Mixed TBM (Tunnel Boring Machine) with multiple-boring mode and tunnel supporting mode

A hybrid and mode technology, applied in the direction of tunnels, earthwork drilling, mining equipment, etc., can solve the problems that cannot meet the modern construction requirements of complex strata, and achieve the effect of expanding the scope of geological adaptation and wide geological adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

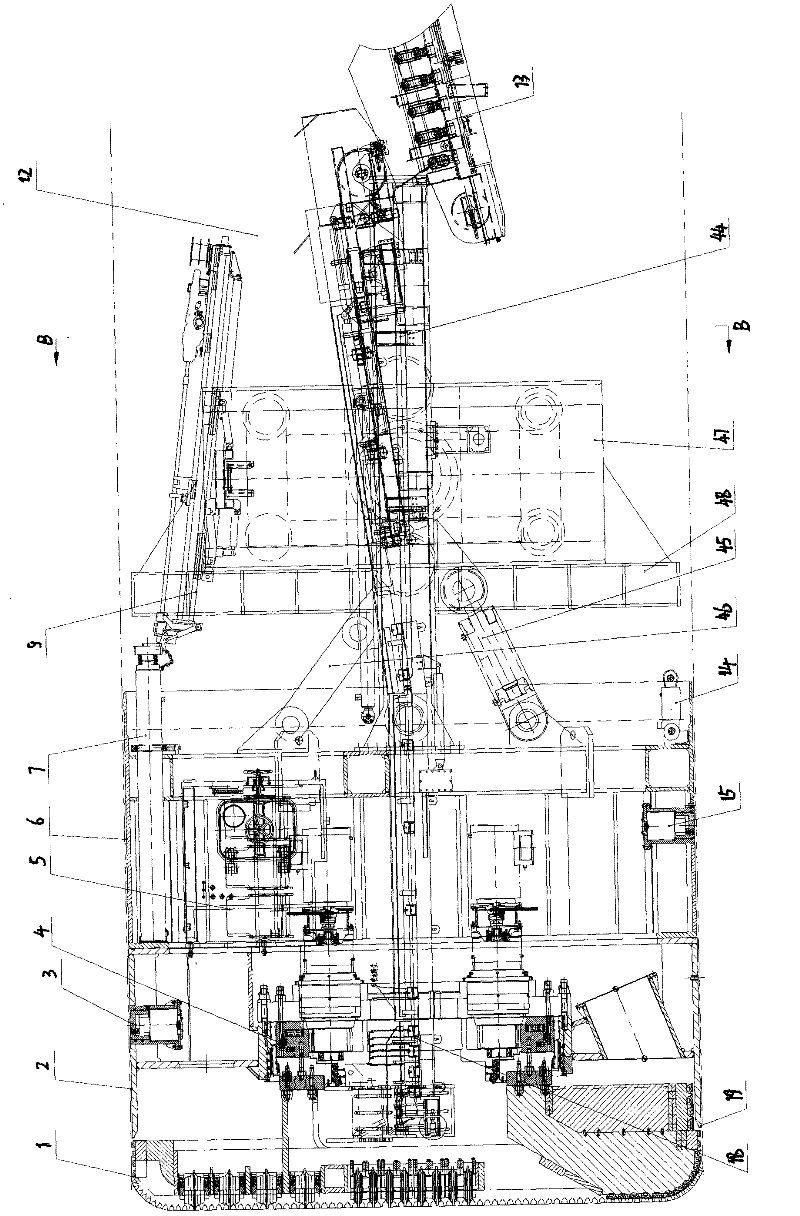

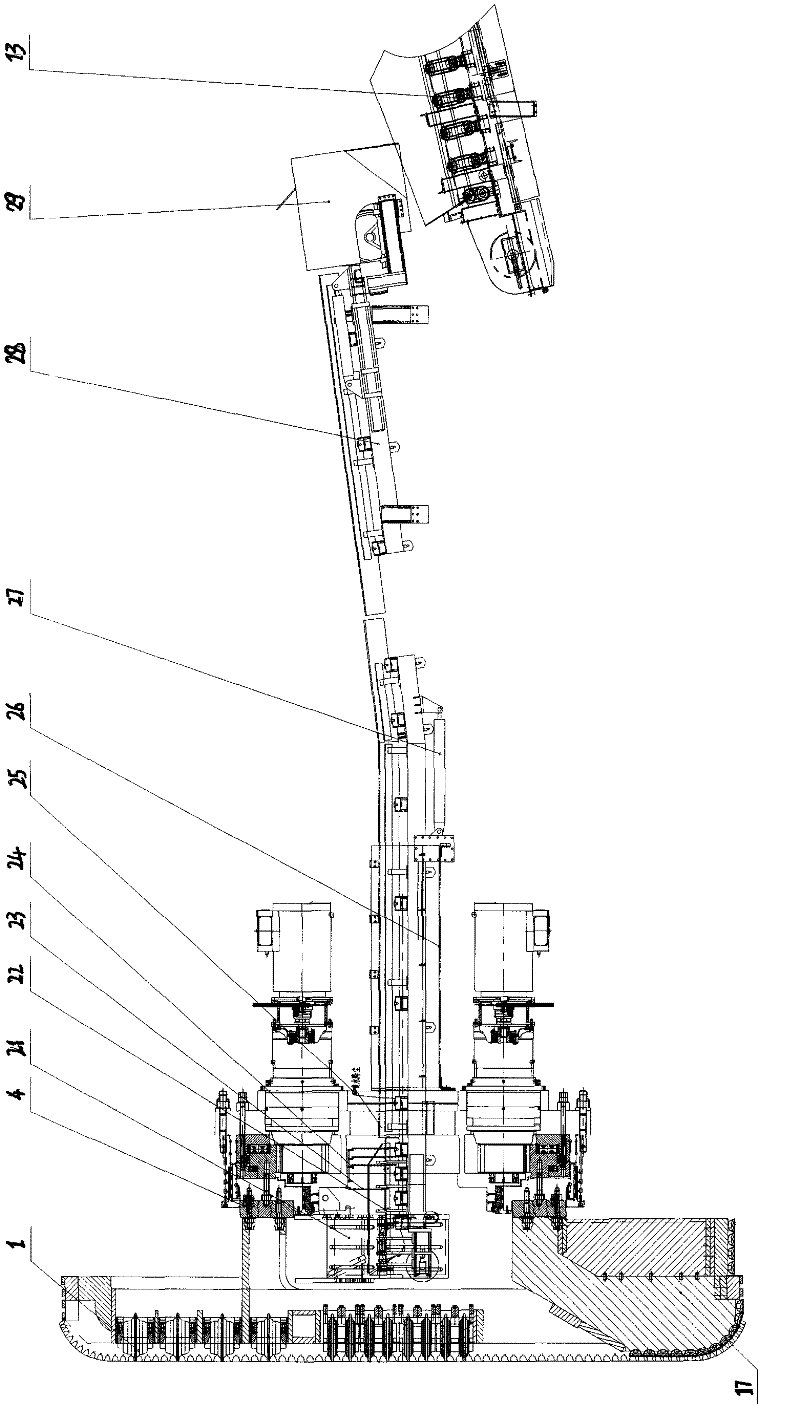

[0029] Below in conjunction with accompanying drawing, the present invention will be further described:

[0030] The hybrid TBM with multiple excavation modes includes a cutter head 1, and a drive system 4 connected to the cutter head, a front shield 2 supporting the drive system 4 and the cutter head 1, a middle shield 6 connected to the front shield 2, The propulsion system 7 installed in the center shield 6, the main beam 44 connected to the center shield 6, the stabilizer 3 installed on the front shield 2, the front shield swing cylinder 31 installed on the front shield 2 and the front shield swing cylinder 31 installed on the center shield The supporting belt conveyor 13 connected with the central shield swing cylinder 15 and the main beam 44 on 6; the earth pressure balance mode and the shield open type also include a central rotary joint 18 connected with the cutter head 1, which is installed on the main beam 44 The segment assembly machine 10; the TBM mode also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com