Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about How to "Particles are small and uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of composite oxide AB2O4 for lithium ion secondary battery cathode material

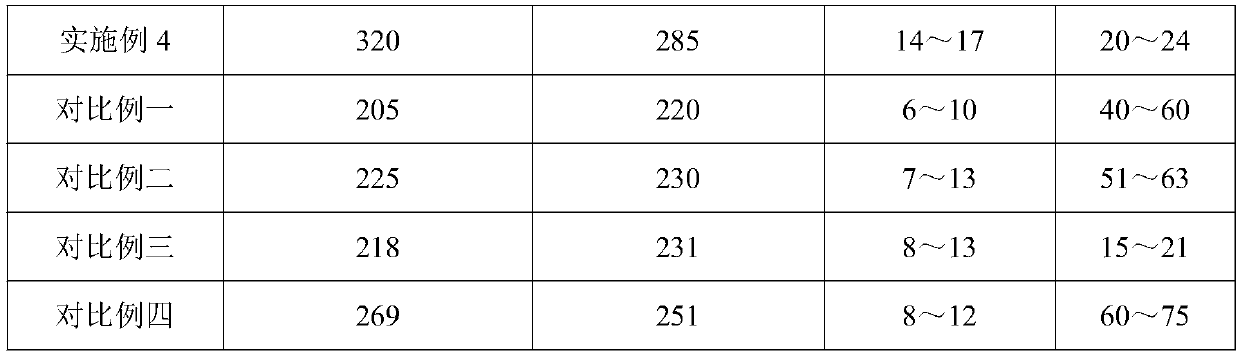

InactiveCN104022261AParticles are small and uniformLarge specific surface areaCell electrodesSecondary cellsFreeze-dryingCombined method

The invention provides a preparation method of a composite oxide AB2O4 (A equals to Mn, Co, Ni, Cu, Zn; B equals to Mn, Fe, Co, Ni, Zn; and A is not equal to B) for lithium ion secondary battery cathode material. The invention uses A, B metal salts and an organic chelating agent as raw materials and employs a sol gel and freeze-drying combined method for synthesis of AB2O4. The AB2O4 synthesized by the method has small particle size and uniform particle size, forms a three-dimensional network structure, and increases the specific surface area of the material, so as to improve the electrochemical performance of the cathode material; and the preparation process is simple and low in cost. The composite oxide AB2O4 is considered to be a promising material.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Industrial preparation method for lithium iron phosphate

InactiveCN101955175AEvenly dispersedParticles are small and uniformCell electrodesPhosphorus compoundsSource materialNew energy

The invention belongs to an energy material, and particularly relates to a method for preparing a lithium iron phosphate anode material suitable to be used by a power type lithium ion battery and the like by using PVP (polyvinylpyrrolidone) as a dispersant and a carbon source at the same time in an aqueous solution. The method comprises the following steps of: weighing a lithium source compound, an iron source compound and a phosphorus source compound in a weight ratio, adding the compounds into water, adding a proper amount of PVP into the mixture, grinding the mixture for certain time, drying the mixture, transferring the obtained precursor into an atmosphere protection furnace, treating the precursor for certain time at a high temperature under inert atmosphere, and cooling the product to obtain the lithium iron phosphate. By observing, one-time particles are uniform and fine, and the first discharge capacity is 157.6mAh / g. The method has the advantages of low energy consumption, high grinding efficiency and environment-friendly and pollution-free production process, and is an excellent method for synthesizing a green new energy source material. The prepared material has the advantages of uniform particle size distribution, good circulating stability and prominent magnification performance, and is a battery anode material suitable for high-capacity energy storage equipment such as substations and the like and large-sized mobile equipment such as electric automobiles and the like.

Owner:BEIJING CENT PRESS UNION TECH

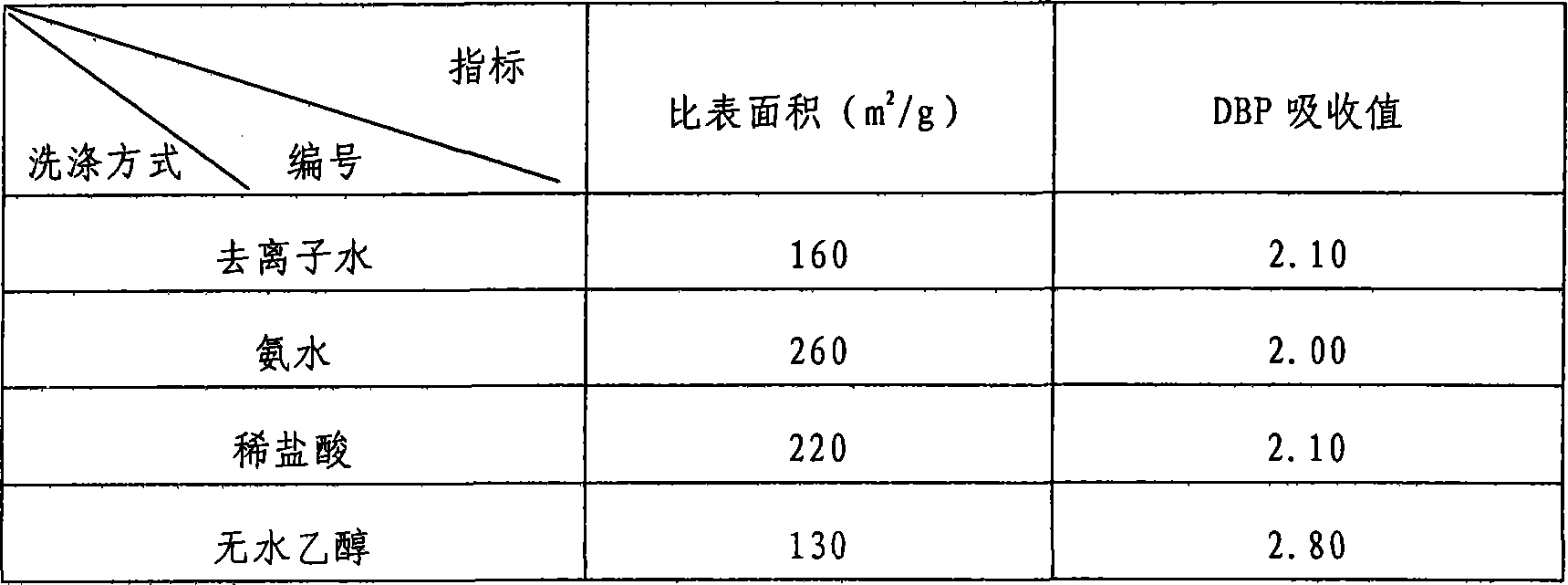

Integrated utilization method for phosphorus chemical industry byproduct fluorosilicic acid

The invention discloses a comprehensive utilization method of hydrofluosilicic acid which is by-product of phosphorus chemical engineering. The method is that hydrofluosilicic acid solution with concentration of 18%-35% is added to a container with intense agitation and rapid heat withdrawing under -5 DEG C to 30 DEG C, the agitation is started with an agitation speed of 500rmp-10000rmp, simultaneously ammonia with concentration of 13%-37% is added, or ammonia gas is added. Silica gel is obtained by filtration, after the silica gel is washed and dried, finished product of white carbon black with surface area of 160-350m2 / g is obtained. The filtering liquid is ammonium fluoride solution with concentration larger than 20%, and the ammonification recovery ratio can reach more than 98%. The invention is simple in technique, the hydrofluosilicic acid is made good use of, and the produced white carbon black has good quality.

Owner:YUNNAN CHEM RES INST

High-capacity lithium-enriched positive electrode material and preparation method thereof

ActiveCN104134797AHigh crystallinityUniform and controllable particle sizeCell electrodesSecondary cellsLithiumCalcination

The invention belongs to the field of electrochemistry and particularly relates to a high-capacity lithium-enriched positive electrode material and a reparation method thereof. The molecular formula of the high-capacity lithium-enriched positive electrode material is Li[Li<x-beta>Na<beta>Mn<1-y-z-alpha>Co<y>Ni<z>Y<alpha>]O2, wherein x is more than or equal to 0 and less than or equal to 0.6, y is more than 0 and less than or equal to 0.4, z is more than 0 and less than or equal to 0.4, alpha is more than or equal to 0 and less than or equal to 0.1 and beta is more than or equal to 0 and less than or equal to 0.2; the result of (1-y-z-alpha) is more than 0 and the result of (x-beta) is more than 0. The lithium-enriched positive electrode material containing Na and Y has the characteristics of low first-time irreversible capacity, large electrochemical capacity, high cycling stability, excellent rate performance and the like. The preparation method has the advantages that a preparation process is simple, raw materials are cheap and easily available, the cost is low, the high-temperature calcination time is very short, the repeatability is good and the industrialization is easy to realize.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

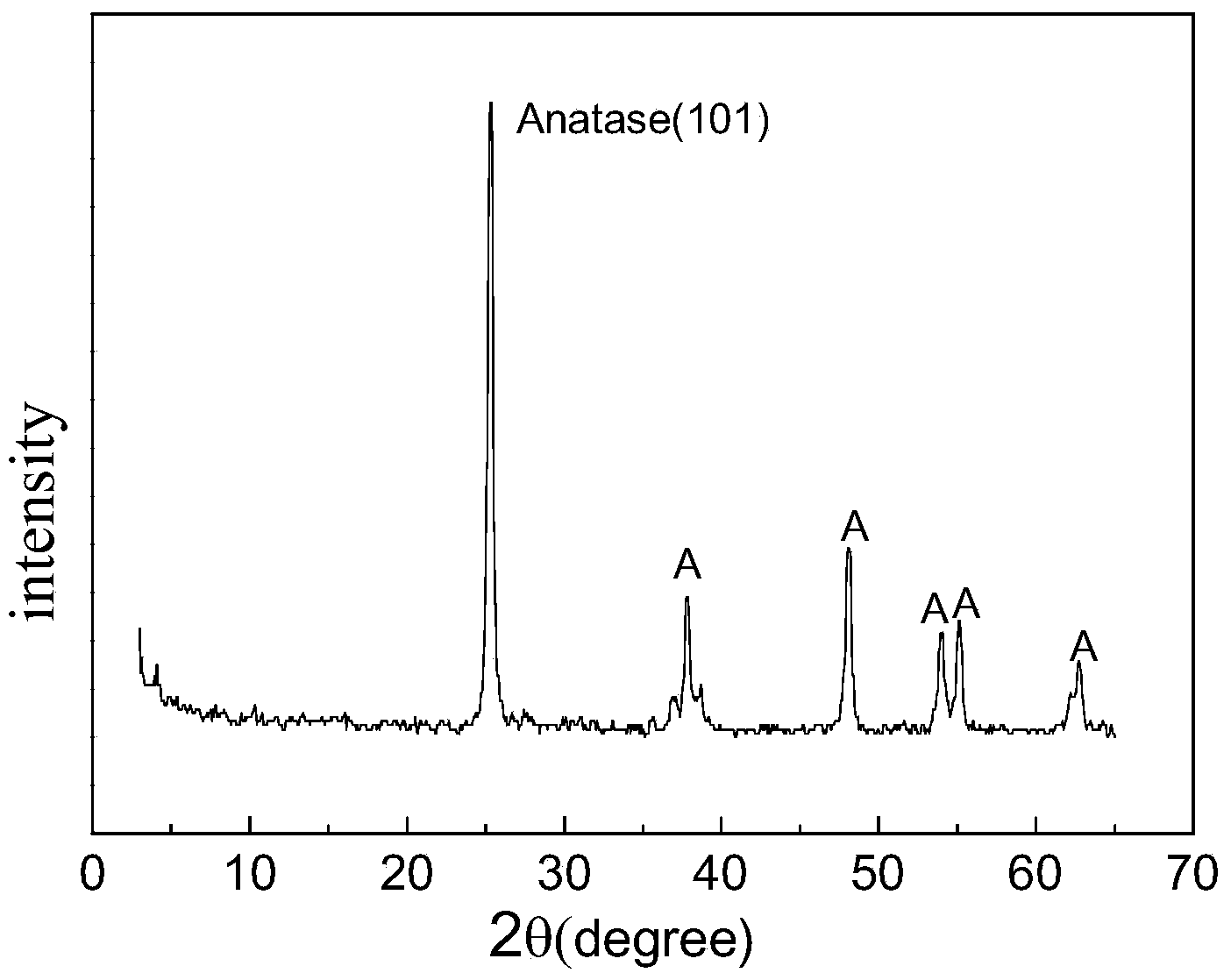

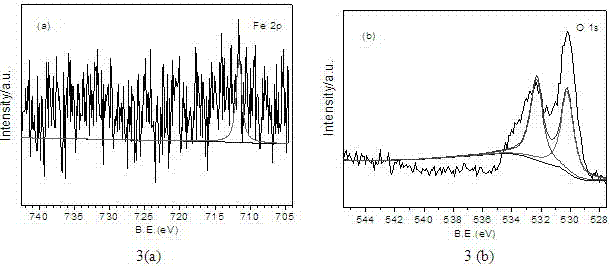

Single-step hydrothermal micro-emulsion method for preparing iron-doped nano titanium dioxide powder

