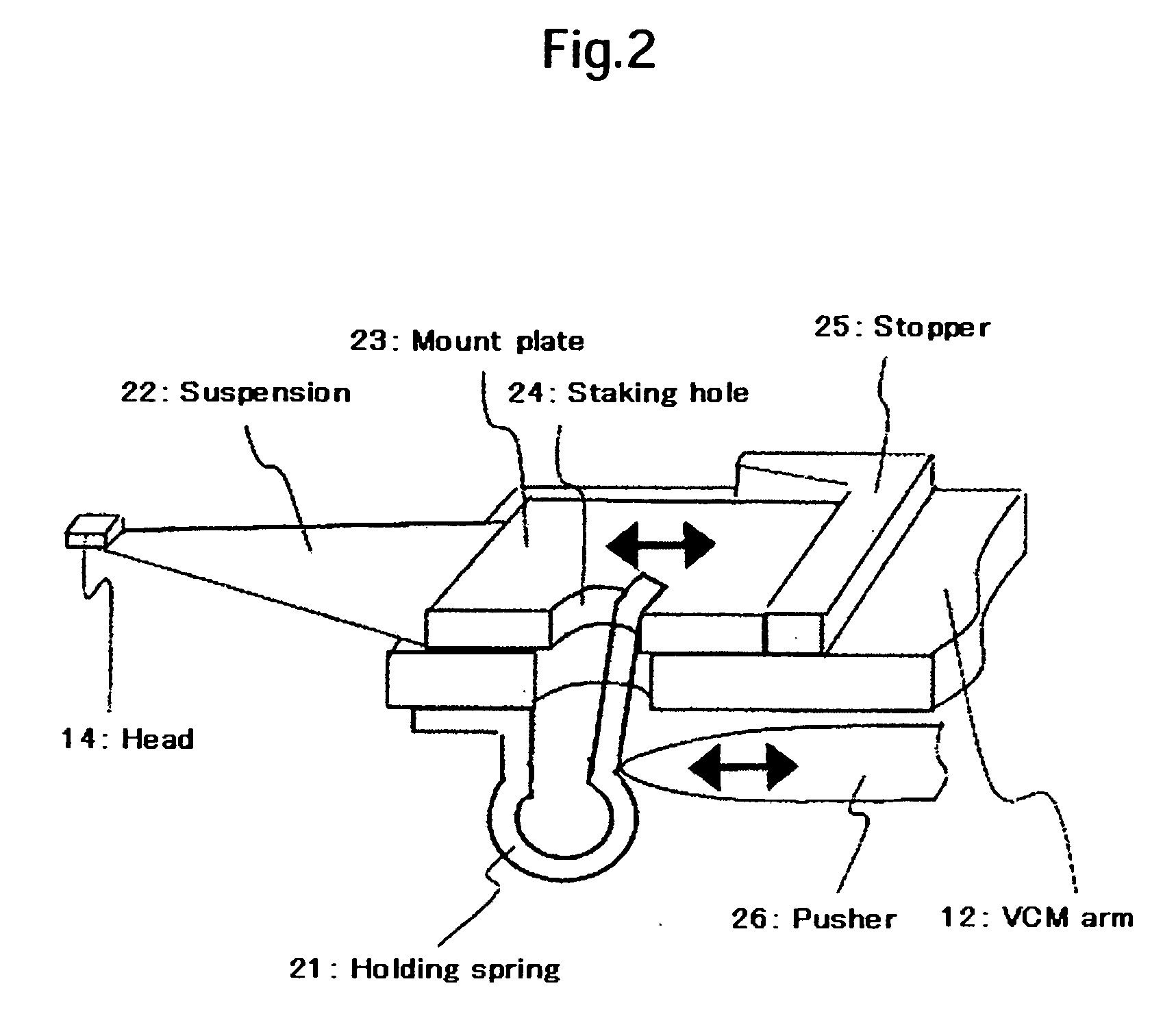

Magnetic head tester and method of manufacturing magnetic disk drive

InactiveUS20070046286A1Prevent runawayAccurate servo patternMagnetic property measurementsRecord information storageTester deviceActuator

Embodiments of the invention provide an inexpensive magnetic head tester employing component parts of a production HDD and capable of exercising functions very close to those of a production HDD. In one embodiment, a magnetic head tester employs the VCM actuator and the control circuit of a production HDD and has a lightweight, simple HGA fixing mechanism mounted on an actuator arm. The HGA fixing mechanism fixes an HGA to the actuator arm by a method using a very light holding spring mounted on the arm, a method of mechanically clamping an HGA by using air pressure, or a method of fixing an HGA to the arm by elastically deforming a rubber clamping member by air pressure. Servo control is achieved by the actuator of a production VCM. An end part of the VCM actuator is stopped by a stopping mechanism and is held by a holding spring to prevent the runaway of the VCM actuator. Servo control is performed by balancing the driving force of the VCM and the resilience of the spring.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Motor driven sampling apparatus for material collection

A motorized sample collection apparatus having a hollow clamshell casing with a contoured grip for the fingers, a horizontal extension to eliminate slippage when held in a user's hand, and a flange bottom portion from which a sample sleeve extends downwards. Within the clamshell casing an electric motor is mounted which drives, via spur gears the sample sleeve in a rotational manner. The distal end of the sample sleeve, is a cutting edge circumscribing a circular region. An ejection rod slides reciprocally within the sample sleeve between a retracted stowed position and an expulsion position. User cuts a sample from a substrate by engaging contact between the cutting edge of the sample sleeve and the substrate, applying pressure against the substrate and activating the motor to rotate the sample sleeve. Activation of the ejection rod towards the expulsion position displaces the sample into an appropriate collecting vessel.

