High-flexibility melamino-formaldehyde foam material and preparation method thereof

A technology of melamine formaldehyde and foam materials, which is applied in the field of polymer foam materials and foam materials, can solve the problems of complicated preparation process, easy powder drop of foam, high production cost, etc., achieve simple production process, improve foam powder drop, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

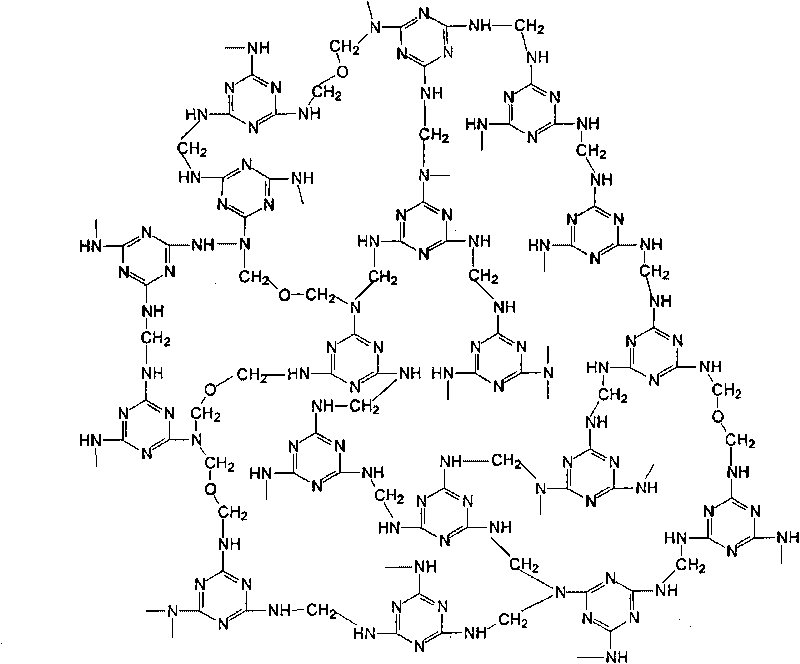

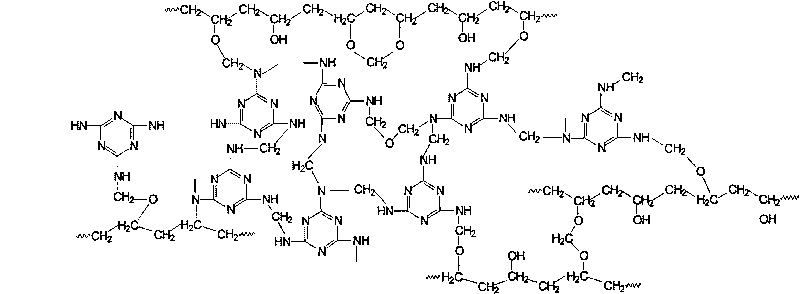

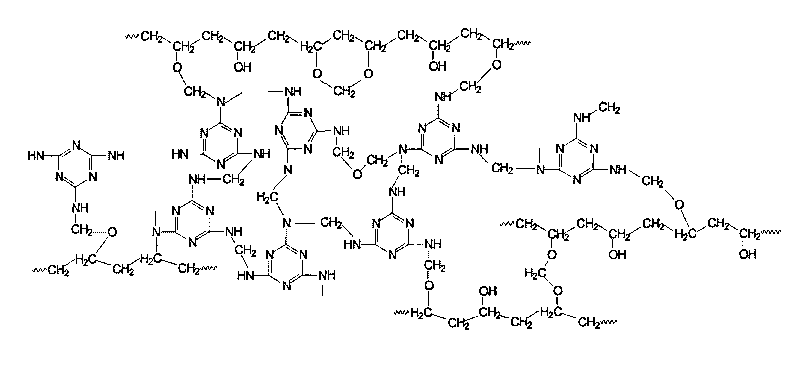

Method used

Image

Examples

Embodiment 1

[0028] (1) Pour the formaldehyde solution with a weight concentration of 37% into the reactor, heat and stabilize it in a water bath at about 30°C, adjust the pH value of the solution to about 8.8 with triethanolamine, and then use the molar ratio of formaldehyde and melamine to be 2.5 / 1 Add melamine, and at the same time raise the temperature to about 90°C and react for about 70 minutes. Then the reactor was separated from the water bath, stirred and cooled to obtain a transparent prepolymer solution.

[0029] (2) Measure 100 parts of the prepolymer solution prepared in step 1 and pour it into a container. In a water bath at about 40°C, add 2 parts of sodium lauryl sulfate and stir at 400 rpm for about 1 minute, then add 9.5 parts of chlorine Ammonium chloride, stir until it is completely dissolved, add 10 parts of petroleum ether and increase the speed to 1200rpm. After the petroleum ether is completely dispersed in the suspension, add 3 parts of hydrochloric acid, then pour...

Embodiment 2

[0031] (1) Pour the formaldehyde solution with a weight concentration of 37% into the reactor, heat and stabilize it in a water bath at about 30°C, adjust the pH value of the solution to about 8.8 with triethanolamine, and then use the molar ratio of formaldehyde and melamine to be 3 / 1 Add melamine and starch, and raise the temperature to about 90°C to react for about 70 minutes. Then the reactor was separated from the water bath, stirred and cooled to obtain a transparent prepolymer solution.

[0032] (2) Measure 100 parts of the prepolymer solution prepared in step 1 and pour it into a container, add 2 parts of sodium dodecylbenzenesulfonate in a water bath at about 40°C and stir at 400 rpm for about 1 minute, then add 7 1 part of ammonium sulfate, stir until it is completely dissolved, add 8 parts of chloroform and increase the speed to 1200rpm, wait until the chloroform is completely dispersed in the suspension, add 4 parts of phosphoric acid, then pour it into a microwave...

Embodiment 3

[0034] (1) Pour 37% formaldehyde solution into a three-necked flask, heat and stabilize it in a water bath at about 35°C, adjust the pH value of the solution to about 9.0 with triethanolamine, and then add melamine according to the molar ratio of formaldehyde and melamine as 3.5 / 1 And polyvinyl alcohol 1099, after the polyvinyl alcohol swells for 1 hour, raise the temperature to 90°C and react for 70 minutes. Lift the flask out of the water bath, stir and cool to obtain a transparent solution.

[0035] (2) Measure 100 parts of the prepolymer solution prepared in step 1 and pour it into a container, put it in a water bath at 50°C, add 1.5 parts of Span 80 and stir at 400 rpm for about 1 minute, then add 6 parts of ammonium bisulfate, and stir After it is completely dissolved, add 12 parts of cyclohexane and increase the rotating speed to 1200rpm. After the cyclohexane is completely dispersed in the suspension, add 2 parts of sulfuric acid, then pour it into a microwave oven bow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com