Method for preparing transparent silicon dioxide aerogel by co-precursor normal atmosphere drying

A co-precursor, atmospheric drying technology, applied in the field of aerogel, can solve the problems of limited practical applicability, consumption of a large amount of solvent, poor mechanical strength, etc., and achieve the effects of good hydrophobicity, uniform internal skeleton, and reduced production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

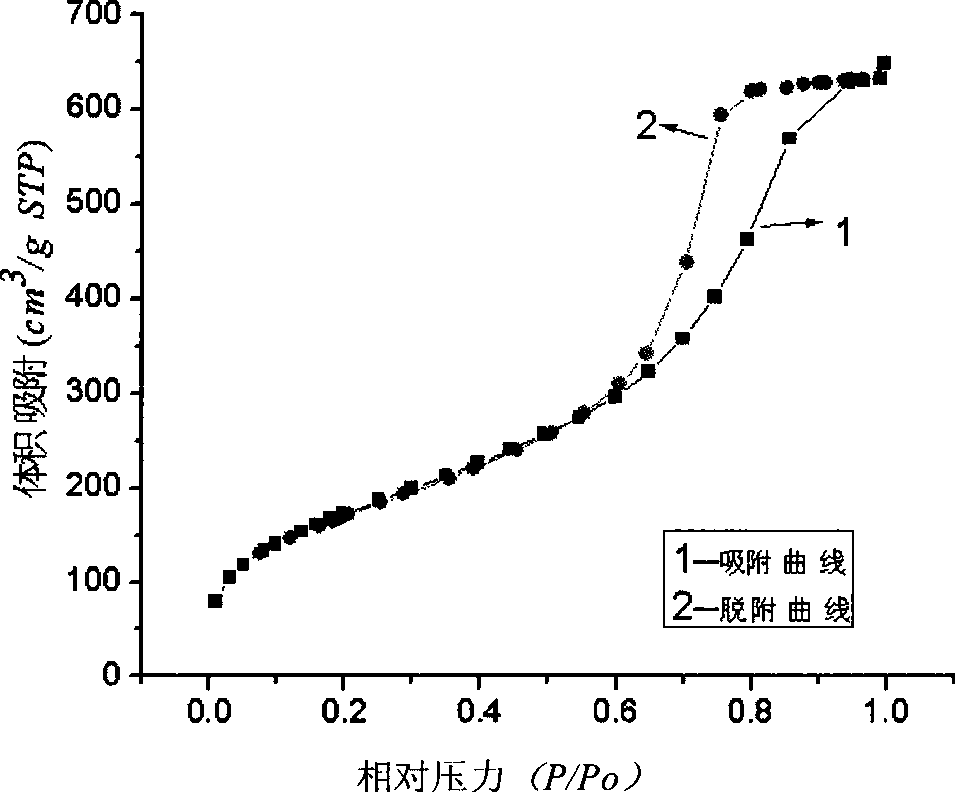

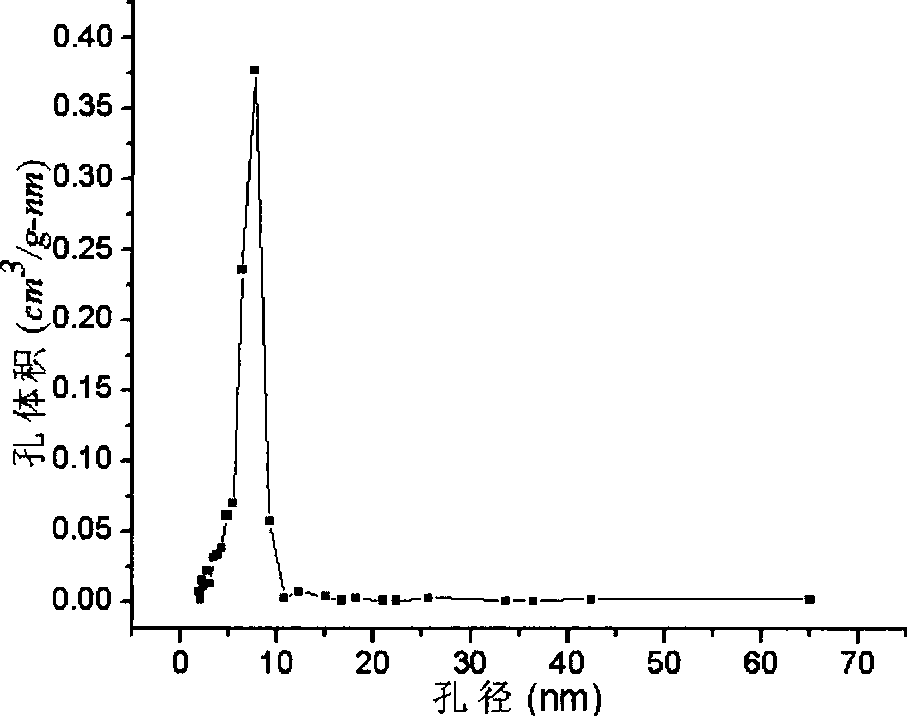

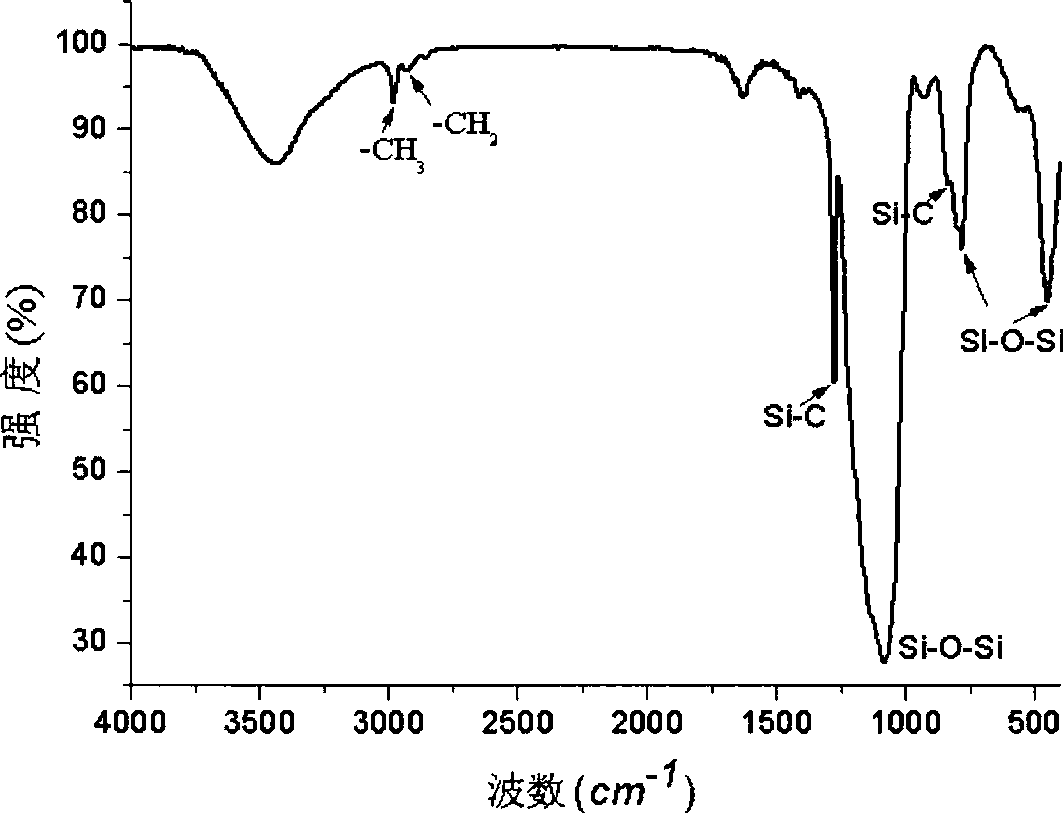

[0033] The molar ratio of raw materials is TEOS: anhydrous ethanol: MTMS: distilled water = 1:20:0.3:8, 11ml of TEOS and 36.5ml of anhydrous ethanol are mixed and added to the container to start stirring, and then 2ml of MTMS modifier is added. Continue stirring, slowly add 7.2ml of distilled water after 15min, add hydrochloric acid after stirring evenly after another 15min, adjust the pH value so that the pH value of the solution is about 2.0; after continuous stirring for 8h, slowly add a certain amount of ammonia to make the system final The pH value is around 8.0. Stop stirring after 10min, add SiO 2 The sol is allowed to stand for 24 hours until the sample gels. Then use the 10% volume concentration of MTES n-hexane solution for solvent exchange and aging, the aging temperature is 30 ℃, solvent exchange once every 2 days, exchange for 3 times; after solvent exchange, the sample is allowed to stand in the n-hexane solution To remove the MTES remaining on the surface, wash it o...

Embodiment 2