Owner:GE HEALTHCARE BIO SCI CORP

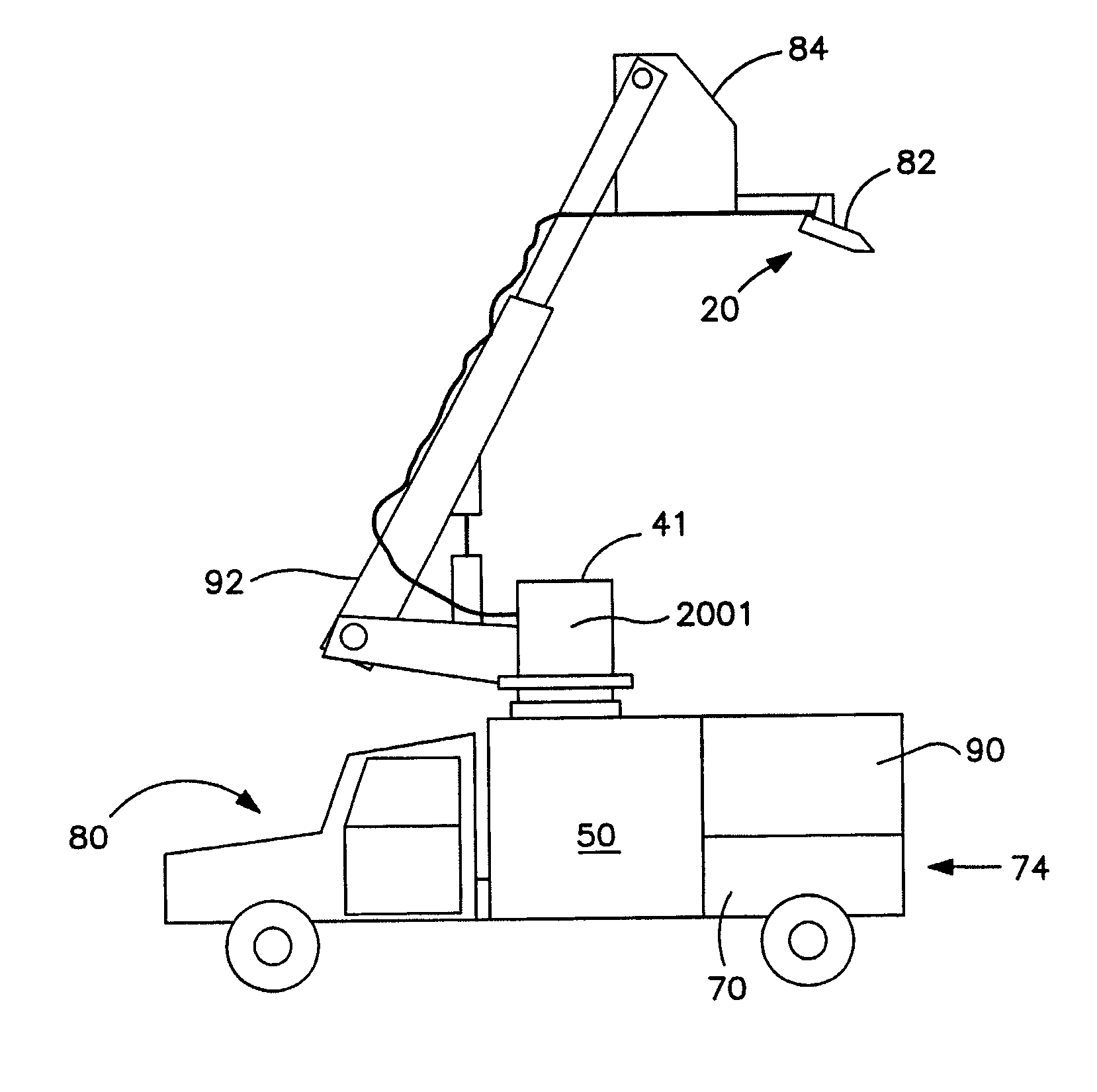

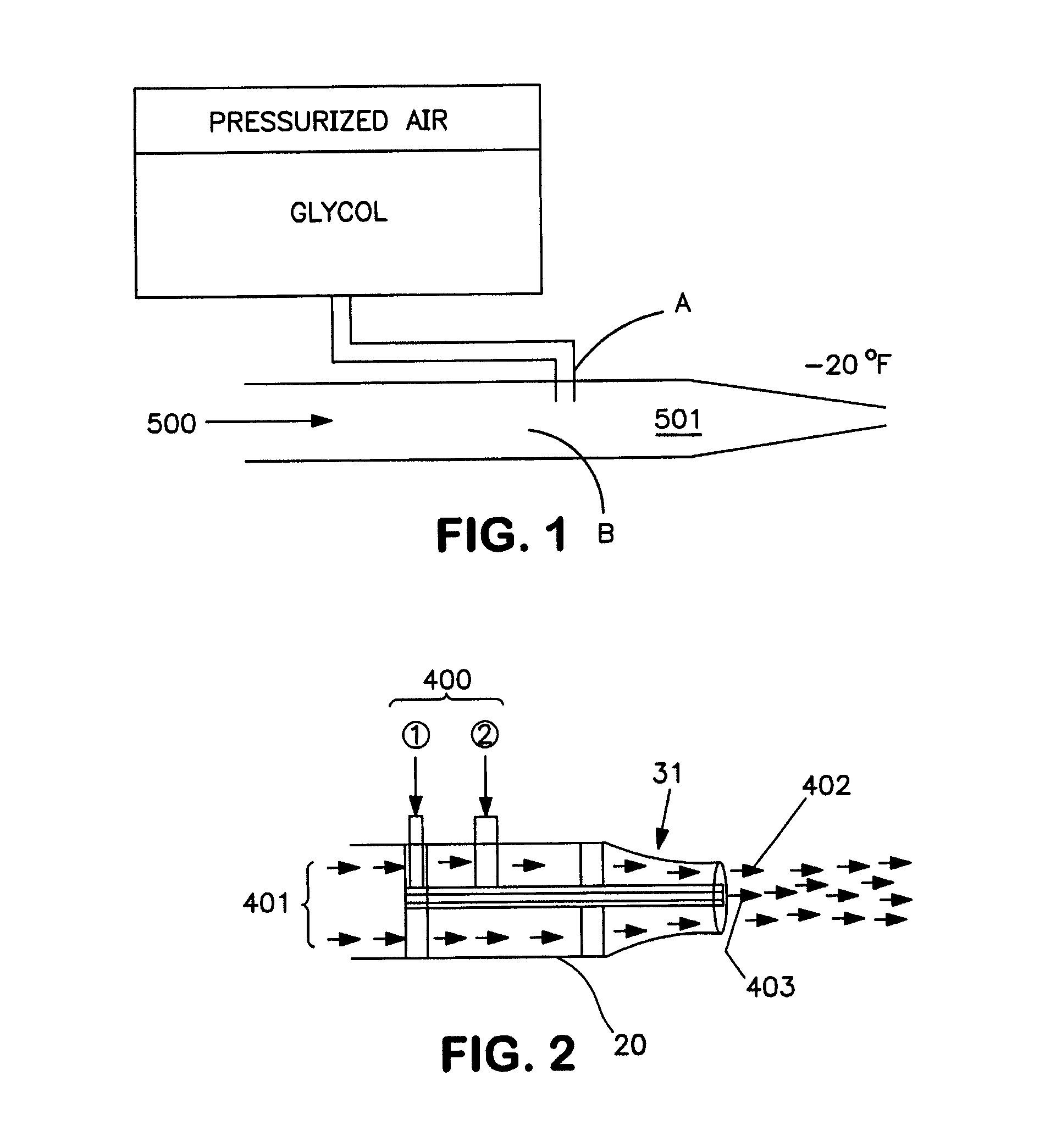

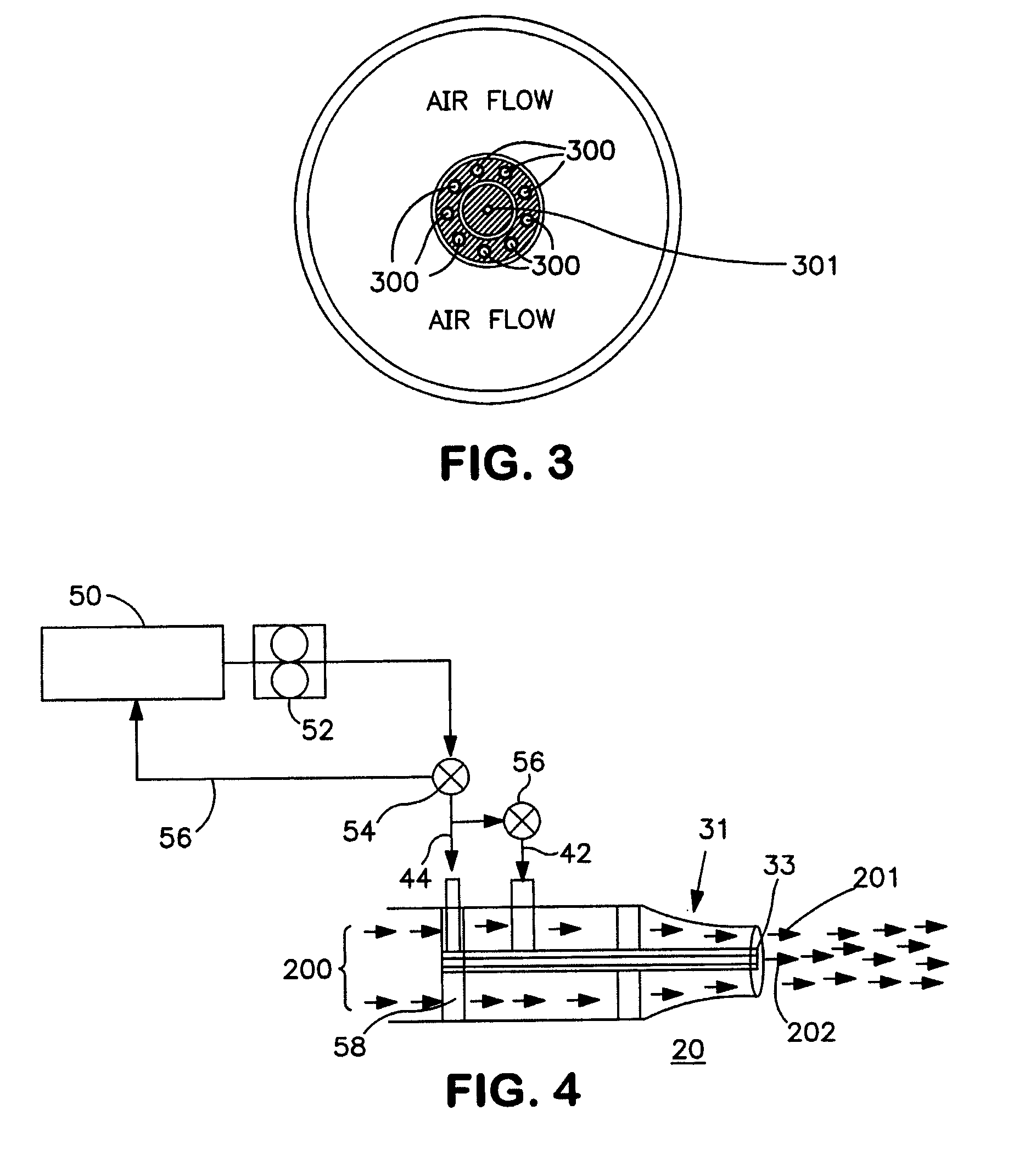

Hybrid deicing system and method of operation

InactiveUS7431240B1Efficiently and effectively removingAvoid prolonged useMovable spraying apparatusDe-icing equipmentsEngineeringHigh pressure

This invention overcome the disadvantage of the prior systems and produces a high velocity specially formed and constituted pressure aerodynamic stream for efficiently and effectively removing ice from an aircraft. The specially formed stream includes a stream within a stream, wherein a deicing fluid such a glycol is entrained within and encased by a surrounding jacket of entraining fluid such air. This deicing is now known as coaxial stream / stream within a stream deicing. The special nozzle allows the stream to maintain fluid separation over its flight path so that aircraft contact is made by to be known as coaxial stream / stream within a stream deicing. The coaxial stream / stream within a stream deicing is further enhanced by pressurizing the stream to deliver the stream as a high pressure high velocity stream to improved the aerodynamic sweeping action of the airstream.

