Method for preparing polymer/graphene composite material

A composite material and polymer technology, applied in the field of nanomaterials, can solve the problems of difficult to restore crystal structure, self-aggregation, structural defects, etc., and achieve the effect of easy large-scale production, overcoming self-aggregation, and realizing large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

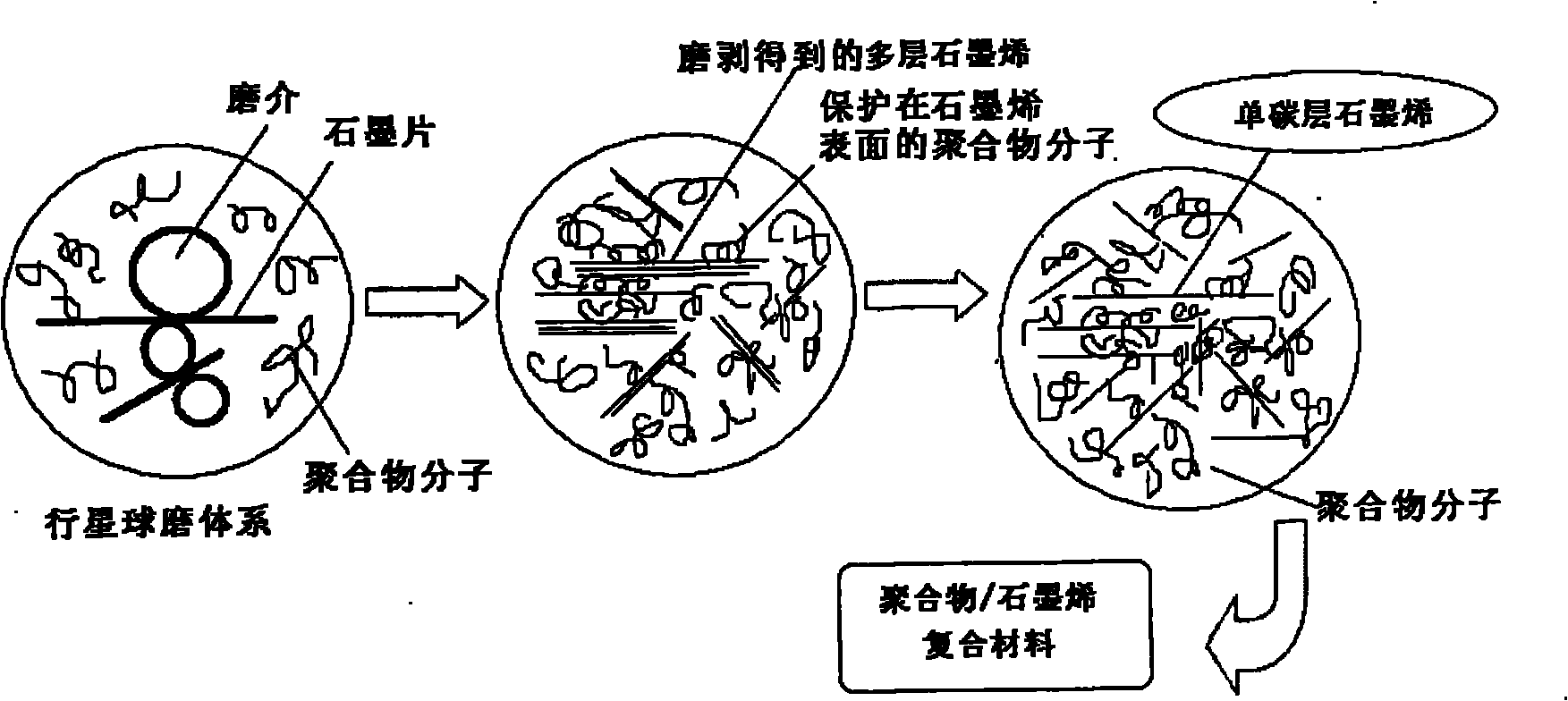

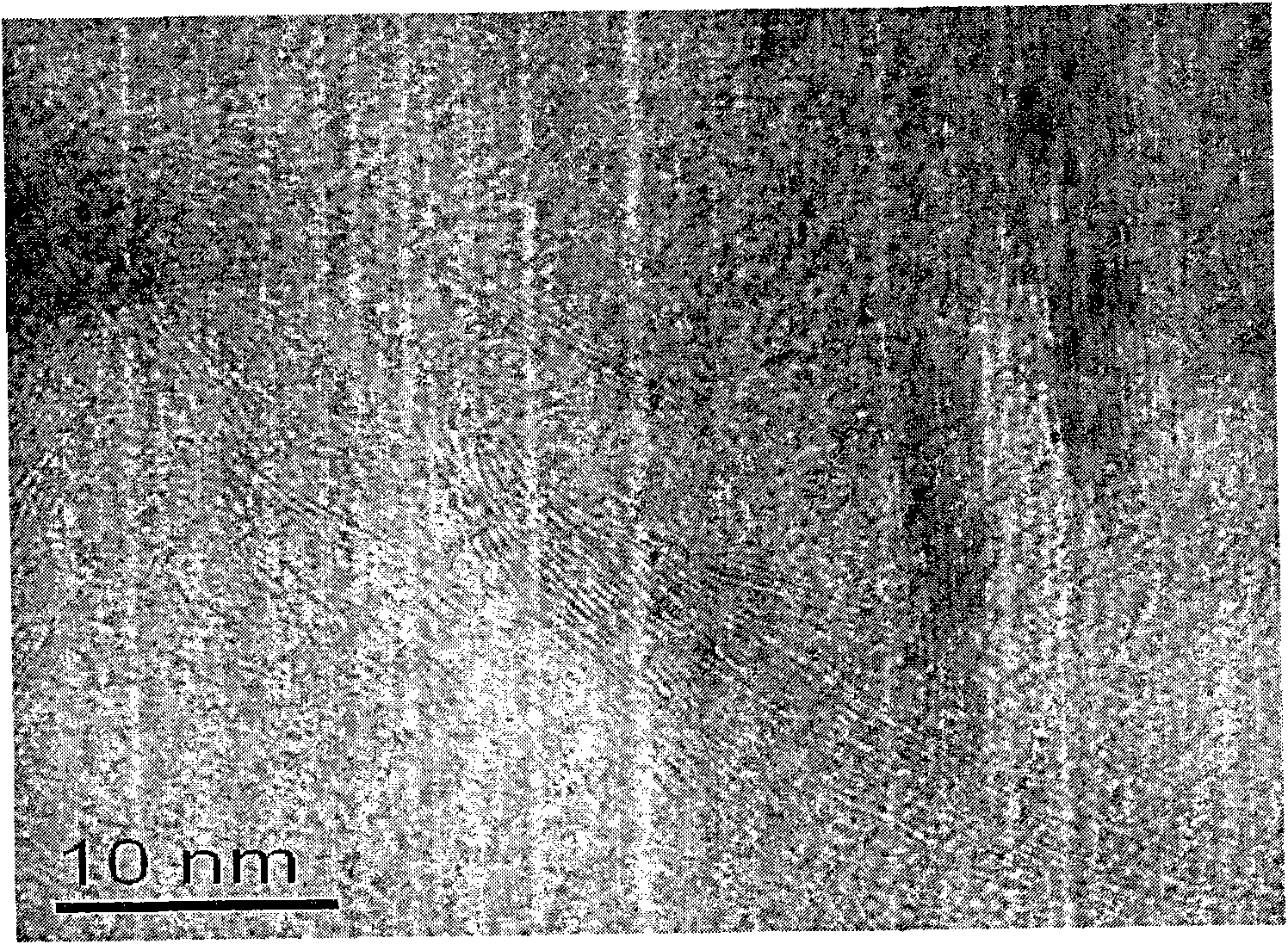

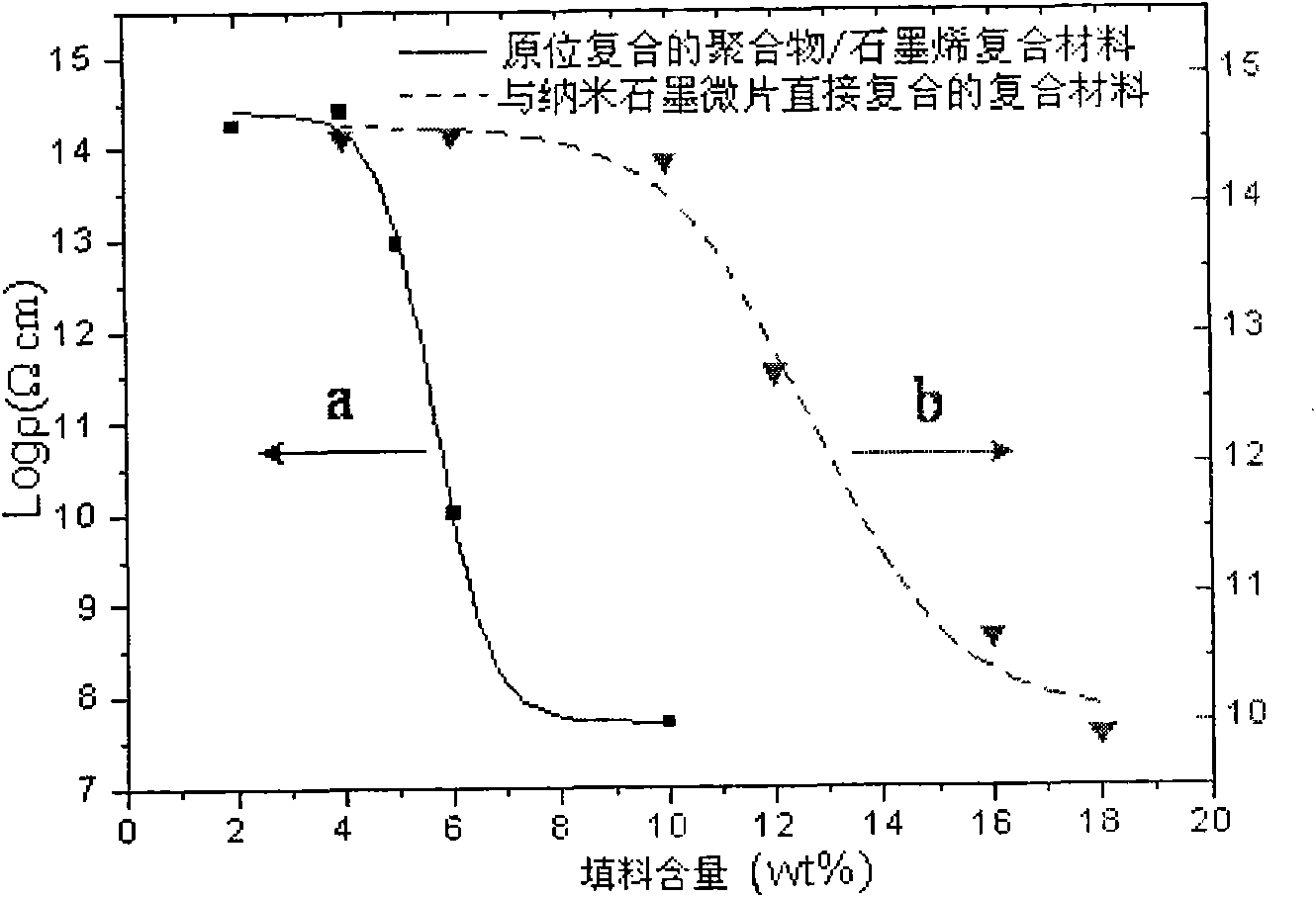

[0028] A method for preparing a polymer / graphene composite material is realized by the following scheme: Accurately weigh 0.1 g of expanded graphite micropowder, and uniformly disperse it in 320mL styrene monomer by mechanical stirring to form a suspension of expanded graphite micropowder, and After this expanded graphite powder suspension is divided into 4 parts on average, each part is packed into a polytetrafluoroethylene ball mill jar with a volume of 100mL together with zirconia grinding balls respectively. The weight ratio is about 10000: 1, put four polytetrafluoroethylene ball mill jars