Supported copper-based catalyst preparation method and applications of supported copper-based catalyst in synthesis of ethylene glycol

A copper-based catalyst, supported technology, applied in the preparation of hydroxyl compounds, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high heat and power consumption, increased by-products, increased production costs, etc., to improve the activity of the reaction center , prolong catalyst life, improve synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

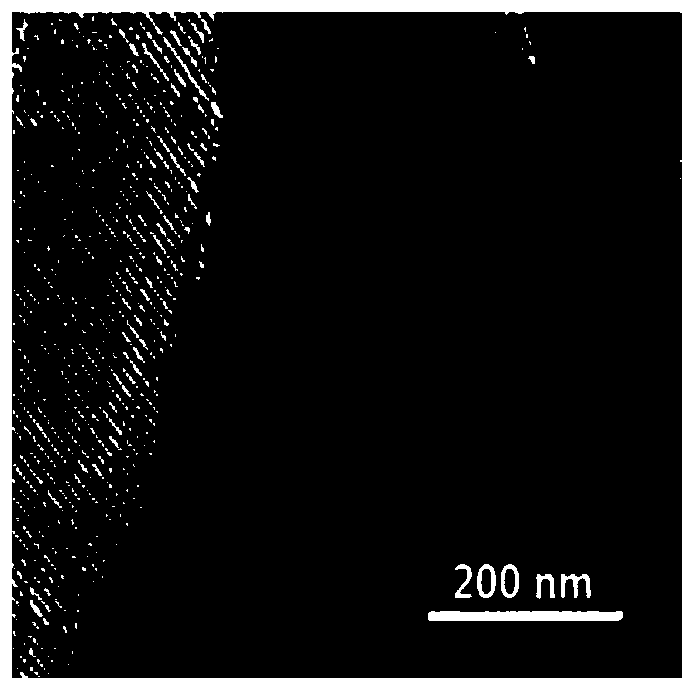

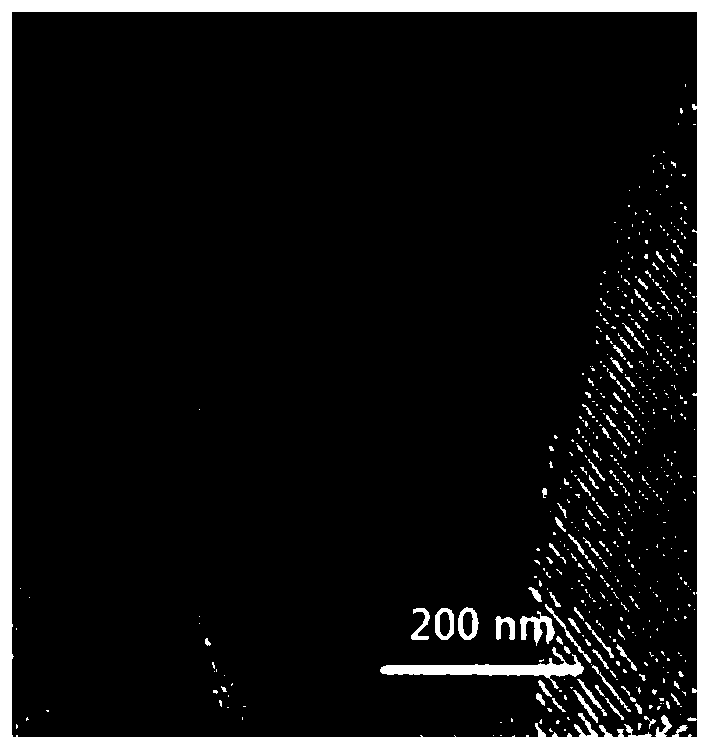

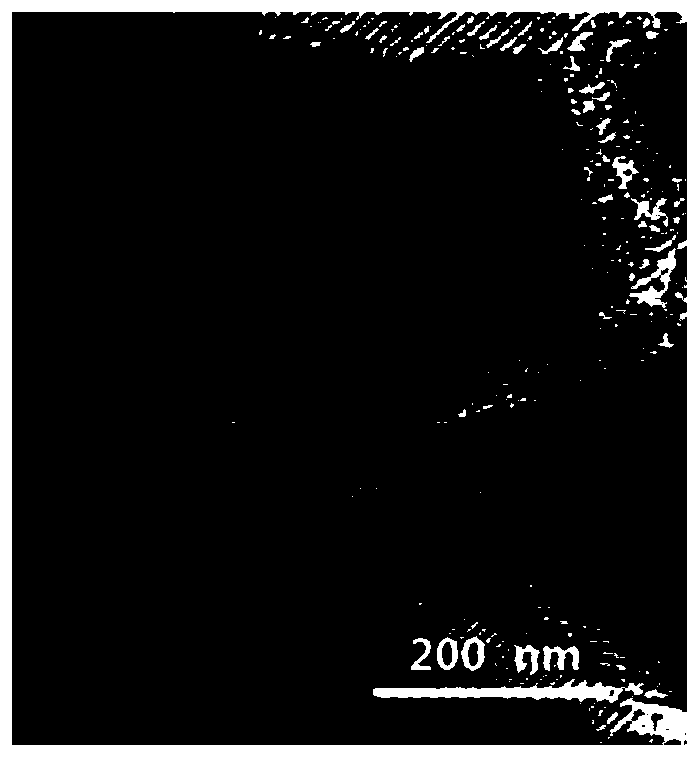

Image

Examples

Embodiment 1

[0028] A preparation method of supported copper-based catalyst:

[0029] 1) Mix 20.0g of silicon mesoporous molecular sieve SBA-15 with 181.56ml of methanesulfonic acid (CH 3 SO 3 H) The solution was fully stirred and mixed at 60° C. for 2 hours, and then the solid was recovered by suction filtration, washed with deionized water to be close to neutral, and vacuum-dried at 80° C. for 12 hours to obtain a surface-modified silicon mesoporous molecular sieve sample.

[0030] 2) Add the surface-modified silicon mesoporous molecular sieve obtained in 1) and 413.34g of γ-methacryloxypropyltrimethoxysilane to 2375.78g of ethanol / water mixed solvent (80% ethanol content) at 60°C React for 6h, and filter the solid sample obtained after the reaction is completed;

[0031] 3) Mix the solid sample in 2) with 0.05954g of ammonium persulfate and 179.90g of acrylic acid in 326.15g of ethanol for graft copolymerization for 4 hours. After the reaction, the product is recovered by filtration, ...

Embodiment 2

[0034] A preparation method of supported copper-based catalyst:

