Carbon-cladded sodium ferric pyrophosphate material and preparation method thereof as well application of carbon-cladded sodium ferric pyrophosphate material serving as sodium-ion battery positive electrode material

A carbon-coated sodium iron pyrophosphate and phosphorus source technology, which is applied in nanotechnology for materials and surface science, battery electrodes, positive electrodes, etc., can solve the problems of poor electronic conductivity, difficult control of high-temperature sintered structure, and ion diffusion rate. Slow and other problems, to achieve the effect of improving stability, excellent electrochemical performance, and short ion diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

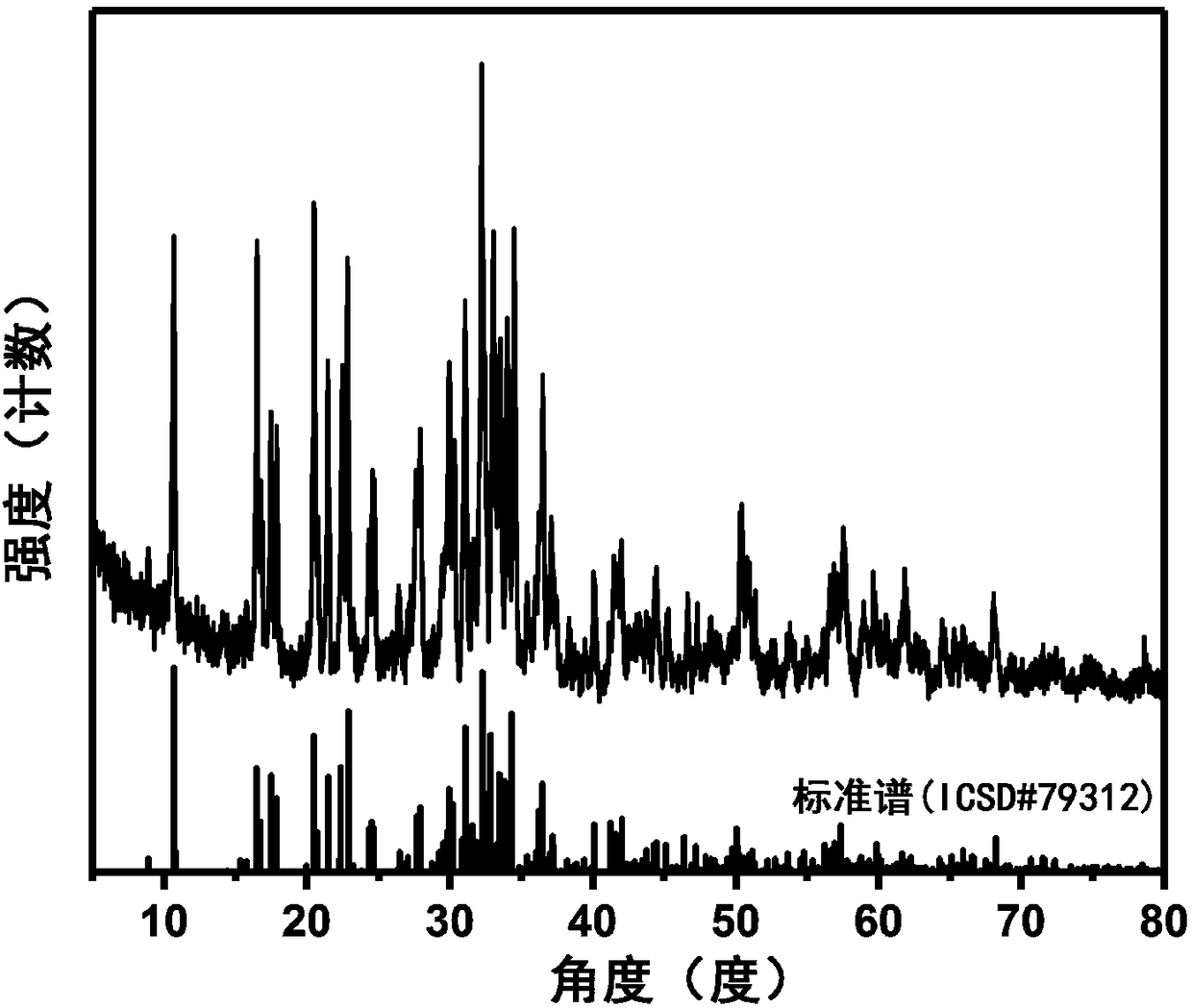

[0051] Add 2.3236g of ammonium dihydrogen phosphate and 8.6467g of oleic acid into a 501L stainless steel ball mill tank, add 20 304 stainless steel balls each with a diameter of 2mm and 4mm as the ball milling medium, and use a high-energy mechanical ball mill to mix for 2 hours to obtain milky white mixture. 11.529 g of sectioned paraffin was added, followed by ball milling for 1 hour. Then 2.216 g of ferrous oxalate dihydrate was added, and ball milling was continued for 1 hour to obtain a yellow viscous mixture. Finally, 1.2926g of anhydrous sodium acetate was added and mixed by ball milling for 2 hours to obtain a viscous uniform mixed precursor. Turn the viscous precursor of sodium ferric pyrophosphate to a H 2 / Ar(Ar and H 2 In a quartz tube furnace with a volume ratio of 95:5), the temperature was raised to 600°C at a rate of 2°C / 1in for calcination at a constant temperature for 12 hours, and the carbon-coated Na 3.12 Fe 2.44 (P 2 o 7 ) 2 powder material. Adop...

