Method and device for producing synthetic natural gas, and natural gas product thereof

A technology for synthesizing natural gas and products, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of catalyst bed overheating, lack of high quality, and low methane concentration, so as to improve energy utilization efficiency and reduce circulating gas The effect of reducing the energy consumption of the system

Inactive Publication Date: 2010-08-25

DATANG INT CHEM TECH RESINST

View PDF0 Cites 66 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main problems of coal hydrogasification to produce methane are: low carbon conversion rate, low methane yield, complex gas composition, low methane concentration, and lack of high-quality synthetic natural gas, etc.

Domestic methanation technology currently only stays at partial methanation, and the catalyst has a narrow temperature range, which greatly limits the comprehensive utilization efficiency of energy; in addition, partial methanation technology under normal pressure is not conducive to reaction and equipment strengthening, and lacks reactor design and matter-energy integrated optimization

The methanation reaction is a fast and strongly exothermic reaction. If the content of carbon monoxide in the feed gas is too high, it will cause a large amount of heat release, which will easily cause the phenomenon of "flying temperature" in the catalyst bed, leading to catalyst deactivation, and even endangering the safety of the reactor.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

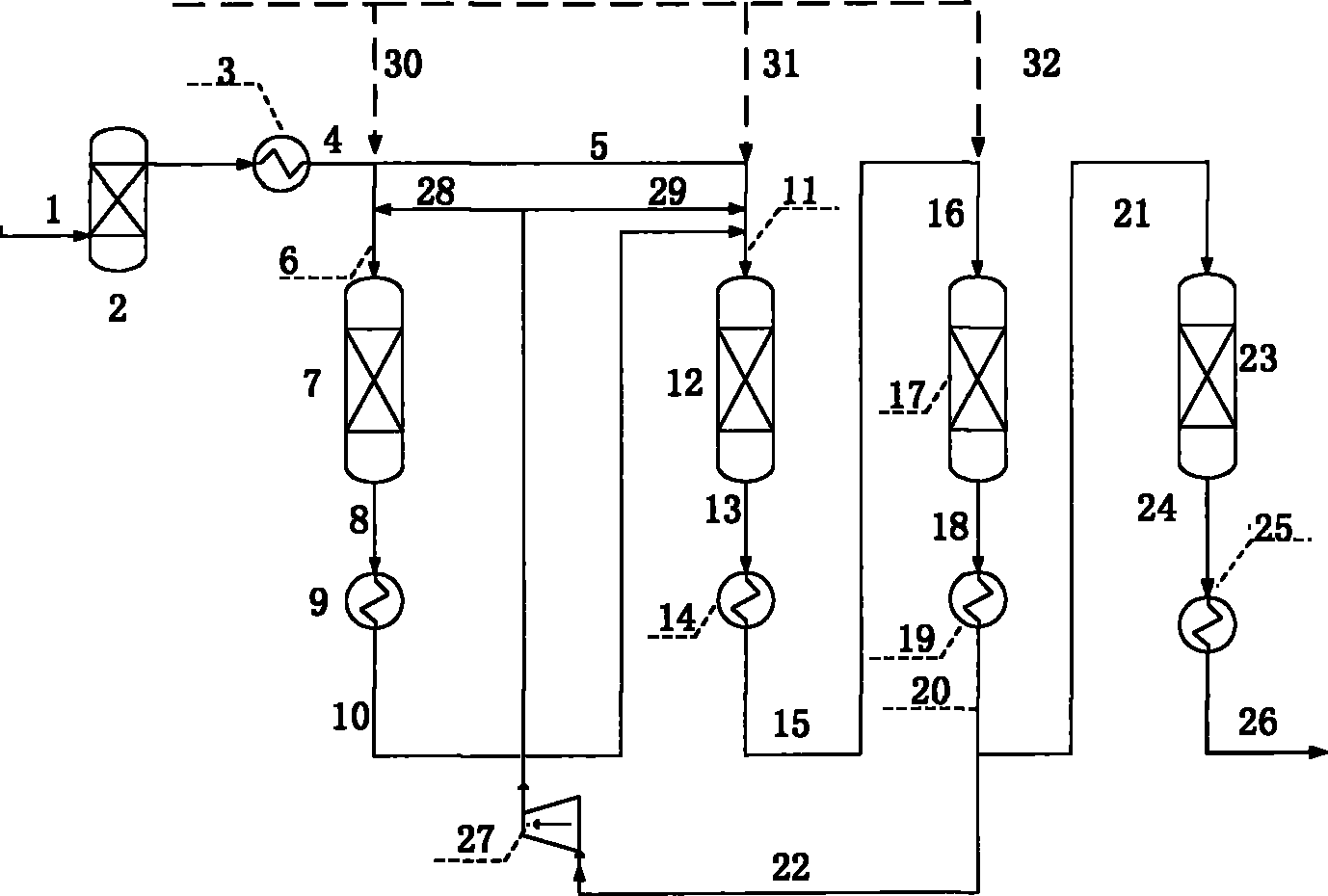

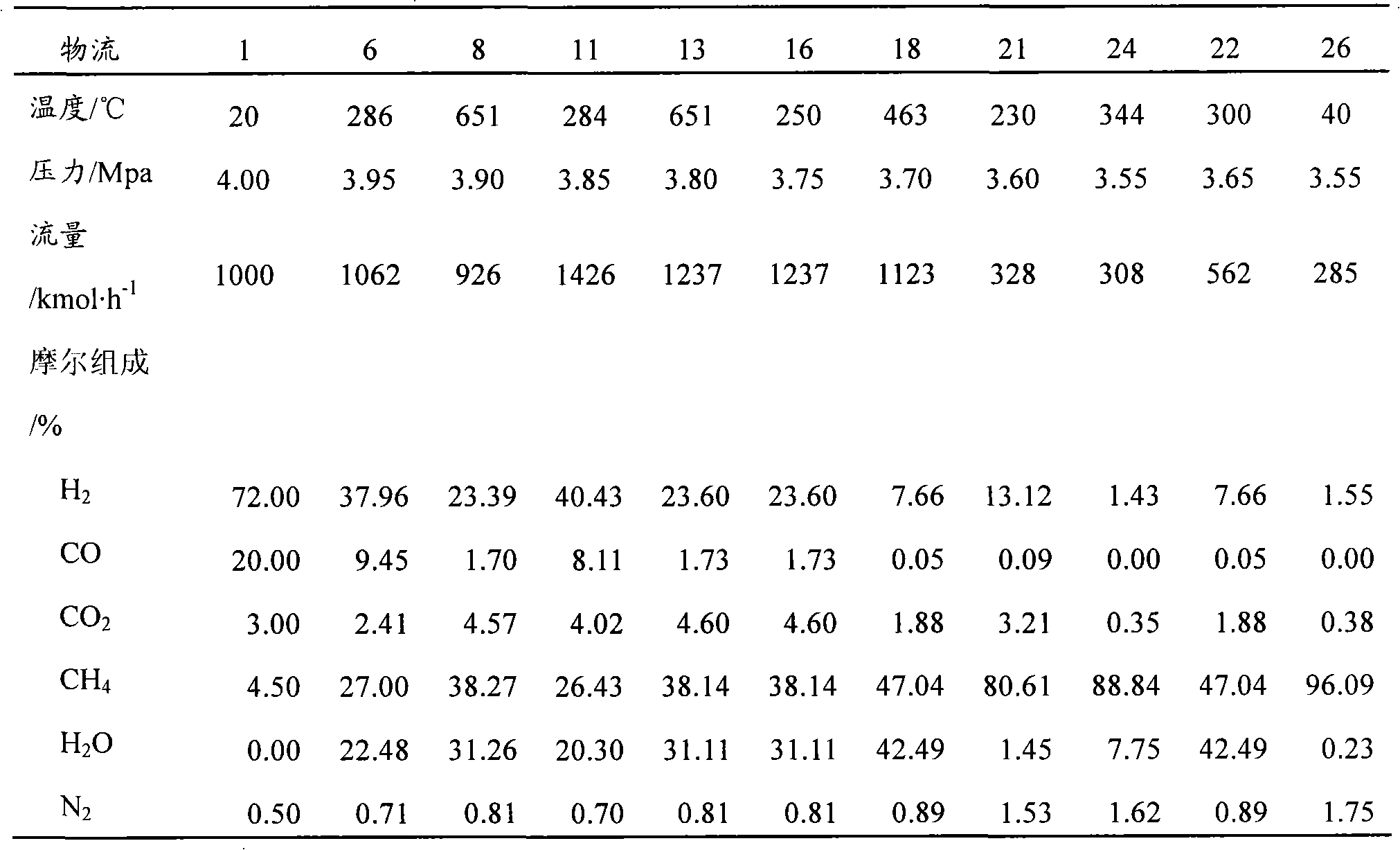

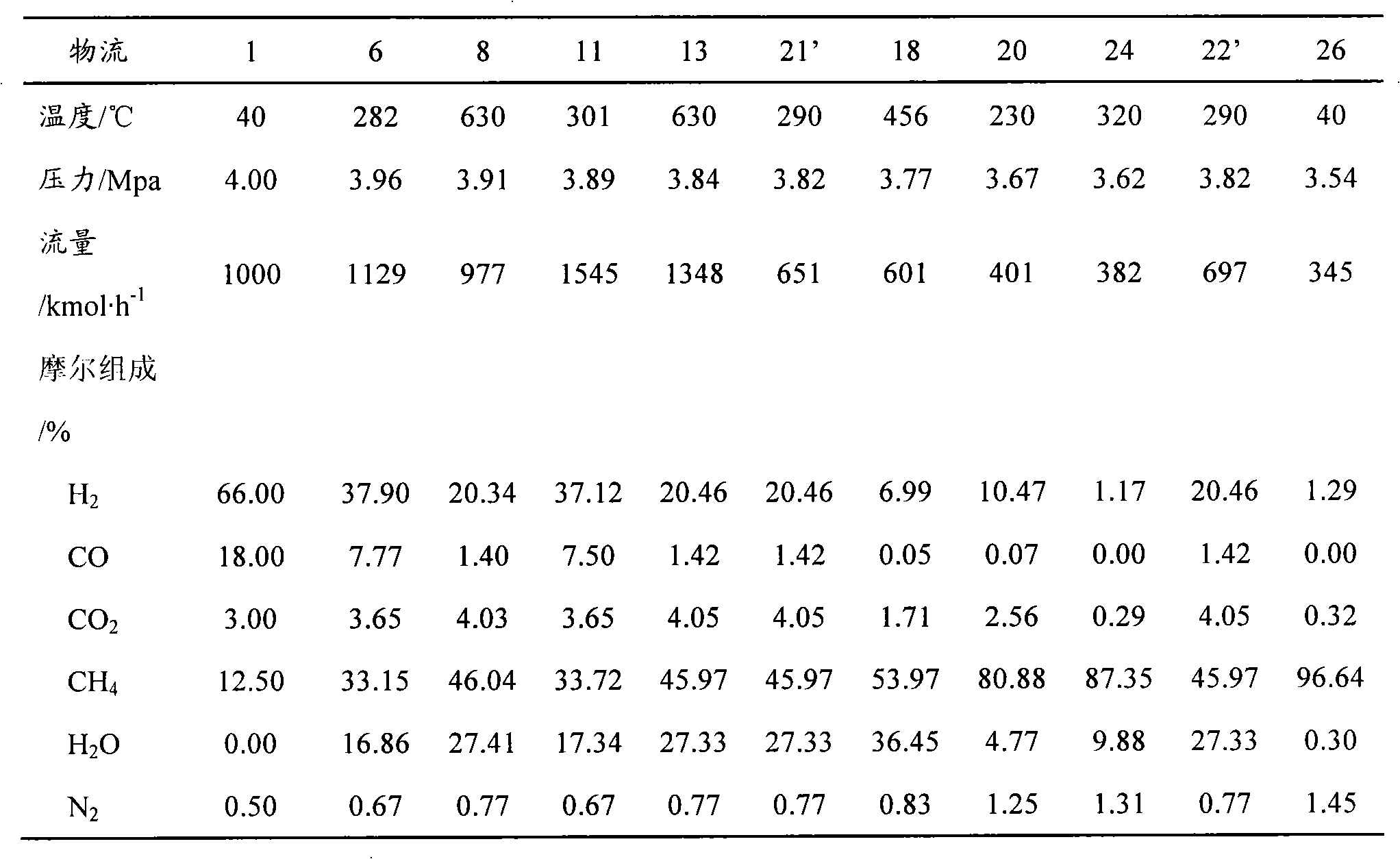

The invention provides a method for producing synthetic natural gas and a device thereof. The continuous technological process of the invention is realized in a way that gasified product gas is used as the raw material for producing high methane gas containing more than 94 mol% of methane. The method can well adjust the methanation reaction temperature and avoid the problems of catalyst temperature-runaway sintering and the like due to improper material composition, excessive fluctuation or unexpected accident, thereby reducing the recycle gas amount and enhancing the energy comprehensive utilization efficiency.

Description

technical field The invention relates to a method for complete methanation. Specifically, the invention relates to a method and device for producing synthetic natural gas (methane-enriched gas) using coal gasification products as raw materials, and belongs to the technical field of synthetic natural gas. Background technique Since the 1970s, along with the oil crisis, coal-to-methane (synthetic natural gas or alternative natural gas) has developed rapidly at home and abroad. The main methods of coal-to-methane include direct production of methane by coal hydrogasification and indirect production of methane through synthesis gas. The main problems of coal hydrogasification to produce methane are: low carbon conversion rate, low methane yield, complex gas composition, low methane concentration, and lack of high-quality synthetic natural gas. Relatively speaking, the process of producing methane from coal through syngas has significant advantages of high technological maturit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10L3/08

Inventor 李春启刘永健邱波左玉帮忻仕河

Owner DATANG INT CHEM TECH RESINST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com