CuPd metal nano catalyst, and preparation and applications thereof

A metal nano-catalyst technology, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high prices, low earth reserves, etc., and achieve synthesis costs The effect of low, mild conditions and simple procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

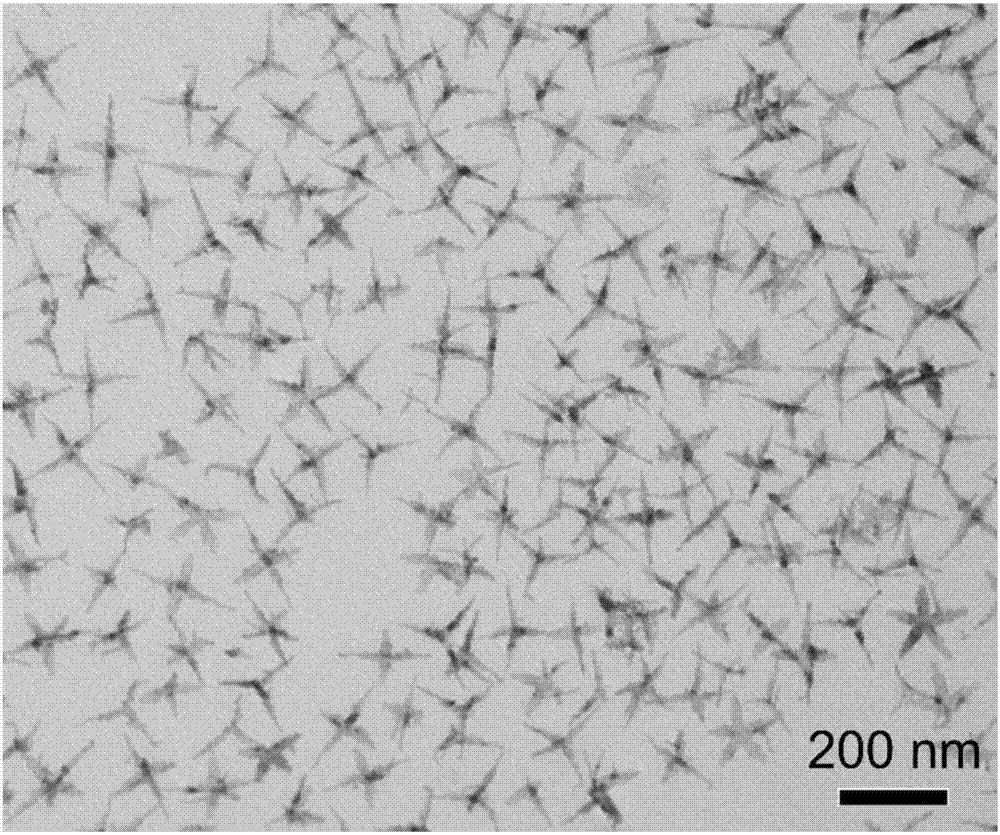

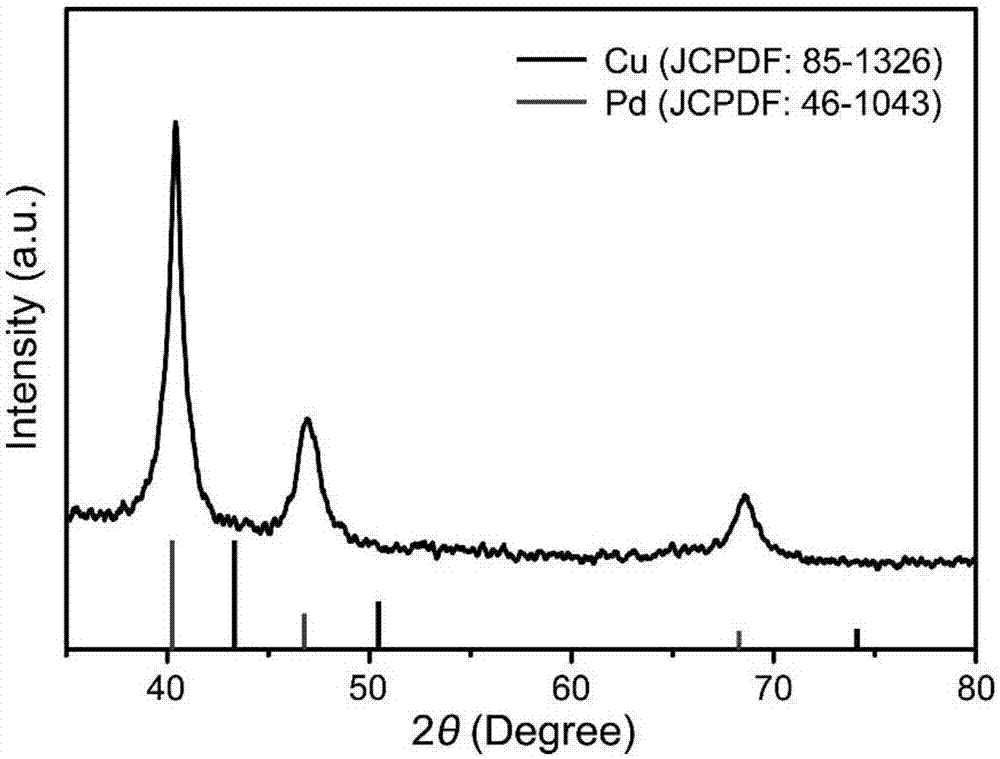

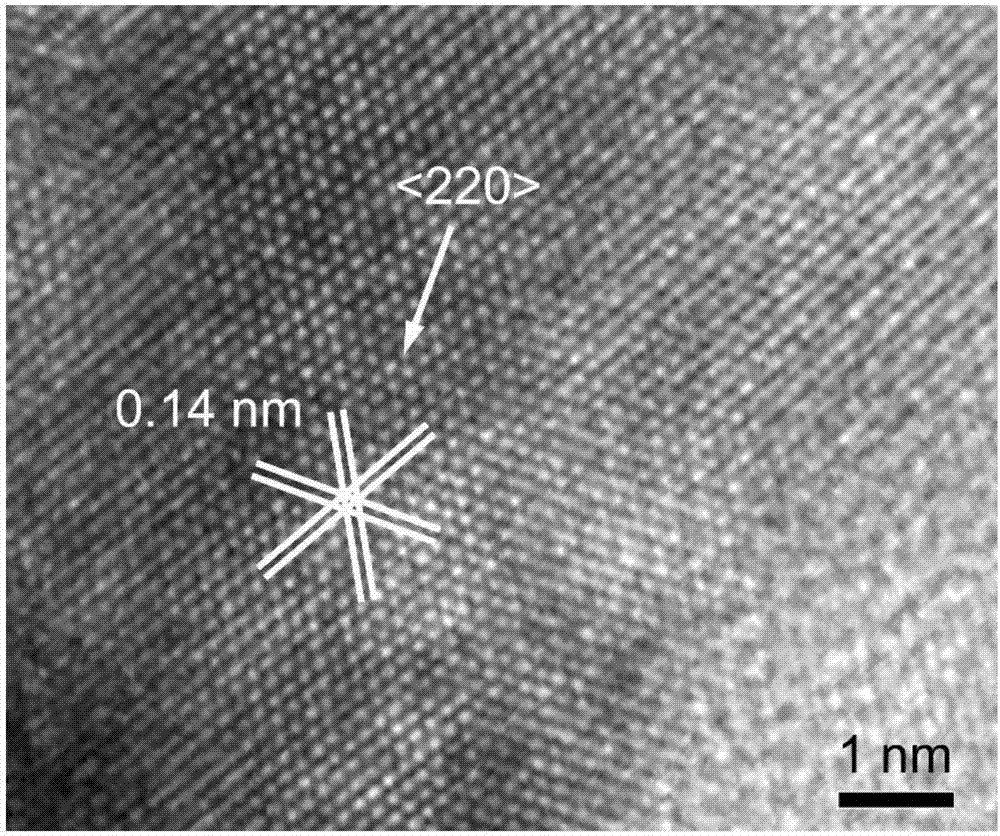

[0038] A kind of preparation method of CuPd metal nano-catalyst proposed by the present invention, under normal temperature, sodium tetrachloropalladate, cuprous chloride, polyvinylpyrrolidone and glucose are added in the mixed solution of decylamine and nitrogen-nitrogen dimethylformamide Stir until dissolved, then hydrothermally react, cool to room temperature, wash, and vacuum dry to obtain CuPd metal nano-catalyst.

[0039] A kind of preparation method of CuPd / C metal nano-catalyst that the present invention proposes, above-mentioned CuPd metal nano-catalyst is added in dehydrated alcohol ultrasonic dispersion obtains solution A; carbon black is added in dehydrated alcohol ultrasonic dispersion obtains solution B; Stir continuously at room temperature, add solution A dropwise to solution B during the stirring process, then wash and dry to obtain CuPd / C metal nano-catalyst.

Embodiment 2

[0041] A kind of preparation method of CuPd metal nano-catalyst proposed by the present invention, under normal temperature, sodium tetrachloropalladate, cuprous chloride, polyvinylpyrrolidone and glucose are added in the mixed solution of decylamine and nitrogen-nitrogen dimethylformamide Stir until dissolved, the weight ratio of sodium