A transition metal element doped and transition metal oxide-coated lithium iron phosphate composite cathode material and preparation method

A technology of transition metal elements and composite cathode materials, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as the inability to fundamentally improve the material structure and hinder the performance of LiFePO4, so as to improve the conductivity and discharge capacity, improve the cycle. Performance, the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

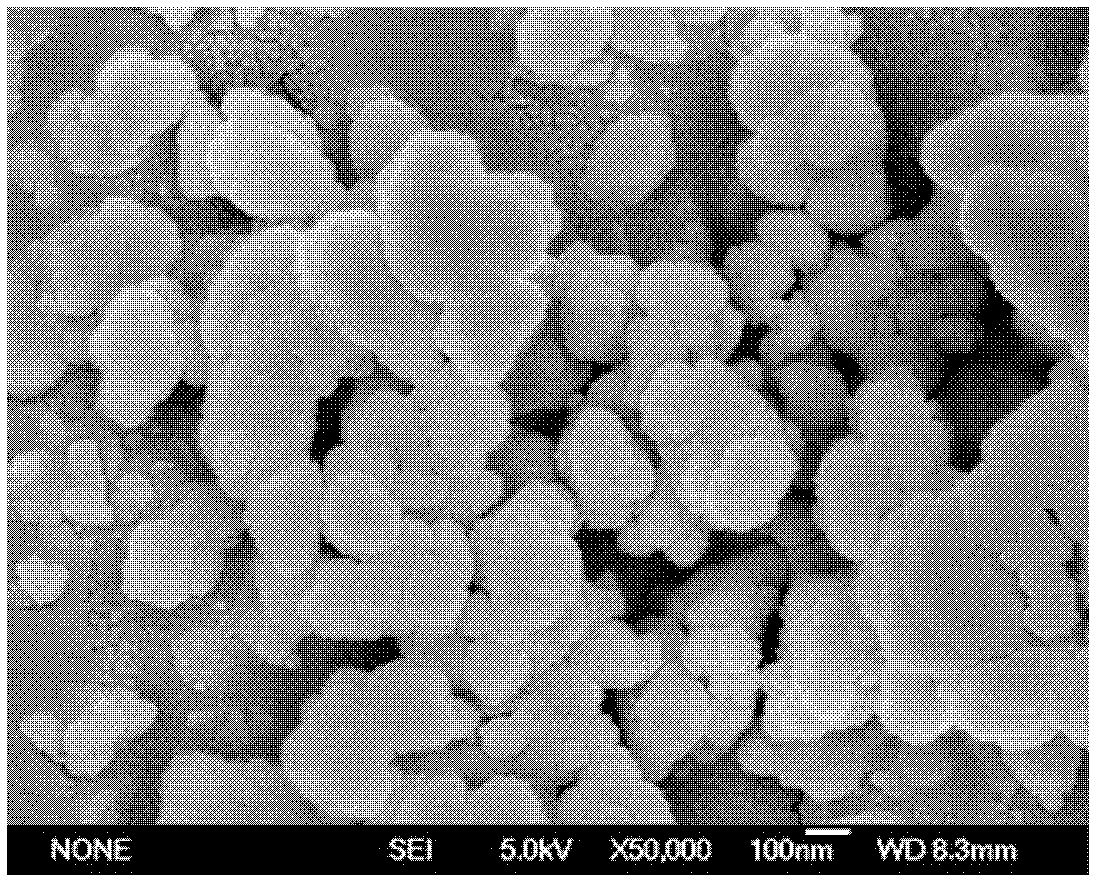

[0031] 1. Mix 0.0995 mol of lithium acetate, 0.1 mol of ferrous acetate, 0.1 mol of diammonium hydrogen phosphate and 0.0005 mol of manganese acetate and add 60ml of absolute ethanol to ball mill for 24 hours. Dry the mixed material at 60°C, and then Under protection, the temperature was raised to 400°C at a heating rate of 5°C / min and kept for 6 hours, and then the temperature was raised to 600°C at a heating rate of 3°C / min and calcined at this temperature for 24 hours, and naturally cooled to room temperature to prepare manganese-doped lithium iron phosphate composite materials;

[0032] 2. Mix 95wt% manganese-doped lithium iron phosphate composite material with 5wt% manganese dioxide and add 60ml of deionized water to ball mill for 24 hours. After drying the mixed material at 60°C, dry it at 5°C / The heating rate of min was raised to 400°C and held for 4 hours, and then naturally cooled to room temperature to prepare manganese-doped and manganese dioxide-coated lithium iro...

