Preparation method for graphene oxide modified polypropylene fiber

A graphene modification, polypropylene fiber technology, applied in fiber chemical characteristics, melt spinning, rayon manufacturing and other directions, can solve problems such as poor dispersion of graphene oxide, achieve easy mass production, thermal stability and the effect of improved tensile properties and simple production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

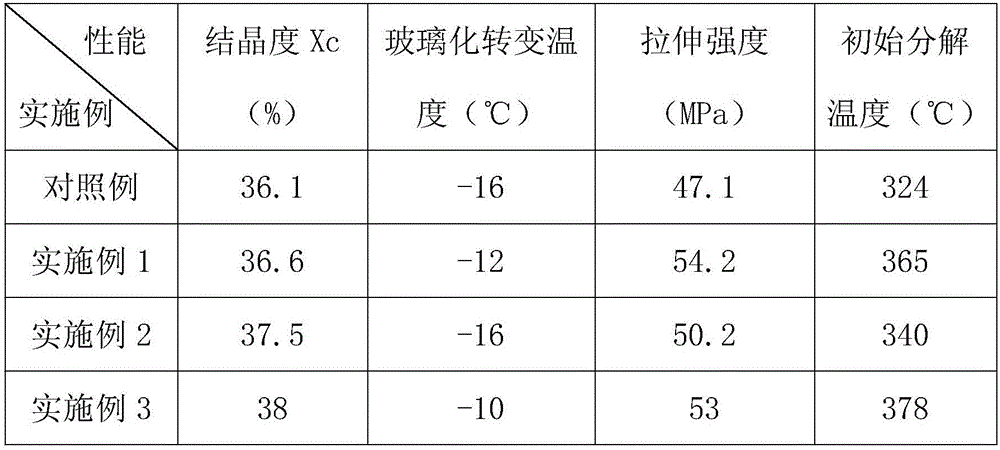

Examples

Embodiment 1

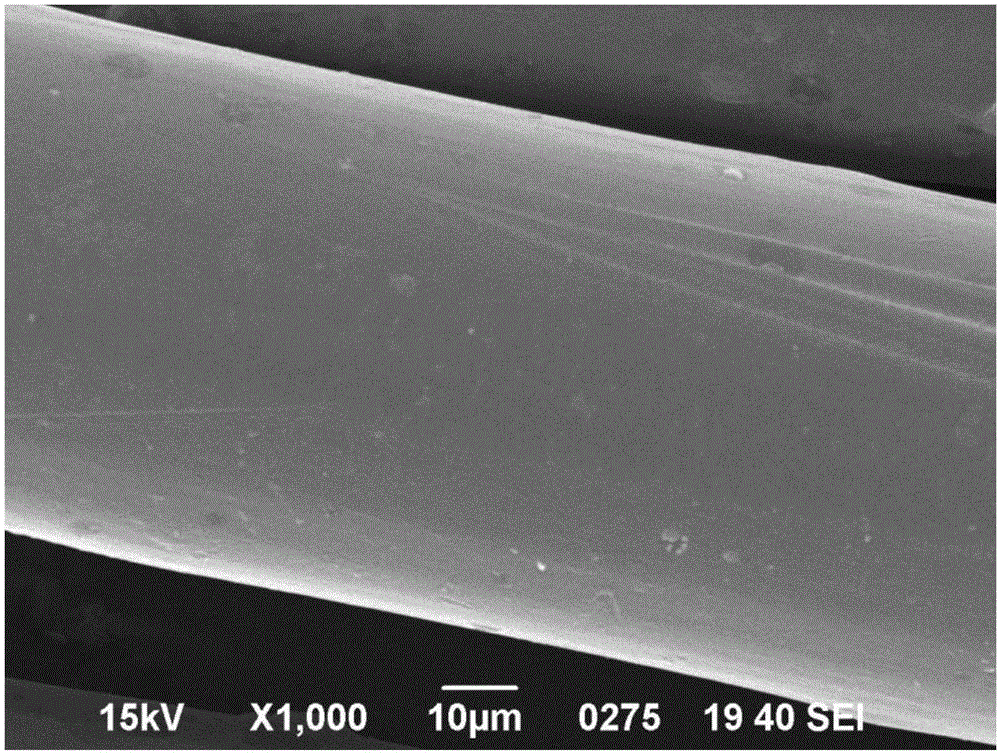

[0026] The transmission electron micrograph of the sample prepared in Example 1 is obtained by the JEOL2011 projection electron microscope detection of JEOL Company of Japan; the scanning electron microscope is obtained by the JSM-6390LV scanning electron microscope detection of JEOL Company of Japan; The test was obtained by the Q50 thermal weight loss instrument; the tensile performance test was obtained by the WDW-20 microcomputer-controlled electronic universal testing machine of Jinan Yinuo Century Experimental Instrument Co., Ltd.

[0027] Example 1

[0028] A preparation method for graphene oxide modified polypropylene fiber, the steps are as follows:

[0029] (1) Dissolve 50 mg of graphene oxide in 100 ml of absolute ethanol under a power of 90 W to prepare a graphene oxide solution.

[0030] (2) Add 5 g of polypropylene into 80 g of xylene, heat and dissolve in a three-necked flask at a stirring rate of 800 r / min at a temperature of 125° C., and prepare a polypropyle...

Embodiment 2

[0034] (1) Graphene oxide is added to ethanol solution, and ultrasonically dissolved to obtain a graphene oxide solution with a concentration of 1.0 mg / mL; the ultrasonic power is 75W, and the ultrasonic time is 0.8h;

[0035] (2) Add polypropylene to xylene at a mass ratio of 1:20, raise the temperature to 115°C; polypropylene is completely dissolved in xylene;

[0036] (3) Slowly add the graphene oxide solution into the polypropylene solution, and mechanically stir at 160°C for 0.5h; place the mixture in an air atmosphere at 45°C and dry for 24h to obtain a graphene oxide-modified polypropylene composite material, The obtained graphene oxide-modified polypropylene composite material is melt-spun to obtain graphene oxide-modified polypropylene fibers.

[0037] The stirring rate described in the step (2)(3) is 600r / min.

Embodiment 3

[0039] (1) Graphene oxide is added to ethanol solution, and ultrasonically dissolved to obtain a graphene oxide solution with a concentration of 0.2mg / mL; the ultrasonic power is 100W, and the ultrasonic time is 0.6h;

[0040] (2) Add polypropylene to xylene at a mass ratio of 1:15, raise the temperature to 135°C; polypropylene is completely dissolved in xylene;

[0041] (3) Slowly add the graphene oxide solution into the polypropylene solution, and mechanically stir at 130°C for 0.5h; place the mixture in an air atmosphere at 55°C and dry for 36h to obtain a graphene oxide-modified polypropylene composite material, The obtained graphene oxide-modified polypropylene composite material is melt-spun to obtain graphene oxide-modified polypropylene fibers.

[0042] The stirring rate described in the step (2) (3) is 1000r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com