Carbon-based chemical energy storage material and preparation method thereof

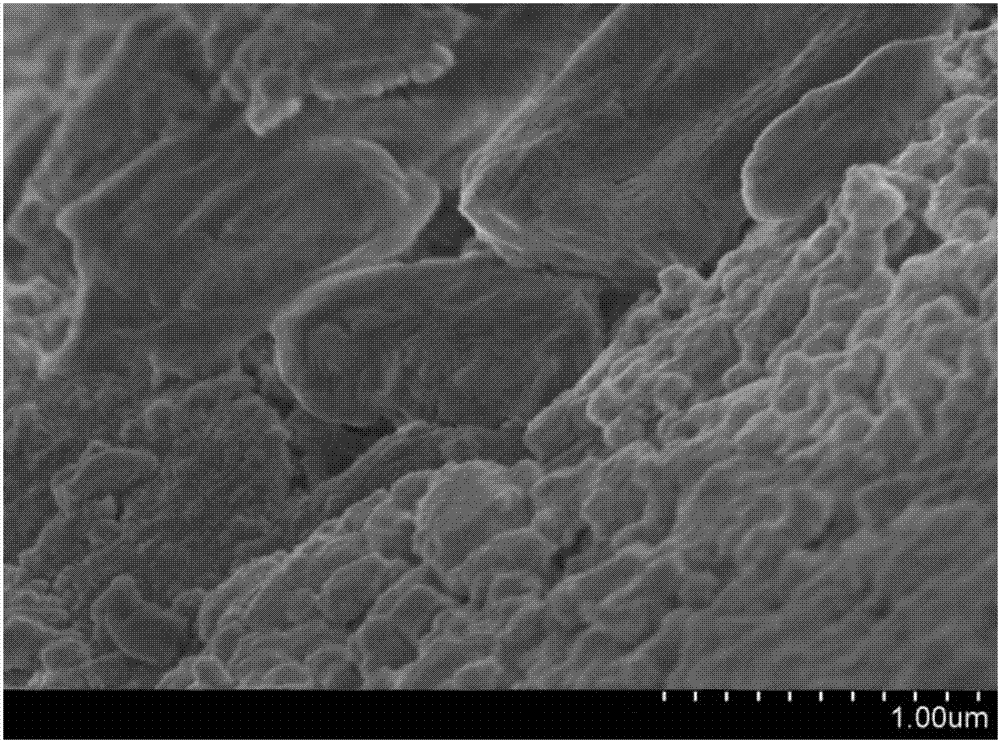

An energy storage material and chemical technology, which is applied in the field of carbon-based chemical energy storage materials and their preparation, can solve the problems of low reaction rate and achieve the effect of good dispersion, small particles, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Add 0.6g catalyst ferrocene to 6ml p-xylene, stir evenly to obtain the precursor;

[0046] (2) Put 3g Ni sheet in the quartz porcelain boat and put it into the quartz tube of the energy-saving tube furnace, heat the tube furnace to 800 ° C under Ar gas atmosphere, and then pass H 2 Make the gas flow ratio Ar:H 2 For 400sccm:60sccm, and keep 2h;

[0047] (3) When the temperature reaches 800°C, start injecting the precursor into the quartz tube with a syringe pump at a rate of 3ml / h;

[0048] (4) 10 minutes after the injection of the precursor, turn off the heat preservation setting of the tube furnace, and wait for the temperature of the furnace to drop to room temperature under an Ar gas atmosphere to obtain Ni-CNTs composite materials;

[0049] (5) Take 3 g of the prepared Ni-CNTs composite material and cut it into small pieces with a side length of 1 cm and immerse it in 100 ml of saturated lithium hydroxide solution (21.6 g of LiOH-H can be dissolved in 100 ml ...

Embodiment 2

[0058] (1) Add 0.6g catalyst ferrocene to 6ml p-xylene, stir evenly to obtain the precursor;

[0059] (2) Put 3g Ni sheet in the quartz porcelain boat and put it into the quartz tube of the energy-saving tube furnace, heat the tube furnace to 800 ° C under Ar gas atmosphere, and then pass H 2 Make the gas flow ratio Ar:H 2 For 400sccm:60sccm, and keep 2h;

[0060] (3) When the temperature reaches 800°C, start injecting the precursor into the quartz tube with a syringe pump at a rate of 3ml / h;

[0061] (4) 10 minutes after the injection of the precursor, turn off the heat preservation setting of the tube furnace, and wait for the temperature of the furnace to drop to room temperature under an Ar gas atmosphere to obtain Ni-CNTs composite materials;

[0062] (5) Take 3 g of the prepared Ni-CNTs composite material and cut it into small pieces with a side length of 1 cm and immerse it in 100 ml of saturated lithium hydroxide solution (21.6 g of lithium hydroxide monohydrate can ...

Embodiment 3

[0070] (1) Add 0.6g catalyst ferrocene to 6ml p-xylene, stir evenly to obtain the precursor;

[0071] (2) Put 3g Ni sheet in the quartz porcelain boat and put it into the quartz tube of the energy-saving tube furnace, heat the tube furnace to 800 ° C under Ar gas atmosphere, and then pass H 2 Make the gas flow ratio Ar:H 2 For 400sccm:60sccm, and keep 2h;

[0072] (3) When the temperature reaches 800°C, start injecting the precursor into the quartz tube with a syringe pump at a rate of 3ml / h;

[0073] (4) 10 minutes after the injection of the precursor, turn off the heat preservation setting of the tube furnace, and wait for the temperature of the furnace to drop to room temperature under an Ar gas atmosphere to obtain Ni-CNTs composite materials;

[0074] (5) Take 3 g of the prepared Ni-CNTs composite material and cut it into small pieces with a side length of 1 cm and immerse it in 100 ml of saturated lithium hydroxide solution (21.6 g of LiOH-H can be dissolved in 100 ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com