Abrasion and pierce proof low-resistance tire rubber compound and preparation method thereof

A production method and low-resistance technology, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as uneven dispersion of carbon black and small materials, troublesome production process, and reduced adhesive ability of rubber materials, etc., to achieve Improve puncture resistance and dynamic fatigue performance, improve aging resistance and deformation resistance, and improve the effect of adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

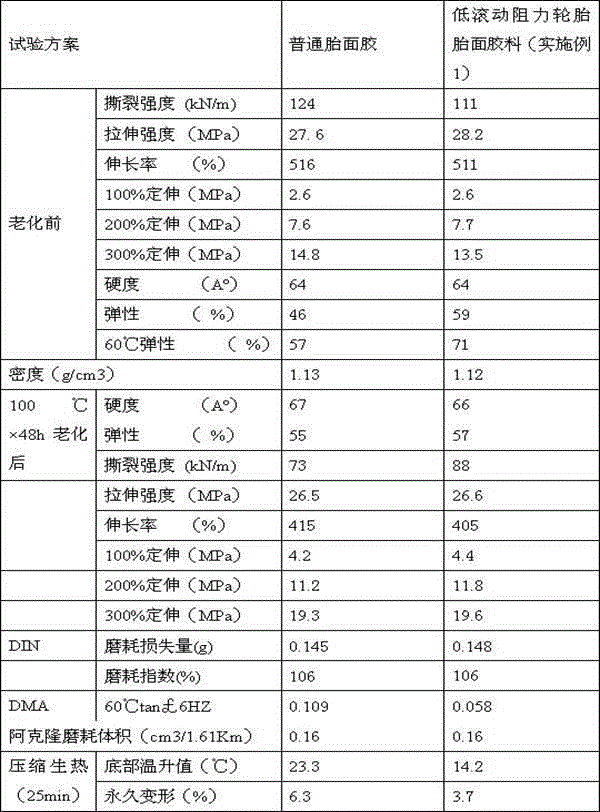

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with embodiment:

[0017] A wear-resistant, puncture-resistant, low-resistance tire rubber compound and a production method thereof are characterized in that the components of the raw materials are composed as follows in parts by weight: 40-70 parts of natural rubber SIR20, 10-15 parts of butadiene rubber, and SBR1500 of styrene-butadiene rubber 3-5 parts, 5-6 parts of N234 high-structure super wear-resistant furnace black, 5-6 parts of white carbon black, 1-1.5 parts of Si-69 silane coupling agent, 1-1.5 parts of polyethylene glycol, toluene 0.5-1.0 parts of diisocyanate, 0.5-1.0 parts of stannous chloride, 0.5-1.0 parts of hydroxyl-terminated polybutadiene, 1-1.5 parts of softening plasticizer aromatic oil, 1-2 parts of stearic acid, 2- 3 parts, tackifier 204 resin 1-1.5 parts, leveling agent UB40001-1.5 parts, zinc oxide 0.5-1.0 parts, sulfur 1-1.5 parts, XY900 anti-reversion agent 0.5-1.0 parts, ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com