InactiveCN103537286AAvoid stabilityMild preparation conditionsMetal/metal-oxides/metal-hydroxide catalystsAlkylphenolOil phase

The invention relates to a single-step hydrothermal micro-emulsion method for preparing iron-doped nano titanium dioxide powder. The single-step hydrothermal micro-emulsion method specifically comprises the following steps of constituting water-in-oil W / O type micro-emulsion by using alkylphenol ethoxylates (OP-10) as a surfactant, using n-butyl alcohol (C4H9OH) as a cosurfactant, using cyclohexane (C6H12) as an oil phase, using butyl titanate (Ti(OC4H9)4) as a titanium source and using hydrochloric acid (HCl) liquor of ferric chloride (FeCl3.6H2O) as a water phase; uniformly stirring, and transferring into a lined polytetrafluoroethylene reaction kettle for keeping heat for 1 hour-5 hours at a constant temperature of 120 DEG C-160 DEG C, naturally cooling to the room temperature; and washing, separating and drying to prepare the iron-doped nano titanium dioxide powder. According to the single-step hydrothermal micro-emulsion method disclosed by the invention, the iron-doped titanium dioxide is obtained by directly reacting in a low-temperature liquid phase, the preparation process is simple, and the prepared iron-doped nano TiO2 powder is controllable in dimension, uniform in size and provided with average diameter of 10 nm-25 nm; moreover, the iron-doped nano TiO2 powder is expected to be widely applied in the fields such as hydrogen production by photodecomposition of water, degradation of organic pollutants, and the like.

Owner:ZHANJIANG NORMAL UNIV

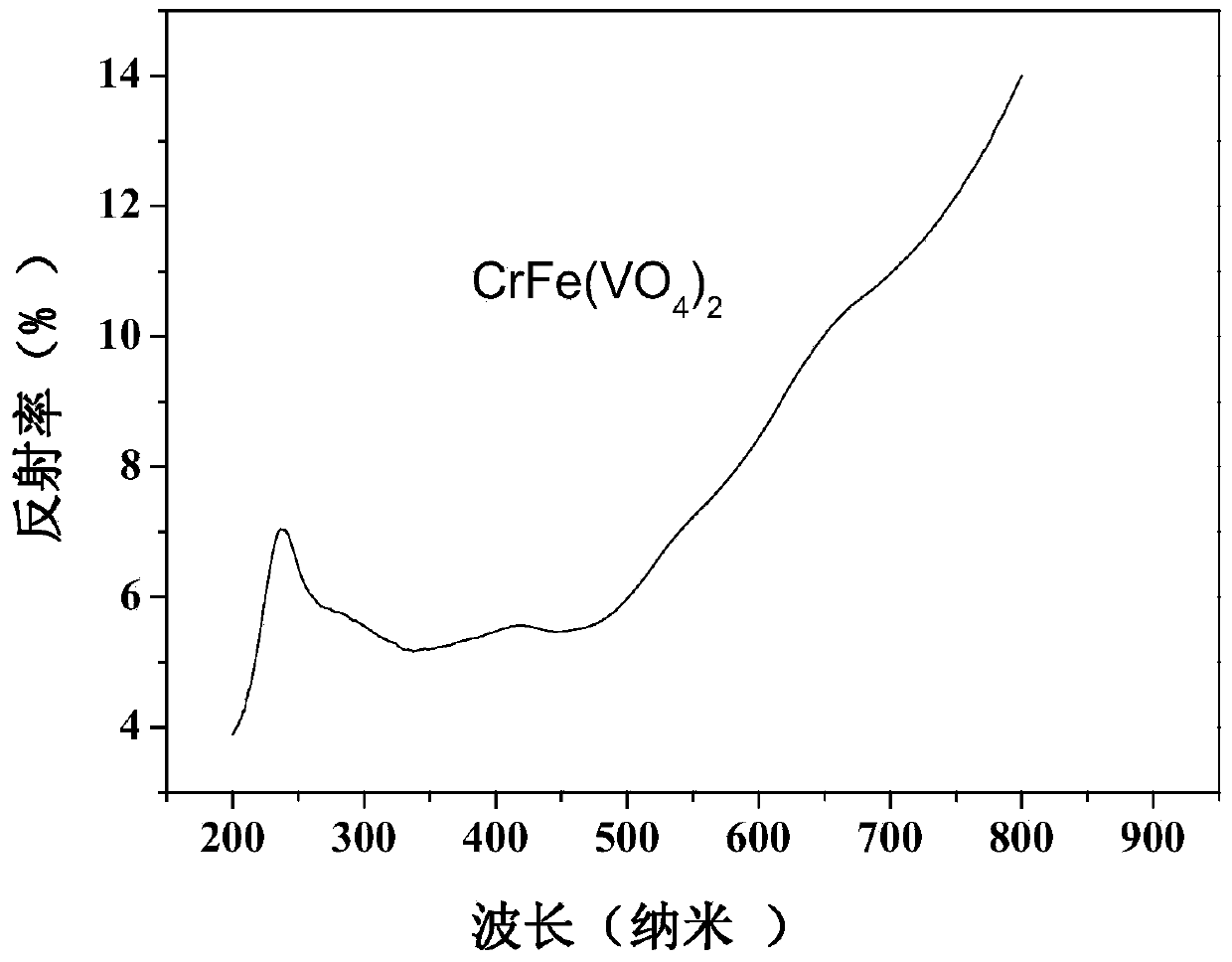

Ferrochrome vanadate photocatalytic material with visible light response as well as preparation method and application thereof

ActiveCN104174408ANo emissionsEasy to prepareWater/sewage treatment by irradiationWater contaminantsChemical solutionSolid state reaction method

The invention discloses a ferrochrome vanadate photocatalytic material CrFe(VO4)2 with visible light response as well as a preparation method and an application thereof. The sample of a photocatalytic material is prepared by using a high-temperature solid-phase reaction method, a chemical solution method and a co-precipitation method; the production cost and device requirement are low; the prepared material is good in dispersion performance, uniform in granularity, good in chemical stability and optic stability; and the prepared photocatalyst sample CrFe(VO4)2 has relatively small spectrum width, excellent photocatalytic performance and good photocatalytic stability and good application prospect and has the effect of decomposing toxic chemical substances under visible light response.

Owner:SUZHOU DEJIE MEMBRANE MATERIAL SCI & TECH

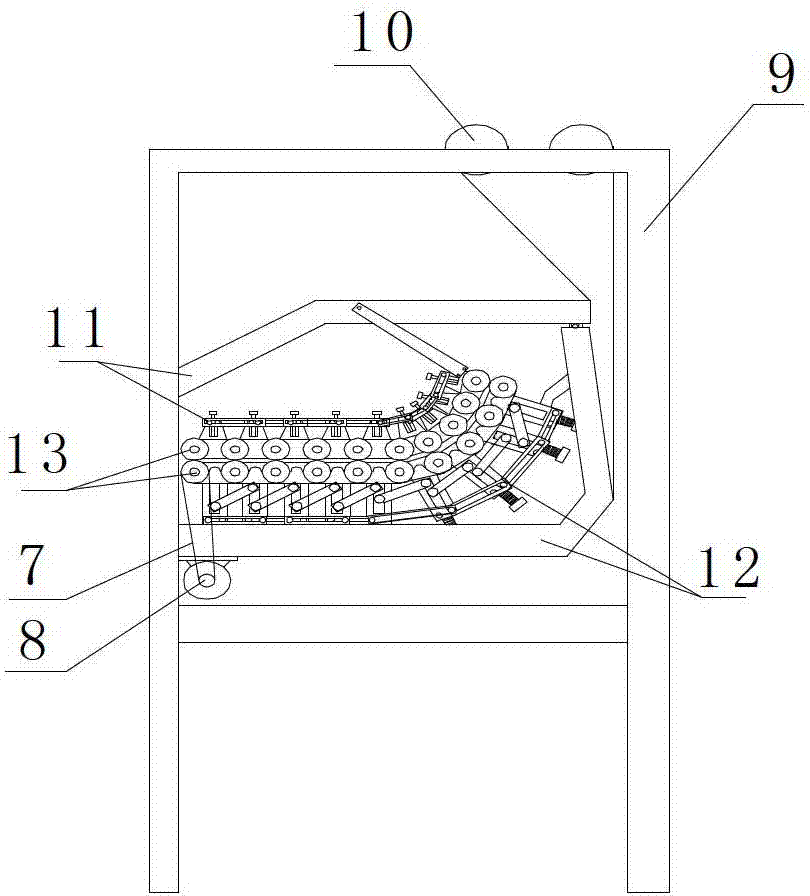

Emulsification device and method for safely preparing emulsion matrix

InactiveCN102976872AImprove the emulsification effectImprove mixing efficiencyExplosive working-up apparatusPolymer chemistryMaterial transfer

The invention relates to an emulsification device for safely preparing an emulsion matrix, which comprises a water-phase emulsification material transfer pump, a water-phase emulsification material transfer pipe, an oil-phase emulsification material transfer pump and an oil-phase emulsification material transfer pipe, wherein the water-phase emulsification material transfer pump and the water-phase emulsification material transfer pipe are connected; and the oil-phase emulsification material transfer pump and the oil-phase emulsification material transfer pipe are connected. The emulsification device is characterized by further comprising an emulsification mixer with a slope-shaped rectangular mixing cavity channel, an emulsification mixture transfer pipe, an emulsification time delay mixer with a built-in honeycombed filling material mixing pipe cavity and an emulsion matrix finished product discharge pipe, wherein the water-phase emulsification material transfer pipe and the oil-phase emulsification material transfer pipe are respectively connected with a water-phase emulsification material inlet cavity and an oil-phase emulsification material inlet cavity of the emulsification mixer; and the emulsification mixer, the emulsification mixture transfer pipe, the emulsification time delay mixer and the emulsion matrix finished product discharge pipe are sequentially connected. According to the emulsification method provided by the invention, two-phase emulsification materials are subjected to primary emulsification of the emulsification mixer and secondary emulsification of the emulsification time delay mixer, thus obtaining the emulsion matrix finished product. The invention has the advantages of high safety, good emulsification quality, high production efficiency and the like.