Owner:PREMIER ENG & MFG

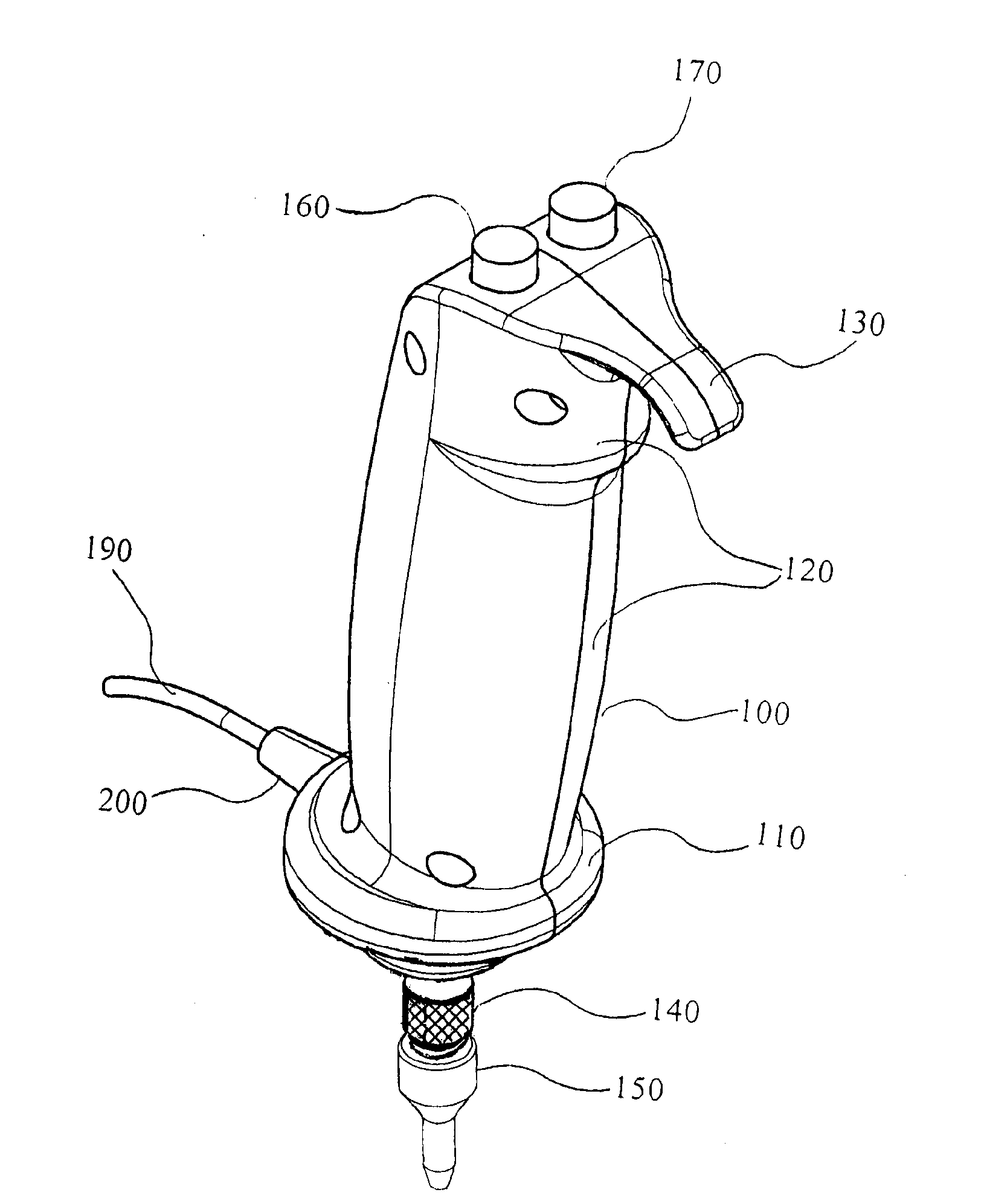

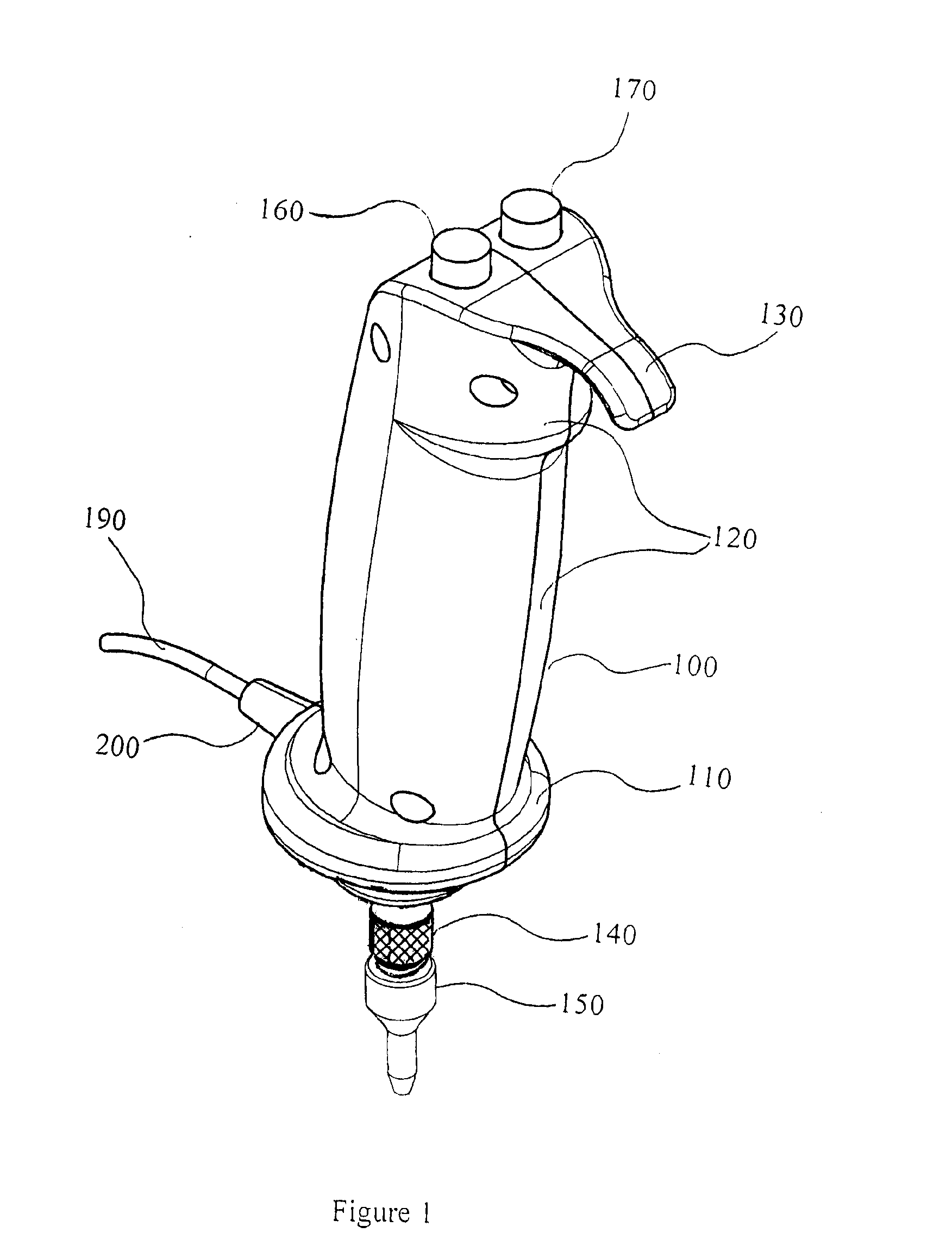

Motor driven rotational sampling apparatus with removable cutting tools for material collection

InactiveUS20130118017A1Comfortable to holdReduce usageWithdrawing sample devicesExcision instrumentsMotor driveDrive shaft

A motorized apparatus to simultaneously excise, retrieve, temporarily store and transport a sample of material has a hollow clamshell casing with a blended contoured grip for the fingers, a horizontal extension to eliminate slippage when held in a user's hand, and a flange bottom portion from which a removable cutting tool threaded to a drive shaft extends downwards. Within the clamshell casing an electric motor is mounted which drives, via gears, a drive shaft which rotates a cutting tool threaded to the distal end of the drive shaft. The end of the cutting tool, distal from the clamshell casing, forms a cutting edge circumscribing a circular region. An ejection rod slides reciprocally within the cutting tool between a stowed position and an expulsion position. Users core a sample from the source material by engaging contact between the cutting edge of the cutting tool and the surface of the source material, applying pressure against the surface of the source material while simultaneously activating the motor to rotate the cutting tool. The cutting region of the cutting tool passes through the source material contacting the support surface below the source material which urges the cored sample into the lumen of the cutting tool. The sample may be stored in the lumen or transported. Activation of the ejection rod moves from the stowed position towards the expulsion position displacing the temporarily stored sample from the lumen space in the cutting tool into the appropriate collection receptacle or onto a desired surface.

Owner:GE HEALTHCARE BIO SCI CORP

Tool for extracting an embedded elongated object

A hand operated tool for extracting an embedded elongated object, including: a) an elongated, movable first handle member with a first, upper end portion divided into two matching legs separated by an opening; b) a corresponding second handle member with a first jaw member and a first, upper end extending through the leg opening, the second handle member being pivotally attached to the first leg and the second leg; c) a floating head portion pivotally attached to the first and second legs, the floating head portion including a second jaw member and an adjacent, upper curved edge; and d) two matching lever bars facing one another from opposite sides of the extraction tool, each being pivotally connected to the second handle member and to the floating head portion; and wherein the second jaw member is engaged against the first jaw member when the extraction tool is in a closed position, and disengaged from the first jaw member when the extraction tool is in an open position.

Owner:WAGNER JEFFERSON L

Magnetic head tester and method of manufacturing magnetic disk drive

InactiveUS7518814B2Quickly and safely attachingSafe and quick removalRecord information storageMagnetic property measurementsActuatorAtmospheric pressure

Embodiments of the invention provide an inexpensive magnetic head tester employing component parts of a production HDD and capable of exercising functions very close to those of a production HDD. In one embodiment, a magnetic head tester employs the VCM actuator and the control circuit of a production HDD and has a lightweight, simple HGA fixing mechanism mounted on an actuator arm. The HGA fixing mechanism fixes an HGA to the actuator arm by a method using a very light holding spring mounted on the arm, a method of mechanically clamping an HGA by using air pressure, or a method of fixing an HGA to the arm by elastically deforming a rubber clamping member by air pressure. Servo control is achieved by the actuator of a production VCM. An end part of the VCM actuator is stopped by a stopping mechanism and is held by a holding spring to prevent the runaway of the VCM actuator. Servo control is performed by balancing the driving force of the VCM and the resilience of the spring.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

