High-chromium grinding ball and secondary modification process thereof

A technology of secondary deterioration and processing technology, applied in the direction of improving process efficiency, can solve the problems of reducing the service life of boilers, high consumption, large steel materials, etc., to save the consumption of raw materials, prolong the service life, and reduce operating costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

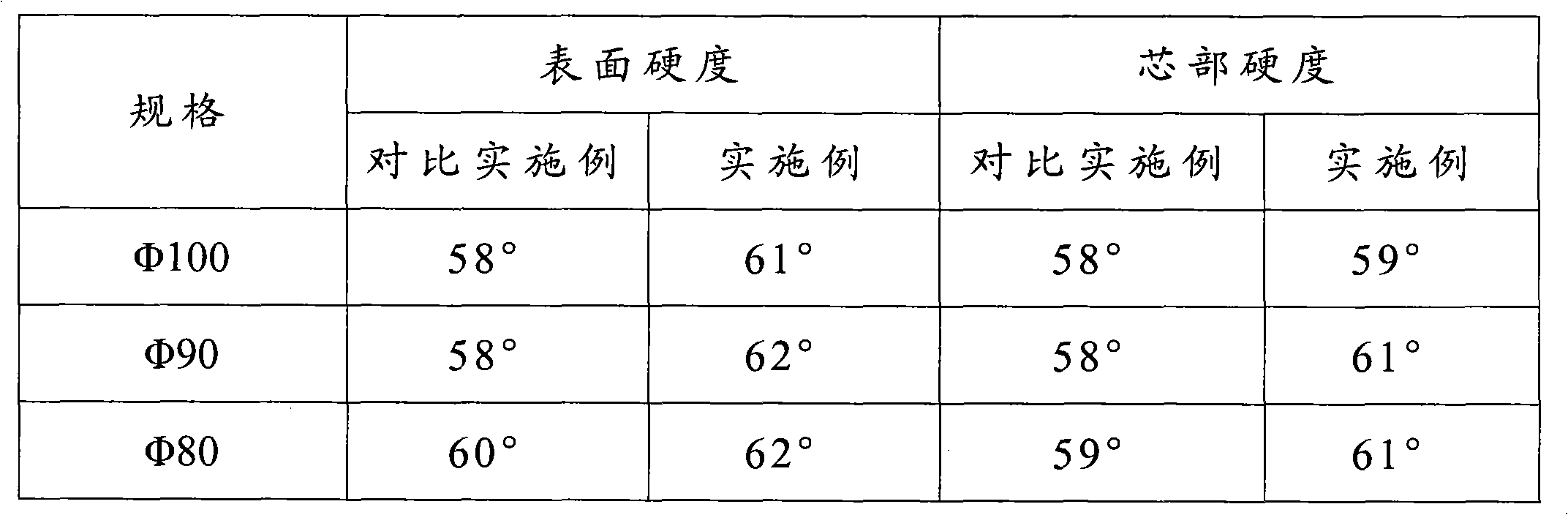

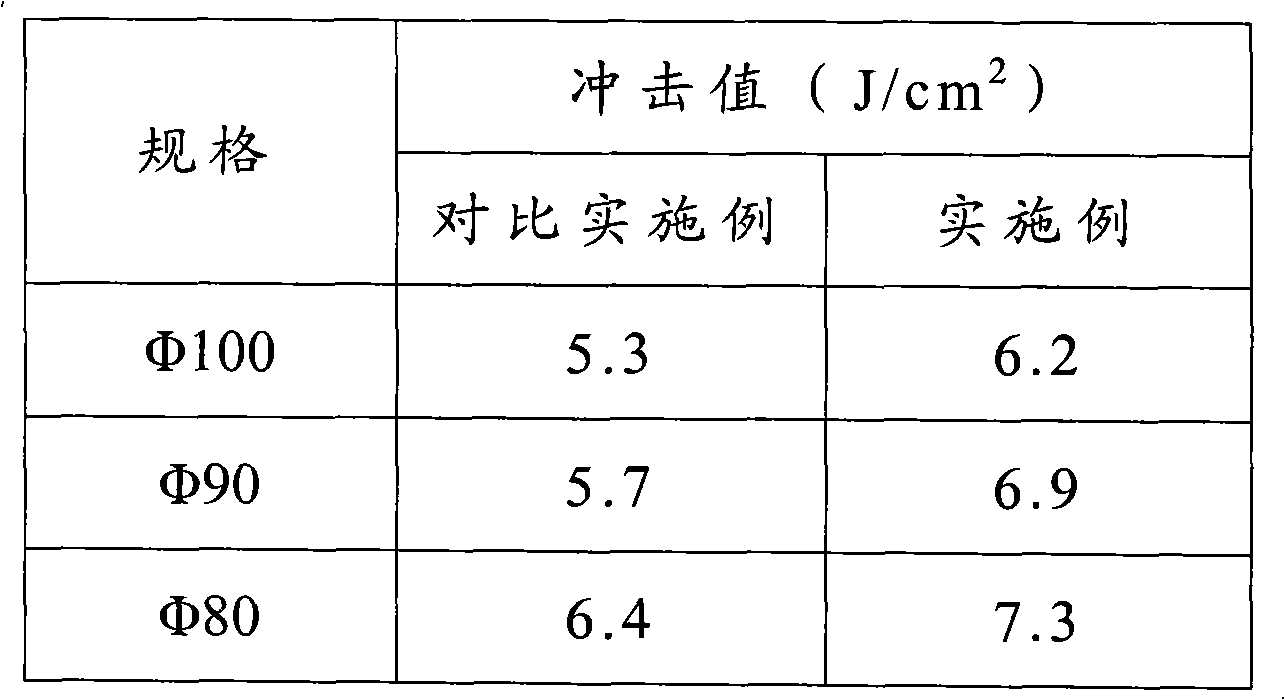

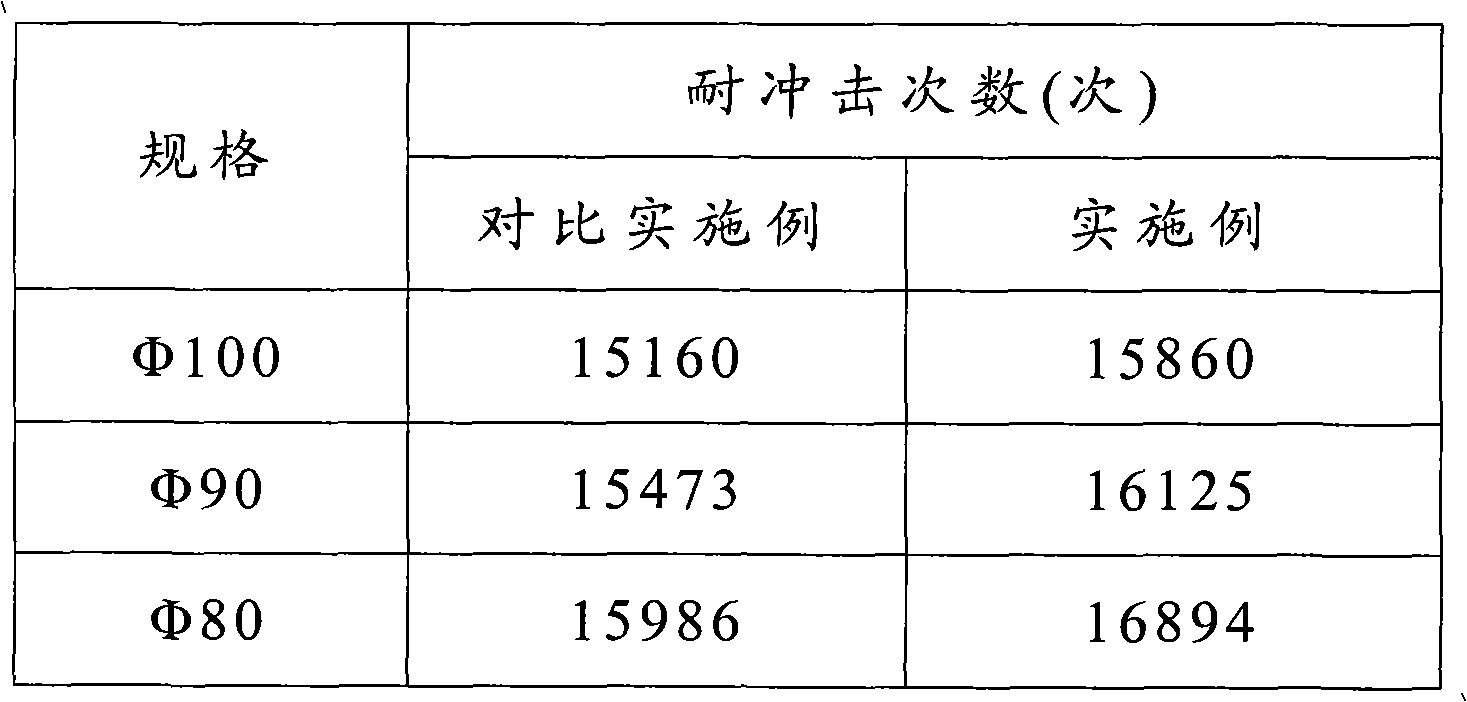

Examples

Embodiment 1

[0017] Prepare high chromium grinding balls as follows:

[0018] (1) 100 kg of steel is tested for composition. According to the test results, the content of C, S, and P (preferably the content results of the supplementary test) are all within the required range, and the types of other elements contained meet the requirements. And the content does not exceed the standard, add 0.7 kg of ferrosilicon with a silicon content of 70%, 0.8 kg of ferromanganese with a manganese content of 60%, 23.5 kg of ferrochrome with a chromium content of 58%, and 0.021 kg of molybdenum in qualified steel. 55% ferromolybdenum is sent to the smelting furnace for heating and smelting. When the temperature of molten iron reaches 1480°C, samples are taken for chemical composition analysis, C: 2.63%, Si: 0.47%, Mn: 0.48%, Cr: 10.86%, P : 0.029%, S: 0.023%, Mo: 0.048, B: 0.0019%, Ti: 0.010%, V: 0.027%, all components are within the required range, without fine-tuning, when the temperature reaches 1550 ℃...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com