A kind of highly adsorbed and highly dispersed silicon dioxide and its preparation method

A silicon dioxide, high dispersion technology, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problems of poor dispersion and large particle size, and achieve the effect of reducing particle size, small particle size and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

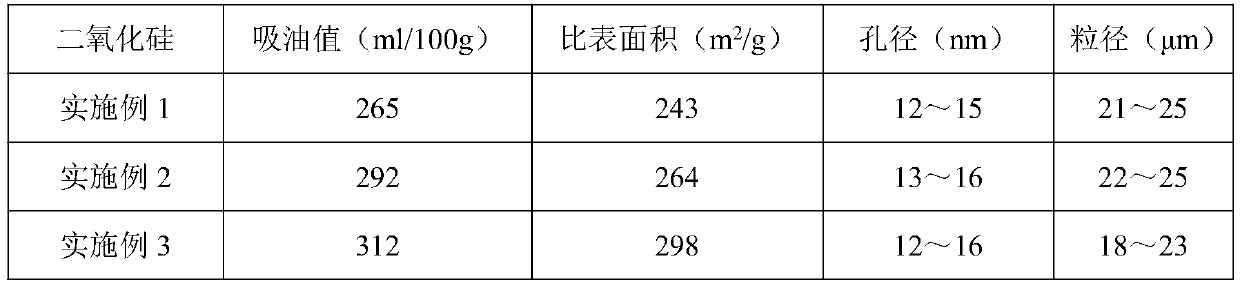

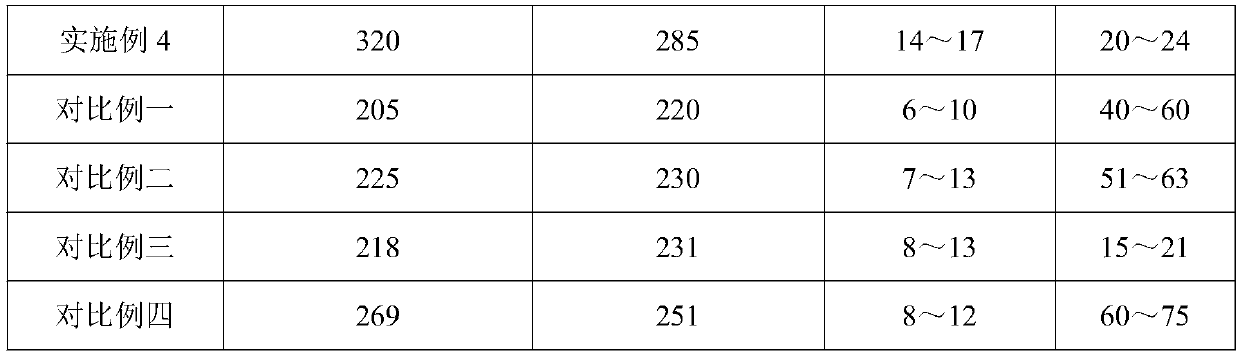

Examples

Embodiment 1

[0028] Example 1. Highly adsorbed and highly dispersed silica of the present invention and its preparation

[0029] The first step, after dispersing 1.8kg of carbomer resin with 4kg of water, add 9m of sodium sulfate solution 3 , stirred for 30 minutes to obtain a mixed solution;

[0030] The second step, add the mixed solution to the reaction kettle, and add 1.5m sodium silicate solution under stirring 3 , heated to 80°C, and then at 3.0m 3 Add sulfuric acid solution at a flow rate of / h to carry out acid-base neutralization reaction. When the pH value reaches 8.0, stop adding acid and mature for 10 minutes; the total time for adding acid in this section is 25 minutes, that is, the reaction time is 25 minutes;

[0031] The third step, add sodium silicate solution 8m at the same time 3 and sulfuric acid solution, carried out co-current neutralization reaction for 30 minutes, during which by regulating the flow velocity of sodium silicate solution and sulfuric acid solution ...

Embodiment 2

[0034] Example 2. Highly adsorbed and highly dispersed silica of the present invention and its preparation

[0035] The first step, after dispersing 8.8kg of carbomer resin with 18kg of water, add 11m of sodium sulfate solution 3 , stirred for 30 minutes to obtain a mixed solution;

[0036] The second step is to add the mixed solution to the reaction kettle, and add 3.0m sodium silicate solution under stirring. 3 , heated to 90°C, and then at 3.5m 3 Add sulfuric acid solution at a flow rate of / h to carry out acid-base neutralization reaction. When the pH value reaches 9.0, stop adding acid and ripen for 10 minutes; the total time for adding acid in this section is 35 minutes, that is, the reaction time is 35 minutes;

[0037] The third step, add sodium silicate solution 10m at the same time 3 And sulfuric acid solution, carry out co-current neutralization reaction 40 minutes, during this period, by regulating the flow velocity of sodium silicate solution and sulfuric acid so...

Embodiment 3

[0040] Example 3, Highly Adsorbed and Highly Dispersed Silica of the Present Invention and Its Preparation

[0041] The first step, after dispersing 5.5kg of carbomer resin with 10kg of water, add 11m of sodium sulfate solution 3 , stirred for 30 minutes to obtain a mixed solution;

[0042] The second step is to add the mixed solution to the reaction kettle, and add 3.0m sodium silicate solution under stirring. 3 , heated to 85°C, then at 3.0m 3 Add sulfuric acid solution at a flow rate of / h to carry out acid-base neutralization reaction. When the pH value reaches 8.0, stop adding acid and ripen for 10 minutes; the total time for adding acid in this section is 30 minutes, that is, the reaction time is 30 minutes;

[0043] The third step, add sodium silicate solution 8m at the same time 3 and sulfuric acid solution, carried out co-current neutralization reaction for 35 minutes, during which by regulating the flow velocity of sodium silicate solution and sulfuric acid soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com