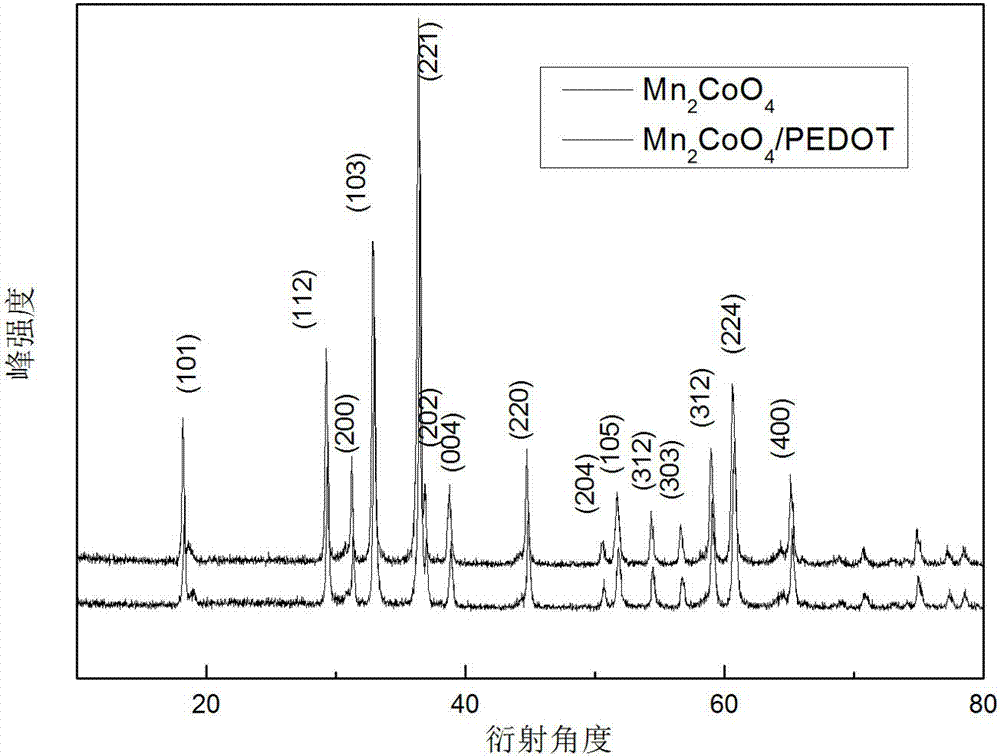

Preparation method of negative electrode material Mn2CoO4/poly(3,4-ethylenedioxythiophene)

A technology of ethylenedioxythiophene and negative electrode materials, which is applied in the direction of battery electrodes, secondary batteries, electrical components, etc., can solve the problems that batteries cannot realize high-current charging and discharging, limit the application range of lithium-ion batteries, and short-circuit lithium dendrites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Dissolve manganese acetate and cobalt acetate in deionized water at a molar volume of 0.01 mol: 0.005 mol; (2) Add a small amount of 0.015 -0.030 mol ethylenediaminetetraacetic acid (EDTA)-polyacrylic acid (PPA) double chelating agent Wet with deionized water, add 0.15 mol (12 ml) ammonia water, shake until a colorless and transparent solution is formed, then add the colorless and transparent double chelating agent EDTA-PPA solution into the saline solution to form a transparent solution, heat and stir at 80 ℃ until the formation gel. (3) Heat and dry the gel material in a blast oven at 240°C for 5 hours; (4) Grind the precursor and calcinate it in a muffle furnace at 600°C for 10 hours at a heating rate of 5°C / min to obtain Mn 2 CoO 4 . (5) Dissolve 0.4 g of iron p-toluenesulfonate hexahydrate in 1 ml of absolute ethanol to a yellow transparent solution that is uniformly stirred, and then add 0.5 g of Mn 2 CoO 4 Add to this solution and stir until evenly spread...

Embodiment 2

[0029] (1) Dissolve manganese acetate and cobalt acetate in deionized water at a molar volume of 0.01 mol: 0.005 mol; (2) Add a small amount of 0.015-0.030 mol ethylenediaminetetraacetic acid (EDTA)-citric acid (CA) double chelating agent Wet with deionized water, add 0.15 mol (12 ml) of ammonia water, shake until a colorless and transparent solution is formed, then add the colorless and transparent double chelating agent EDTA-CA solution into the saline solution to form a transparent solution, heat and stir at 70°C until it forms gel. (3) Heat and dry the gel material in a blast oven at 240°C for 5 hours; (4) Grind the precursor and calcinate it in a muffle furnace at 800°C for 5 hours at a heating rate of 2°C / min to obtain Mn 2 CoO 4 . (5) Dissolve 0.4 g of iron p-toluenesulfonate hexahydrate in 1 ml of acetone until a uniformly stirred yellow transparent solution is obtained, and then add 0.5 g of Mn 2 CoO 4 Add to this solution and stir until evenly spread on a clean g...

Embodiment 3

[0031](1) Dissolve manganese acetate and cobalt acetate in deionized water at a molar volume of 0.01 mol: 0.005 mol; (2) Add a small amount of deionized water to 0.015 -0.030 mol of ethylenediaminetetraacetic acid (EDTA)-acetylacetone double chelating agent Wet, add 0.15 mol (12 ml) ammonia water, shake until a colorless and transparent solution is formed, then add the colorless and transparent double chelating agent EDTA-acetylacetone solution into the saline solution to form a transparent solution, heat and stir at 80°C until a gel is formed . (3) Heat and dry the gel material in a blast oven at 200 °C for 5 hours; (4) Grind the precursor and calcinate it in a muffle furnace at 850 °C for 5 hours at a heating rate of 2 °C / min to obtain Mn 2 CoO 4 . (5) Dissolve 0.2 g of iron p-toluenesulfonate hexahydrate in 0.5 ml of acetone until a uniformly stirred yellow transparent solution is obtained, and then add 0.25 g of Mn 2 CoO 4 Add to this solution and stir until evenly spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com