equipped with zirconia balls and expanded graphite suspension symmetrically into the planetary mill and ball mill for 30 hours at a speed of 300 rpm to obtain graphene / styrene suspension, the graphene / styrene suspension obtained by ball milling is poured into a beaker, and azobisisobutyronitrile is added as an initiator to initiate polymerization relative to 1.0-1.5wt% mass fraction of ...

Embodiment 2

[0030] A method for preparing a polymer / graphene composite material is realized by the following scheme: accurately weigh 20.0 g of graphite flake powder, and uniformly disperse it in 1000 mL of methyl methacrylate by mechanical stirring to form graphite flake powder suspension, This flaky graphite micropowder suspension and alumina grinding balls are packed into a basket mill grinding tank with a volume of 1500 mL, and ball milled at a speed of 320 rpm for 50 hours to obtain a graphene / methyl methacrylate suspension. Pour the graphene / methyl methacrylate suspension obtained by ball milling into a beaker, and add 0.1-2.5 wt% dibenzoyl peroxide relative to the methyl methacrylate monomer as an initiator to initiate polymerization , to obtain polymethyl methacrylate / graphene composites.

Embodiment 3

[0032] A method for preparing a polymer / graphene composite material is realized by the following scheme: Accurately weigh 30.0g of highly oriented graphite powder and uniformly disperse it in 3000mL of N,N-dimethylformaldehyde containing 100g of polystyrene by mechanical stirring In the amide solution, a high-oriented graphite powder suspension is formed, and the high-oriented graphite powder suspension and agate balls are put into a horizontal ball mill tank with a volume of 5000mL. The weight ratio between the agate ball and the high-oriented graphite powder is About 4500:1, ball milling at a speed of 350 rpm for 60 hours to obtain a graphene styrene solution suspension, pour the graphene styrene solution suspension obtained by ball milling into a beaker, and add a sufficient amount of water Alternatively, alcohol is used as a precipitant to precipitate the polystyrene / graphene composite from the solvent, and the polystyrene / graphene composite is filtered out, washed thorough...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com