Automatic detection system for hardware appearance

A detection system and automatic detection technology, applied in the direction of measuring devices, optical testing defects/defects, instruments, etc., can solve problems affecting the overall quality of products, high labor intensity, low efficiency, etc., to improve detection accuracy and production efficiency, overcome Labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

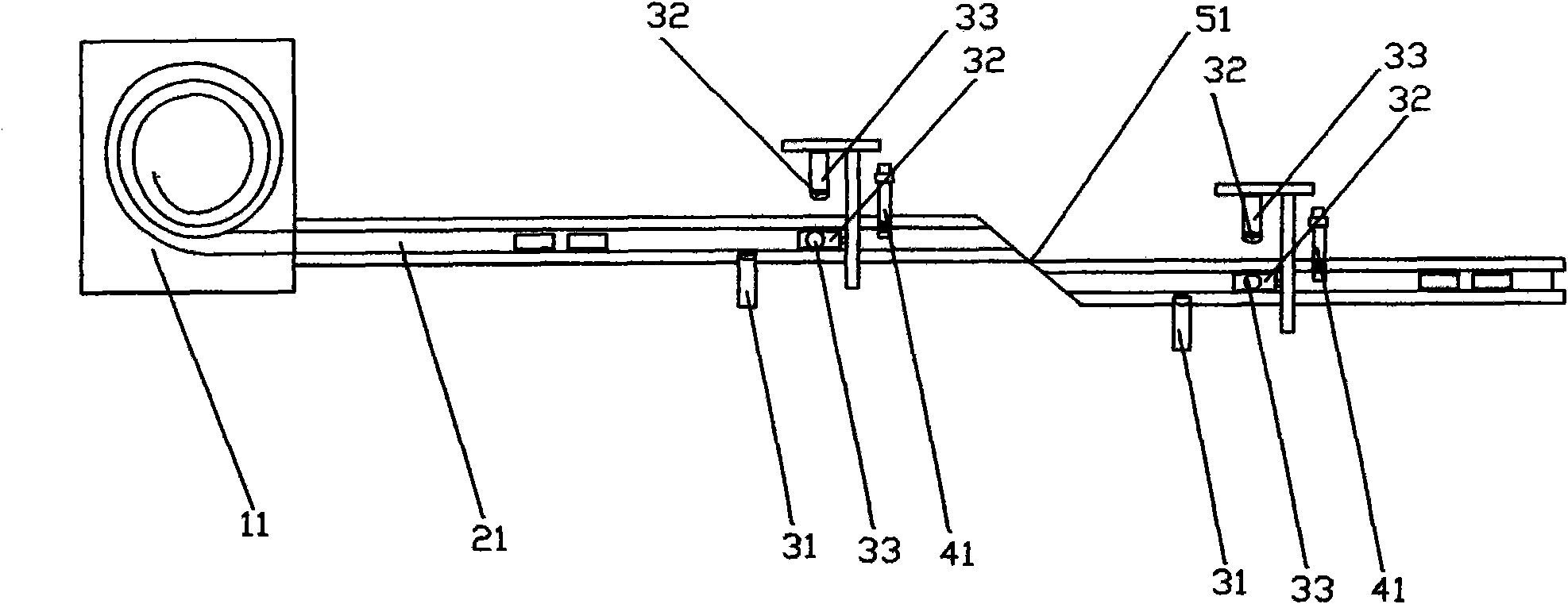

[0032] Below in conjunction with accompanying drawing embodiment, illustrate the structural principle of the present invention as follows:

[0033] like figure 1 As shown, the structure of the automatic hardware appearance detection system of the present invention includes five parts: a feeding mechanism, a feeding mechanism, a detection device, a sorting device and a control system. in:

[0034] The feeding mechanism is used to send the hardware to be inspected to the conveyor belt;