Owner:NANJING UNIV OF SCI & TECH +1

Acanthopanax root feed additive and its preparing method

InactiveCN1985619AIncrease feed intakeImprove conversion rateAnimal feeding stuffWorking-up animal fodderFeed conversion ratioBioavailability

The present invention relates to manyprickle acanthopanax root feed additive and its preparation process. Manyprickle acanthopanax root feed additive is prepared with manyprickle acanthopanax root and through produced into meal, adding solid alkaline matter and mechanically crushing into powder. It has fine mouth feeling, easy ingestion, high bioavailability, and capacity of raising animal's ingestion amount, feed converting rate and animal's productivity.

Owner:DALIAN SEM BIOLOGICAL ENG TECH

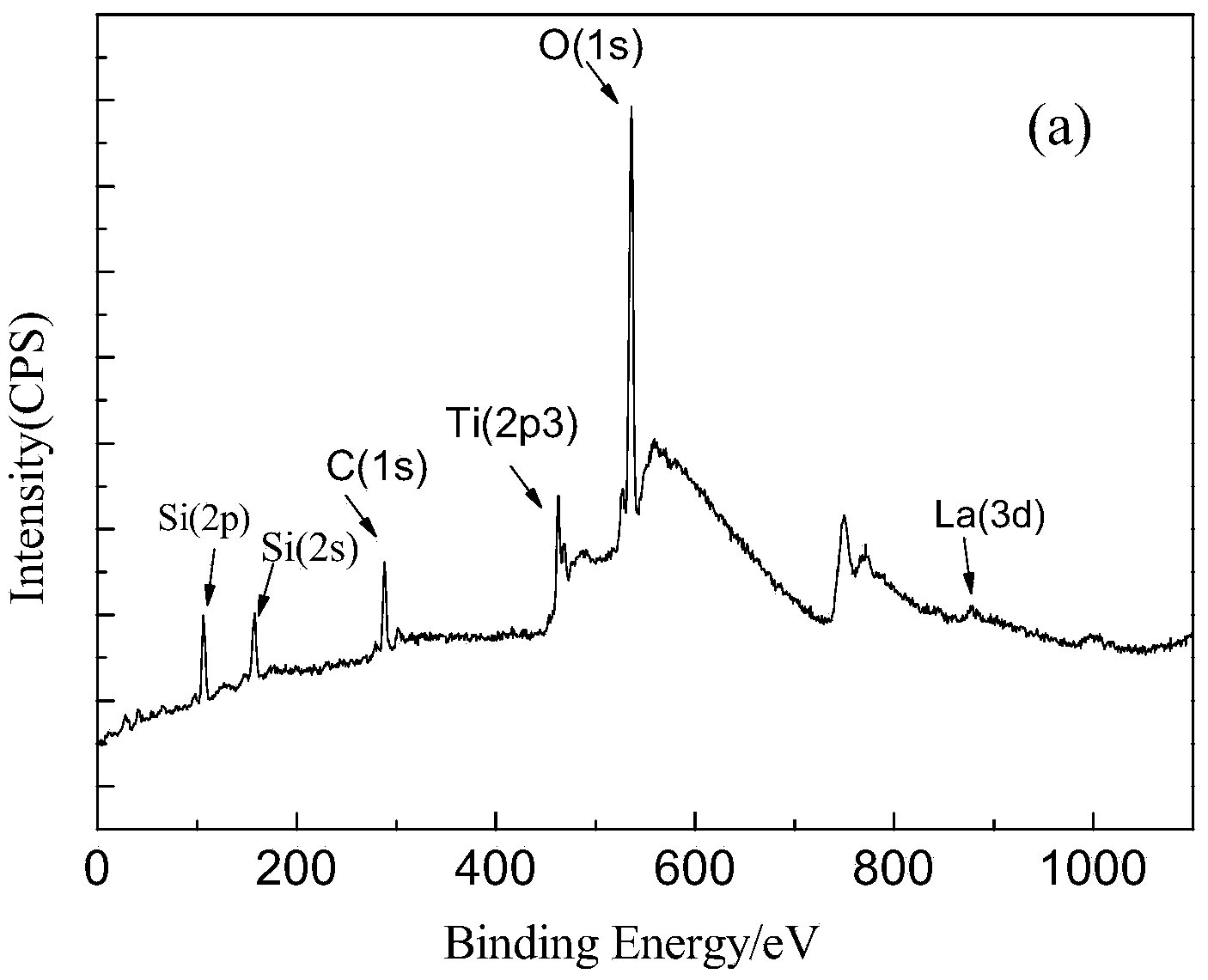

Silicon dioxide compounded titanium dioxide catalyst for degrading coking wastewater as well as preparation method thereof

InactiveCN103846090AMild preparation conditionsHigh UVWater/sewage treatment by irradiationEnergy based wastewater treatmentCopper nitrateHYDROSOL

The invention discloses a silicon dioxide compounded titanium dioxide catalyst for degrading coking wastewater as well as a preparation method thereof. The catalyst is prepared by comprising the following steps: dissolving butyl titanate into absolute ethyl alcohol; then mixing by taking copper nitrate as a copper source and taking lanthanum nitrate as a lanthanum source, then adding ethyl orthosilicate, and mixing together, stirring and aging, moving to a far infrared drying box, and drying at 105 DEG C, thereby obtaining gel; then roasting gel for 3 hours, and then grinding into powder to obtain the catalyst. The photocatalytic material prepared by the invention is relatively mild in preparation condition, is simple in equipment, and selects butyl titanate and alcohol with low cost as raw materials without a complex technology adopting the sol-gel method for synthesizing traditionally, thereby preventing the influences of high-temperature treatment on morphology and stability of products; doped and compounded elements can be combined with the titanium dioxide catalyst well, thereby impacting the structure of the titanium dioxide catalyst. The catalyst has high catalytic activity, and improves the coking wastewater treatment efficiency greatly.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

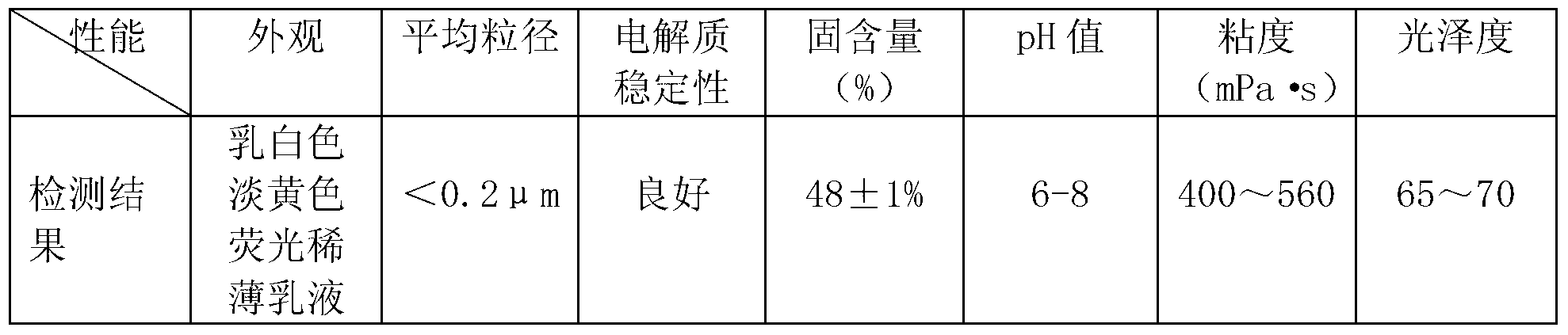

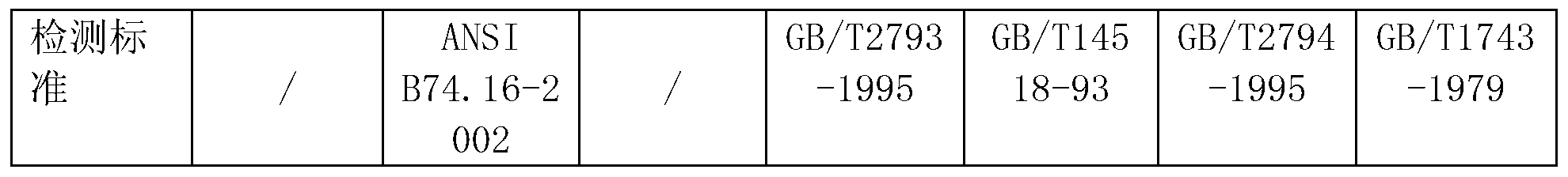

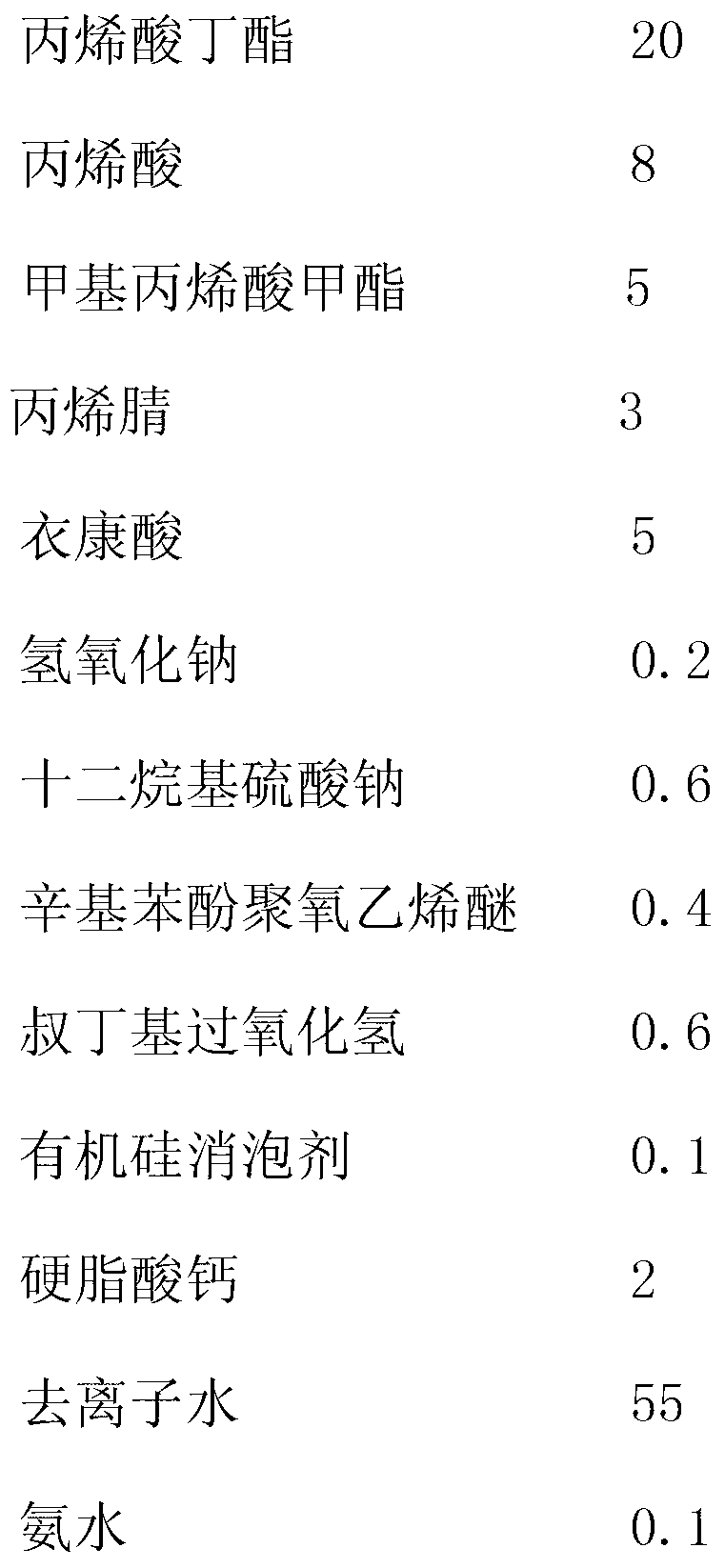

Acrylate copolymer emulsion paper-plastic composite adhesive and manufacturing method thereof

The invention relates to an acrylate copolymer emulsion paper-plastic composite adhesive which is prepared from the following raw materials in percentage by weight: 16-37% of butyl acrylate, 8-16% of acrylic acid, 5-11% of methyl methacrylate, 3-8% of acrylonitrile, 1-5% of itaconic acid, 0.1-0.3% of sodium hydroxide, 0.4-0.6% of initiator, 0.1-2% of composite emulsifier, 0.05-0.1% of ammonia water, 0.05-0.1% of defoaming agent, 2-6% of stabilizer and 15-64% of deionized water. The invention also relates to a preparation method of the acrylate copolymer emulsion paper-plastic composite adhesive. The invention has the advantages of abundant raw material sources, low synthesis cost and simple and stable production technique; and the prepared acrylate copolymer emulsion paper-plastic composite adhesive has the advantages of small and uniform particles, high drying rate and favorable storage stability, and is suitable for compounding paper-base presswork and plastics.

