Electrode structure, thin film transistor, array substrate and display panel

A technology of thin film transistors and electrode structures, which is applied in the direction of transistors, electric solid-state devices, circuits, etc., and can solve problems affecting the performance of thin film transistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] preparation figure 1 The electrode structure shown may specifically include the following steps:

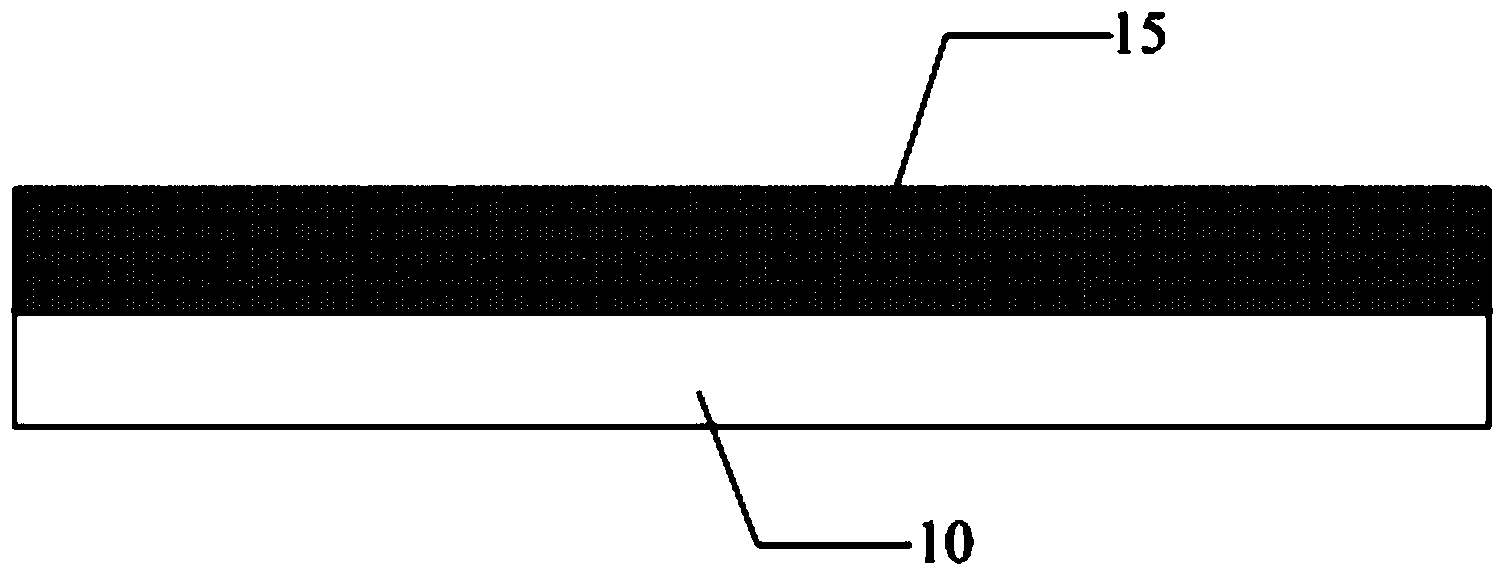

[0057] (1) The first metal thin film 15 is formed on the base substrate 10 by sputtering, such as Figure 3a shown;

[0058] Specifically, the material of the first metal thin film may be copper (Cu) or a copper alloy, which is not limited herein.

[0059] (2) Patterning the first metal thin film 15 to form the pattern of the first metal layer 11, such as Figure 3b shown;

