Clean steel spectral standard sample and preparation method thereof

A spectral standard sample, pure steel technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of no direct reading spectrometer, online inspection error of pure steel products, and misjudgment of inspectors, etc., to achieve uniform chemical composition and compact structure , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment the present invention is further described:

[0028] The present invention further illustrates the content of the invention through the examples, but is not limited by the examples.

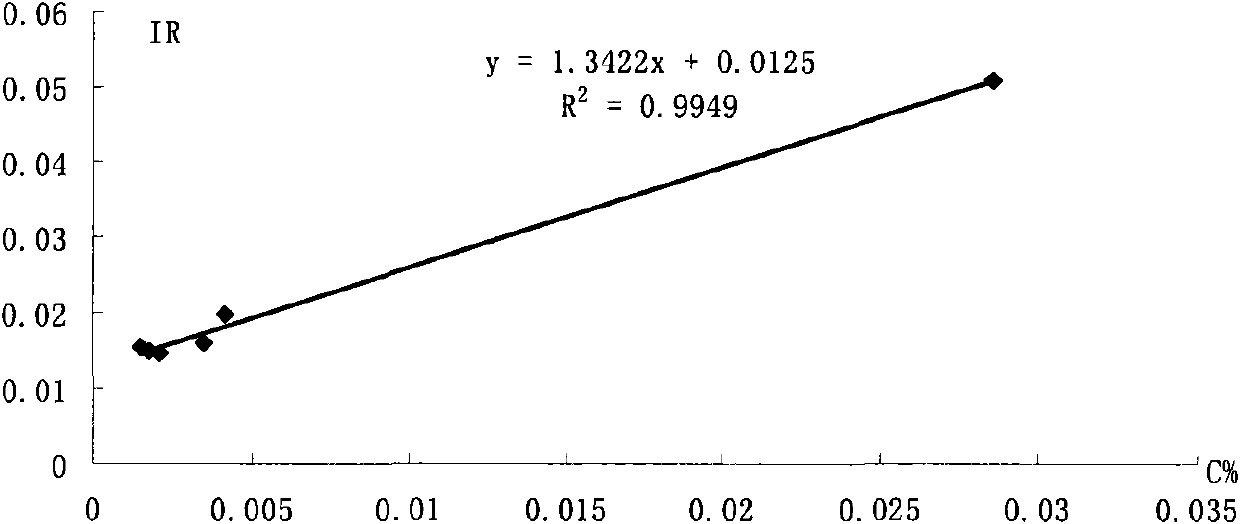

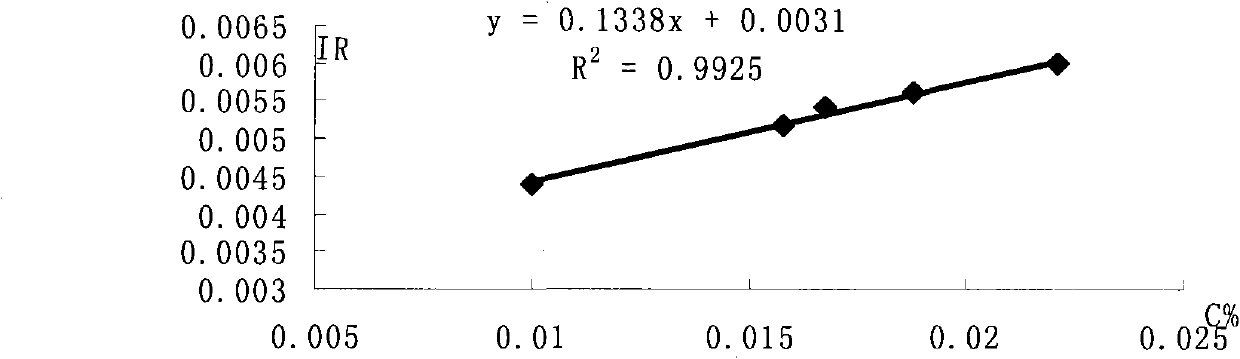

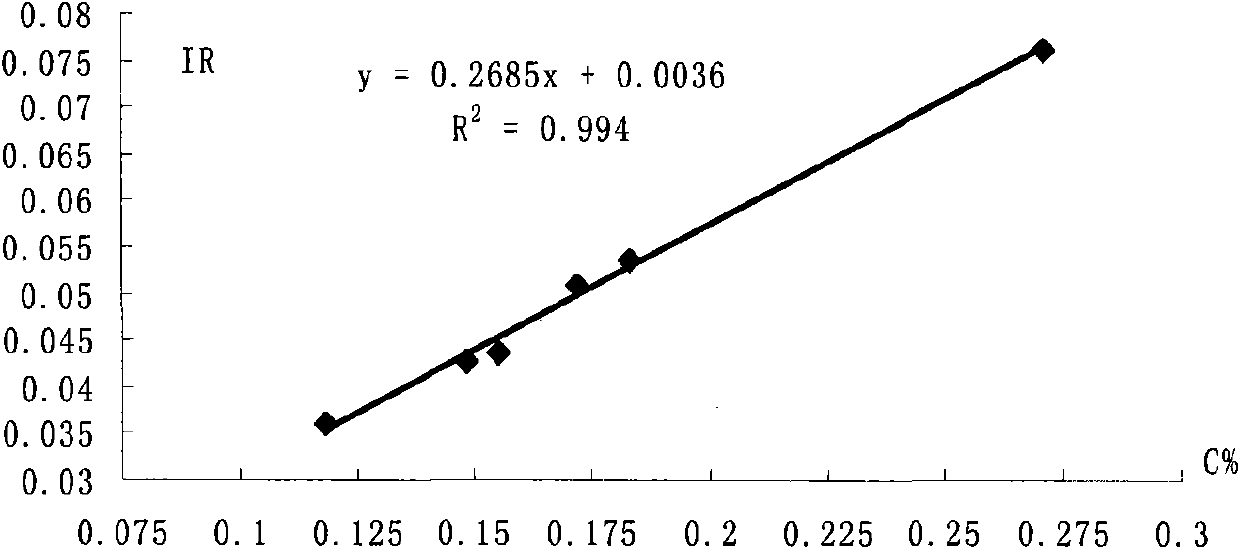

[0029] The pure steel spectral standard sample of the present invention comprises six points, and the weight percent of each point component content sees the following table:

[0030] Summary table of total weight percentage of pure steel spectral standard samples CJG1#~CJG6# chemical elements (ω%)

[0031] serial number project C Si mn P S Ni Cr CJG-1# standard value 0.0023 0.0158 0.183 0.0083 0.0042 0.0021 0.0151 CJG-2# standard value 0.0017 0.0221 0.172 0.0078 0.0037 0.0064 0.0168 CJG-3# standard value 0.0019 0.0168 0.148 0.0082 0.0045 0.0031 0.0176 CJG-4# standard value 0.0034 0.0170 0.118 0.0067 0.0056 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com