Owner:海南赛高新材料有限公司

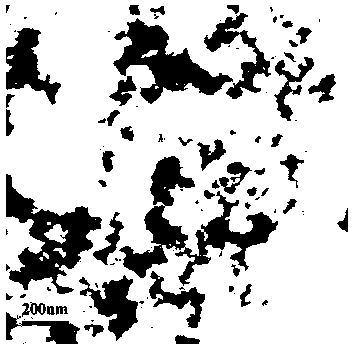

Nitrogen-doped titanium dioxide solvent thermal preparation method

InactiveCN1935668AAvoid growing upMild preparation conditionsPhysical/chemical process catalystsTitanium dioxideGas phaseSolvent

The invention provides a solvent-heat preparing method of N-doped TiO2, comprising: adding TiO2 into the solvent of N-containing organic alkali and water or alcohol, ultrasonic vibrating, pouring the mixture into a corrosion-resistant stainless steel hydrothermal reactor at room temperature, raising temperature to make solvent heat reaction, filtering, washing and drying and making it. And the invention overcomes the aggregation growth in the high temperature gas-phase reacting course, directly adopts TiO2 to one-step synthesize it by simple solvent heat synthesis process. And it has good dispersivity, small and uniform particles, high nitrogen doping quantity, high catalytic activity in the sun, etc.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of self-doped titanium dioxide nanorod

InactiveCN103240068AHigh catalytic activityAvoid profilePhysical/chemical process catalystsReduction treatmentPolyvinyl fluoride

The invention provides a preparation method of a self-doped titanium dioxide nanorod. The method comprises the following steps of: adding butyl titanate [Ti(OC4H9)4] into liquor of hydrazine (N2H4.H2O) and ethylene glycol (C2H6O2); powerfully stirring; then, transferring to a reaction kettle lined with polyvinyl fluoride; maintaining the constant temperature at 200 DEG C for 12-24 hours; naturally cooling to room temperature; and filtering, washing and drying to obtain the self-doped titanium dioxide nanorod provided by the invention. According to the method provided by the invention, self-doped titanium dioxide is directly reduced in a liquid phase without thermal reduction treatment. The preparation method is simple in process, and the self-doped TiO2 nanorod is controllable in size and uniform in dimension, and the average length is 50-80nm and the average diameter is 8-15nm. The self-doped titanium dioxide nanorod prepared by the method provided by the invention is expected to be widely applied to the fields of hydrogen generation by photolysis of water, degradation of organic pollutants and the like.

Owner:ZHANJIANG NORMAL UNIV

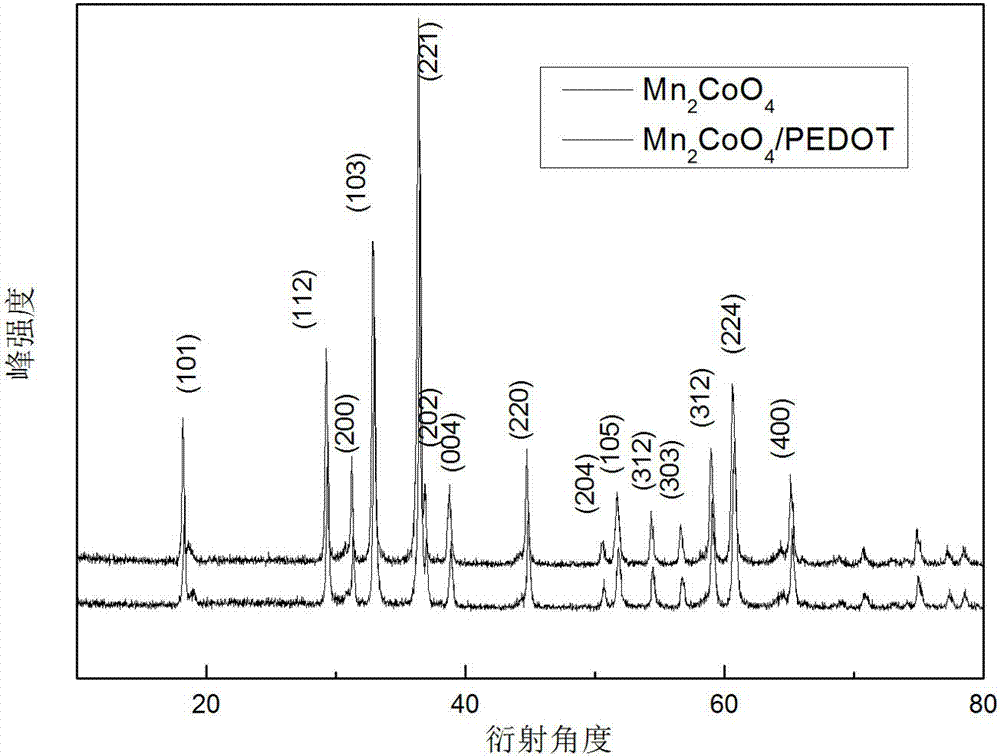

Preparation method of negative electrode material Mn2CoO4/poly(3,4-ethylenedioxythiophene)

InactiveCN104332626ALarge specific surface areaImprove conductivityCell electrodesSecondary cellsVapor deposition polymerizationConductive polymer

The invention provides a preparation method of a lithium ion secondary battery negative electrode material composite oxide Mn2CoO4 / poly(3,4-ethylenedioxythiophene) (PEDOT). The method comprises the steps of synthesizing Mn2CoO4 through a sol-gel process by using a manganese salt, a cobalt salt and an organic chelating reagent as raw materials, carrying out vapor deposition polymerization on EDOT to form PEDOT, and compounding the PEDOT with the Mn2CoO4 material. Mn2CoO4 particles synthesized through the method are small, have uniform dimension sizes and form a three dimensional netted structure, so the specific surface area of the material is increased, and the PEDOT is an excellent conductive polymer and has high conductivity, so the electrochemical performances of the composite negative electrode material are improved, has the advantages of simple preparation method and low cost, and is a promising material.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Dust control and noise reduction type feed crushing device

InactiveCN108355791AAvoid enteringReduce vibrationFeeding-stuffUsing liquid separation agentDust controlEngineering

The invention discloses a dust control and noise reduction type feed crushing device. The feed crushing device comprises a machine frame; an engine is arranged on the upper surface of the left side ofthe machine frame; damping devices are arranged at the bottom of the engine; a rotating shaft is arranged at the right end of the engine; bearings are arranged at the left end and the right end of the rotating shaft; sealing boxes are arranged between a feed crushing box and the bearings; magnetic strips are arranged at the left end and the right end of the inner wall of a feed port; an opening and closing bolt is arranged at the left end of a box cover; a coarse crushing wheel is arranged at the upper end of the inner wall of the feed crushing box; hammer carrier plates are arranged at the upper end and the lower end of the rotating shaft in the feed crushing box; the bottom of the feed crushing box communicates with a discharging device through a first pipeline; the discharging device communicates with a dust removal box through a second pipeline; a water tank is arranged on the upper surface of the dust removal box; spray heads are arranged at the top end of the inner wall of the dust removal box; and a filter screen is arranged at the left end of the inner wall of the dust removal box. The feed crushing device relates to the technical field of feed crushing. The dust control and noise reduction type feed crushing device has the advantages that the purposes of dust control and noise reduction and good crushing effect can be achieved, and dust pollution and noise pollution can be reduced.

Owner:佛山杰致信息科技有限公司

LiCoVO4 as well as preparation method and application thereof

ActiveCN107482169AFacilitated DiffusionRegular shapeCell electrodesSecondary cellsCobalt acetateLithium hydroxide

The invention relates to LiCoVO4 as well as a preparation method and an application thereof. The preparation method of LiCoVO4 comprises the following steps: a lithium hydroxide aqueous solution is uniformly mixed with an ammonium metavanadate suspension, and a reaction temperature is kept at 75 DEG C or higher until a colorless settled solution is obtained; the colorless settled solution and a cobalt acetate aqueous solution are uniformly mixed, the reaction temperature is kept at 75 DEG C or higher until a pale yellow suspension is obtained; the pale yellow suspension is subjected to a hydrothermal reaction, the reaction temperature is kept at 160-220 DEG C, the reaction time is kept for 18-24 h, and LiCoVO4 is obtained. With adoption of the preparation method of LiCoVO4, morphology of obtained LiCoVO4 can be controlled, obtained LiCoVO4 is regular in morphology, particles are smaller and uniform, and diffusion of Li ions is facilitated, so that the application is facilitated.

