Device for collecting needle number of industrial sewing machine and piece counting method

An industrial sewing machine and collection device technology, which is applied to sewing machine control devices, sewing machine components, program-controlled sewing machines, etc., can solve the problems of high installation cost and complex structure, and achieve the effect of improving accuracy and processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

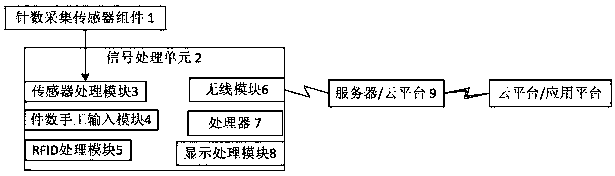

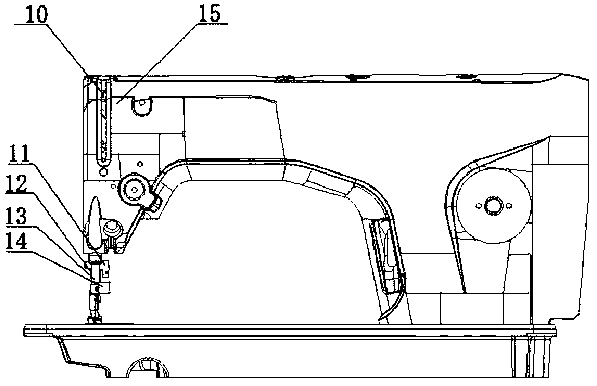

[0027] Such as figure 1 with figure 2 As shown, the present invention includes a sewing machine, a stitch number acquisition sensor assembly 1 , a signal processing unit 2 , and a server / cloud platform 9 . The signal processing unit 2 includes a sensor processing module 3, a manual number input module 4, an RFID processing module 5, a wireless module 6, a processor 7, a display processing module 8 and buttons. Processor 7 can be MCU, also can be other processors, and processor 7 is connected with sensor processing module 3, piece number manual input module 4, RFID processing module 5, wireless module 6, display processing module 8 respectively. The sensor processing module 3 receives the pulse signal of the needle number collection sensor component 1, and after filtering, it processes the data for the MCU. The MCU calculates the speed, numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com