Integrated utilization method for phosphorus chemical industry byproduct fluorosilicic acid

A technology of fluorosilicic acid and by-products, applied in the field of phosphorus chemical industry, can solve the problems of single use of sodium fluorosilicate and limited sales of sodium fluorosilicate, and achieve the effects of high equipment utilization rate, inhibition of agglomeration and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

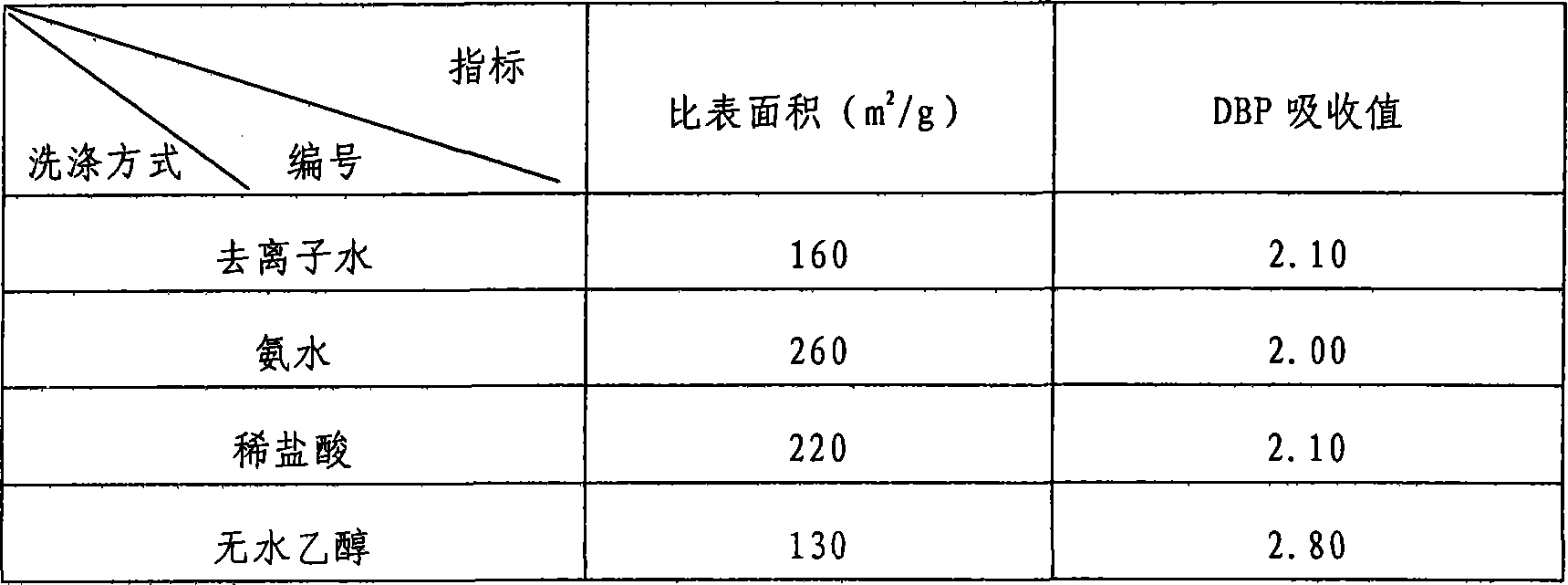

Embodiment 1

[0022] At a temperature of 0°C, add 100 g of fluorosilicic acid solution with a concentration of 18% into the reactor, start stirring, and at the speed of 3000 rpm, add 150 g of ammonia water with a concentration of 13% dropwise at the same time, and remove the heat of reaction during the ammoniation reaction , After the reaction is completed, filter to obtain a silica gel filter cake, and the filter cake is washed and dried to obtain white carbon black. The main economic indicator of white carbon black is that the specific surface area is 350m 2 / g; DBP absorption value is 2.10.

Embodiment 2

[0024] At a temperature of 30°C, add 60g of a solution of 30% fluosilicic acid into the reactor, start stirring, and at a speed of 4000rpm, add 70g of ammonia water with a concentration of 30% dropwise at the same time to remove the heat of reaction while the ammoniation reaction is in progress. , After the reaction is completed, filter to obtain a silica gel filter cake, and the filter cake is washed and dried to obtain white carbon black. The main economic indicator of white carbon black is that the specific surface area is 160m 2 / g; DBP absorption value is 2.00.

Embodiment 3

[0026] At a temperature of 20°C, add 100g of fluorosilicic acid solution with a concentration of 18% into the reactor, start stirring, and at the speed of 1000rpm, add 105g of ammonia water with a concentration of 20% dropwise at the same time, and remove the heat of reaction during the ammoniation reaction , After the reaction is completed, filter to obtain a silica gel filter cake, and the filter cake is washed and dried to obtain white carbon black. The main economic indicator of white carbon black is that the specific surface area is 240m 2 / g; DBP absorption value is 2.15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com