Megawatt ten-shunt wind power generation speed increasing box

A speed-increasing box, megawatt-level technology, applied in the field of megawatt-level ten-flow wind power speed-increasing boxes, can solve the problems of poor mechanical strength, increased processing errors, installation errors, temperature differences, etc. Cost, single light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

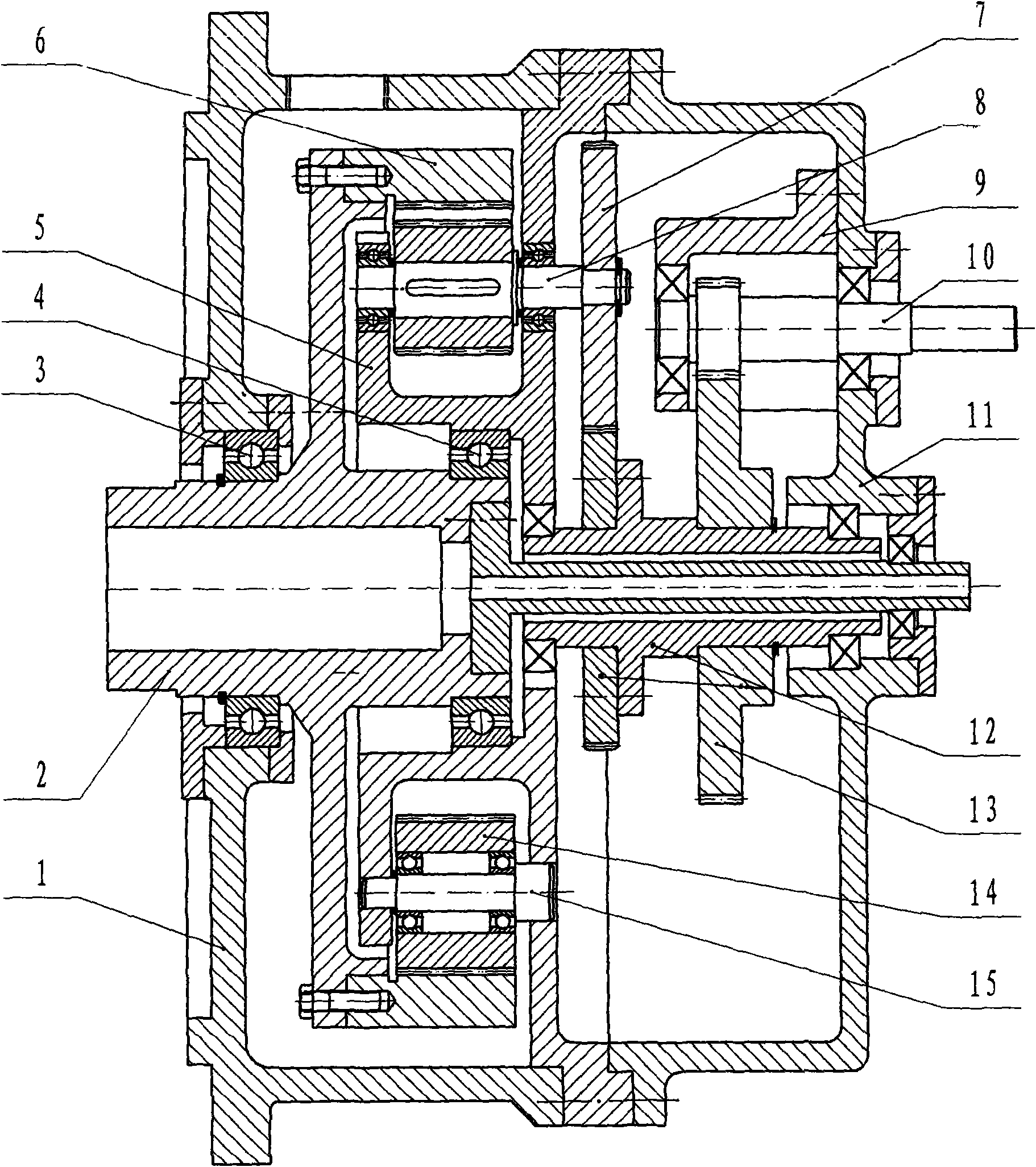

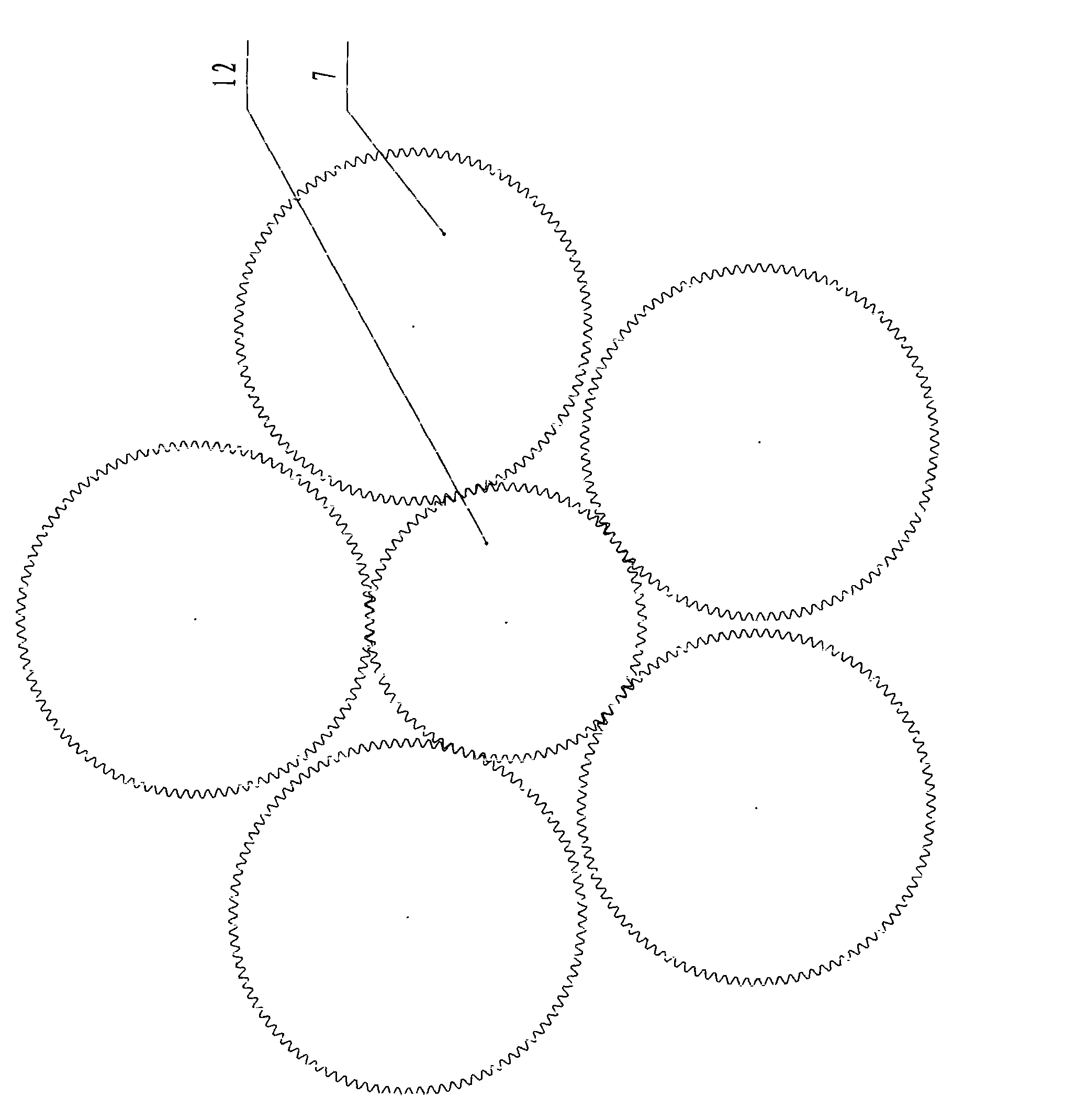

[0009] refer to figure 1 , 2 , 3. a kind of megawatt class very current wind power generation speed increasing box, by support (1), input shaft (2) and its support bearing (3) (4), the internal ring gear that is connected with disc on the input shaft ) (6), duplex gear, end cover (11) and center shaft gear sleeve (12), wherein the duplex gear is composed of shaft gear (8) and transmission gear (7) mounted on its shaft extension end, shaft gear (8) Supported by bearings in the corresponding holes of the frame (5), the center shaft gear sleeve is an assembly of the center wheel and the shaft sleeve, which is characterized in that:

[0010] A. The frame (5) is an annular thin-walled short cylindrical casting with reinforcing ribs. The flange of the frame is connected to the output end of the frame, and the main body of the frame is placed in the inner cavity of the inner tooth enclosure (6);

[0011] B. Duplex gears are five evenly distributed, of which: (α) There are two ident...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com