Owner:苏州协鑫集成储能科技有限公司 +2

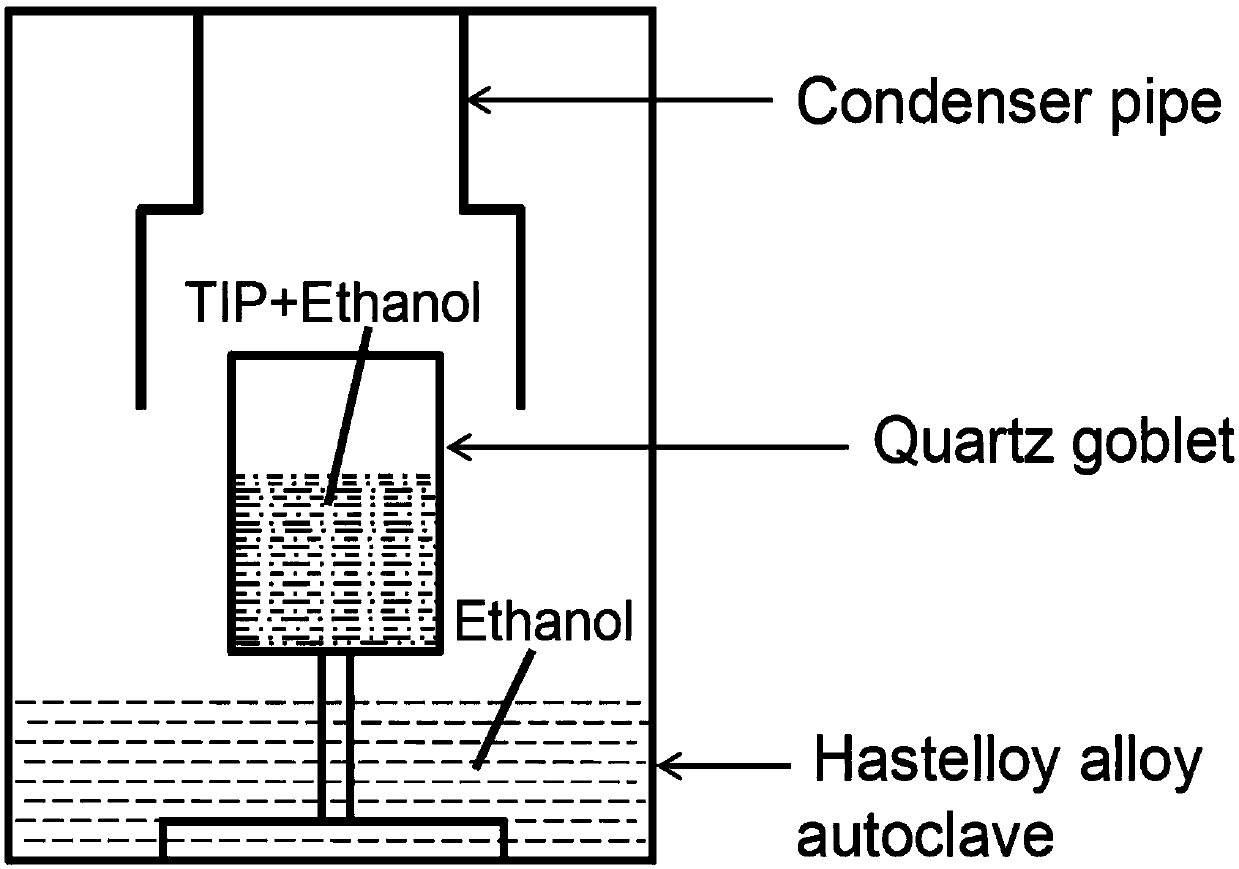

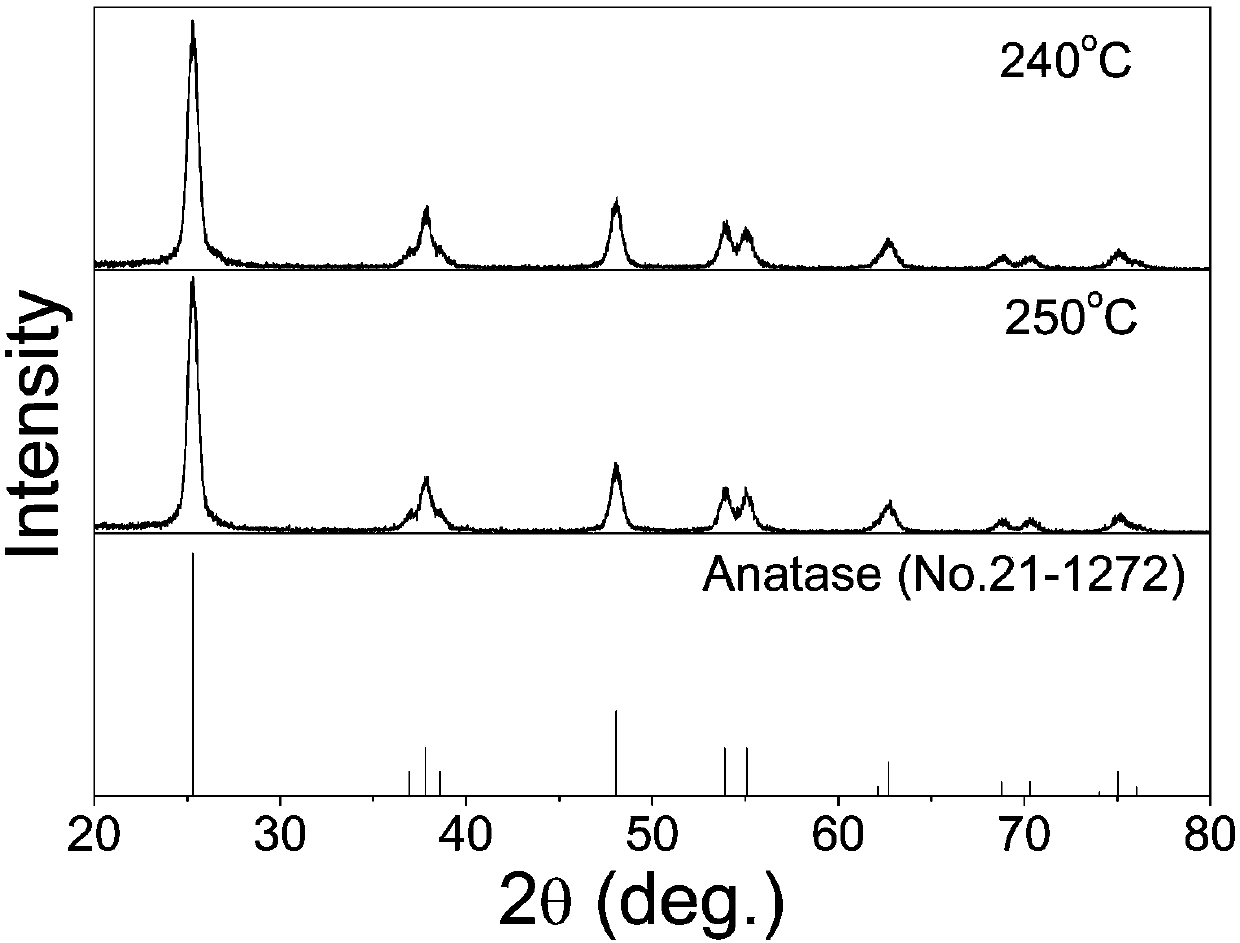

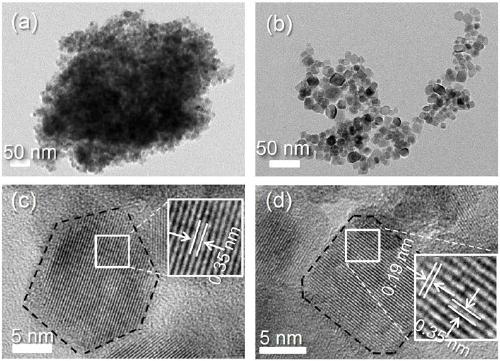

Method for preparation of TiO2 by steam hot solution evaporation

InactiveCN110156073AReduce the rate of hydrolysisHigh crystallinityPhysical/chemical process catalystsTitanium dioxideOrganic solventLiquid state

The invention discloses a method for preparation of TiO2 by steam hot solution evaporation. The method includes: dripping a titanium salt into an organic solvent, performing magnetic stirring and mixing, transferring the mixture into a standing quartz cup, then adding an organic solvent into a Hadtelloy alloy reaction kettle, and putting the standing quartz cup into the reaction kettle, carrying out steam hydrothermal reaction for 5h, then introducing cooling water to a condenser pipe in the reaction kettle to rapidly lower the temperature inside the kettle, after cooling to room temperature,taking out the product from the cup, when the product in the cup is in a solid state, performing levigating to obtain a TiO2 photocatalyst, and when the product in the cup is in a liquid state, conducting solid-liquid separation, then adding ethanol and performing washing, and then conducting drying in a vacuum oven to obtain the TiO2 photocatalyst. The TiO2 photocatalyst obtained by the method provided by the invention has the characteristics of excellent catalytic performance and simple and safe preparation process, and has good application prospects in the field of photocatalysis.

Owner:ANHUI UNIVERSITY

Bent tempered glass manufacturing device and manufacturing process

InactiveCN102951835AImprove flatnessHigh mechanical strengthGlass reforming apparatusGlass tempering apparatusEngineeringHeating furnace

The invention relates to a bent tempered glass manufacturing device and a manufacturing process; the device comprises an upper piece bench, a heating furnace body, a hot bending section, a sharp quenching tempering section, a continuously cooling section and a lower piece bench; independent transmission chains are arranged in all the sections; all the sections are matched by program to complete the transmission of glass in a whole set of equipment; the transmission chains are controlled by transmission motors; air cooling devices are arranged at the sharp quenching tempering section and the continuously cooling section; and according to the bent tempered glass manufacturing device and the manufacturing process, the defects of traditional tempered glass processing devices and processes are overcome, so that the levelness of the processed glass, particularly the levelness and the mechanical strength of an arc side are very good, particles are small and uniform after the glass is cracked.

Owner:CHANGZHOU NANXIN GLASS

Preparation method and application of catalyst of novel light degradation phosphate organic dye

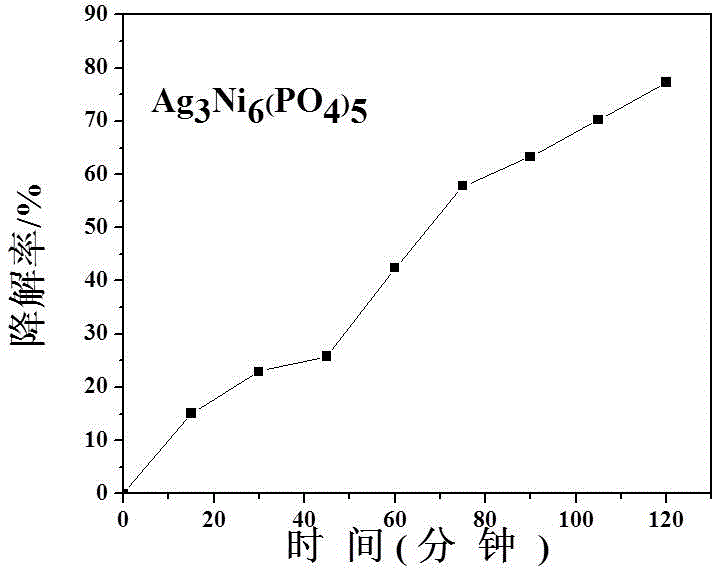

InactiveCN104549387AEasy to prepareSimple process equipmentPhysical/chemical process catalystsWater/sewage treatment by irradiationChemical solutionPhosphate

The invention relates to a novel phosphate photocatalytic material Ag3Ni6 (PO4)5 and a preparation method thereof, and belongs to the field of novel inorganic photocatalytic materials. The photocatalytic material is prepared by a high-temperature solid-phase method, a chemical solution method, and a co-precipitation method. The technology is simple and easy to operate, and is convenient for industrial production, and the prepared material has uniform particles, good chemical stability, relatively good photocatalytic effects, and good stability, can be used for degrading organic pollutants under the radiation of ultraviolet light and visible light, and is an ideal material for the photocatalyst.

