Method for manufacturing metal part solidification structure by non-contact control added material and magnetron metal 3D printing device

A technology for metal parts and additive manufacturing, which is used in the field of metal parts solidification structure control technology and equipment to achieve flexible installation, avoid shrinkage cavities, and expand the range of printable materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention are described in detail as follows:

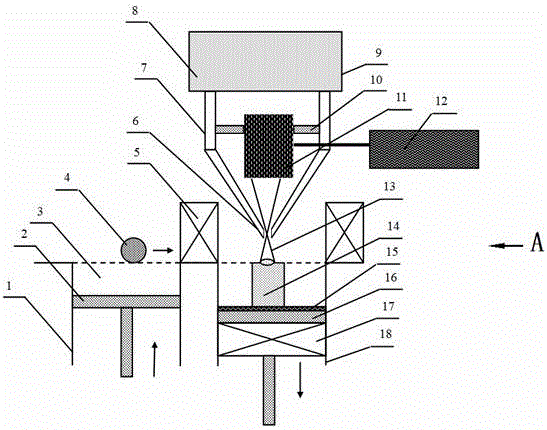

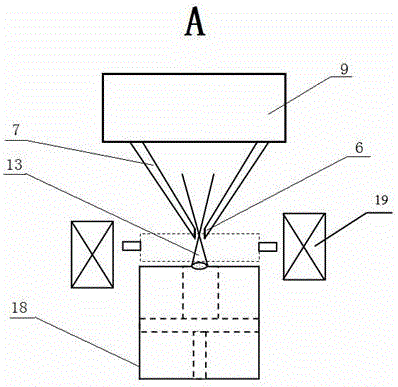

[0039] In this example, see figure 1 and figure 2 , a magnetically controlled metal 3D printing device, composed of a raw material supply unit, a melting and sintering system unit, a main controller and a power supply, the power supply provides electric energy for each system, the main controller controls each working unit of the 3D printing device, and the raw material supply device The unit is a comprehensive raw material supply device that is used in conjunction with the vertical gravity feed material device and the horizontal spreading feed material device. The vertical gravity feed material device is composed of a powder feeder feed tank 9 and a powder feed pipe 7. The raw material powder chamber 8 of the powder feeder is formed inside the feeding tank 9, and the expansion section of the powder feeding pipe 7 is installed under the feeding tank 9 of the powder feeding device to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com