[0035] 1) Mix 20.0g of silicon mesoporous molecular sieve MCM-41 and 443.82ml of β-naphthalenesulfonic acid (C10H8O3S) solution with a concentration of 0.90mol / L at 55°C for 4 hours, then recover the solid by suction filtration, and use deionized water Washing was close to neutrality, and vacuum drying was performed at 80°C for 16 hours to obtain a surface-modified silicon mesoporous molecular sieve sample.

[0036] 2) Add the surface-modified silicon mesoporous molecular sieve obtained in 1) and 394.73g of vinyltrimethoxysilane into 1289.64g of ethanol / water mixed solvent (71% ethanol content) to react at 60°C for 6h, and filter after the reaction is completed The solid sample obtained;

[0037] 3) Mix the solid sample in 2) with 0.4774g of potassium persulfate and 733.60g of methacrylic acid in 2522.93g of ethanol for graft copolymerization for 6 hours. After the reaction, the product is recovered by filtrati...

Embodiment 3

[0040] A preparation method of supported copper-based catalyst:

[0041] 1) Mix 20.0g of silicon mesoporous molecular sieve MSU-1 and 457.69ml of benzenesulfonic acid (C6H6O3S) solution with a concentration of 0.8mol / L at 60°C for 2 hours, then recover the solid by suction filtration, wash with deionized water close to Neutral, vacuum-dried at 80°C for 12 hours to obtain a surface-modified silicon mesoporous molecular sieve sample.

[0042] 2) Add the surface-modified silicon mesoporous molecular sieve obtained in 1) and 870.06g of methacryloxypropyltriethoxysilane to 1878.54g of ethanol / water mixed solvent (67% ethanol content) at 60°C React for 6h, and filter the solid sample obtained after the reaction is completed;

[0043] 3) Mix the solid sample in 2) with 0.1286g of azobisisobutyronitrile and 399.47g of phenylacrylic acid in 978.77g of ethanol for a graft copolymerization reaction for 4 hours. After the reaction, the product is recovered by filtration and fully washed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com