Owner:SUZHOU DEJIE MEMBRANE MATERIAL SCI & TECH

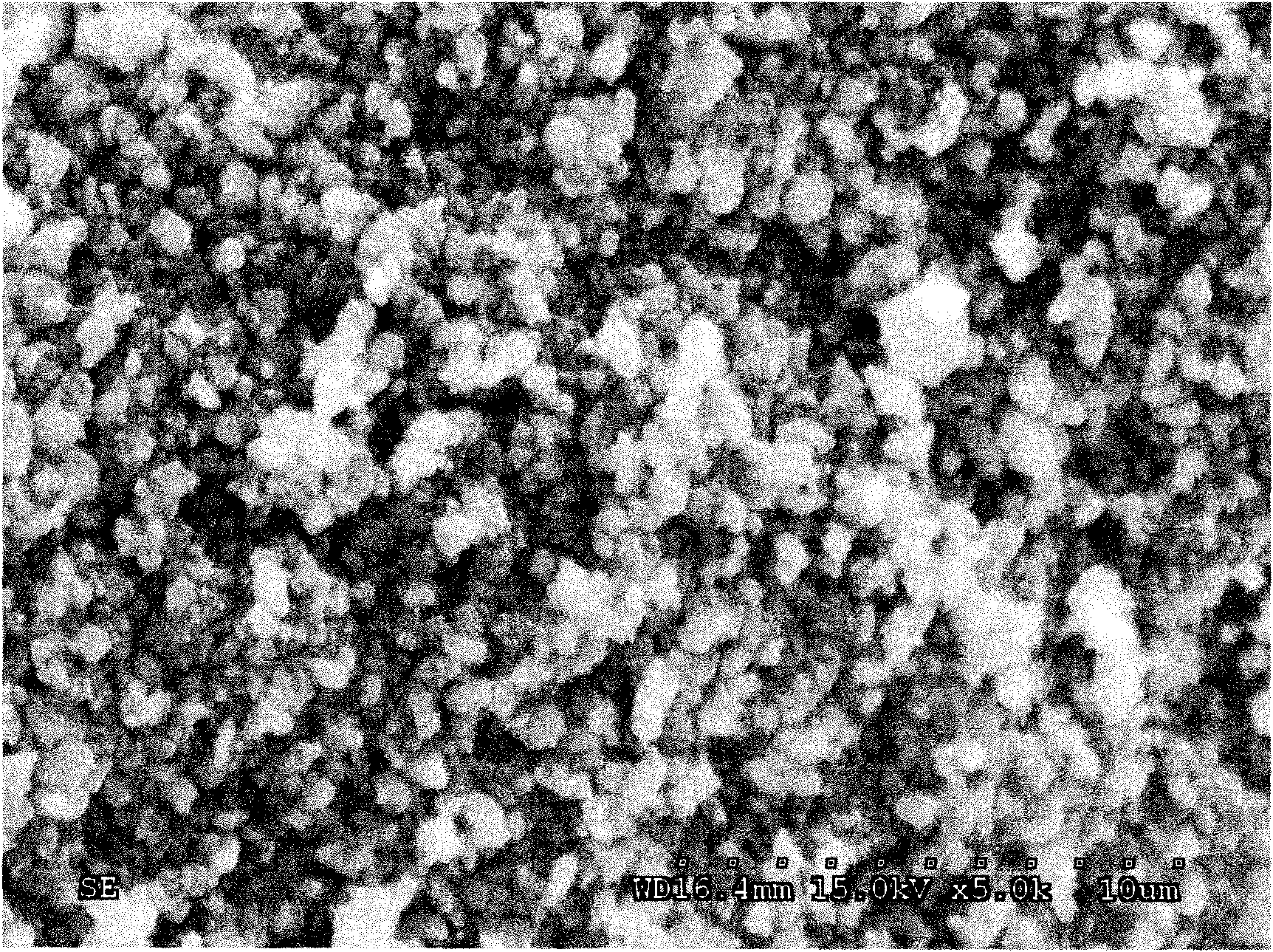

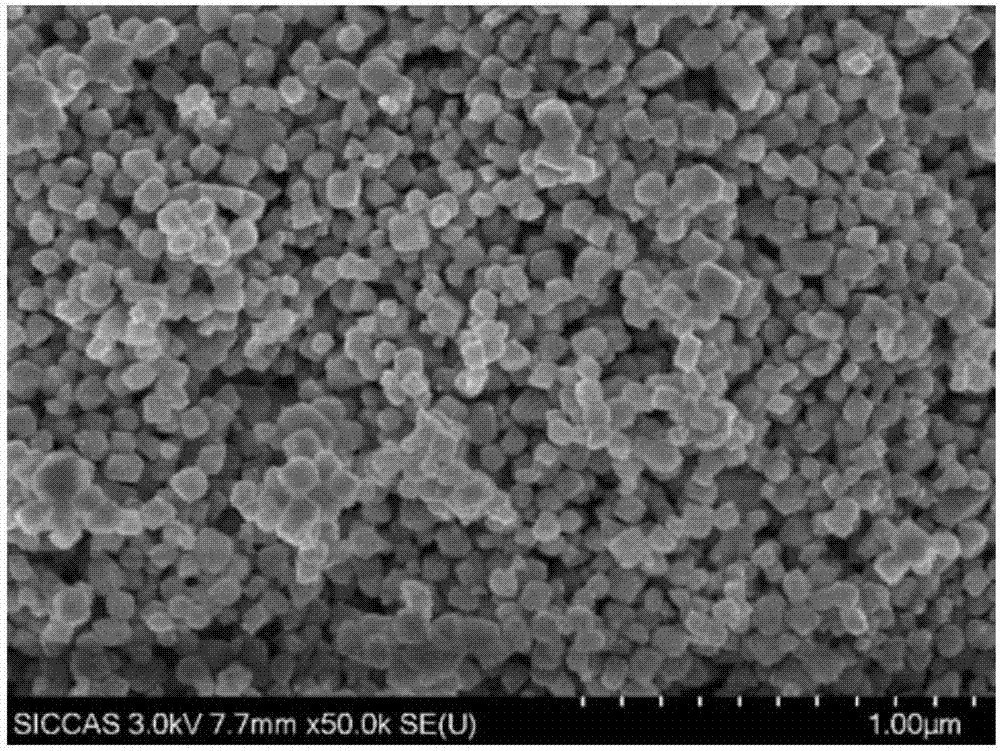

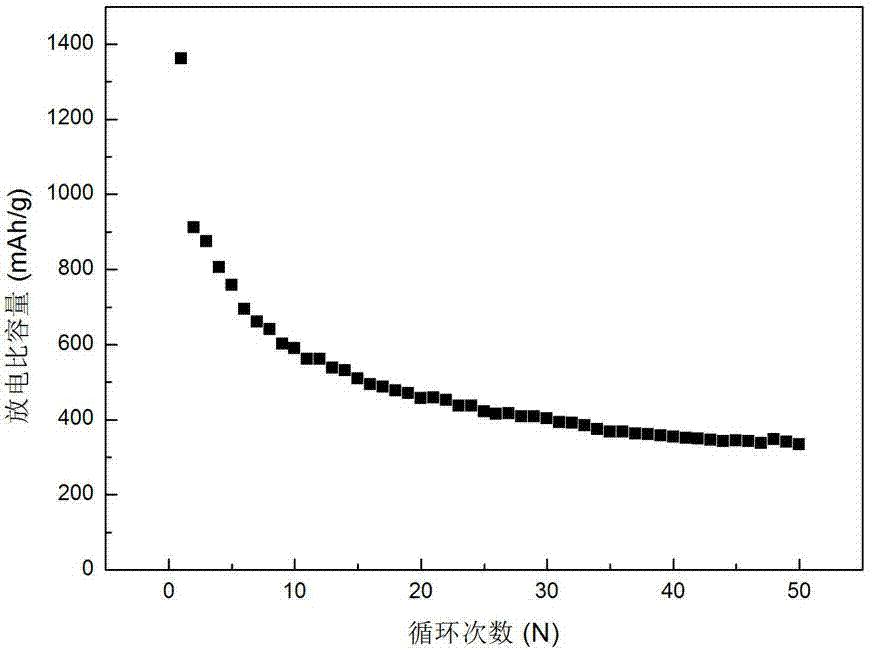

Preparation method of lithium ion secondary battery negative material manganese cobalt oxide

InactiveCN104332623AParticles are small and uniformLarge specific surface areaCell electrodesCobalt compoundsInorganic saltsManganese

The invention provides a preparation method of a lithium ion secondary battery negative material manganese cobalt oxide. The method comprises the following steps: dissolving a manganese salt and a cobalt salt in an uniform medium, magnetically stirring until complete dissolving, adding a bifunctional chelating agent into deionized water to wet the bifunctional chelating agent, adding ammonia water, shaking to form a colorless transparent solution, and adding the colorless transparent bifunctional chelating agent solution into an aqueous solution of an inorganic salt to form a transparent solution; and drying the finally obtained solution by a spray dryer to obtain powder, and calcining the powder at 700-850DEG C to obtain the required product manganese cobalt oxide (Mn2CoO4). Synthesized Mn2CoO4 particles are small and have a uniform dimension size, so the specific surface area of the material is increased, thereby the electrochemical performances of the negative material are improved; and the material also has the advantages of simple preparation method and low cost, and is a promising material.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Functional health microcapsule of turtle oil and for blood fat reduction and preparation method thereof

InactiveCN102511825AGood for lowering blood fatImprove immunityFood preparationAdditive ingredientActive component

The invention discloses a functional health microcapsule of turtle oil. Active components of the microcapsule comprise, by weight, 500-600 parts of turtle oil, 800-900 parts of oil tea seed oil, 100-200 parts of Chinese torreya oil and 10-15 parts of vitamin E. The functional health microcapsule of turtle oil of the invention utilizes synergistic effects of the turtle oil, the oil tea seed oil, the Chinese torreya oil and vitamin E and has good immunity function enhancement effects and the blood fat reduction function; and the microcapsule can be used to prepare health products or medicines for the blood fat reduction and / or the immunity increase. The invention also discloses a preparation method of the microcapsule. The preparation process of the method is simple, so the method is suitable for the industrialized production.

Owner:ZHEJIANG CHENGDA BIOLOGICAL TECH DEV

Catalyst for preparing acrylic acid through propane selective oxidation and preparation method of catalyst

ActiveCN103691457ASmall particlesLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationActive componentPetrochemical

The invention belongs to the technical field of petrochemical engineering, in particular relates to a catalyst for preparing acrylic acid through propane selective oxidation and a preparation method of the catalyst. The catalyst has a formula of MoaVbTecNbdOx, wherein Mo, V, Te and Nb are active components; a : b : c : d is 1 : (0.2-0.3) : (0.2-0.3) : (0.1-0.2). When the catalyst is adopted to prepare the acrylic acid, the conversion rate of the propane and the once-through yield of the acrylic acid are high.

Owner:临沂星火知识产权服务有限公司

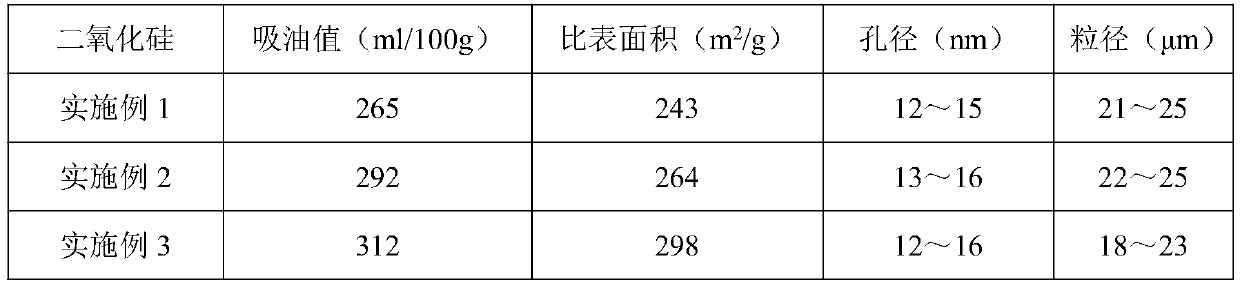

A kind of highly adsorbed and highly dispersed silicon dioxide and its preparation method

ActiveCN108821298BGood dispersionGood suspensionInorganic/elemental detergent compounding agentsSilicaSilica particlePhysical chemistry

Disclosed are a preparation method for a high-adsorption and high-dispersion silicon dioxide and the silicon dioxide prepared thereby. The method comprises: I. adding Carbopol resin to a sodium sulfate solution and stirring same to obtain a mixed solution; II. adding the mixed solution to a reaction kettle, adding a sodium silicate solution under stirring, heating same to 80ºC-90ºC, adding sulphuric acid, stopping the addition of the sulphuric acid when the pH value is 8.0-9.0, and curing same; III. adding the sodium silicate solution and sulphuric acid simultaneously, and controlling the pH value at 8.0-9.0, continuing to add the sulphuric acid when the addition of the sodium silicate solution is completed, stopping the addition of the sulphuric acid when the pH value is 3.5-4.0, and stirring same to obtain a silicon dioxide slurry; and IV. filter pressing and washing the silicon dioxide slurry, and subjecting same to spray drying so as to obtain the high-adsorption and high-dispersion silicon dioxide with a particle diameter of 18-25 µm. The silicon dioxide particles are small and uniform, have high adsorption and high dispersion properties, and can be used as a detergent auxiliary which can be directly added to detergent and can bring about good anticaking and flow-aiding effects.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