tetrachloropalladate, cuprous chloride, polyvinylpyrrolidone and glucose is 7.8:4:280:260, the volume ratio of decylamine and nitrogen-nitrogen dimethylformamide is 80:5200 , the mass volume ratio (mg / μL) of glucose and decylamine is 240:120, followed by hydrothermal reaction, the temperature of hydrothermal reaction is 68 ℃, the time of hydrothermal reaction is 2.5h, cooled to room temperature, will be cooled to room temperature Centrifugal separation of the material, the rotational speed of centrifugal separation is 12000 rpm, the time of centrifugal separation is 12min, the product obtained by centrifugation is ultrasonically washed with a p...

Embodiment 3

[0044] A kind of preparation method of CuPd metal nano-catalyst proposed by the present invention, under normal temperature, sodium tetrachloropalladate, cuprous chloride, polyvinylpyrrolidone and glucose are added in the mixed solution of decylamine and nitrogen-nitrogen dimethylformamide Stir until dissolved, the weight ratio of sodium tetrachloropalladate, cuprous chloride, polyvinylpyrrolidone and glucose is 9.8:2:320:240, the volume ratio of decylamine and nitrogen-nitrogen dimethylformamide is 120:4800 , the mass volume ratio (mg / μL) of glucose and decylamine is 260:80, followed by hydrothermal reaction, the temperature of hydrothermal reaction is 72 ℃, the time of hydrothermal reaction is 2h, cooled to room temperature, the The material is centrifuged, the speed of centrifugation is 13000 rpm, and the time of centrifugation is 10 minutes. The product obtained by centrifugation is ultrasonically washed with a polar solvent, and then centrifuged. The separation time is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com