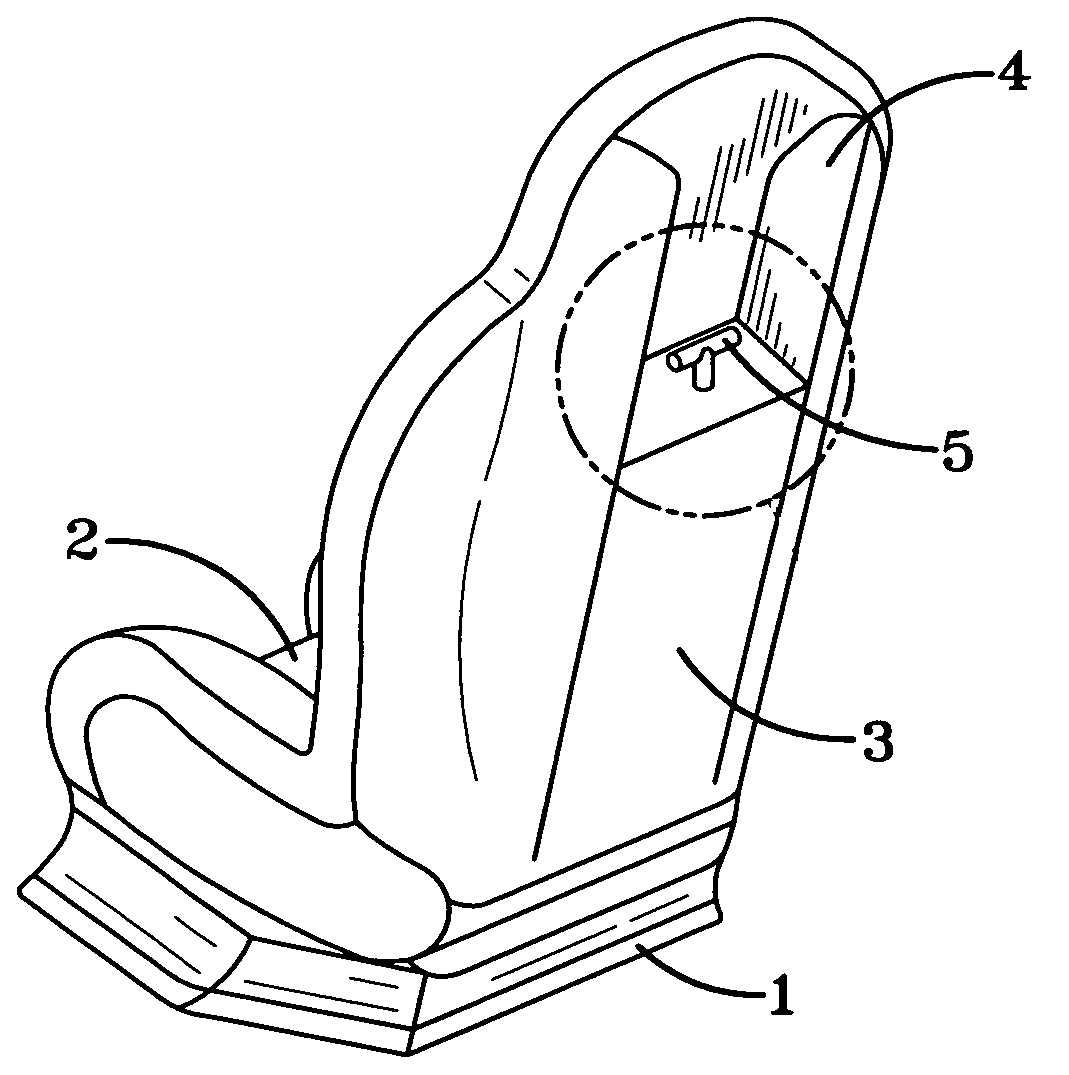

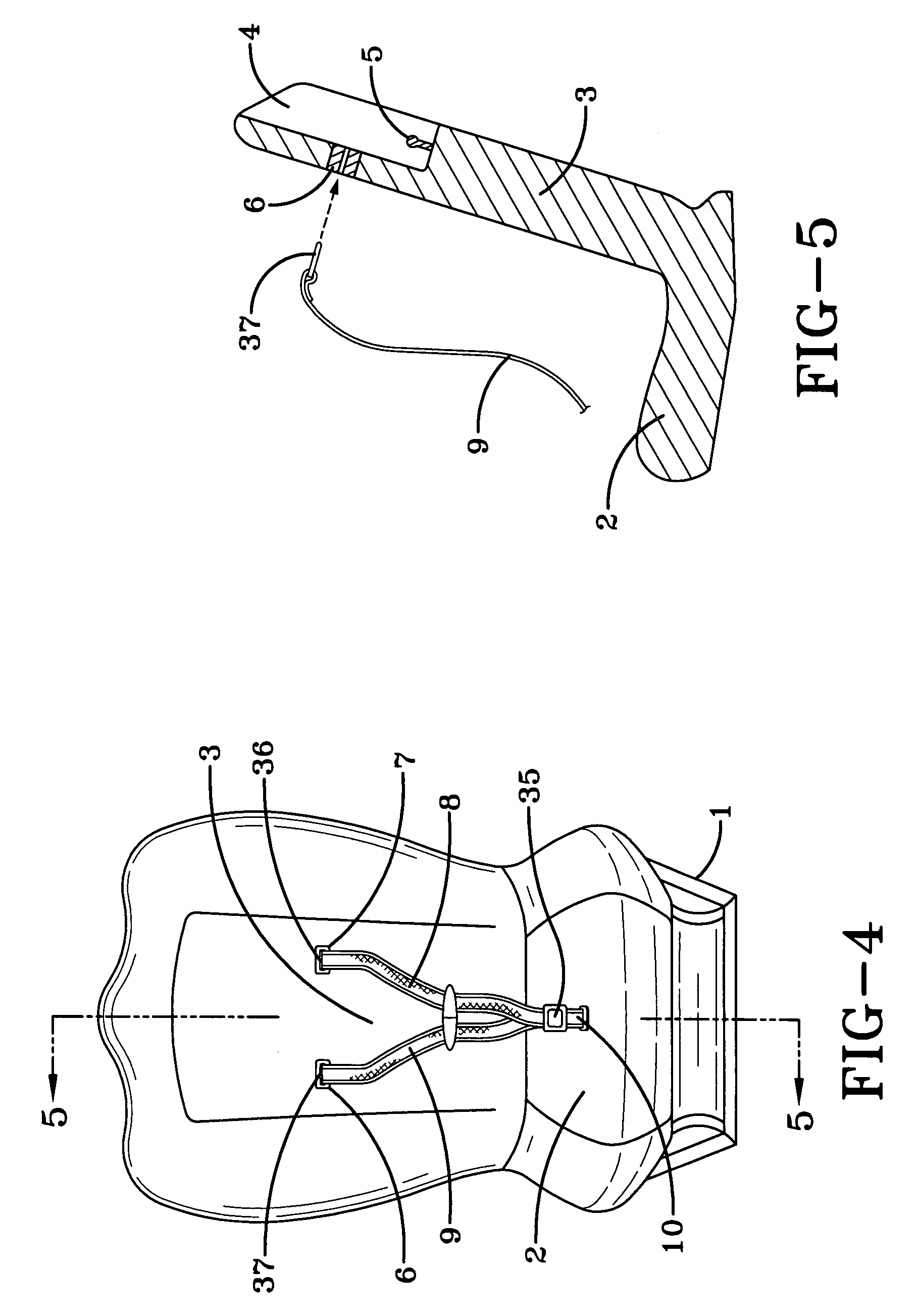

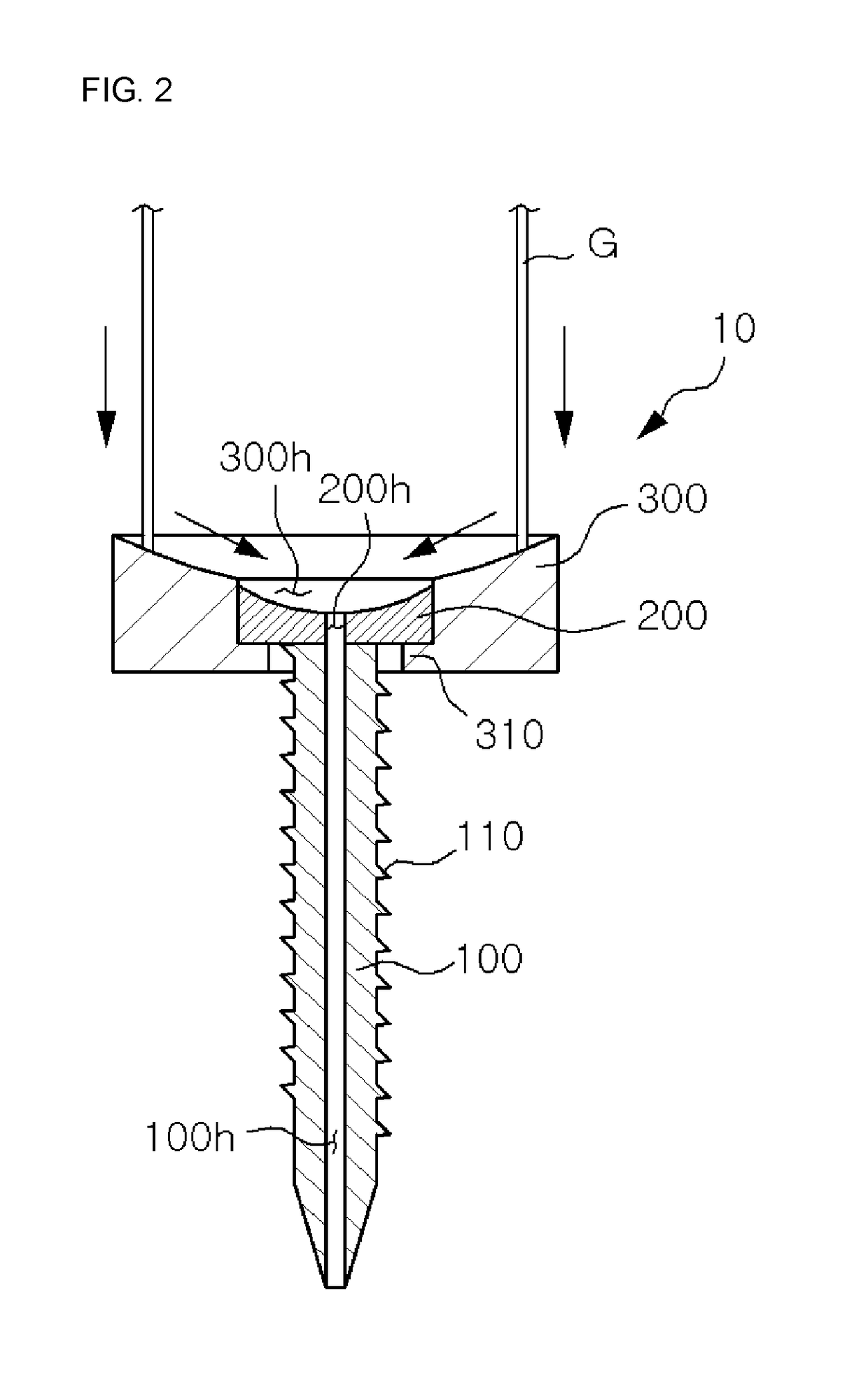

Child safety seat with emergency harness release

ActiveUS20090134678A1Fast and easy removalQuickly and easily removedSafety beltsPedestrian/occupant safety arrangementEngineeringBelt safety

The present disclosure discloses a child safety seat comprising: (a) a supporting base structure adapted to be secured to a vehicle seat; (b) a child seating surface wherein the seating surface comprises a seat bottom and a seat back, and wherein the seat back has disposed therein at least one pair of laterally spaced shoulder belt restraints; (c) a child harness wherein the harness comprises a pair of shoulder belts running from the restraints in the seat back to a seat bottom locking tongue, each shoulder belt having a restraint engaging means affixed to an extreme end of the belt for insertion into the laterally spaced pair of restraints in the seat back, and a buckle affixed to the front center portion of the seat bottom for receiving the seat bottom locking tongue; and (d) an emergency means of disengaging at least one of shoulder belts from at least one of the restraints in the back of the seat, the disengaging means being actuated from the rear face or side of the seat.

Owner:BLACKMON MICHAEL M

Motor driven rotational sampling apparatus with removable cutting tools for material collection

InactiveUS20110258857A1Comfortable to holdReduce usageWithdrawing sample devicesPortable power-driven toolsMotor driveSource material

A motorized apparatus to simultaneously excise, retrieve, temporarily store and transport a sample of material has a hollow clamshell casing with a blended contoured grip for the fingers, a horizontal extension to eliminate slippage when held in a user's hand, and a flange bottom portion from which a removable cutting tool threaded to a drive shaft extends downwards. Within the clamshell casing an electric motor is mounted which drives, via gears, a drive shaft which rotates a cutting tool threaded to the distal end of the drive shaft. The end of the cutting tool, distal from the clamshell casing, forms a cutting edge circumscribing a circular region. An ejection rod slides reciprocally within the cutting tool between a stowed position and an expulsion position. Users core a sample from the source material by engaging contact between the cutting edge of the cutting tool and the surface of the source material, applying pressure against the surface of the source material while simultaneously activating the motor to rotate the cutting tool. The cutting region of the cutting tool passes through the source material contacting the support surface below the source material which urges the cored sample into the lumen of the cutting tool. The sample may be stored in the lumen or transported. Activation of the ejection rod moves from the stowed position towards the expulsion position displacing the temporarily stored sample from the lumen space in the cutting tool into the appropriate collection receptacle or onto a desired surface.