Embodiment 2

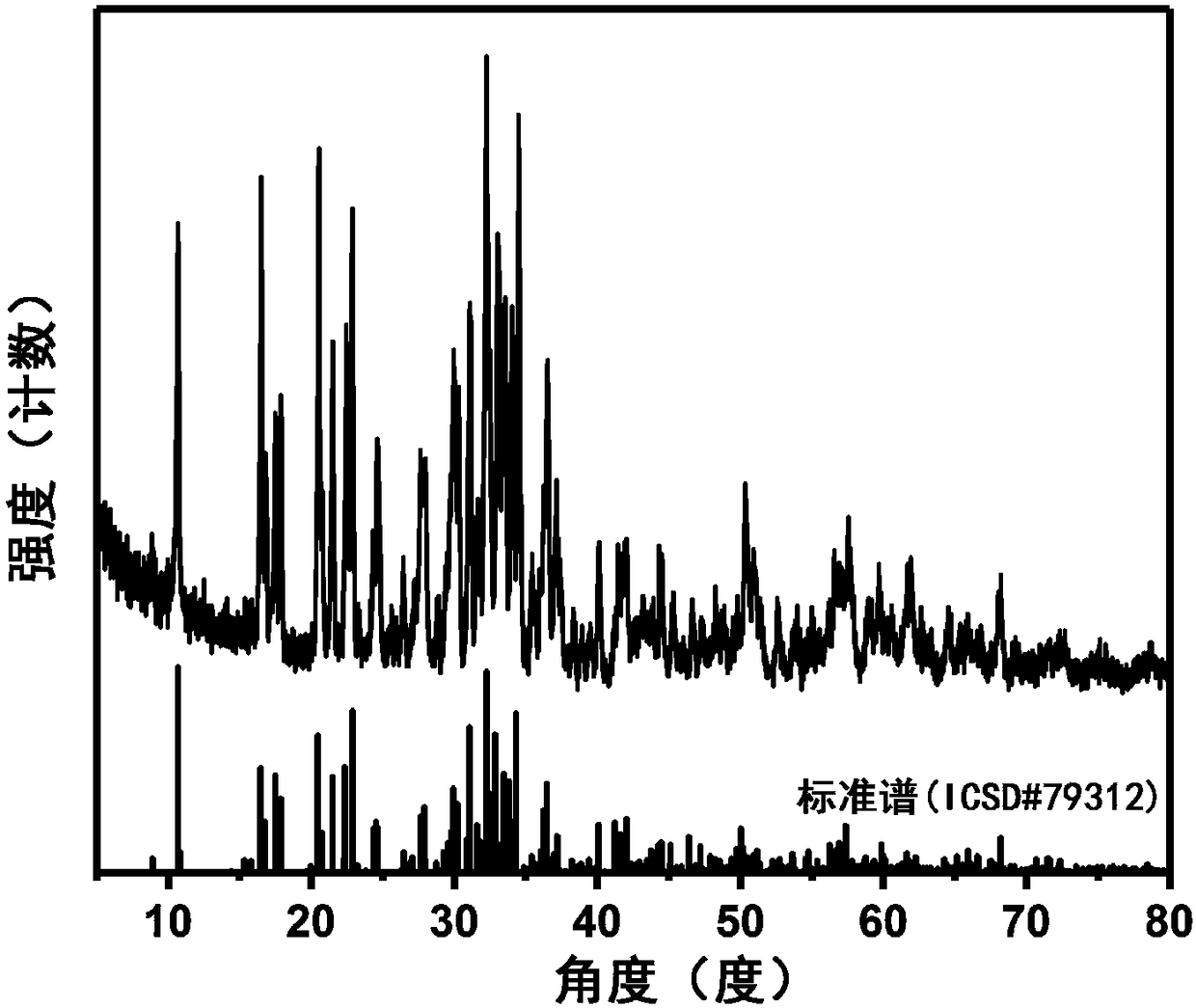

[0053] Add 2.3236g of ammonium dihydrogen phosphate and 8.6467g of oleic acid into a 501L stainless steel ball mill tank, add 20 304 stainless steel balls each with a diameter of 2mm and 4mm as the ball milling medium, and use a high-energy mechanical ball mill to mix for 2 hours to obtain milky white mixture. 11.529 g of sectioned paraffin was added, followed by ball milling for 1 hour. Then 2.216 g of ferrous oxalate dihydrate was added, and ball milling was continued for 1 hour to obtain a yellow viscous mixture. Finally, 1.2926g of anhydrous sodium acetate was added and mixed by ball milling for 2 hours to obtain a viscous uniform mixed precursor. Turn the viscous precursor of sodium ferric pyrophosphate to a H 2 / Ar(Ar and H 2 In a quartz tube furnace with a volume ratio of 95:5), the temperature was raised to 650°C at a rate of 2°C / 1in for calcination at a constant temperature for 12 hours, and the carbon-coated Na 3.12 Fe 2.44 (P 2 o 7 ) 2 powder material. Adop...

Embodiment 3

[0055] Add 2.3236g of ammonium dihydrogen phosphate and 8.6467g of oleic acid into a 501L stainless steel ball mill tank, add 20 304 stainless steel balls each with a diameter of 2mm and 4mm as the ball milling medium, and use a high-energy mechanical ball mill to mix for 2 hours to obtain milky white mixture. 11.529 g of sectioned paraffin was added, followed by ball milling for 1 hour. Then 2.216 g of ferrous oxalate dihydrate was added, and ball milling was continued for 1 hour to obtain a yellow viscous mixture. Finally, 1.2926g of anhydrous sodium acetate was added and mixed by ball milling for 2 hours to obtain a viscous uniform mixed precursor. Turn the viscous precursor of sodium ferric pyrophosphate to a H 2 / Ar(Ar and H 2 In a quartz tube furnace with a volume ratio of 95:5), the temperature was raised to 700°C at a rate of 2°C / 1in for calcination at a constant temperature for 12 hours, and the carbon-coated Na 3.12 Fe 2.44 (P 2 o 7 ) 2 powder material. Adop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com