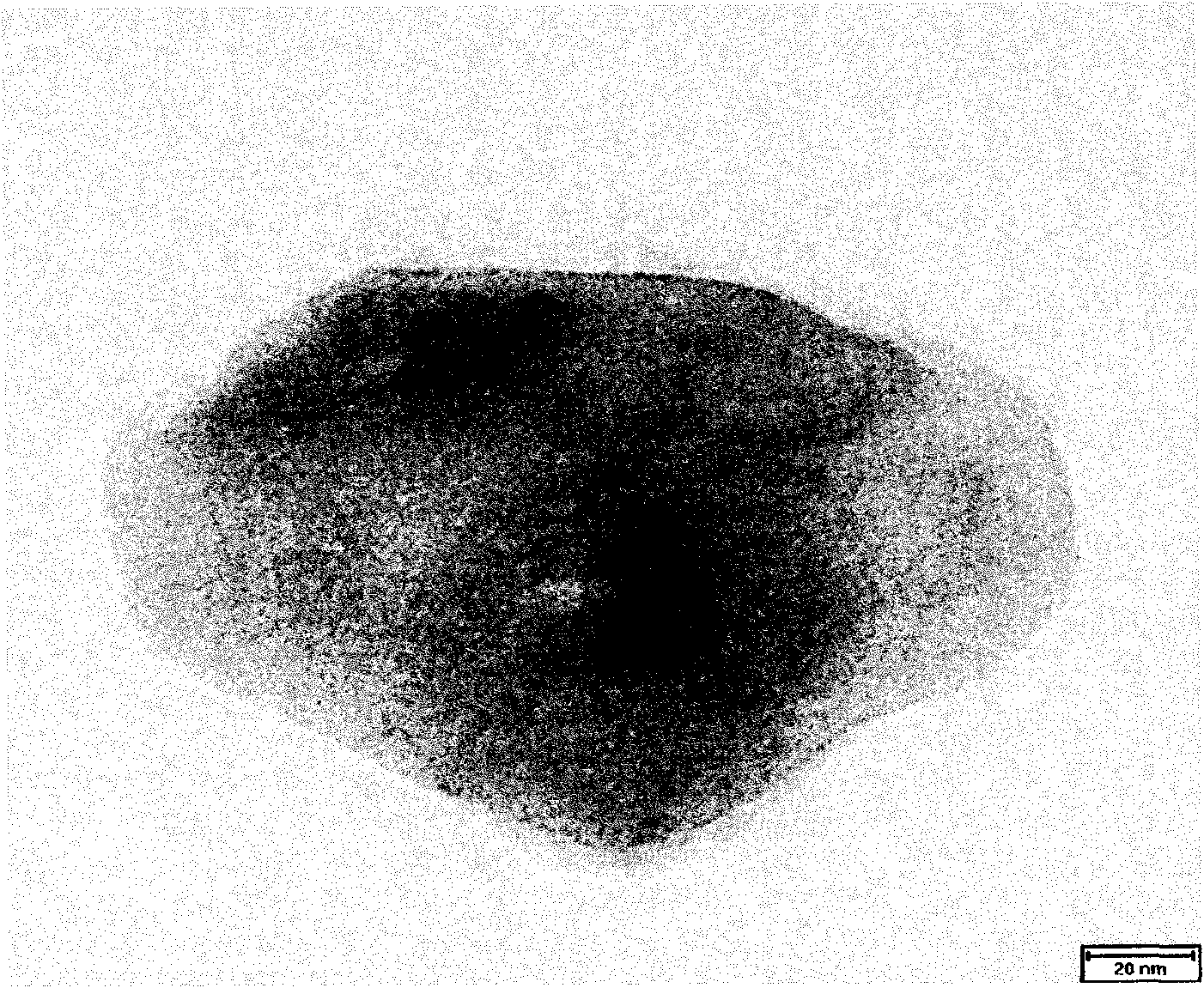

Carbon-based chemical energy storage material and preparation method thereof

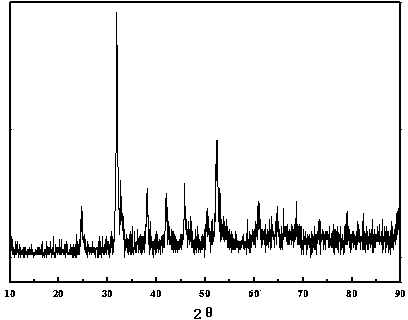

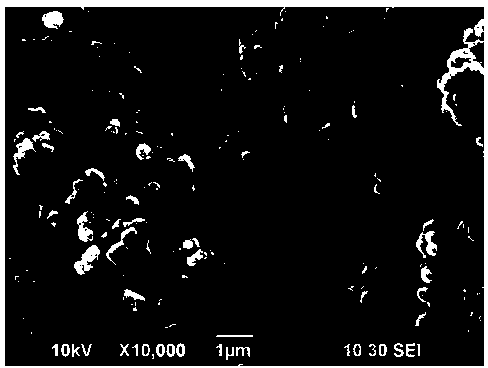

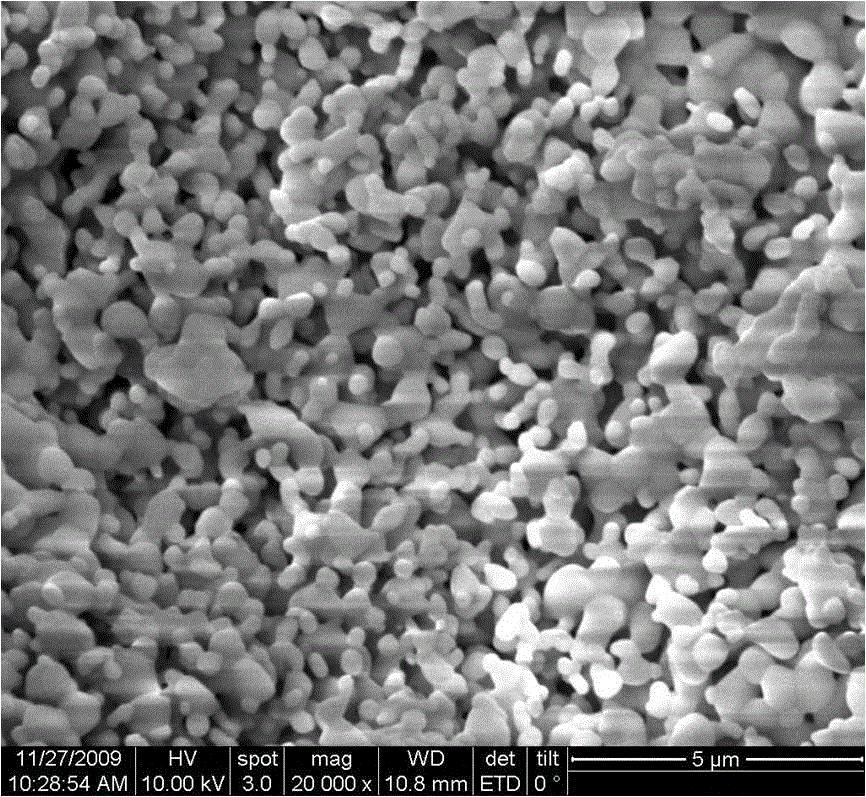

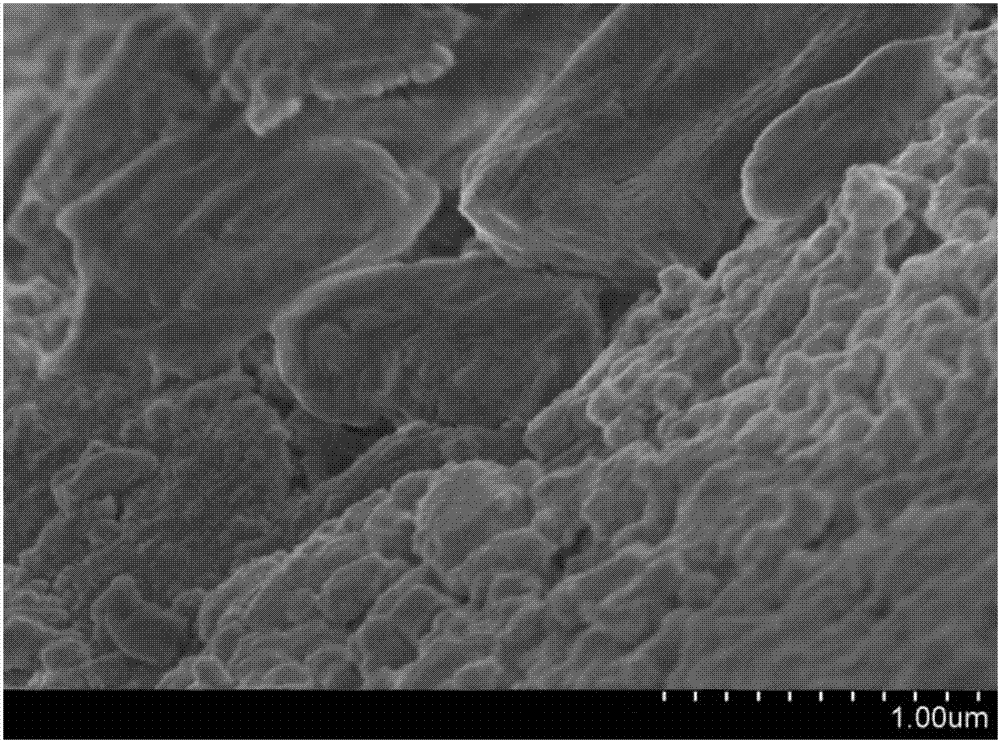

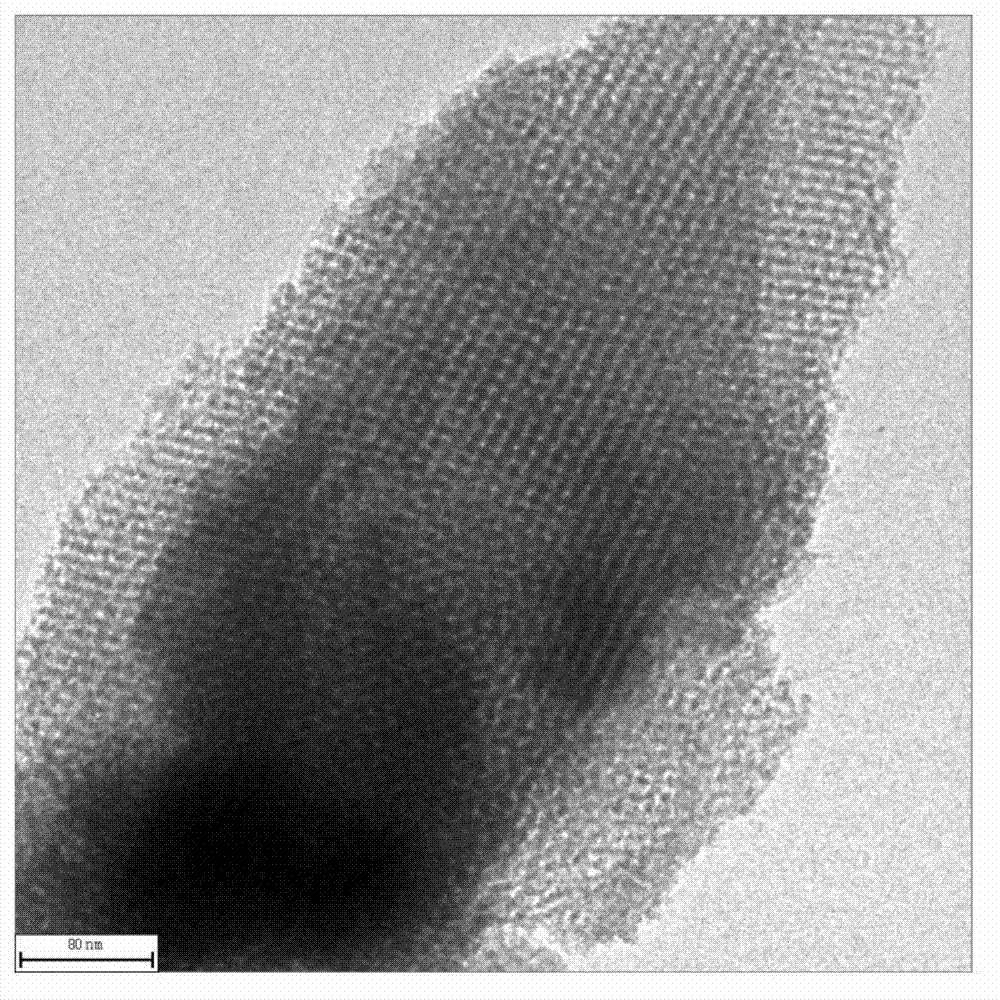

InactiveCN107236525AGood dispersionParticles are small and uniformHeat-exchange elementsX-rayScanning electron microscope