Owner:GE HEALTHCARE BIO SCI CORP

Child safety seat with emergency harness release

InactiveUS20080018149A1Quickly freeFast and easy removalSafety beltsPedestrian/occupant safety arrangementMechanical engineeringChild restraint

The present invention discloses a child safety seat comprising: (a) a supporting base structure adapted to be secured to a vehicle seat; (b) a child seating surface wherein the seating surface comprises a seat bottom and a seat back, and wherein the seat back has disposed therein at least one pair of laterally spaced buckles; (c) a child restraint harness wherein the harness comprises a pair of shoulder restraint belts running from the laterally spaced buckles in the seat back to a seat bottom locking tongue, each shoulder restraint belt having a locking tongue affixed to an extreme end of the belt for insertion into the laterally spaced pair of buckles in the seat back, and a buckle affixed to the front center portion of the seat bottom for receiving the seat bottom locking tongue; and (d) an emergency means of disengaging the pair of shoulder restraint belt locking tongues from the seat back buckles, the disengaging means being actuated from the rear face of the seat back.

Owner:BLACKMON MICHAEL M

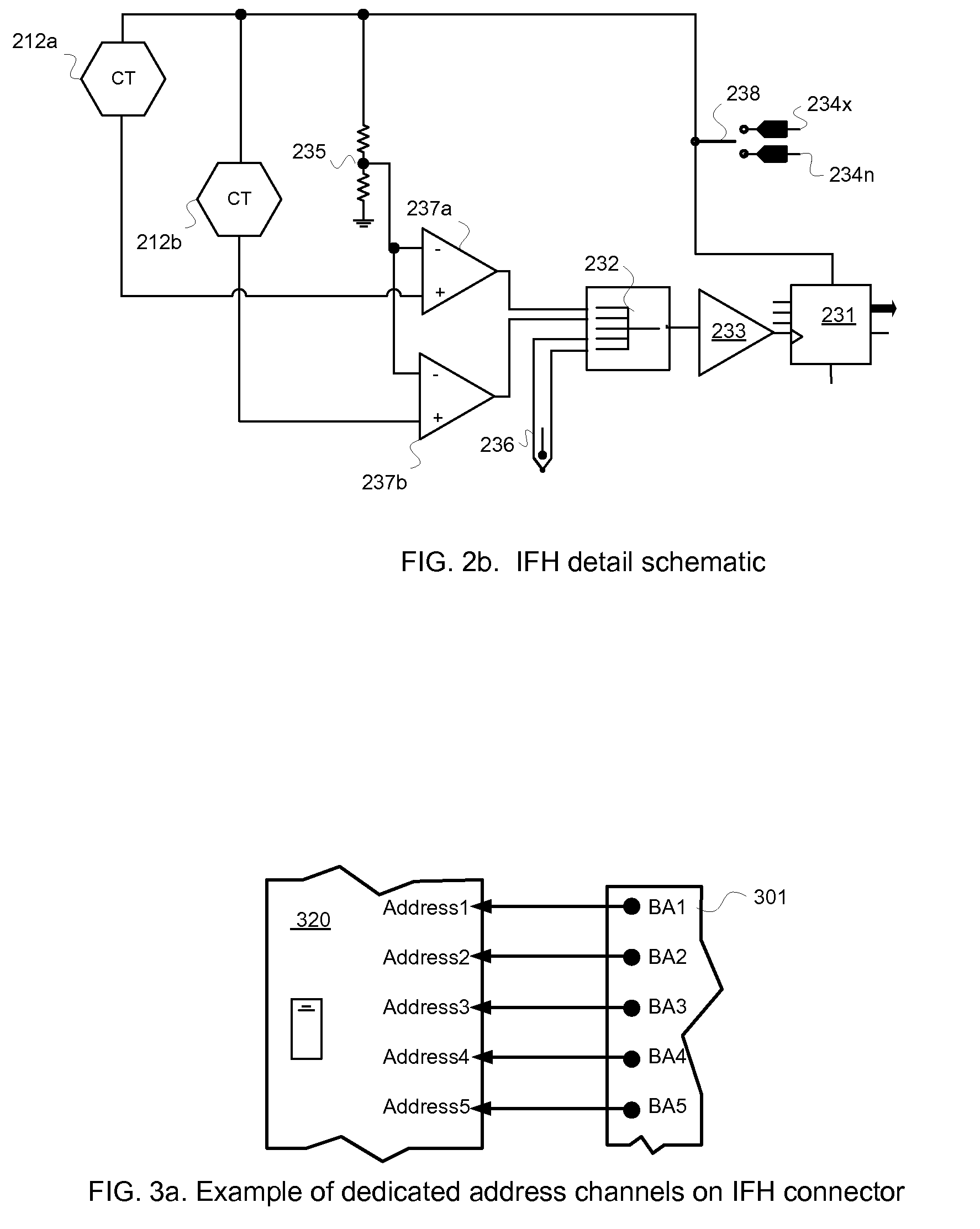

Intelligent fuse-holder

InactiveUS20100246080A1Enhance versatility and adaptabilityMinimize wasteCircuit arrangements on conductive chasisArrangements responsive to excess currentElectronicsBuilt in current sensor

In high-current electrical devices protected by fuses, additional performance data besides whether or not a fuse is blown is useful for diagnostics, repair, and preventing emerging failures from reaching a level that damages the device. An intelligent fuse-holder includes a built-in current sensor. The current sensor signals are passed through an A / D converter and analyzed by a microcontroller. Through an interface, a user can program the fuse-holder to periodically degauss the current sensor coil to improve performance or turn the sensor power off to conserve power. The user may also control various I / O signals carrying information about the fuse, the intelligent electronics, or the host board on which the fuse-holder is mounted.

Owner:ETM ELECTROMATIC +1

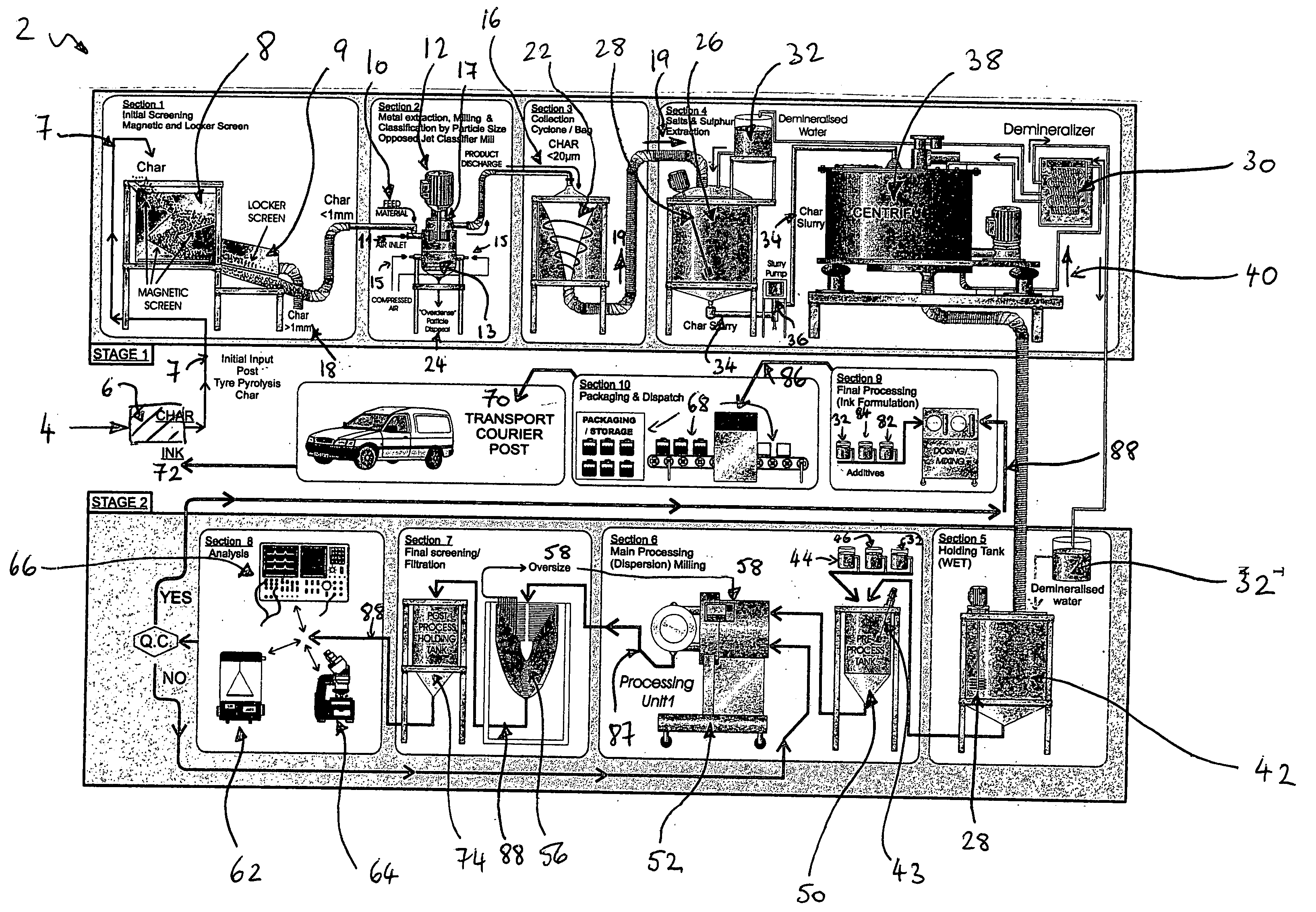

Method of refining carbon black char

InactiveUS20050072337A1Safe and quick removalSimple working processPigmenting treatmentMaterials scienceChar

A method of refining carbon black char, the method comprising removing particles greater than approximately 1 mm in size from a carbon black char feed.

Owner:DSL PROCESSING EURO

Child safety seat with emergency harness release

InactiveUS7448690B2Quickly freeFast and easy removalVehicle seatsSafety beltsChild restraintBelt safety

The present invention discloses a child safety seat comprising: (a) a supporting base structure adapted to be secured to a vehicle seat; (b) a child seating surface wherein the seating surface comprises a seat bottom and a seat back, and wherein the seat back has disposed therein at least one pair of laterally spaced buckles; (c) a child restraint harness wherein the harness comprises a pair of shoulder restraint belts running from the laterally spaced buckles in the seat back to a seat bottom locking tongue, each shoulder restraint belt having a locking tongue affixed to an extreme end of the belt for insertion into the laterally spaced pair of buckles in the seat back, and a buckle affixed to the front center portion of the seat bottom for receiving the seat bottom locking tongue; and (d) an emergency means of disengaging the pair of shoulder restraint belt locking tongues from the seat back buckles, the disengaging means being actuated from the rear face of the seat back.