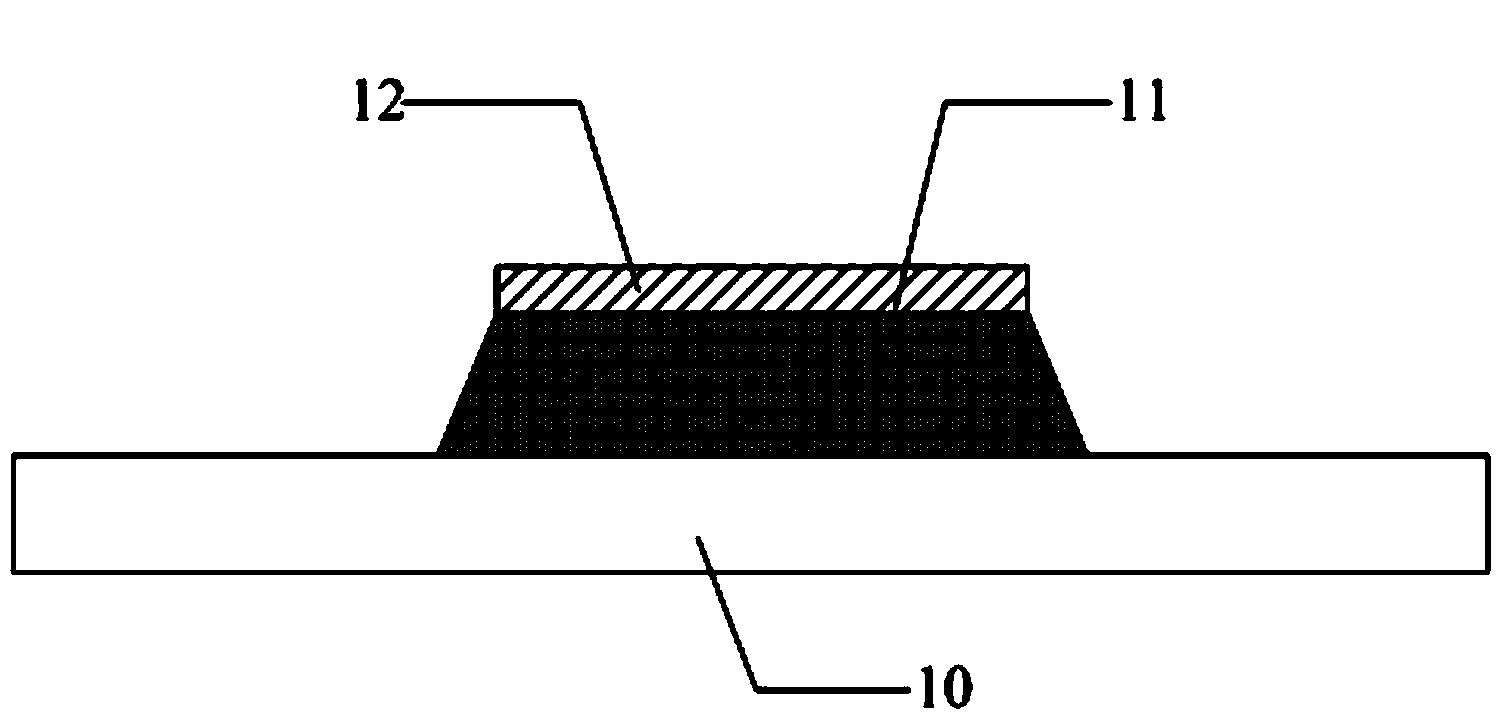

[0060] (3) take the first metal layer 11 as the metal catalyst substrate and the growth substrate for preparing graphene, adopt the CVD method to form the first graphene layer 12 on the first metal layer 11, as figure 1 shown.

[0061] Specifically, in specific implementation, it is better to form the first graphene layer as single-layer graphene.

example 2

[0063] preparation figure 2 The electrode structure shown may specifically include the following steps:

[0064] (1) The second metal thin film 16 is formed on the base substrate 10 by sputtering, such as Figure 4a shown;

[0065] Specifically, the material of the second metal thin film is copper alloy. Further, the copper alloy may be binary or multi-component alloys such as copper-molybdenum, copper-calcium, copper-magnesium, copper-manganese, copper-magnesium-aluminum, etc., which is not limited herein.

