A kind of high insulation matt black polyimide film and preparation method thereof

A black polyimide, high-insulation technology, applied in the field of high-insulation matt black polyimide film and its preparation, can solve the problems of low insulation of matt black PI film, unable to meet the needs of consumers, etc. Reduce the generation of pinholes and air bubbles, improve insulation, and avoid the effect of self-agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

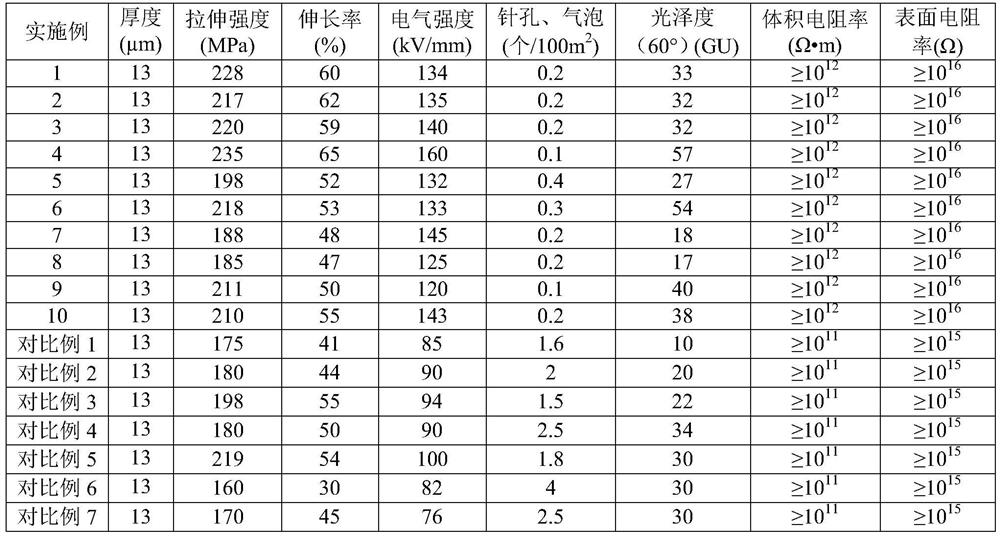

Examples

Embodiment 1

[0043] 1) Preparation of nanocomposite sol:

[0044] Mix 500g of absolute ethanol and 22g of deionized water evenly, add 84g of ethyl orthosilicate, then adjust the pH of the system to 5 with acetic acid, stir and react for 5h, then add 5g of KH550, continue stirring for 20h to obtain a nanocomposite sol, spare;

[0045] 2) Preparation of black filler dispersion:

[0046] 2.1) Mix 4.2kg carbon black (primary particle size is 20nm) and 38kg DMAc evenly, use high-speed shearing machine to shear and disperse (rotating speed is 2000r / min, dispersion time is 2h), and then use homogenizer to disperse (pressure is 50MPa, and the homogenization time is 20min), to obtain a black dispersion, for subsequent use;

[0047] 2.2) Mix 4.2kg of silicon dioxide (average particle size of 4 μm) and 24kg of DMAc evenly, place in a high-speed shearing machine and shear and disperse at a speed of 3000r / min for 3h to obtain a white dispersion, which is set aside;

[0048] 2.3) Mix the black disper...

Embodiment 2

[0052]Repeat Example 1, the difference is:

[0053] In step 1), the non-metal alkoxide is butyl titanate, the amount of deionized water is 11g, the pH of the adjustment system is 6, and the amount of KH550 is 3g;

[0054] In step 2) and 3), the polar aprotic solvent is changed to NMP;

[0055] Step 3) in, the total amount of PMDA is 0.1994mol.

Embodiment 3

[0057] Repeat Example 1, the difference is:

[0058] In step 1), the consumption of deionized water is 1.7g, the consumption of KH550 is 6g, and the silane coupling agent is KH560, and its consumption is 1.3g;

[0059] In step 2.1), the primary particle size of carbon black is 300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com