Owner:BLACKMON MICHAEL M

Tool for extracting an embedded elongated object

A hand operated tool for extracting an embedded elongated object, includes: a) an elongated, movable first handle member with a first, upper end portion divided into two matching legs separated by an opening; b) a corresponding second handle member with a first jaw member and a first, upper end extending through the leg opening, the second handle member being pivotally attached to both legs; c) a floating head portion pivotally attached to the first and second legs, the floating head portion including a second jaw member and an adjacent, upper curved edge; and d) two matching lever bars facing one another from opposite sides of the tool, each being pivotally connected to the second handle member and to the floating head portion; and wherein the second jaw member is engaged against the first jaw member in a closed tool position, and disengaged from the first jaw member in an open tool position.

Owner:WAGNER JEFFERSON L

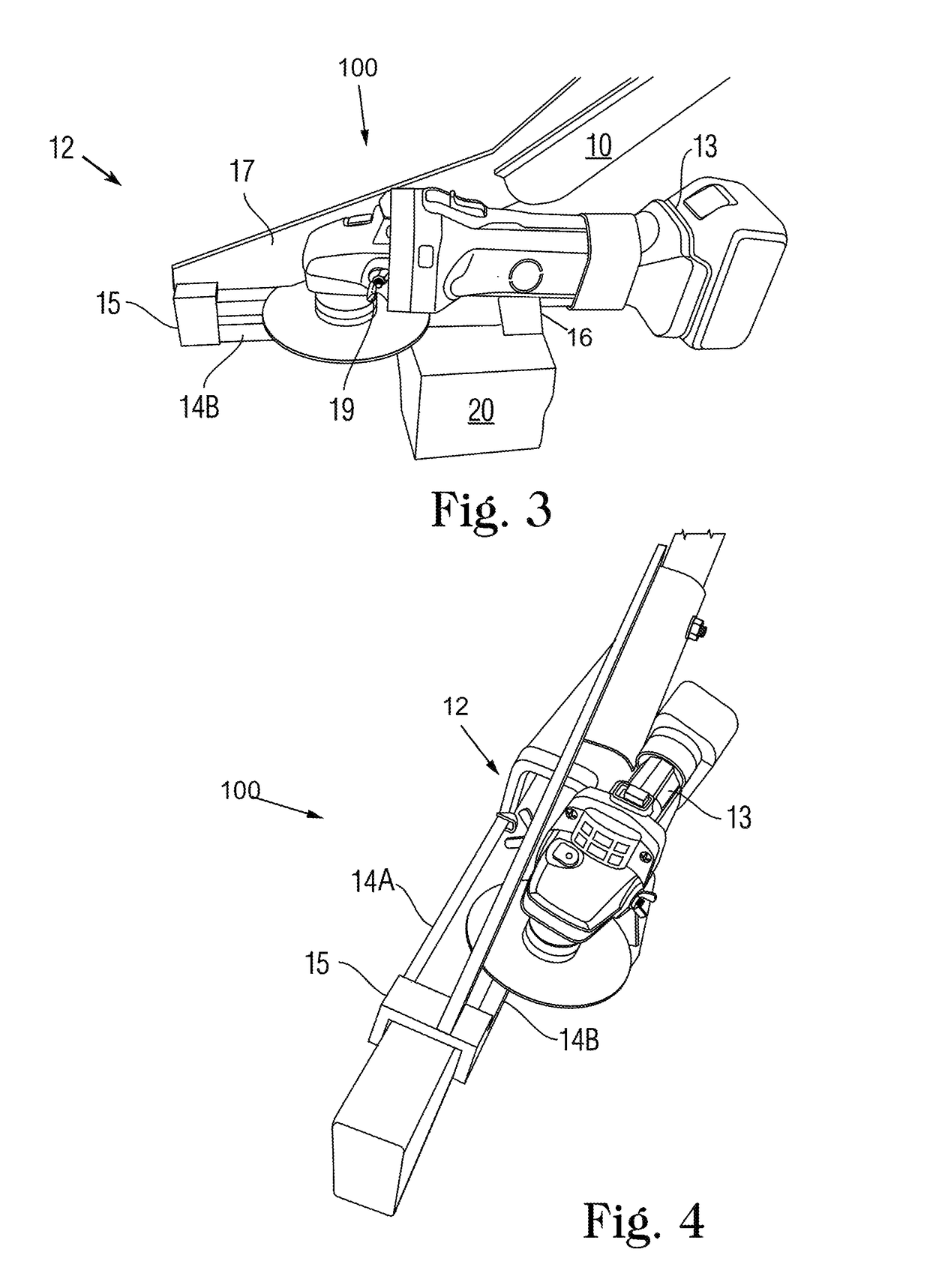

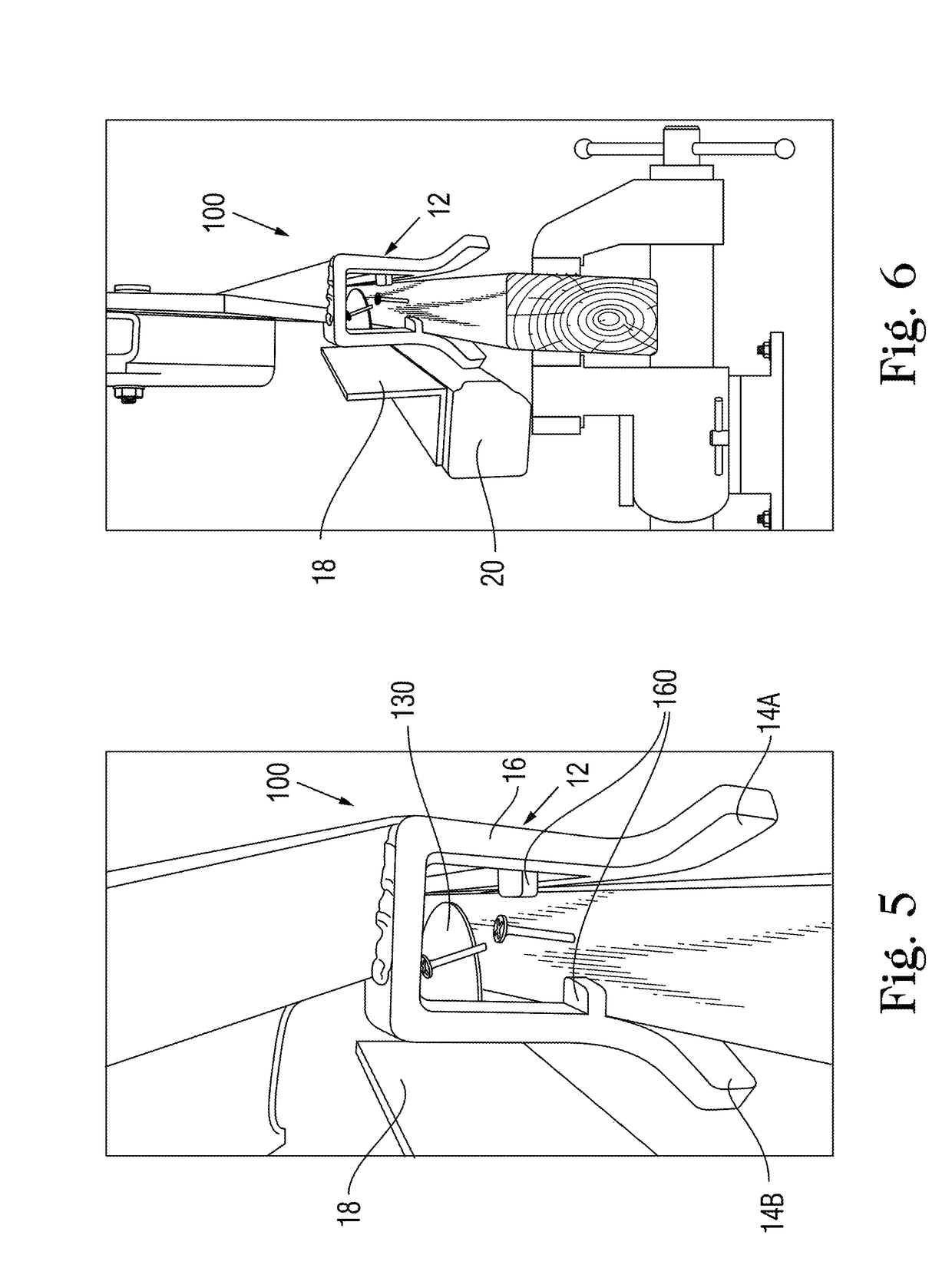

Deck fastener removal tool

ActiveUS10137513B2Safe and quick removalMetal sawing devicesMetal sawing accessoriesIn planeAngle grinder

An improved deck fastener removal tool comprising a fixture with an extended handle to hold the cutting blade of an angle grinder or like tool in plane with the top of the joist and removed a safe distance away from the operator's body. The handle may be extendable and adjustable to render it comfortable for use by multiple operators. The fixture utilizes a series of guards to ensure that the cutting blade remains level with the top of the joist along the entire length thereof, allowing the operator to walk steadily along the top of or next to the joist to quickly and safely remove each residual fastener protruding therefrom. An integrated collection tray automatically gathers the severed portions of the fasteners as they are cut.

