LiCoVO4 as well as preparation method and application thereof

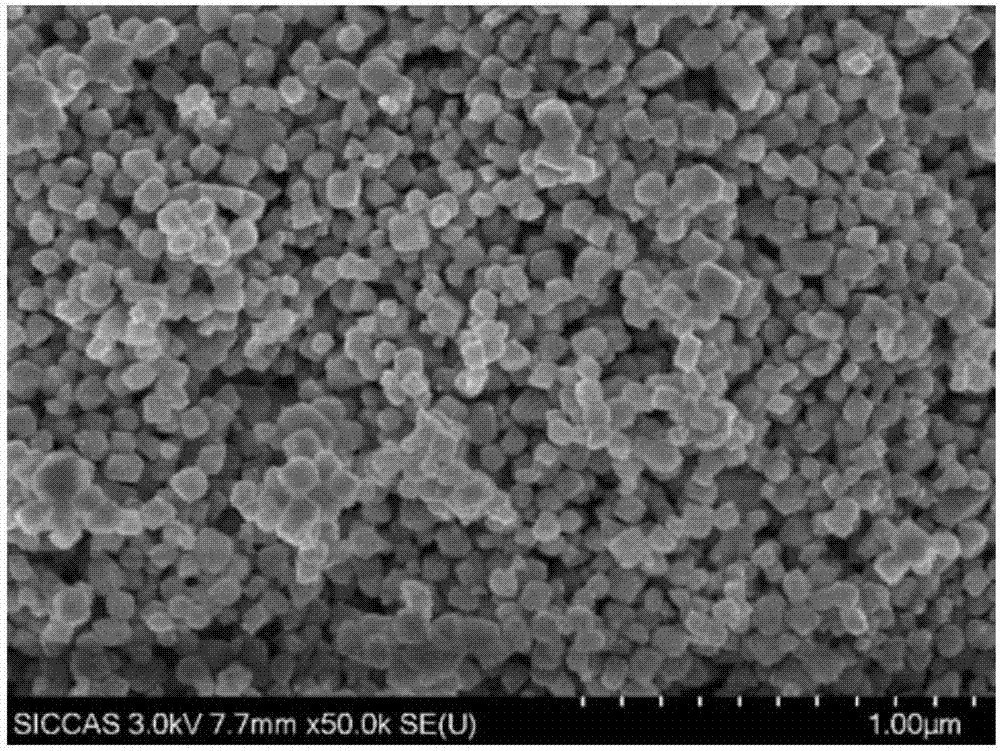

A technology of lithium cobalt vanadate and cobalt acetate, applied in the field of lithium ion batteries, can solve the problems of irregular morphology and uneven particle size distribution of lithium cobalt vanadate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] like figure 1 The preparation method of shown cobalt lithium vanadate comprises the steps:

[0029] S10. Mix the lithium hydroxide aqueous solution and the ammonium metavanadate suspension evenly, and maintain the reaction temperature above 75° C. until a colorless and clear solution is obtained.

[0030] Preferably, the molar concentration of lithium hydroxide in the lithium hydroxide aqueous solution is 0.4mol / L to 0.6mol / L, and the molar concentration of ammonium metavanadate in the ammonium metavanadate suspension is 0.4mol / L ~0.6mol / L.

[0031] Preferably, when the lithium hydroxide aqueous solution and the ammonium metavanadate suspension are uniformly mixed, the temperature of the ammonium metavanadate suspension is maintained at 75° C. to 85° C. The solubility of ammonium metavanadate in normal temperature water is small, so the temperature of ammonium metavanadate suspension is maintained at 75°C to 85°C. On the one hand, the solubility of ammonium metavanada...

Embodiment 1

[0064] Preparation of lithium cobalt vanadate:

[0065] Add lithium hydroxide aqueous solution dropwise to the ammonium metavanadate suspension, maintain the reaction temperature at 80°C, keep warm and keep stirring until a colorless and clear solution is obtained.

[0066] Add the above colorless and clear solution dropwise to the cobalt acetate aqueous solution, maintain the reaction temperature at 80°C, keep it warm for 45min, and obtain a light yellow suspension after sufficient reaction. Among them, the solubility of the light yellow suspension is 1mol / L.

[0067] Put the above light yellow suspension into an ultrasonic mixer and mix for 30 minutes, then put the light yellow suspension into a closed high temperature and high pressure resistant reaction kettle. Put the reaction kettle with the light yellow suspension into the homogeneous reactor, maintain the reaction temperature at 200° C., and the reaction time at 20 h. After the reaction was completed, it was cooled n...

Embodiment 2

[0069] Preparation of lithium-ion batteries:

[0070] A PVDF (polyvinylidene fluoride) solution with a mass fraction of 4% was prepared: the PVDF was placed in a vacuum drying oven, dried overnight at 80° C., and then 2 g of PVDF was weighed for use. Weigh 48g of NMP (N-methylpyrrolidone) and pour it into the reagent bottle, slowly pour the weighed PVDF into the NMP, then seal the bottle mouth with a parafilm, put it into a constant temperature heating magnetic stirrer and heat at 50°C, Continue for 20 hours until the PVDF solution becomes a uniform transparent viscous liquid, ready for use.

[0071] The lithium cobalt vanadate and graphite powder in Example 1 were vacuum-dried at 80° C. for use. Weigh 0.6 g lithium cobalt vanadate and 0.075 g graphite powder of Example 1, and vibrate and mix the lithium cobalt vanadate and graphite powder of Example 1. Put the mixed powder into an agate mortar and grind for 3 to 5 minutes, then prepare PVDF according to the mass ratio of co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com