Ferrochrome vanadate photocatalytic material with visible light response as well as preparation method and application thereof

A photocatalytic material, iron vanadate technology, applied in the field of inorganic photocatalytic materials, can solve the problems of low photocatalytic activity and poor stability, and achieve the effects of environmental friendliness, easy industrial production, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

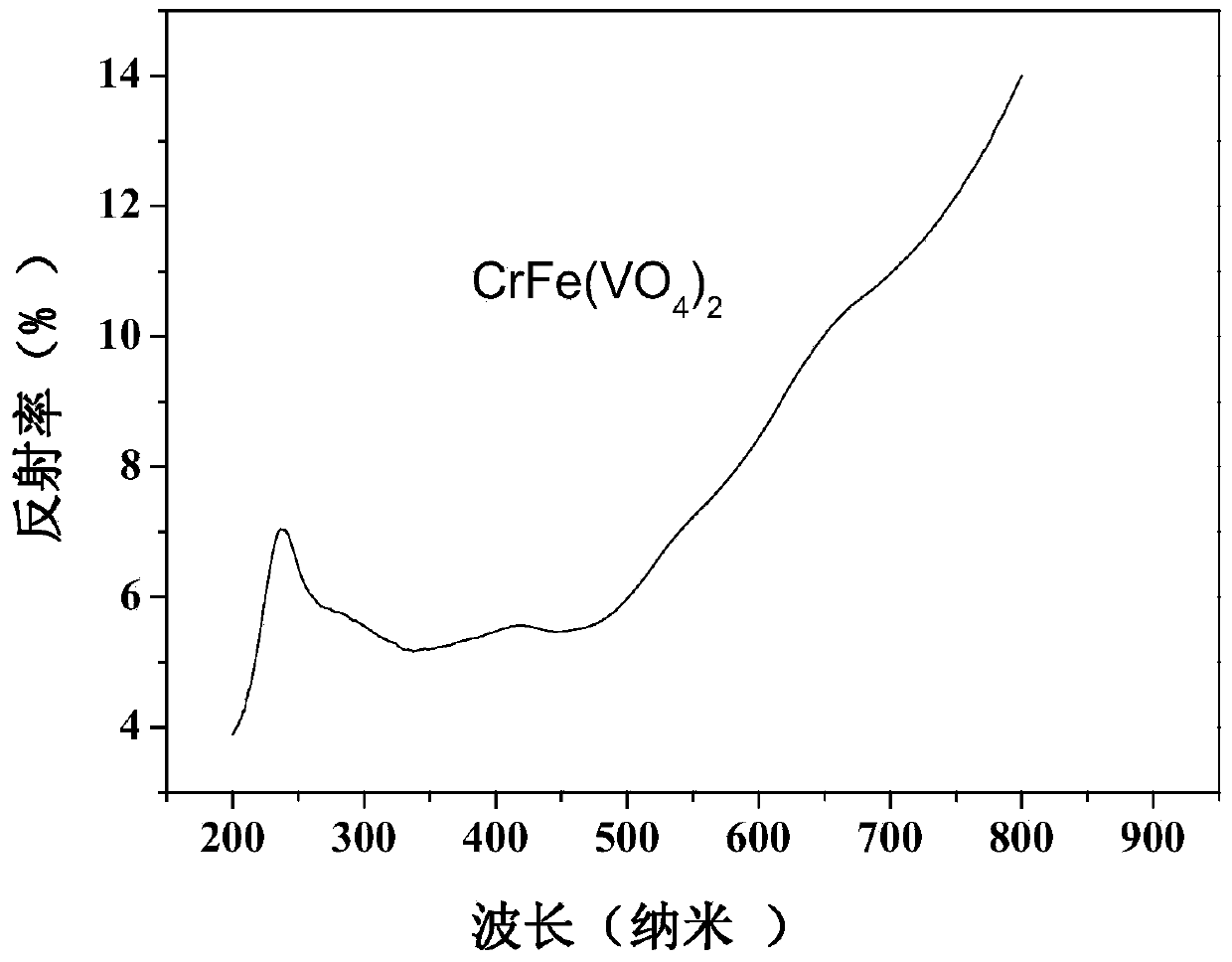

[0047] Embodiment 1: solid phase reaction method prepares CrFe(VO 4 ) 2 And its degradation experiment of methylene blue

[0048] Its preparation steps are as follows:

[0049] (1) According to the chemical formula CrFe(VO 4 ) 2 The stoichiometric ratio of the corresponding elements in the chromium oxide Cr was weighed respectively 2 o 3 : 0.95 g, iron oxide Fe 2 o 3 : 1.00 g, ammonium metavanadate NH 4 VO 3 : 2.925 g, ground in an agate mortar and mixed well to obtain a mixture;

[0050] (2) Take the mixture in the above step (1), select an air atmosphere for pre-calcination, the calcination temperature is 300 ° C, the calcination time is 15 hours, and naturally cool;

[0051] (3) Take out the sample, fully mix and grind the pre-calcined mixture again, put it in a muffle furnace, and calcinate it in an air atmosphere at a calcination temperature of 1000°C and a calcination time of 5 hours to obtain ferrochrome vanadium Salt CrFe(VO 4 ) 2 powder.

[0052] For the...

Embodiment 2

[0058] Embodiment 2: solid phase reaction method prepares CrFe(VO 4 ) 2 And its degradation experiment of methylene blue

[0059] Its preparation steps are as follows:

[0060] (1) According to the chemical formula CrFe(VO 4 ) 2 The stoichiometric ratio of the corresponding elements in the chromium hydroxide Cr(OH) was weighed respectively 3 : 1.29 g, iron oxide Fe 2 o 3 : 1.00 g, ammonium metavanadate NH 4 VO 3 : 2.925 g, ground in an agate mortar and mixed well to obtain a mixture;

[0061] (2) Take the mixture of the above step (1), select an air atmosphere for pre-calcination, the pre-calcination temperature is 500 ° C, the calcination time is 3 hours, and naturally cool;

[0062] (3) Take out the sample, fully grind the pre-calcined mixture again, put it in a muffle furnace, and carry out calcination under an air atmosphere. The calcination temperature is 500° C., and the calcination time is 20 hours to obtain chromium iron vanadate CrFe ( VO 4 ) 2 powder.

...

Embodiment 3

[0065] Embodiment 3: solid state reaction method prepares CrFe(VO 4 ) 2 And its degradation experiment of methylene blue

[0066] Its preparation steps are as follows:

[0067] (1) According to the chemical formula CrFe(VO 4 ) 2 Dosage ratio of corresponding chemical elements in , respectively weigh chromium sulfate Cr 2 (SO 4 ) 3 : 1.96 g, iron oxide Fe 2 o 3 : 0.80 g, ammonium metavanadate NH 4 VO 3: 2.34 g, ground in an agate mortar and mixed well to obtain a mixture;

[0068] (2) Take the mixture of the above step (1), select the air atmosphere for pre-calcination, the pre-calcination temperature is 350 ° C, the calcination time is 7 hours, and naturally cool;

[0069] (3) Take out the sample, place the pre-calcined raw material in the muffle furnace after fully grinding again, and carry out calcination under air atmosphere, the calcination temperature is 900 DEG C, and the calcination time is 13 hours, promptly obtains chromium iron vanadate CrFe ( VO 4 ) 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com