Owner:WEINREICH BENJAMIN

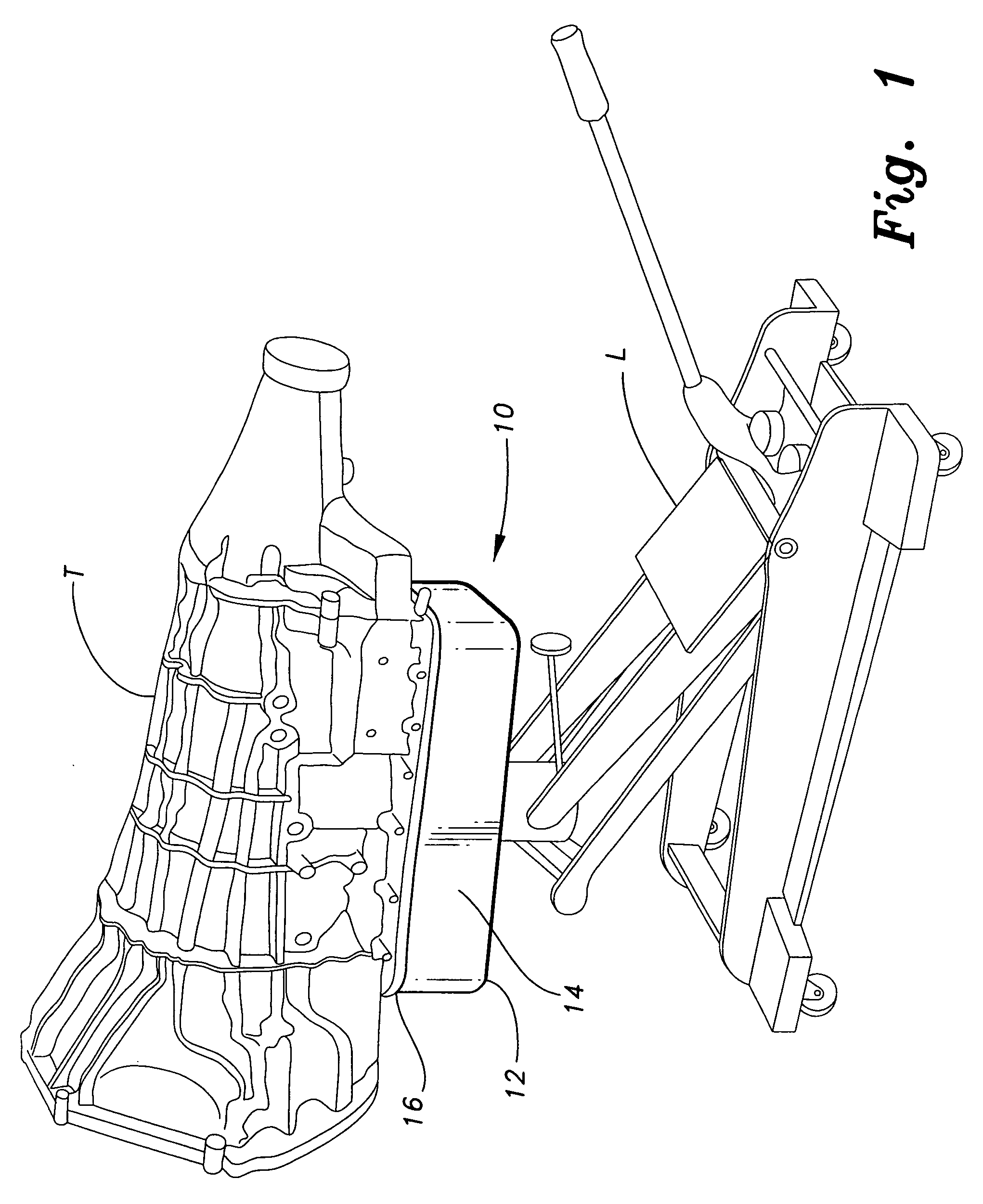

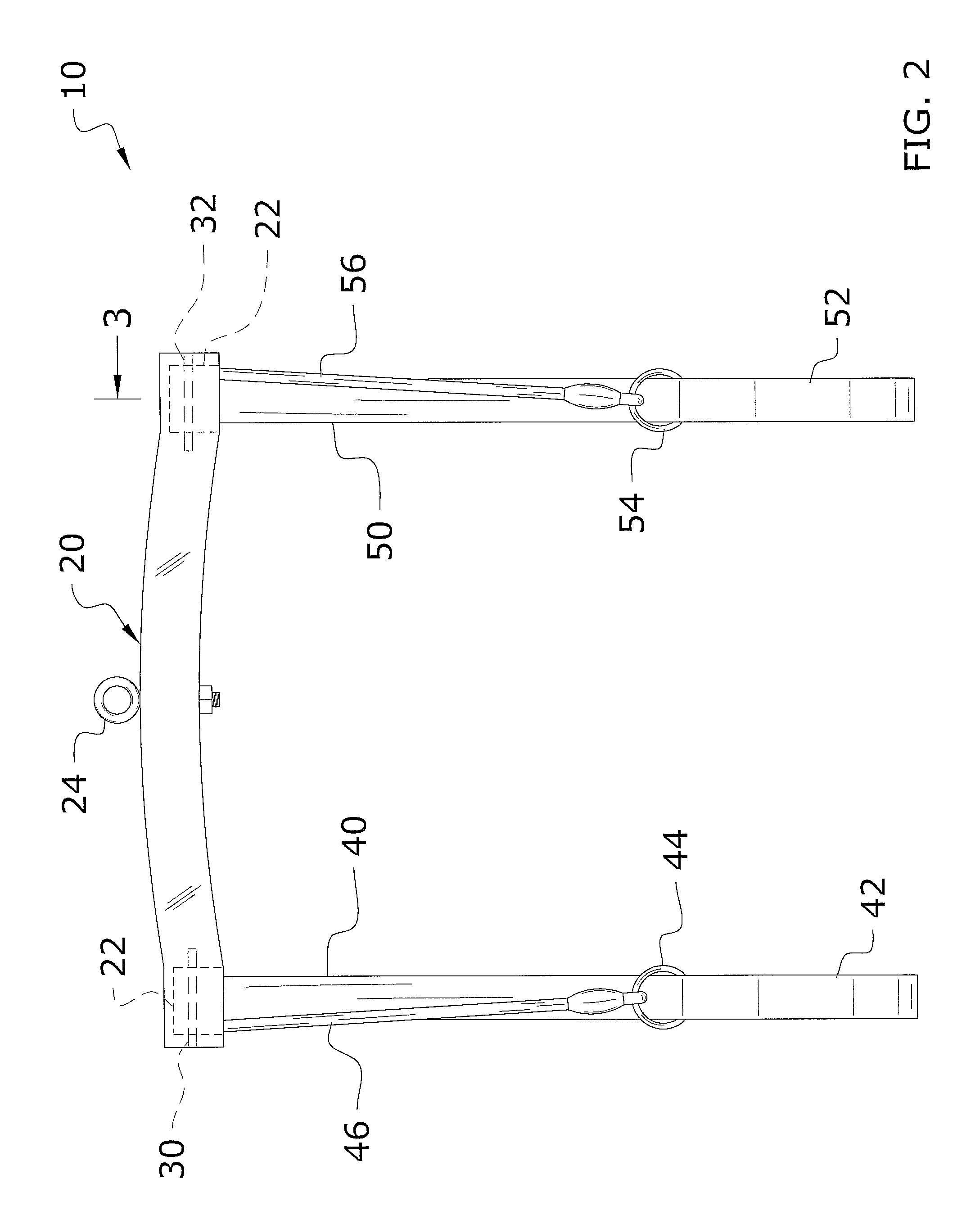

Stabilizer to aid in installation and removal of a transmission

InactiveUS20070151880A1Evenly distributedQuick changePackaging vehiclesContainers for machinesEngineeringMechanical engineering

Owner:CHAPMAN JARVIS A +1

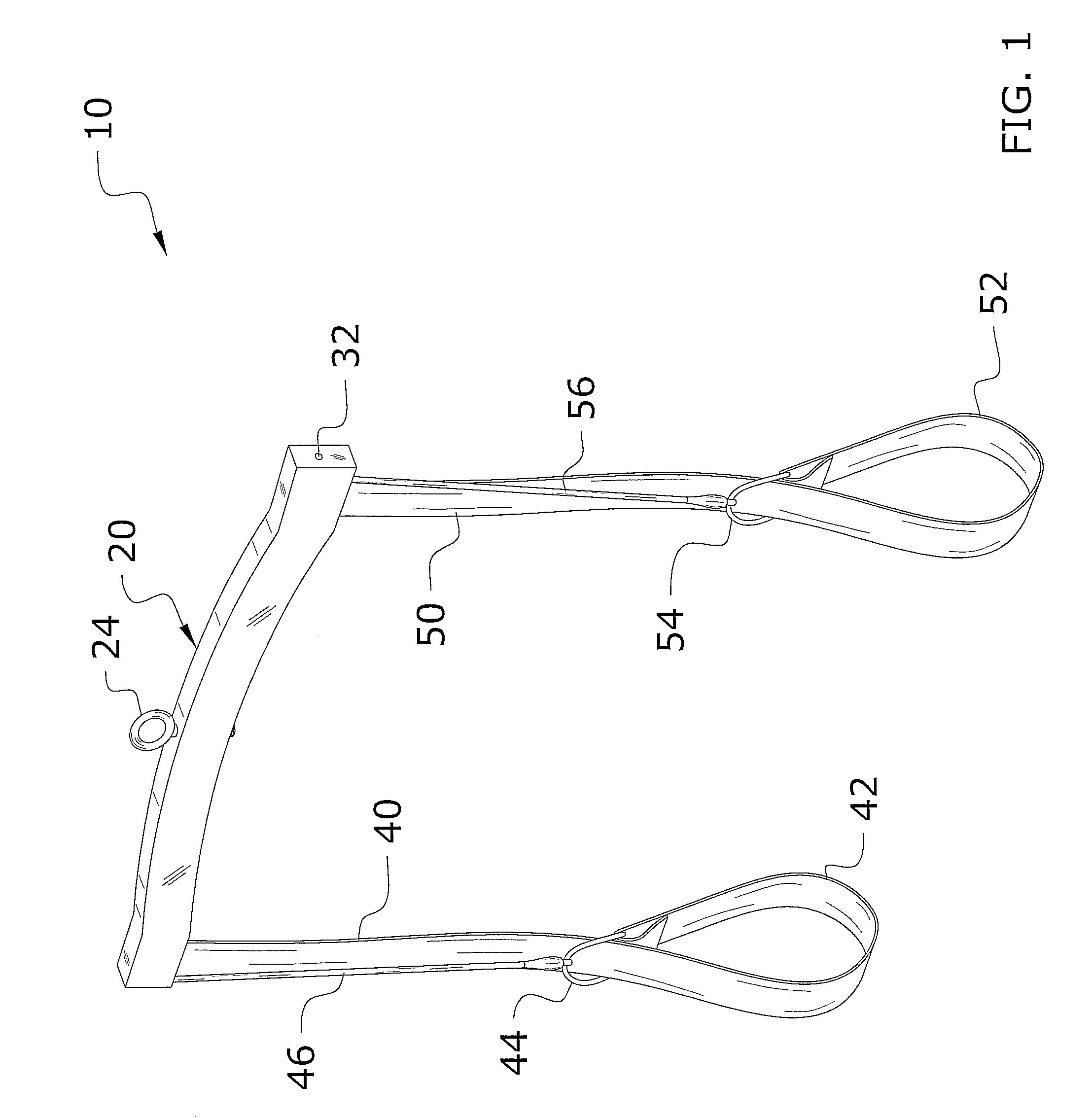

Human transporting system

InactiveUS7740298B1Efficient removalSafe and quick removalBreathing protectionTravelling carriersEngineeringWrist

A human transporting system for efficiently removing an injured person out of water. The human transporting system generally includes a handle, a pair of straps attached to the handle, a pair of sliding loops attached to the straps forming looped portions for receiving the wrists of an injured human, and a pair of biasing members attached between the handle and the sliding loops. The looped portions receive the wrists of the injured human and the user pulls the injured human from the water by pulling upon the handle which tightens the looped portions upon the wrists. Once the injured human is pulled out of the water, the handle is lowered thereby allowing the biasing members to loosen the looped portions about the wrists.

