Perforated packaging

a perforated and packaging technology, applied in the direction of packaging, non-removalbe lids/covers, lids, etc., can solve the problems of increasing the potential for cutting injuries often associated with the use of these cutting tools, and achieve the effect of sealing the package quickly and eliminating the potential for cutting injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

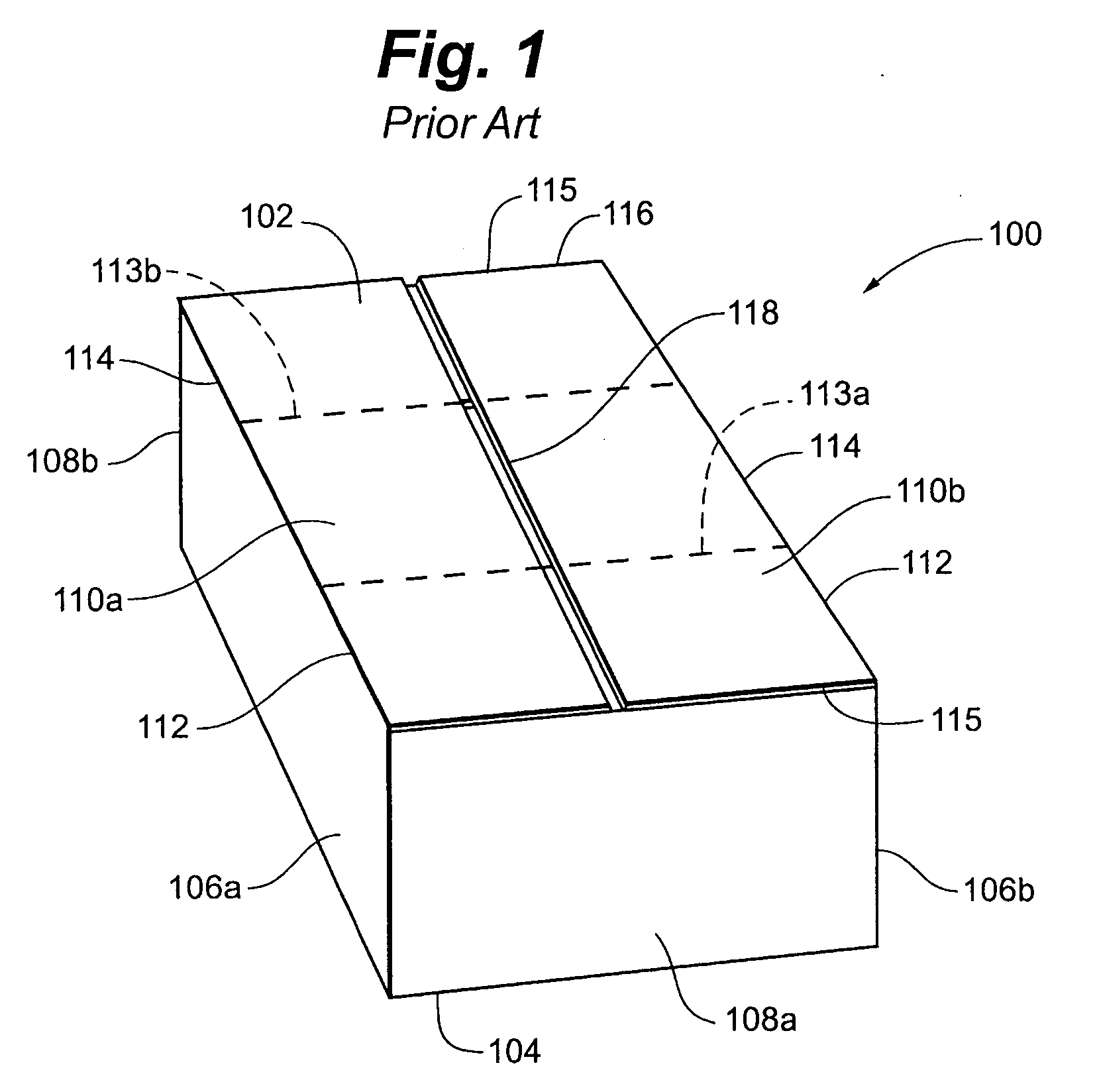

[0021] As illustrated in FIGS. 1 and 2, a packaging box 100 of the prior art can comprise a top surface 102, a bottom surface 104, a pair of side surfaces 106a, 106b and a pair of end surfaces 108a, 108b. Top surface 102 can comprise a pair of hinged major flaps 110a, 110b rotatably attached to the corresponding side surface 106a, 106b at a hinge member 112. Additionally, top surface 102 can comprise a pair of hinged minor flaps 113a, 113b rotatably attached to the corresponding end surfaces 108a, 108b at a hinge member 115. Hinge member 112 and hinge member 115 generally comprise a scored portion 114 or scored line distinguishing the hinged flaps from the corresponding side or end surface. Though not depicted in detail, bottom surface 104 can substantially resemble top surface 102 in construction and appearance. Packaging box 100 can comprise suitable materials of construction such as, for example, single or multi-wall construction utilizing cardboard, paperboard, corrugated paper,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com