Industrial preparation method for lithium iron phosphate

A lithium ferrous phosphate, industrial technology, applied in the field of lithium ferrous phosphate materials for lithium ion batteries and their manufacturing fields, can solve the problems of high energy consumption and low efficiency, and achieve the effects of high purity and improved grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

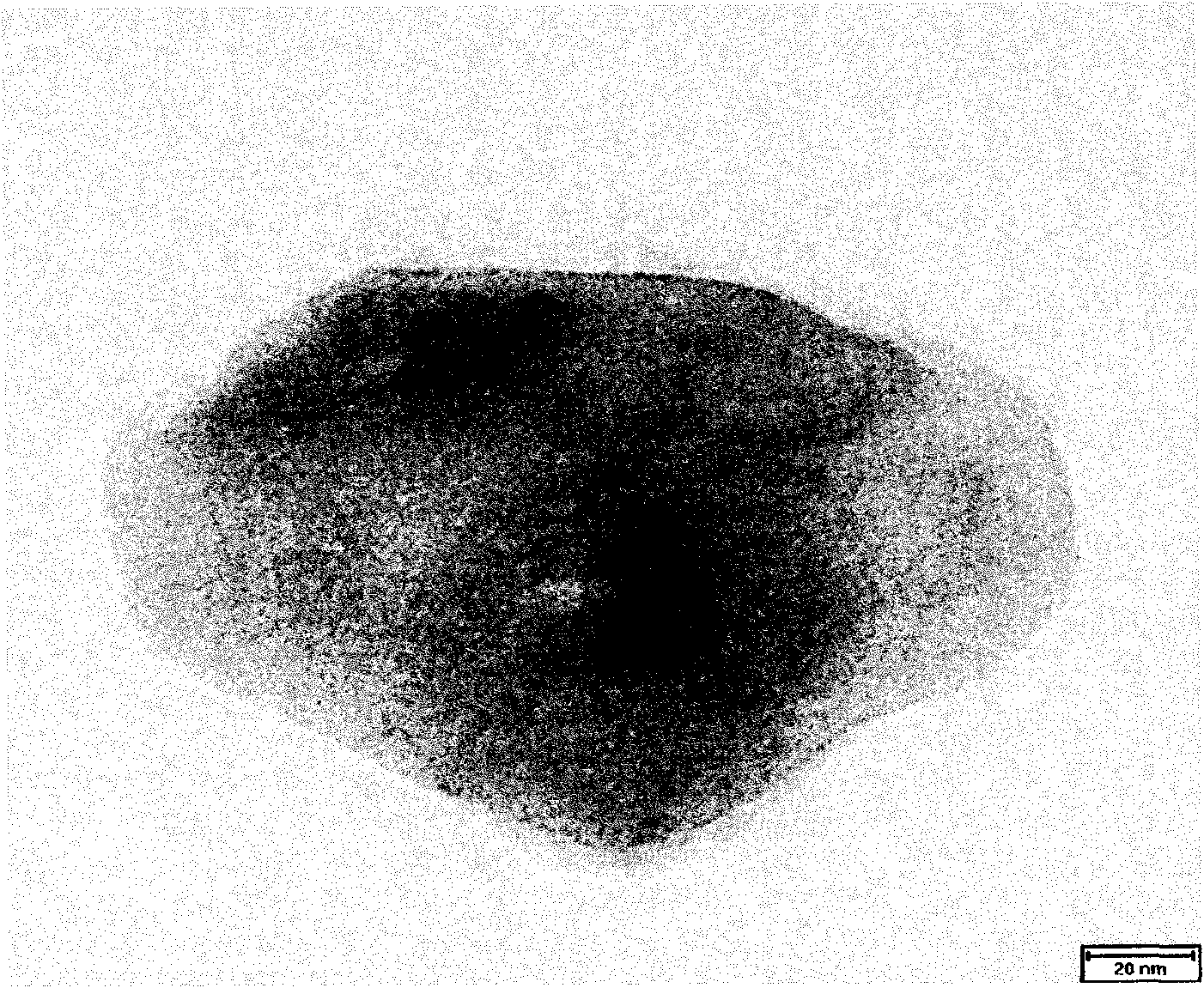

[0028] Weigh 6.65g of lithium hydroxide, 29.61g of iron phosphate, and 4.40g of polyvinylpyrrolidone into 125g of water, ball mill at a speed of 300r / min for 2 hours, and then move to an oven. The temperature in the oven is 80°C. After drying, move to a heating furnace. The heating furnace was protected by Ar, and the temperature was raised to 350°C at 2°C / min, and then the temperature was raised to 650°C at 2°C / min after holding for 4 hours. After holding for 8 hours, it was cooled to obtain the lithium iron phosphate cathode material. Assemble the button battery to test the electrochemical performance of the lithium iron phosphate powder cathode material: the cathode sheet is LiFePO 4 : Acetylene black: PTFE (polytetrafluoroethylene) = 75: 20: 5, mixed evenly and then pressed into tablets. The polar piece was vacuum dried at 80°C for 12h. The counter electrode is metal lithium sheet, the separator is polypropylene porous membrane (Celgard-2400), and the electrolyte is 1.0mo...

