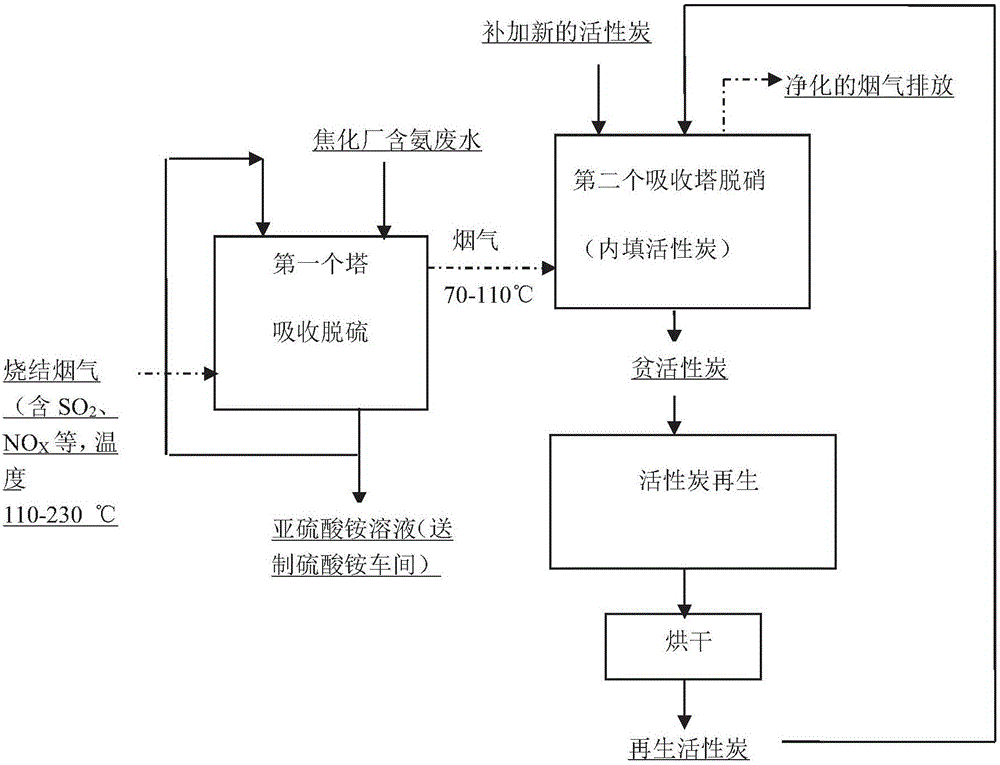

Ammonia-carbon combined desulfurization and denitration method for sintering flue gas

A technology for sintering flue gas, desulfurization and denitrification, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of unsatisfactory treatment effect, low safety, high treatment cost, etc., and solve the problem of by-product utilization. , improve the denitrification rate, improve the effect of desulfurization and denitrification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Iron ore oxidized pellets are preheated to 400°C and added to the rotary kiln. The mass ratio of semi-coke (5-20mm) to iron ore oxidized pellets (5-16mm) is controlled at 2.5:1, and the temperature in the rotary kiln is controlled at 1050°C. The residence time of the control material in the kiln is 3 hours. The yield of the activated carbon product obtained is 60.3%, the metallization rate of the metallized material is 94.3%, and the iron grade is 89.10%. The properties of activated carbon products are as follows: 78.2% of the particle size is 5-15mm, and the specific surface area is 305cm 2 / g, pore volume 0.247cm 3 / g, moisture 0.90%, ash 9.0%, iodine adsorption 620mg / g, compressive strength 1300N / cm 2 .

[0099] The composition of flue gas is SO 2 The concentration is 2017mg / Nm 3 , NO concentration is 396mg / Nm 3 , CO concentration is 11250mg / Nm 3 , CO 2 The concentration is 7.5%, O 2 For sintering flue gas with a concentration of 13%, the flue gas flow rate ...

Embodiment 2

[0101] The activated carbon in this example is prepared by the following method: iron ore oxidized pellets are preheated to 900°C and added to a rotary kiln, and the mass ratio of semi-coke (5-20 mm) to iron ore oxidized pellets (5-16 mm) is controlled at 5:1 , The temperature in the rotary kiln is controlled at 900°C, and the residence time of the materials in the kiln is controlled to be 3 hours. The yield of the activated carbon product obtained was 79.0%, the metallization rate of the metallized material was 92.0%, and the iron grade was 86.21%. The properties of activated carbon products are as follows: 79.0% of the particle size is 5-15mm, and the specific surface area is 290cm 2 / g, pore volume 0.239cm 3 / g, moisture 0.8%, ash 9.0%, iodine adsorption 550mg / g, compressive strength 1240N / cm 2 .

[0102] The composition of flue gas is SO 2 The concentration is 2017mg / Nm 3 , NO concentration is 396mg / Nm 3 , CO concentration is 11250mg / Nm 3 , CO 2 The concentration i...

Embodiment 3

[0104] The activated carbon in this example is prepared by the following method: iron ore oxidized pellets are preheated to 750°C and added to a rotary kiln, and the mass ratio of semi-coke (5-20 mm) to iron ore oxidized pellets (5-16 mm) is controlled at 4.0:1 , The temperature in the rotary kiln is controlled at 1050°C, and the residence time of the materials in the kiln is controlled to be 1 hour. The yield of the activated carbon product obtained was 72.3%, the metallization rate of the metallized material was 94.3%, and the iron grade was 89.16%. The properties of activated carbon products are as follows: 79.6% of the particle size is 5-15mm, and the specific surface area is 290cm 2 / g, pore volume 0.223cm 3 / g, moisture 1.0%, ash 8.9%, iodine adsorption 610mg / g, compressive strength 1210N / cm 2 .

[0105] The composition of flue gas is SO 2 The concentration is 1720mg / Nm 3 , NO concentration is 396mg / Nm 3 , CO concentration is 13500mg / Nm 3 , CO 2 The concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com