Embodiment 2

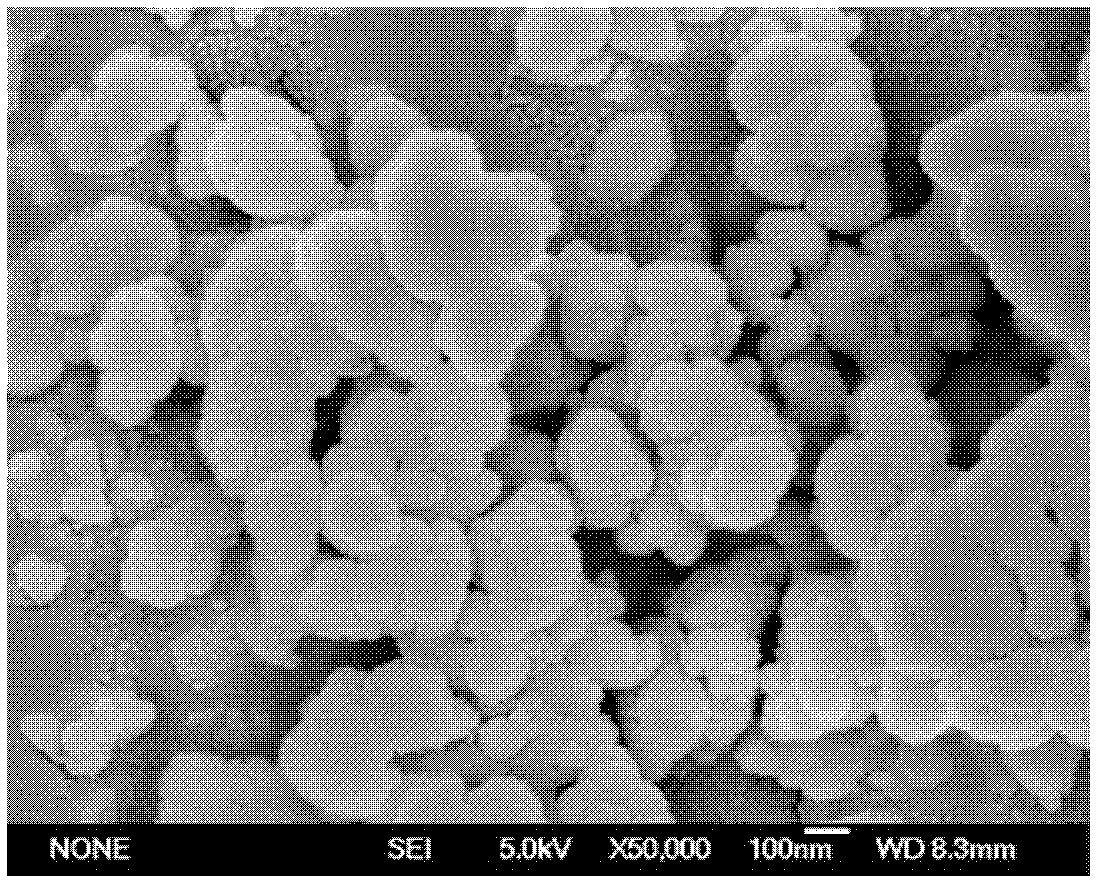

[0035]1. Mix 0.095 moles of lithium hydroxide, 0.1 moles of ferrous oxalate, 0.1 moles of ammonium dihydrogen phosphate and 0.005 moles of nickel hydroxide and add 80 mL of deionized water to ball mill for 12 hours. Dry the mixed materials at 70 °C, and then Under the protection of argon, the temperature was raised to 500°C at a heating rate of 10°C / min and kept for 12 hours, and then the temperature was continued to be raised to 850°C at a heating rate of 8°C / min and calcined at this temperature for 12 hours, and naturally cooled to room temperature to obtain nickel Doped lithium iron phosphate composite material;

[0036] 2. Mix 97wt% nickel-doped lithium iron phosphate composite material with 3wt% nickel oxide, add 80mL acetone ball mill for 12h, dry the mixed material at 70°C, and dry it under the protection of argon at 10°C / min The heating rate is raised to 600°C, kept for 6 hours, and then naturally cooled to room temperature to prepare nickel-doped and nickel oxide-coat...

Embodiment 3

[0039] 1. Mix 0.097 mole of lithium carbonate, 0.1 mole of ferrous chloride, 0.1 mole of diammonium hydrogen phosphate and 0.003 mole of nickel carbonate, add 80 mL of acetone and ball mill for 20 hours, dry the mixed material at 60 ° C, and then protect it under nitrogen The temperature was raised to 450°C at a heating rate of 6°C / min and kept for 10 hours, then continued to be heated at a heating rate of 5°C / min to 800°C and calcined at this temperature for 20 hours, and naturally cooled to room temperature to obtain nickel-doped lithium iron phosphate composite materials;

[0040] 2. Mix 99.9wt% nickel-doped lithium iron phosphate composite material with 0.1wt% vanadium pentoxide, add 80mL of absolute ethanol to ball mill for 20 hours, dry the mixed material at 70°C, and dry it under nitrogen protection with Raise the temperature to 500°C at a heating rate of 5°C / min, hold the temperature for 5 hours, and then cool naturally to room temperature to prepare nickel-doped and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com