Belt conveyor control system and method capable of adjusting belt speeds automatically according to material flows or material levels

A technology of belt conveyor and control system, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., to achieve the effect of consistent current, improved safety production capacity, and consistent speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

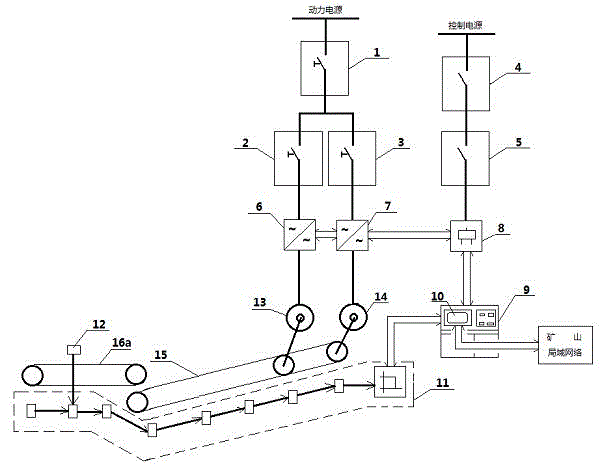

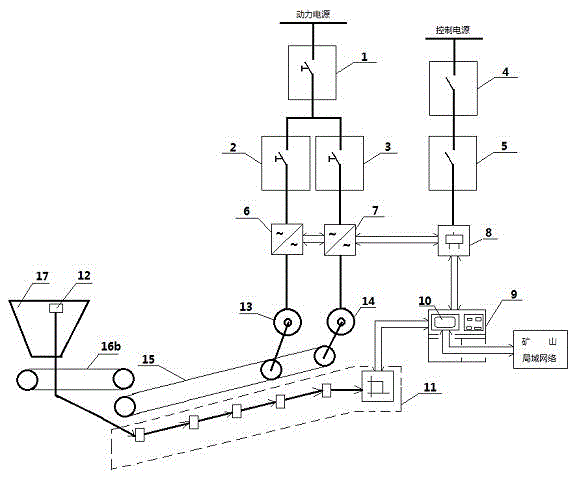

[0026] Embodiment of the present invention is described in conjunction with accompanying drawing:

[0027] In the figure, the present invention proposes a belt conveyor control system that automatically adjusts the belt speed according to material flow or material level, including a frequency conversion system, a PLC system, a monitoring system and a detection system.

[0028] The frequency conversion system includes: a power supply incoming device (1), a power supply feeding device (2 and 3), a frequency converter (6 and 7), and a motor (13 and 14) for driving a belt conveyor (15) ) to provide an AC power supply with variable frequency and voltage, the stator windings of the motors (13) and (14) are respectively connected to the output terminals of the frequency converters (6) and (7), and the input terminals of the frequency converters (6) and (7) The terminals are respectively connected to the output terminals of the power supply feeding devices (2) and (3), and the input t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com