The invention discloses a carbon-based chemical energy storage material and a preparation method thereof. The method comprises the step of adopting a direct physical impregnation method, an ultrasonic method or a hydrothermal method for compounding a carbon-based carrier material (Ni-CNTs composite) with an active component LiOH-H2O, thereby obtaining the carbon-based chemical energy storage material. The representation means, such as, scanning electron microscope (SEM), transmission electron microscopy (TEM), X ray diffraction analysis meter (XRD) and thermogravimetry / synchronous differential thermal analyzer (TGA-DSC), are adopted for obtaining key thermophysical parameters, such as appearance, loading components and thermal storage density, of the composite. The compounding of the nanometer carbon material can greatly promote the hydration rate of the LiOH monomer while the energy storage density is increased at various degrees. Besides, the overall heat conductivity coefficient of the material is also obviously increased due to the compounding of the nanometer carbon material.

Owner:SOUTH CHINA UNIV OF TECH

Method for synthesizing SiO2 lithium ion battery cathode material lithium titanate

InactiveCN102903899AImproved magnification performanceImprove cycle performanceMaterial nanotechnologyCell electrodesSynthetic materialsTube furnace

The invention discloses a method for synthesizing SiO2 lithium ion battery cathode material lithium titanate, which provides the method for preparing a nano lithium titanate material with excellent high rate performance and cycle performance. The method comprises the following steps: weighting a certain amount of P123, dissolving with deionized water, stirring to completely dissolve, adding 2mol / L of hydrochloric acid, performing micro-thermal agitation, slowly adding TEO drop by drop, stirring with high speed for 10-30 hours under water bath at the temperature of 20-50 DEG C, then conversing to a stainless steel reaction kettle, crystallizing for 24-28 hours at the temperature of 80-120 DEG C; using deionized water to wash the product to neutrality, drying under the temperature of 100 DEG C, heating the synthetic material in a muffle furnace with the heating speed of 1-5 DEG C / min to the temperature of 450-650 DEG C, keeping the temperature for 12-24 hours to obtain a nano mesoporous SiO2 template, heating the nano mesoporous SiO2 template to the temperature of 80-120 DEG C, dissolving a certain amount of lithium resource and titanium source by a corresponding solvent, adding into the template drop by drop, then sintering in a tube furnace under the temperature of 750-850 DEG C for 8-12 hours, removing the template by a hot highly concentrated alkali solution, washing by distilled water, drying and crushing to obtain the lithium titanate.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Single-step hydrothermal micro-emulsion method for preparing iron-doped nano titanium dioxide powder

InactiveCN103537286BAvoid stabilityMild preparation conditionsMetal/metal-oxides/metal-hydroxide catalystsAlkylphenolOil phase

The invention relates to a single-step hydrothermal micro-emulsion method for preparing iron-doped nano titanium dioxide powder. The single-step hydrothermal micro-emulsion method specifically comprises the following steps of constituting water-in-oil W / O type micro-emulsion by using alkylphenol ethoxylates (OP-10) as a surfactant, using n-butyl alcohol (C4H9OH) as a cosurfactant, using cyclohexane (C6H12) as an oil phase, using butyl titanate (Ti(OC4H9)4) as a titanium source and using hydrochloric acid (HCl) liquor of ferric chloride (FeCl3.6H2O) as a water phase; uniformly stirring, and transferring into a lined polytetrafluoroethylene reaction kettle for keeping heat for 1 hour-5 hours at a constant temperature of 120 DEG C-160 DEG C, naturally cooling to the room temperature; and washing, separating and drying to prepare the iron-doped nano titanium dioxide powder. According to the single-step hydrothermal micro-emulsion method disclosed by the invention, the iron-doped titanium dioxide is obtained by directly reacting in a low-temperature liquid phase, the preparation process is simple, and the prepared iron-doped nano TiO2 powder is controllable in dimension, uniform in size and provided with average diameter of 10 nm-25 nm; moreover, the iron-doped nano TiO2 powder is expected to be widely applied in the fields such as hydrogen production by photodecomposition of water, degradation of organic pollutants, and the like.

Owner:ZHANJIANG NORMAL UNIV

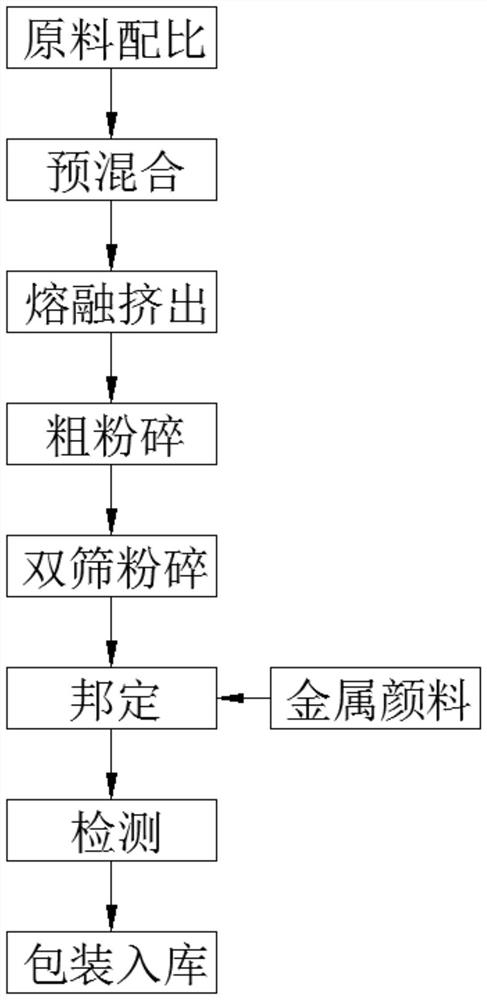

Novel high-grade powder coating and preparation method thereof

InactiveCN111635691AHigh impact strengthAcid resistantPowdery paintsGrain treatmentsCoated surfaceWeather resistance

The invention discloses a novel high-grade powder coating and a preparation method thereof. The problems that the existing powder coating is poor in impact strength and acid and alkali resistance, thelubricity of the powder coating cannot meet the use requirements, in addition, in the powder coating production process, the problem of oxidative decomposition of body resin is easily caused due to the problems of an agent discharging method, the quality of the powder coating is further influenced are solved. The matching of the powder coating and the synthesis method of the powder coating are improved and optimized, so the powder coating has high impact strength, strong acid resistance, alkali resistance, salt spray resistance and weather resistance, and flat and smooth coating surface, thecuring time can be shortened, the purposes of energy conservation, low carbon and environmental protection are achieved, and the use performance of the powder coating is improved; and matrix resin oxygenolysis can be avoided by adopting a deep thread low-temperature extrusion method in the production process of the powder coating. Double-screening fine grinding is adopted to guarantee that matrixresin particles are small and uniform, so thin coating can be conducted, and the coating effect is better.

Owner:ANHUI MEIJIA NEW MATERIAL

Catalyst for preparing acrylic acid by selective oxidation of propane and preparation method thereof

ActiveCN103691457BSmall particlesLarge specific surface areaPhysical/chemical process catalystsOrganic compound preparationActive componentPetrochemical

The invention belongs to the technical field of petrochemical engineering, in particular relates to a catalyst for preparing acrylic acid through propane selective oxidation and a preparation method of the catalyst. The catalyst has a formula of MoaVbTecNbdOx, wherein Mo, V, Te and Nb are active components; a : b : c : d is 1 : (0.2-0.3) : (0.2-0.3) : (0.1-0.2). When the catalyst is adopted to prepare the acrylic acid, the conversion rate of the propane and the once-through yield of the acrylic acid are high.

Owner:临沂星火知识产权服务有限公司

Mosquito repellent IR3535 loaded ethyl cellulose microparticles and preparation method thereof

InactiveCN103622840AGood adhesionParticles are small and uniformCosmetic preparationsToilet preparationsCellulosePolyvinyl alcohol

The invention discloses mosquito repellent IR3535 loaded ethyl cellulose microparticles and a preparation method thereof. The mosquito repellent IR3535 loaded ethyl cellulose microparticles have a core-shell structure in which the core is mosquito repellent IR3535 and the shell is ethyl cellulose; at 25 DEG C, the mean grain size of the mosquito repellent IR3535 loaded ethyl cellulose microparticles ranges from 500nm to 5873nm. The preparation method comprises the steps: dissolving polyvinyl alcohol and an emulsifier Tween80 in deionized water at the room temperature, and stirring so that the polyvinyl alcohol and the emulsifier Tween80 are dissolved into a water phase; dissolving the IR3535 and the ethyl cellulose and span-80 in methyl acetate to obtain a mixture as an oil phase; mixing the obtained oil phase with the water phase, homogenizing and emulsifying to obtain an emulsion; and continuing stirring at the room temperature, centrifuging after the methyl acetate volatilizes completely, thus finally, obtaining the mosquito repellent IR3535 loaded ethyl cellulose microparticles having an embedding rate ranging from 33.5% to 77.1%.

Owner:SHANGHAI INST OF TECH

Preparation technique for soft-magnetic manganese-zinc ferrite powder

The invention discloses a manufacturing technique of magnetic ferrite material, in particular to a manufacturing technique of flexible magnetic manganese-zinc ferrite powder, which comprises the following steps: wetting to grind; spraying; graining; pre-sintering; vibrating and balling the pre-sintered material; proceeding secondary wet-grinding and secondary spraying graining. The invention is beneficial to finish solid phase completely during pre-sintering, which reduces power consumption and power dust pollution with high original magnetic conductivity.

Owner:MIANYANG KAIYUAN MAGNETIC MATERIAL

Technology for preparing nanometer rare-earth oxide

InactiveCN1296282CPromote generationGuaranteed uniformityOxygen/ozone/oxide/hydroxideRare earth metal compoundsRare earthMicroemulsion

A process for preparing nano rearearth oxide wherein the rearearth carbonic acid is used as raw material, dissolved in nitric acid, filtered, added with slow released precipitator and dispersant after being filtered, added with dispersant after obtaining fore unit, through ultrasonic wave oscillating, microemulsion ultrasonic washing, filtering, drying, calcinating to obtain said nano rearearth oxide. In said invention, microemulsion homogeneous precipitation process is used which is favour to form precipitation grain kernel and adverse to kernel growth to keep the productive grain size small and uniform and eliminate agglomeration.

Owner:BAOTOU HUAMEI RE PRODS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com