Embodiment 2

[0030] Weigh 16.47g of lithium dihydrogen phosphate, 12.65g of ferric oxide, 5g of glucose and 0.315g of polyvinylpyrrolidone into 100g of water, ball mill at a speed of 600r / min for 6h, then move to an oven, the temperature in the oven is 100°C, and dry After moving to the heating furnace, the heating furnace passes N 2-Ar mixed gas protection, heat up to 400°C at 6°C / min, keep warm for 6h, cool to room temperature, take out the dry mill for 2h, move to the furnace and continue to pass N 2 -Ar mixed gas protection and heating up to 700°C at a rate of 6°C / min, and cooling for 10 hours to obtain lithium iron phosphate cathode material. Assemble the button battery to test the electrochemical performance of the lithium iron phosphate powder cathode material: the cathode sheet is LiFePO 4 : Acetylene black: PTFE (polytetrafluoroethylene) = 75: 20: 5, mixed evenly and then pressed into tablets. The polar piece was vacuum dried at 80°C for 12h. The counter electrode is metal lith...

Embodiment 3

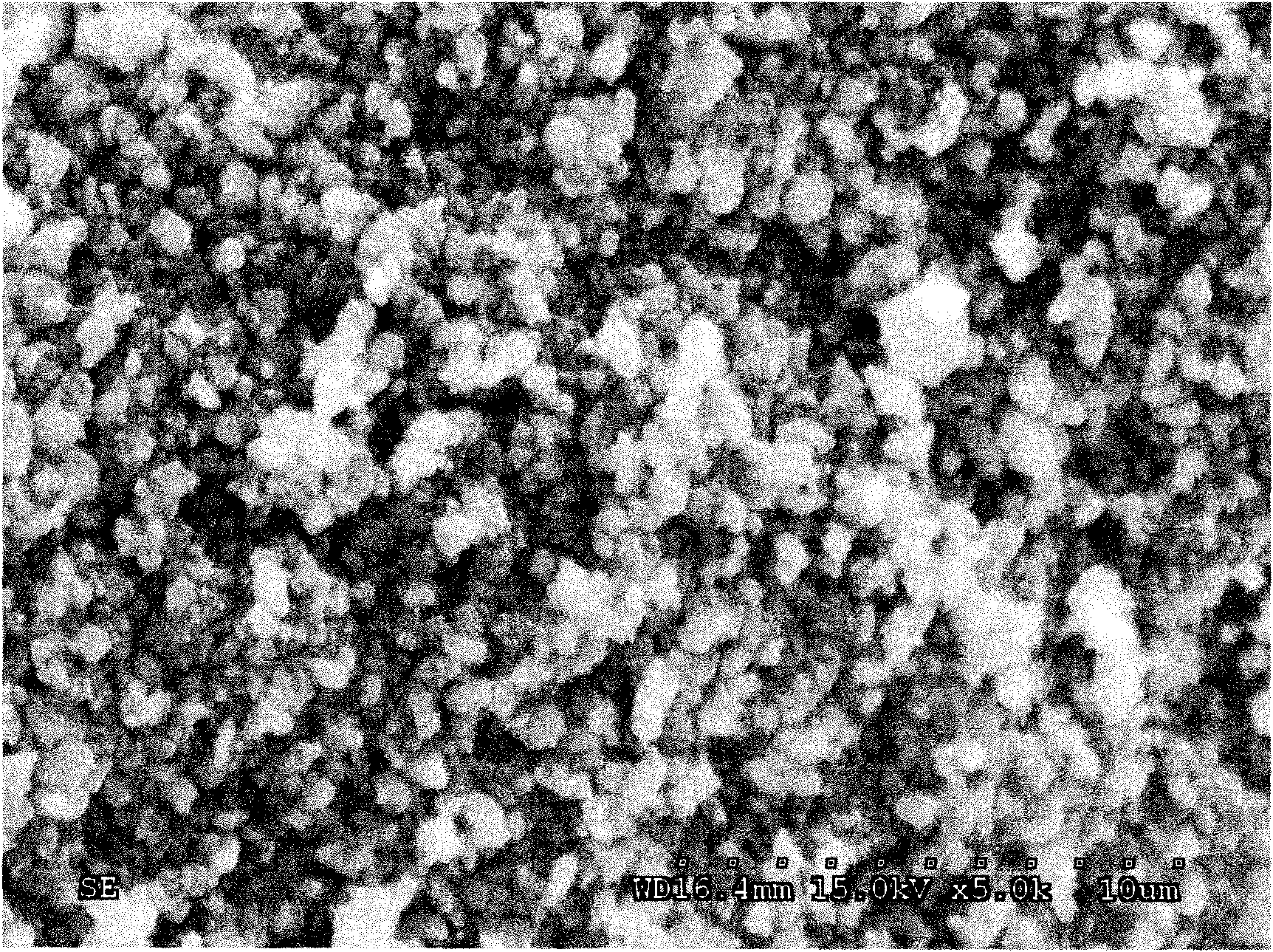

[0032] Weigh 6.12kg of lithium dihydrogen phosphate, 29.61kg of iron phosphate, 3kg of sucrose and 0.315g of polyvinylpyrrolidone into 105kg of water, ball mill at a speed of 1200r / min for 12h, spray dry at 120°C, and move to a heating furnace after drying , through N in the heating furnace 2 Protection, heat up to 450°C at 10°C / min, keep warm for 10h, cool to room temperature, take out the dry mill for 6h, move to the furnace and continue to pass N 2 Protect and heat up to 750°C at 10°C / min, keep warm for 20 hours and cool to obtain lithium iron phosphate cathode material. Assemble the button battery to test the electrochemical performance of the lithium iron phosphate powder cathode material: the cathode sheet is LiFePO 4 : Acetylene black: PTFE (polytetrafluoroethylene) = 75: 20: 5, mixed evenly and then pressed into tablets. The polar piece was vacuum dried at 80°C for 12h. The counter electrode is a metal lithium sheet, the separator is a polypropylene porous membrane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com