Automatic carrying, replacing and blowing device for tunnel air purification material modules

A technology to purify materials, tunnel air, used in transportation and packaging, lifting devices, mining devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

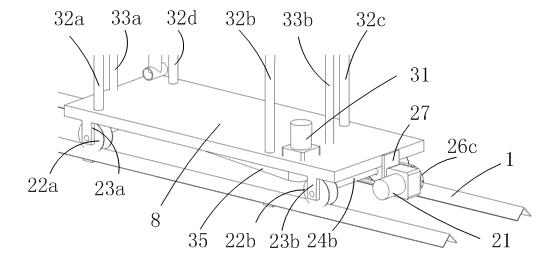

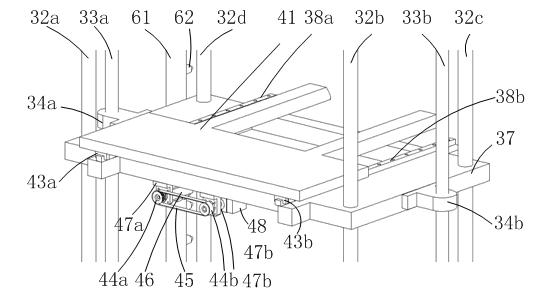

[0033] Example 1: see figure 1 with Figure 8 , the tunnel air purification material module automatic handling, replacement and purging device, including the purification material rack 9 arranged in the tunnel and the auxiliary guide rail 1 located in front of the purification material rack 9, is characterized in that: (1), there is a Bottom plate 8 is fixedly connected to the purifying material module carrying rack formed by top plate 7 by four vertical rods 32, and described base plate 8 is rested on described guide rail 1 by a walking mechanism 2, makes purifying material module carrying rack move along guide rail 1 length direction; (2), a lifting mechanism 3 is housed on the described purification material module handling frame, and a telescopic mechanism 4 is housed on the described lifting mechanism 3, and the purified material module carried is placed on the described telescopic mechanism 4; (3), An anti-tilt mechanism 5 is installed on the top of the purifying mate...

Embodiment 2

[0034] Example 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows: figure 2 with Figure 5Among them, 1 is a guide rail, and the drive motor 21 is a motor that drives the device to walk along the guide rail 1, so it is called a travel motor. The travel motor 21 is fixed on the base plate 8 through a support plate 27, and the main shaft of the travel motor 21 is connected with the sprocket 26c , the chain 25 connects the sprockets 26a, 26b, 26c, the sprocket 26a is fixedly connected to the wheel shaft 24a, the wheel shaft 24a is fixedly connected to the walking wheels 22a, 22d at the positions near both ends, and the wheel shaft 24b is respectively connected to the walking wheels at the positions near the two ends. The wheels 22b, 22c are fixedly connected, and the two ends of the wheel shaft are inserted into the circular holes of the support plate.

[0035] see figure 2 with Image 6 , the structure of the lifting mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com