Acrylate copolymer emulsion paper-plastic composite adhesive and manufacturing method thereof

A technology of acrylate and copolymer emulsion, which is applied in the direction of ester copolymer adhesive, adhesive type, etc., can solve the problems of inability to combine ink with BOPP film, weak adhesion, slow drying speed, etc., and achieve production The process is simple and stable, the mechanical adaptability is good, and the latex particle size is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

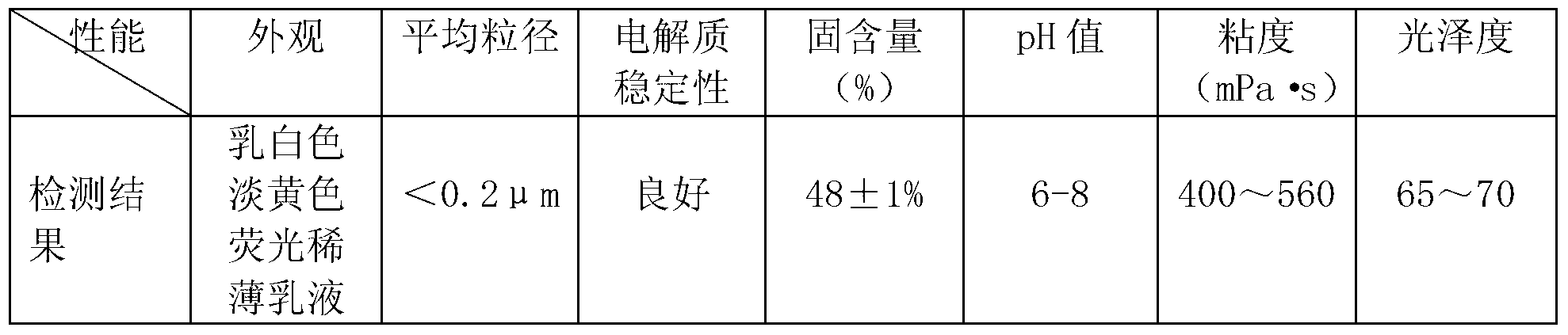

[0028] Prepared according to the following weight ratio of raw materials (%):

[0029]

[0030] (1) Washing and pre-emulsification of monomers: Add 200kg of butyl acrylate, 80kg of acrylic acid, 50kg of methyl methacrylate, 30kg of acrylonitrile, 50kg of itaconic acid, and 150kg of deionized water into the pre-emulsification device, decompressed distillation to remove the polymerization inhibitor, and washed with 2kg of 10% sodium hydroxide solution, started stirring for 30min, the appearance of the mixed solution was uniform milky white, stopped stirring, and obtained pre-emulsion A.

[0031] (2) Preparation of compound emulsifier: put 6kg of anionic emulsifier sodium lauryl sulfate and 4kg of nonionic emulsifier octylphenol polyoxyethylene ether in a clean container at a ratio of 3:2, and stir for 15 minutes to make Mix them evenly to obtain compound emulsifier B.

[0032] (3) Seed emulsion polymerization: Add 400kg of deionized water, all of the compound emulsifier B, 3...

Embodiment 2

[0036] Prepared according to the following weight ratio of raw materials (%):

[0037]

[0038]

[0039] (1) Washing and pre-emulsification of monomers: Add 160kg of butyl acrylate, 120kg of acrylic acid, 5kg of methyl methacrylate, 3kg of acrylonitrile, 10kg of itaconic acid, and 120kg of deionized water into the pre-emulsification device, remove the polymerization inhibitor by distillation under reduced pressure, and wash with 1kg of 10% sodium hydroxide solution, start stirring for 30 minutes, the appearance of the mixed solution is uniform milky white, stop stirring to obtain pre-emulsion A.

[0040] (2) Preparation of compound emulsifier: put 0.6kg of anionic emulsifier sodium lauryl sulfate and 0.4kg of nonionic emulsifier octylphenol polyoxyethylene ether in a clean container at a ratio of 3:2, and stir for 15 minutes to make Mix them evenly to obtain compound emulsifier B.

[0041](3) Seed emulsion polymerization: add 450kg of deionized water, all of the compoun...

Embodiment 3

[0045] Prepared according to the following weight ratio of raw materials (%):

[0046]

[0047] (1) Washing and pre-emulsification of monomers: Add 370kg of butyl acrylate, 10kg of acrylic acid, 5kg of methyl methacrylate, 3kg of acrylonitrile, 10kg of itaconic acid, and 100kg of deionized water into the pre-emulsification device , remove the polymerization inhibitor by distillation under reduced pressure, wash with 1kg10% sodium hydroxide solution, start stirring for 30min, the appearance of the mixed solution is uniform milky white, stop stirring to obtain pre-emulsion A.

[0048] (2) Preparation of compound emulsifier: put 0.6kg of anionic emulsifier sodium lauryl sulfate and 0.4kg of nonionic emulsifier octylphenol polyoxyethylene ether in a clean container at a ratio of 3:2, and stir for 15 minutes to make Mix them evenly to obtain compound emulsifier B.

[0049] (3) Seed emulsion polymerization: Add 330kg of deionized water, all of the compound emulsifier B, 2kg of i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com