Automatic edge control device of industrial sewing machine

An industrial sewing machine and automatic technology, applied in sewing equipment, sewing machine components, cloth feeding mechanism, etc., can solve the problems of inability to use computer programs and servo motors, poor sewing effect, high cost investment, etc., and achieve simple structure and small investment , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings and specific embodiments.

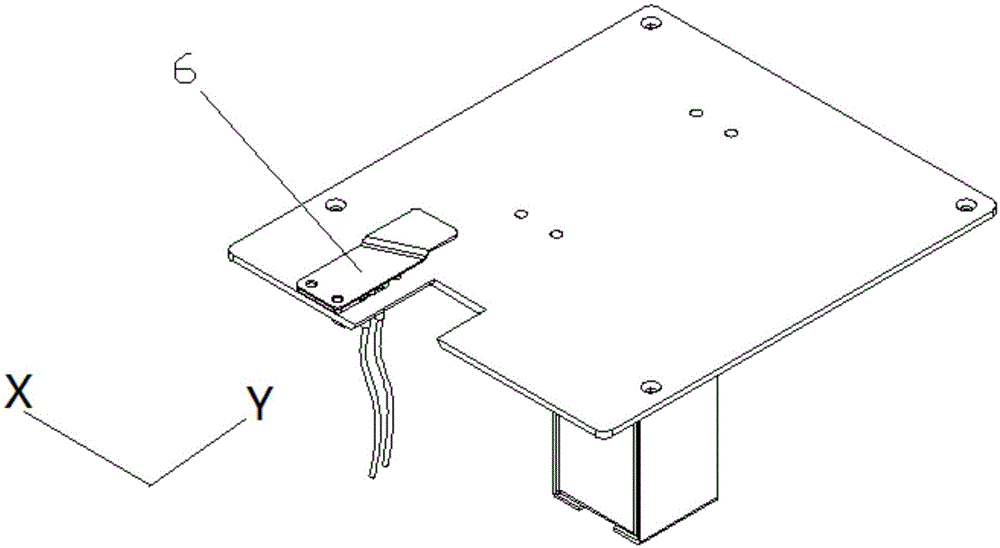

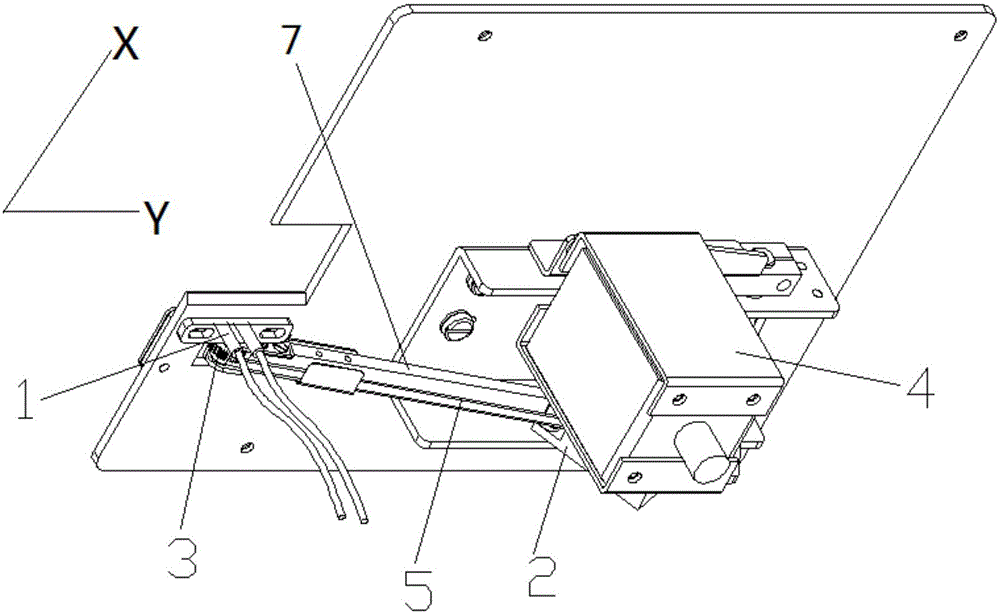

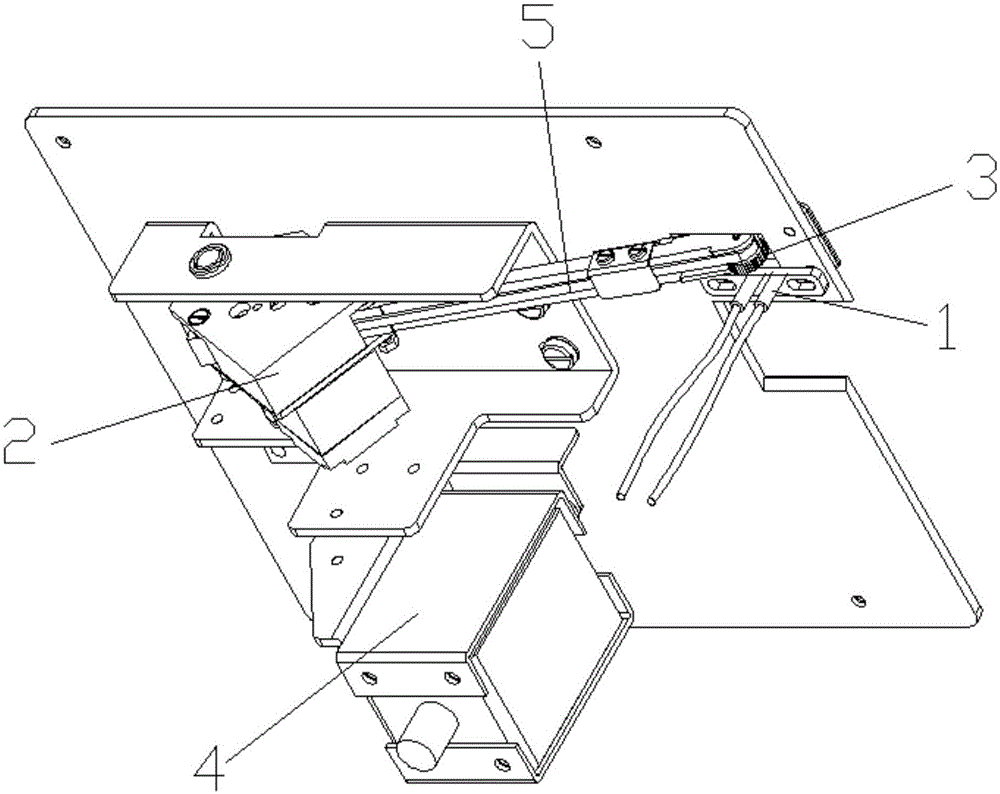

[0021] See Figure 1-Figure 3 , An automatic edge controller of an industrial sewing machine, comprising a platform on which a material pressing plate 6 is fixed; the sewing material feed direction is the X direction, and the horizontal and vertical direction is the Y direction; the lower part of the platform is fixedly provided with a motor 2. Electromagnet 4, the motor drives the timing belt 5 to rotate. The timing belt 5 is installed on the rigid rocker arm 7, and the ejector rod of the electromagnet 4 lifts the rigid rocker arm 7 upwards, so that the upper end of the ratchet 3 presses the cloth on the press On the lower end surface of the material plate 6, the friction force between the sewing material and the pressing plate 6 is much smaller than the friction force between the ratchet wheel 3 and the cloth; a pair of photoelectric switches 1 are provided o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com