Owner:LARSON DONALD O +1

Bootjack

PendingCN109463967ASimple structureSafe and quick removalApparel holdersCompound (substance)Engineering

The invention discloses a bootjack which comprises a base and a boot removing device arranged on the base, wherein the boot removing device comprises a pedal, a toe clamping plate, a heel clamping plate, a tension spring and a rear upright post; the rear upright post is fixed on the base, the heel clamping plate is fixed on an upper part of the rear upright post, a front end of the heel clamping plate is provided with a U-shaped opening, the pedal can be arranged on the base in a sliding way and is positioned in front of the rear upright post, the front end of the pedal is provided with the toe clamping plate, a rear end surface of the toe clamping plate is provided with a groove matched with a toe in shape, one end of the tension spring is connected with a rear end of the pedal, and the other end is connected with the rear upright post. Compared with the prior art, the bootjack has the advantages of being simple in structure, capable of removing polluted chemical prevention boots without help of hand force, and capable of ensuring that a user can safely and rapidly remove the polluted chemical prevention boots in a working process.

Owner:GUANGZHOU TERRA TRUST TECH SERVICE CO LTD +2

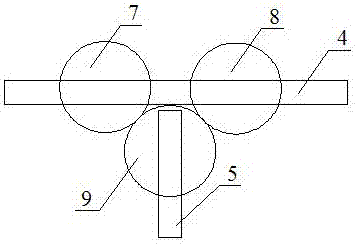

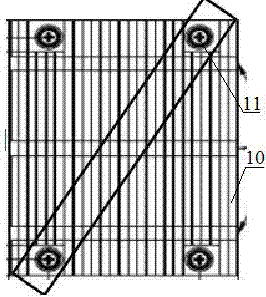

Device and method for rapidly dismounting and mounting CPU radiator

The invention discloses a device and method for quickly disassembling and assembling a CPU heat sink, belonging to the technical field of heat sink installation. The device for quickly disassembling and assembling the CPU radiator of the present invention includes a gear module, a screwdriver head A, a screwdriver head B, a slide rail A and a slide rail B, the gear module is composed of a gear A, a gear B and a gear C, and the gear A And gear B is arranged on slide rail A, and slides with slide rail A, and gear C is arranged on slide rail B, slides with slide rail B, and gear A, gear B mesh with gear C respectively, and the screwdriver head A Connect with gear A, screwdriver bit B connect with gear B. The device for quickly disassembling and assembling the CPU heat sink of the invention has a simple and reasonable structural design, is convenient to operate and use, can ensure the safety of the CPU or the CPU card slot, and can improve efficiency, and has good popularization and application value.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Safe moving and withdrawing method of complex-structured thick coal seam fully mechanized heavy equipment

ActiveCN102094675BGuarantee support safetyGive full play to the maximum effectUnderground transportAnchoring boltsAditHeavy equipment

Owner:DATONG COAL MINE GRP

Battery component disconnection control system, battery component and vehicle having same

ActiveCN104917215BGuarantee job securitySafe and quick removalBatteries circuit arrangementsElectric powerElectrical batteryControl signal

The invention discloses a battery assembly disconnection control system and a battery assembly and a vehicle thereof. The battery assembly includes a plurality of battery units connected in series, and the disconnection control system includes a manual circuit breaker detachably installed between the battery units in series, A disconnect switch arranged between the battery units, a circuit information sensor arranged in the battery assembly, and a disconnect control module connected with the disconnect switch and the circuit information sensor. The disconnect switch is integrated in the manual circuit breaker and can be triggered by the manual circuit breaker to break the circuit and / or remove from between the battery cells in series. The circuit information sensor is used to detect circuit information and transmit the circuit information to the circuit breaker control module, and the circuit breaker control module is used to generate a first circuit breaker control signal when the circuit information meets a preset fault judgment condition, and the circuit breaker switch is also configured to receive the first circuit breaker It is disconnected when the control signal is disconnected.

Owner:QOROS

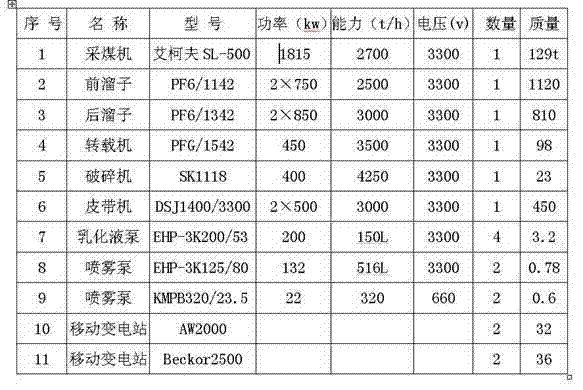

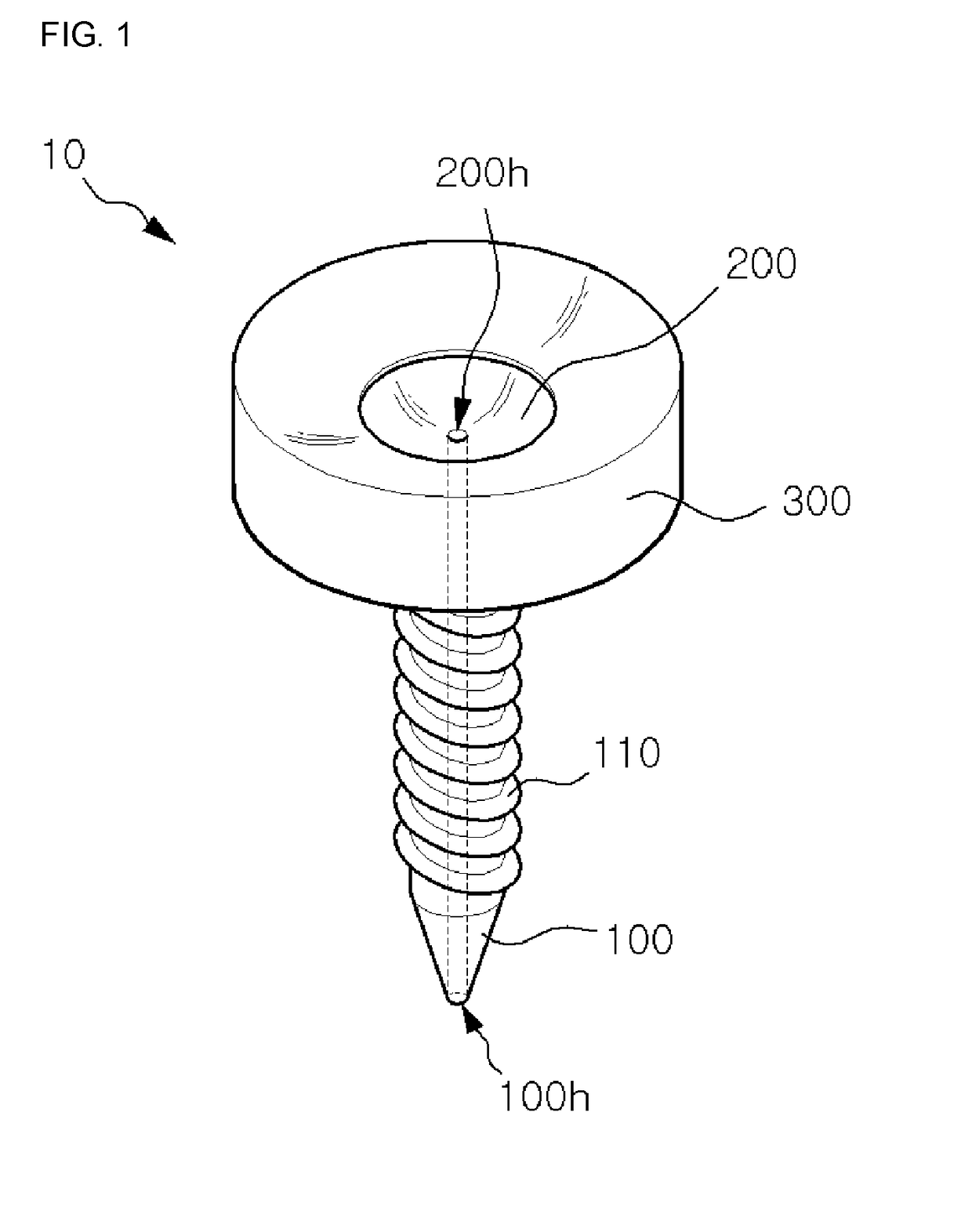

Cannulated screw

ActiveUS20190021775A1Easily inserted into connection holeSafe and quick removalFastenersScrew threadBiomedical engineering

A cannulated screw includes: a body portion that comprises a screw thread formed by protruding along an outer surface and has a through-hole at a center of the body portion; and a head portion that has one side surface combined to one end of the body portion, another side surface formed in a curved surface in which a center portion has a concave shape, and a connection hole communicating with the through-hole at a center of the head portion.

Owner:INJE UNIV IND ACADEMIC COOP FOUND

Keyboard disinfectant

The invention provides a keyboard disinfectant characterized in that the disinfectant comprises the following components calculated by part by weight: 50-90 parts of lemon extract, 1-2 parts of garlic extract, 1-2 parts of mint extract, 10-20 parts of surfactant, and 10-50 parts of sterile distilled water. Compared with the prior art, the invention has the characteristics of good disinfectant effect, natural environment protection and the like.

Owner:DONGHUA UNIV

Child safety seat with emergency harness release

ActiveUS8132864B2Fast and easy removalQuickly and easily removedVehicle seatsSafety beltsBelt safetyEmergency situations

Owner:BLACKMON MICHAEL M

A treatment method for broken rolls in finish rolling

ActiveCN107282644BAvoid leaningAvoid blindnessMetal rolling stand detailsMetal rolling arrangementsHydraulic cylinderDual action

Owner:ANGANG STEEL CO LTD

Transport device

Owner:R E D D SLED LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com