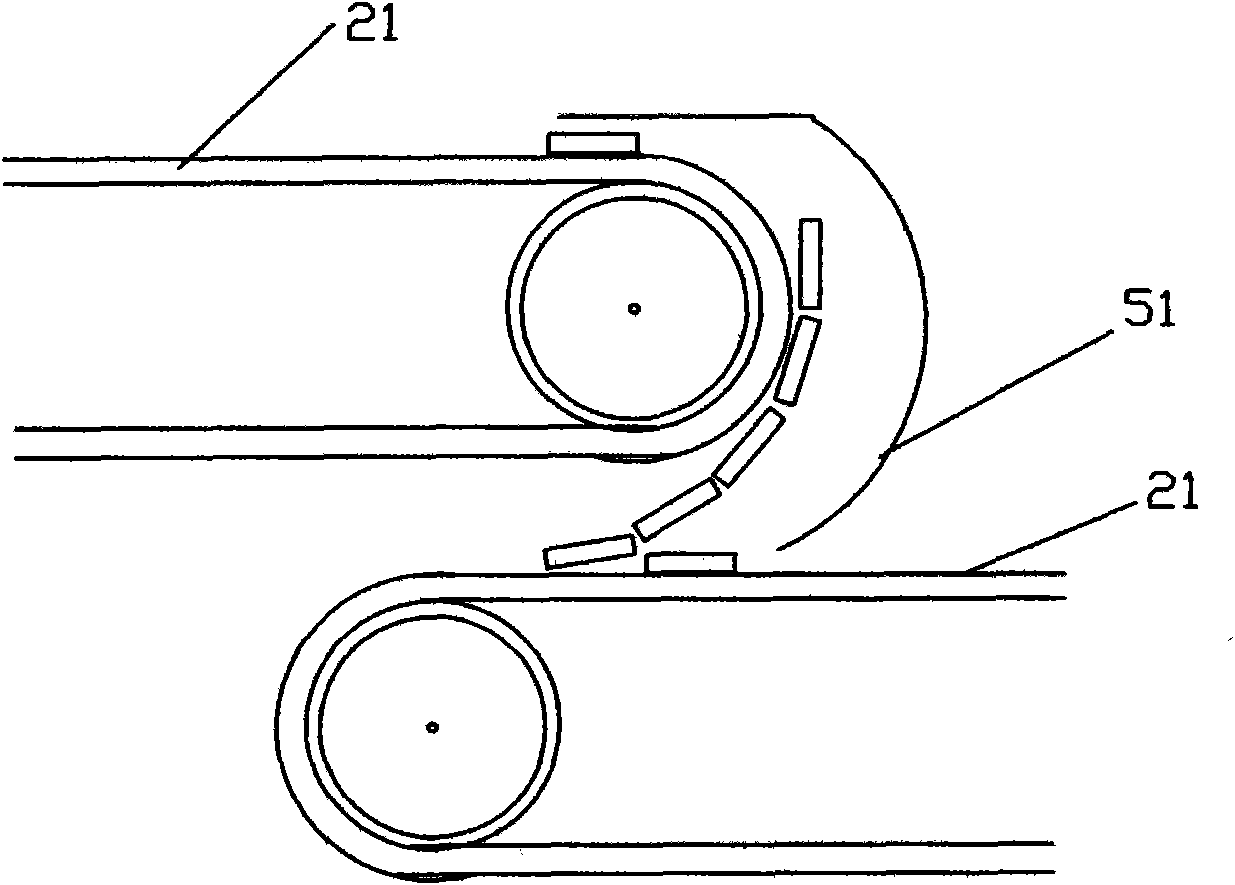

[0035] The feeding mechanism is used to transmit the hardware through the detection position, sorting position, and flipping position to undergo detection and sorting;

[0036] The detection device is used to detect the surface appearance, size and surface defects of the hardware; and send the data to the control system;

