Gear grinding machine with numerical control forming grinding wheel

A technology for forming grinding wheels and gear grinding machines, which is applied in the directions of gear teeth, gear cutting machines, gear teeth manufacturing devices, etc. Wide range of uses, improving accuracy, ensuring the effect of accuracy and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

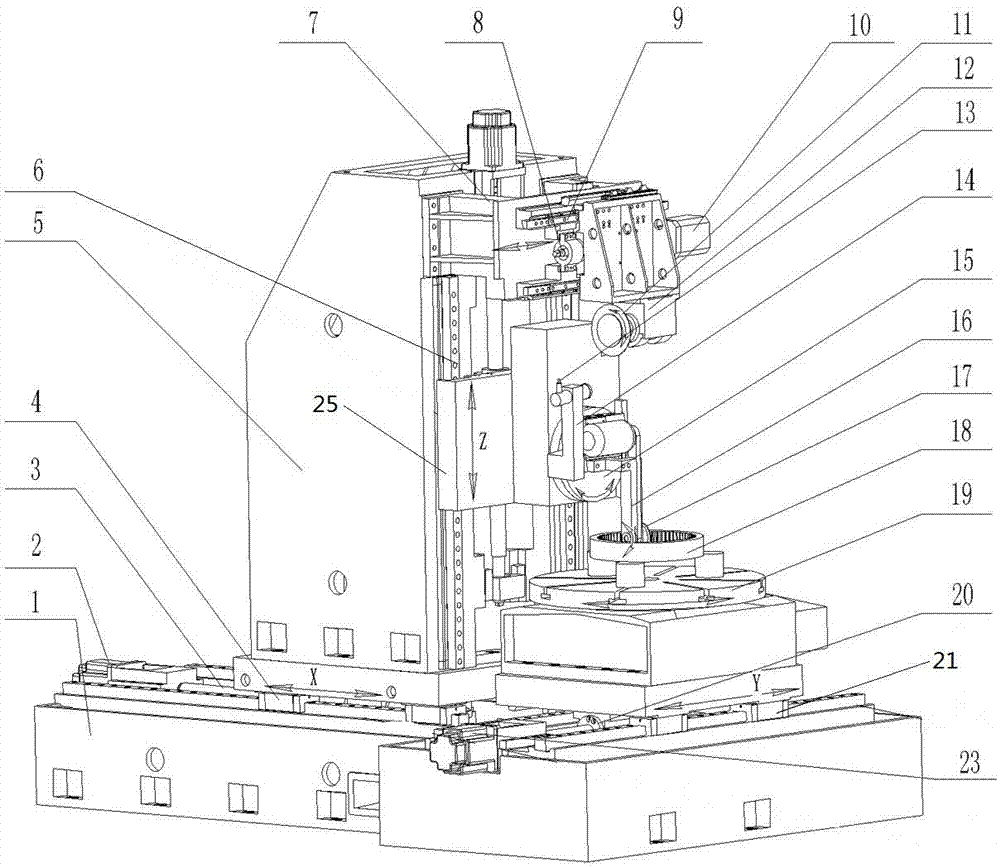

[0013] Examples of CNC shaped grinding wheel gear grinding machines figure 1 Shown: includes machine base 1, is provided with horizontal sliding guide rail 4 and longitudinal sliding guide rail 21 on the machine base, and the vertical column 5 that is used to install the vertical column 5 that is used for installing the grinding wheel 17 is installed on the guiding slide on the horizontal sliding guide rail 4, and the vertical sliding guide rail 21 guides A workpiece turning part 19 for installing the processed gear 18 is slidably mounted and its axis extends vertically. The workpiece turning part 19 has a horizontally disposed gear mounting surface. The base 1 is provided with a vertical column assembly lead screw 3 that drives the vertical column 5 to guide and slide along the horizontal sliding guide rail 4, and a vertical column assembly screw servo motor 2 that provides power for the vertical column assembly screw 3; 1 is also provided with a workpiece turning part assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com