Stabilizer to aid in installation and removal of a transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

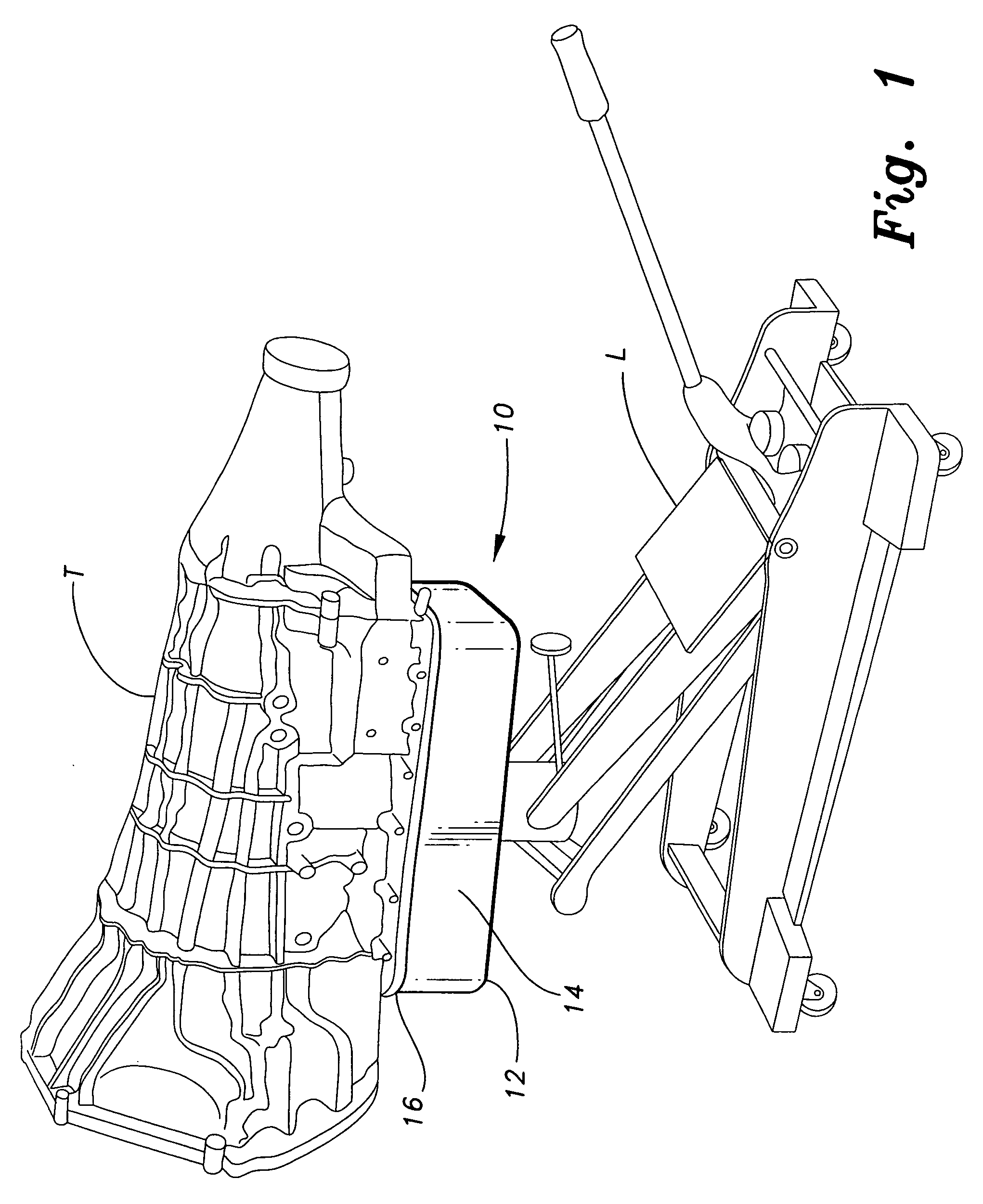

[0015] The present invention is a transmission stabilizer, designated generally as 10 in the drawings. As shown in FIG. 1, the stabilizer 10 is designed to support a transmission T during the removal and installation of the transmission T from a vehicle. One such type of transmission to be supported by device 10 could be the E40D, for example. The stabilizer 10 has a bottom 12 that is flat so that the bottom 12 may rest safely on the lift platform of a hydraulic jack L.

[0016] As shown in FIG. 2, a sidewall 14 extends around the bottom 12 and projects upwardly therefrom. The transmission T rests in the stabilizer 10 such that the top edge 16 of the sidewall 14 supports the transmission T. The top edge 16 of the sidewall 14 is shaped so that the top edge 16 supports the transmission T in a balanced, stable manner.

[0017] When a transmission T, such as an E40D, must be repaired, the stabilizer 10 is placed on the lift platform of a hydraulic jack L, then raised until it is positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com