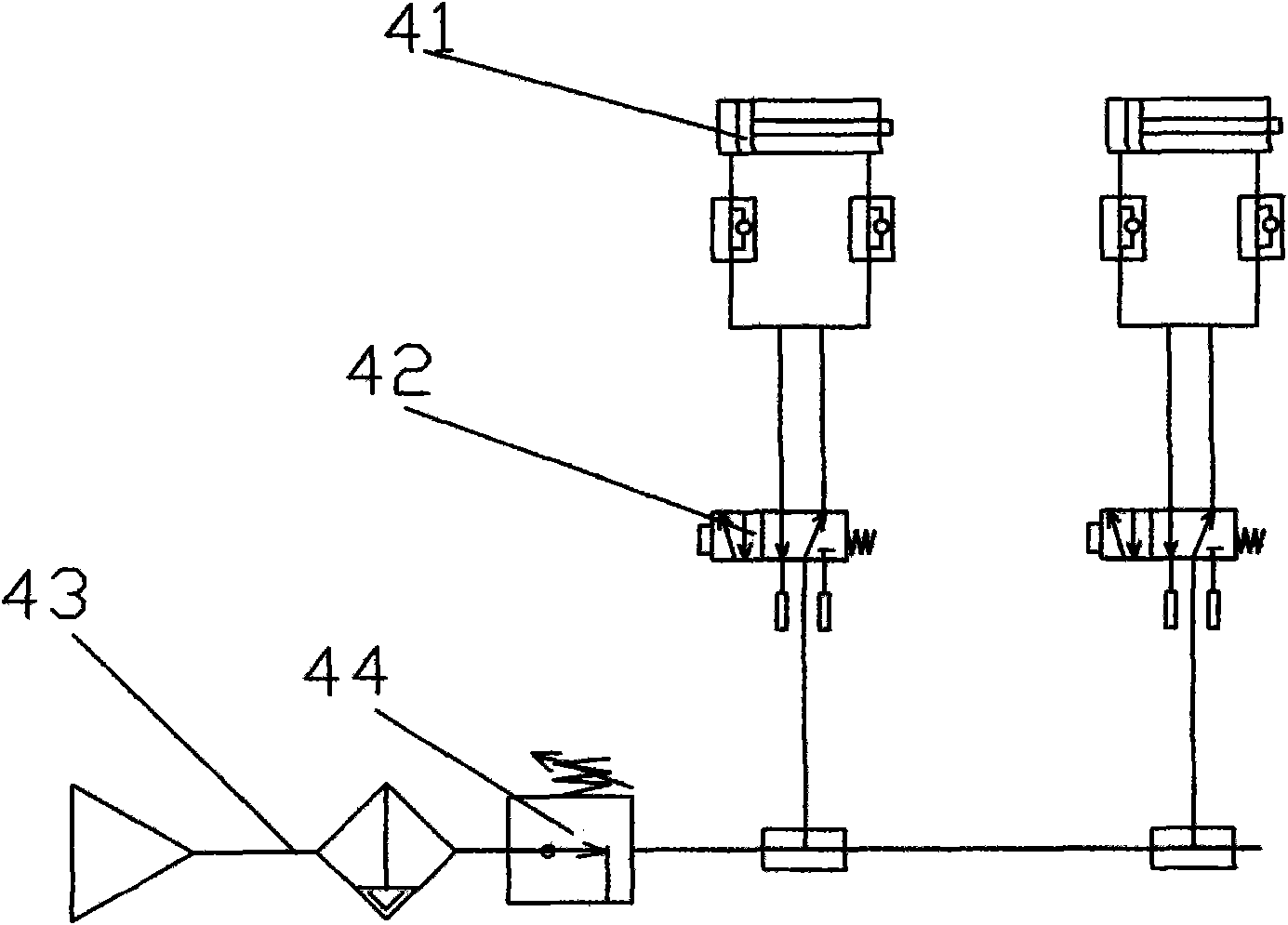

[0037] The sorting device is used to separate unqualified workpieces out of the transmission mechanism under the control of the control system;

[0038] The overturning de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com