[0038] According to the molar ratio, TEOS: anhydrous ethanol: MTMS: water = 1:15:0.3:10, mix 11ml of TEOS and 27.4ml of anhydrous ethanol into the container and start stirring, then add 2ml of MTMS modifier, Continue to stir, slowly add 9ml of distilled water after 15min, add hydrochloric acid after stirring evenly after another 15min, adjust the pH of the solution to around 2; after continuous stirring for nearly 8h, slowly add a certain amount of ammonia to make the pH of the system finally 8~ Between 8.5. Stop stirring after 15min, add SiO 2 The sol is allowed to stand for 24 hours until the sample gels. Then use the 20% volume concentration of MTES n-hexane solution for solvent exchange and aging, the aging temperature is 60 ℃, solvent exchange once every 2 days, continuous exchange 3 times; then the sample is allowed to stand in the n-hexane solution for carrying out Wash, wash once every 2 days, wash 2 times.

[0039] Drying process: first heat the gel sample at 50°C for 6 h...

Embodiment 3

[0043] The molar ratio of raw materials is TEOS: anhydrous ethanol: MTMS: distilled water = 1:18:0.4:8, 11ml of TEOS and 29.5ml of anhydrous ethanol are mixed and added to the container to start stirring, and then 2.7ml of MTMS modifier is added After stirring for 15 minutes, slowly add 7.2ml of distilled water. After another 15 minutes, add hydrochloric acid and adjust the pH value so that the pH value of the solution is about 2.0. After stirring for 8 hours, slowly add a certain amount of ammonia catalyst to make the system The final pH is around 8.5. Stop stirring after 15min, add SiO 2 The sol is allowed to stand for 24 hours until the sample gels. Then, the solvent was exchanged with n-hexane solution and aged at room temperature. The solvent exchange was performed once every 2 days for 5 consecutive exchanges.

[0044] The drying process is as follows: first heat the gel sample at 50°C for 6 hours, then heat up to 65°C at a rate of 1°C / min, hold for 7 hours, then heat up to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com