[0066] (2) Patterning the second metal film 16 to form the pattern of the second metal layer 13, such as Figure 4b shown;

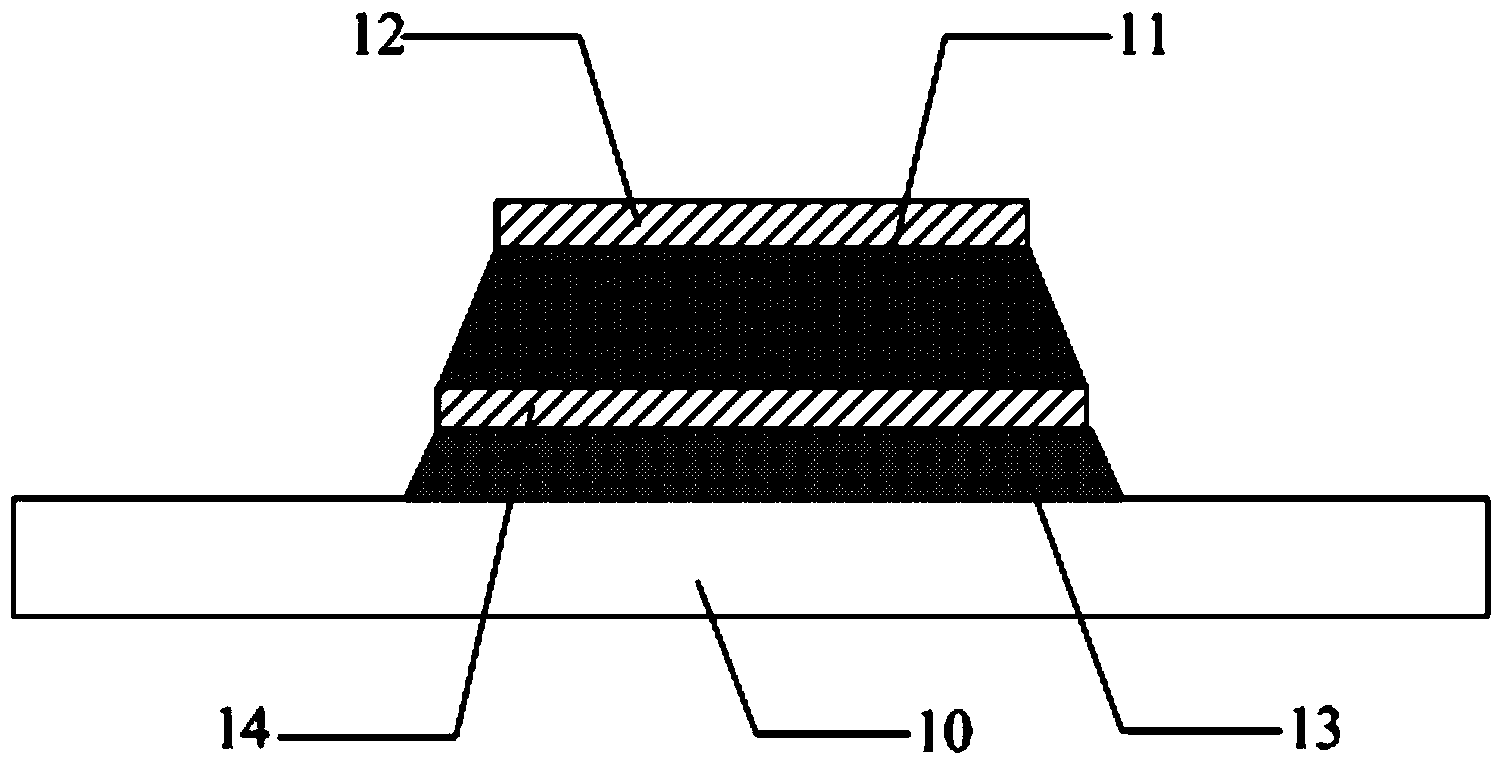

[0067] (3) take the second metal layer 13 as the metal catalyst substrate and the growth substrate for preparing graphene, adopt the CVD method to form the second graphene layer 14 on the second metal layer 13, as Figure 4c shown;

[0068] Specifically, it is better to form the second graphene layer as single-layer graphene.

[0069] (4) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com