Method for enhancing yield of linear alpha-olefins

A technology of olefin yield and linearity, applied in the direction of chemical instruments and methods, hydrocarbons, organic compounds/hydrides/coordination complex catalysts, etc., can solve problems affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

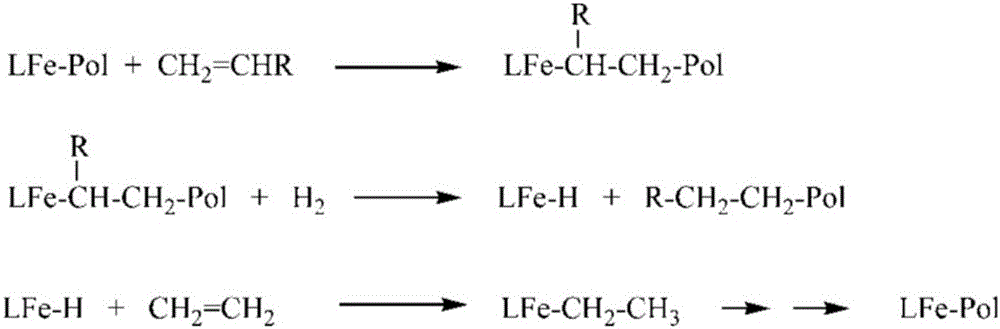

Method used

Image

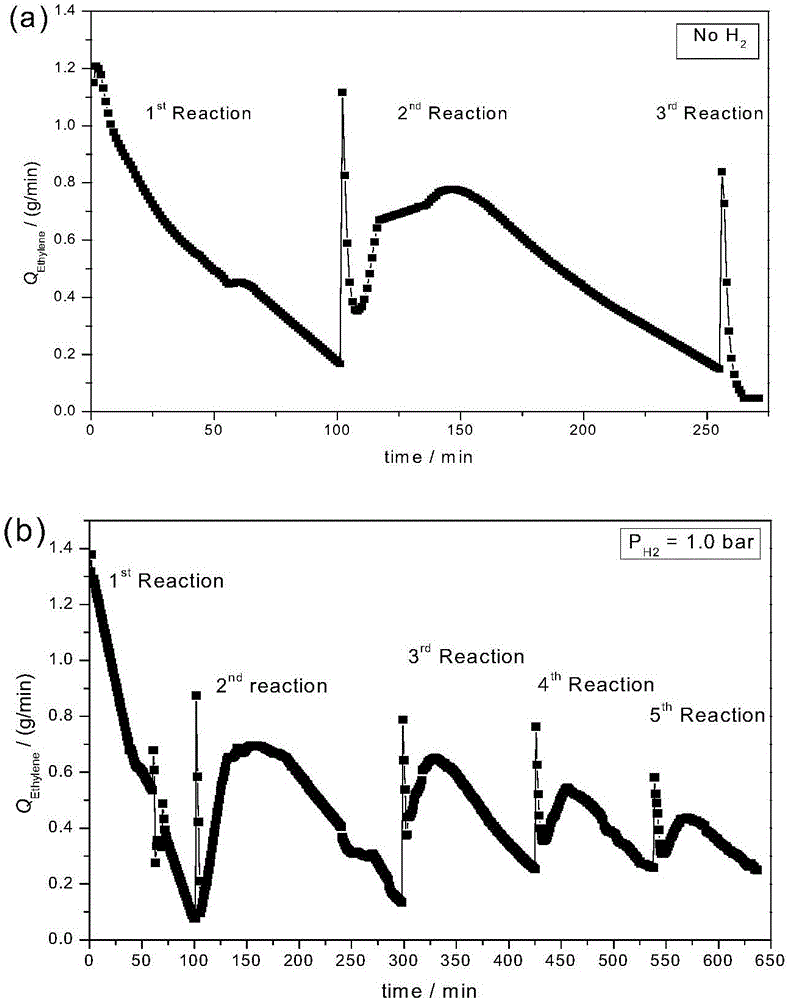

Examples

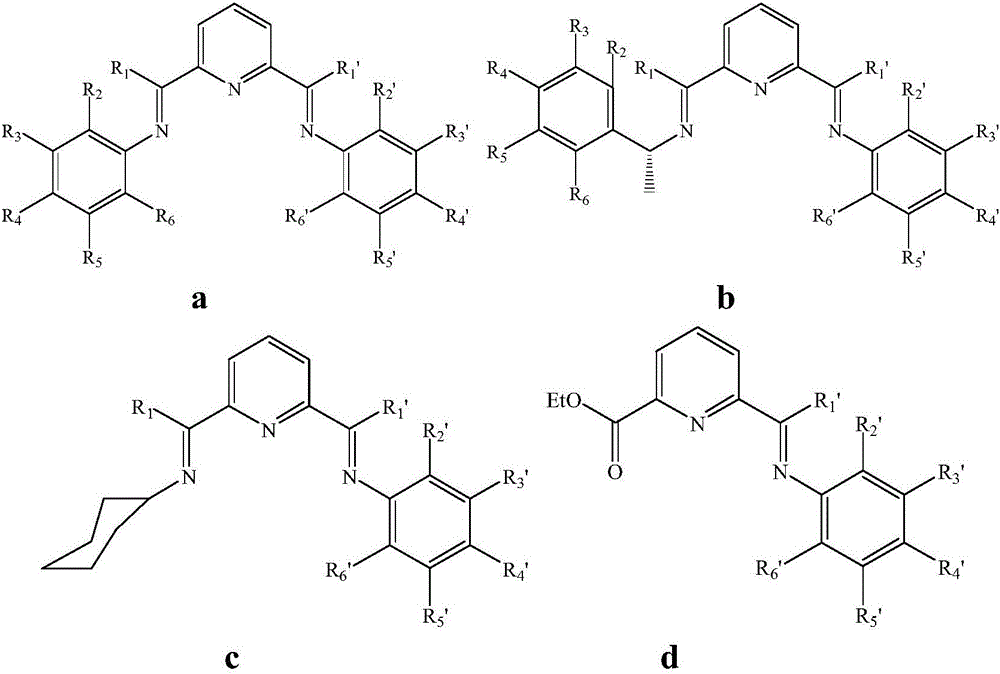

Embodiment 1

[0051] Under the protection of nitrogen, the pyridine bis-imine ligand L{2,6-bis-[(2-methyl-4-methoxyanilinoethyl)pyridine]} shown in formula a and iron acetylacetonate After mixing at a molar ratio of 1:1, use anhydrous toluene as a solvent to prepare 4×10 -6 mol / ml of the main catalyst solution. The cocatalyst methylaluminoxane (MAO) is a 10 wt% toluene solution, and the concentration of the substance is about 1.5 mol / L.

[0052] The structural formula of 2,6-bis-[(2-methyl-4-methoxyanilinoethyl)pyridine]:

[0053]

[0054] Heat a 1L stirred tank reactor to above 90°C, vacuumize and bake for 2 hours, during which time it is replaced with high-purity nitrogen several times. Subsequently, the temperature of the reactor was adjusted to a reaction temperature of 50° C. by circulating jacketed cooling water, and 300 ml of toluene was added as an organic solvent. Set the concentration of the iron-based catalyst in the reaction medium to be 0.67×10 -5 mol / L, add a certain am...

Embodiment 2

[0057] Add hydrogen 0.10MPa at a time to ensure that the partial pressure of ethylene is 0.30MPa. At this time, the partial pressure ratio of hydrogen and ethylene is 0.33. Other operations are the same as in Example 1.

[0058] The reaction product was separated by gas-liquid-solid to obtain linear α-olefin, which was analyzed by gas chromatography to obtain 152.2g; α=0.79; the activity was 7.6×10 7 g / mol-Fe / h.

Embodiment 3

[0060] Add hydrogen 0.20MPa at a time to ensure that the partial pressure of ethylene is 0.30MPa. At this time, the partial pressure ratio of hydrogen and ethylene is 0.67. Other operations are the same as in Example 1.

[0061] The reaction product obtained linear α-olefins after gas-liquid-solid separation, and was analyzed by gas chromatography to obtain 175.4g; α=0.80; the activity was 8.8×10 7 g / mol-Fe / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com