Iron-nitrogen codope carbon microspheres as well as preparation method, application and oxygen reduction electrode

A technology of co-doping, carbon microspheres, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult large-scale synthesis, harsh conditions, complex synthesis process, etc., and achieve great application potential and industrial value, excellent performance, the effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

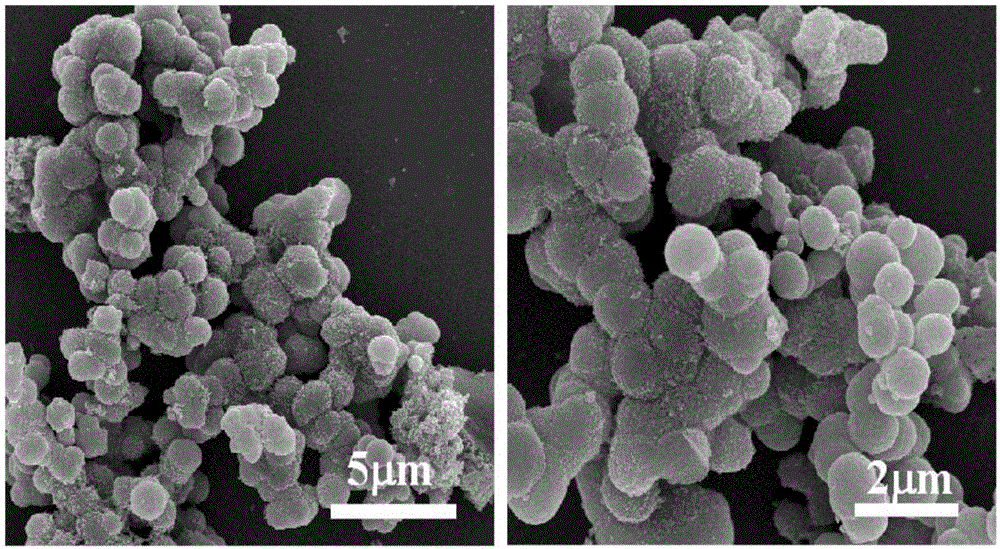

[0068] S1: React hexachlorobutadiene, ferrocene and pyridine in a polytetrafluoroethylene-lined autoclave at 200°C and 1.5MPa for 6 hours, wherein the hexachlorobutadiene and ferrocene The mass ratio is 1:2, and the molar ratio of hexachlorobutadiene to pyridine is 1:1;

[0069] S2: After the reaction, the pressure was released to normal pressure, and naturally cooled to room temperature, and the obtained solid was dried at 115° C. for 7 hours to obtain a dry sample;

[0070] S3: The dry sample was calcined at a high temperature of 1000° C. for 2 hours under the protection of nitrogen to obtain an iron-nitrogen co-doped carbon microsphere composite material, which was named M1.

Embodiment 2-11

[0071] Embodiment 2-11: the investigation of material consumption ratio in step S1

Embodiment 2-5

[0072] Example 2-5: Except that the mass ratio of hexachlorobutadiene and ferrocene in step S1 is replaced by 1:0.2, 1:0.5, 1:1 and 1:4, other operations are unchanged, thus repeating Example 1 was operated, so that Examples 2-5 were carried out in sequence, and the obtained composite materials were named M2, M3, M4 and M5 in sequence.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com