Silver coated nickel powder conductive adhesive and preparation method thereof

A silver-coated nickel powder, conductive adhesive technology, applied in conductive adhesives, adhesives, epoxy resin adhesives and other directions, can solve the problems of conductive adhesive storage, application and stability, difficult conductivity, adhesion, viscosity control , the mutual reaction of conductive adhesive components, etc., to achieve the effect of improving antioxidant performance, low cost, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

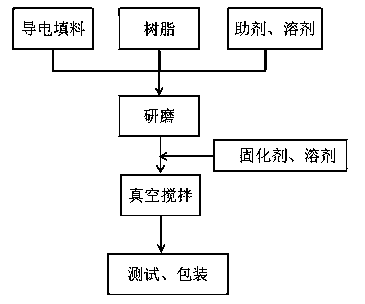

Method used

Image

Examples

Embodiment 1

[0045] According to the components in Table 1 and their parts by weight, materials such as resin, additives, conductive fillers, etc. were put into a dispersion tank and stirred, and ground for 3 hours with a three-roll mill, and the fineness was detected by a scraper fineness meter until The fineness is less than 5 microns, add curing agent and solvent to the ground material, and disperse at 500 rpm for 60 minutes under vacuum conditions, and adjust the viscosity to 22 Pa s (25 ℃), inspect and pack, that is A low-cost silver-coated nickel powder nano-conductive adhesive is obtained.

[0046] Coat the prepared nano-conductive adhesive on a glass plate or pour it into a mold, let it stand at room temperature for 10 minutes (to let part of the solvent evaporate), and then put the sample into an oven at 150°C for 45 minutes to cure.

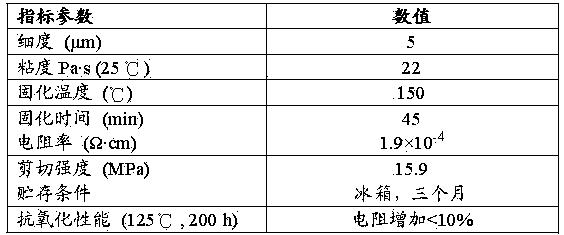

[0047] Table 1: Components and parts by weight of Example 1:

[0048] The technical indicators of the silver-coated nickel powder conductive adhes...

Embodiment 2

[0053] Table 3: Components and parts by weight of Example 2:

[0054]

[0055] The preparation method of embodiment 2 is the same as embodiment 1, and difference is: the selection of each component and its parts by weight, and the fineness that reaches in the preparation process, viscosity requirement, curing temperature and curing time, then according to embodiment 1 The preparation method finally prepares the silver-coated nickel powder conductive glue that is a kind of low-cost micronano silver-coated nickel powder conductive glue, and its technical indicators are as shown in table 4:

[0056] Table 4: Technical indicators of low-cost micro-nano silver-coated nickel powder conductive adhesive:

[0057]

[0058] The micro-nano silver-coated nickel powder conductive adhesive prepared in Example 2 is due to the combination of three conductive powders, the sheet-like micro-silver-coated nickel powder, the sheet-like nano-silver-coated nickel powder, and the spherical nano...

Embodiment 3

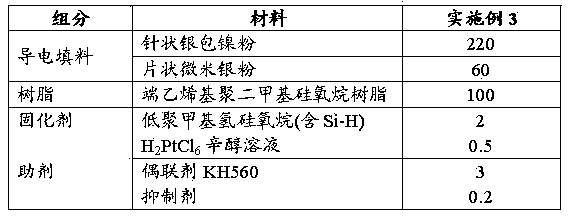

[0060] Table 5: Components and parts by weight of Example 3:

[0061]

[0062] The preparation method of embodiment 3 is the same as that of embodiment 1, and the difference is: the selection of each component and its parts by weight, and the fineness, viscosity requirement, curing temperature and curing time achieved in the preparation process, according to the composition of table 5 The distribution ratio and the parts by weight of each component are then finally prepared according to the preparation method of Example 1 to obtain a one-component silicone-based silver-coated nickel powder conductive adhesive.

[0063] The technical indicators of the silver-coated nickel powder conductive adhesive of the single-component silicones prepared in Example 3 are shown in Table 6:

[0064] Table 6: Technical indicators of low-cost single-component silicone silver-coated nickel powder conductive adhesive

[0065]

[0066] The one-component silicone silver-coated nickel powder c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com