Intelligent full-automatic bobbin line winding machine

A fully automatic, winding machine technology, applied in the direction of bobbin winding in sewing machines, embroidery machines, sewing machine components, etc., can solve the problems of high manufacturing cost and complex structure, and achieve the effect of low manufacturing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

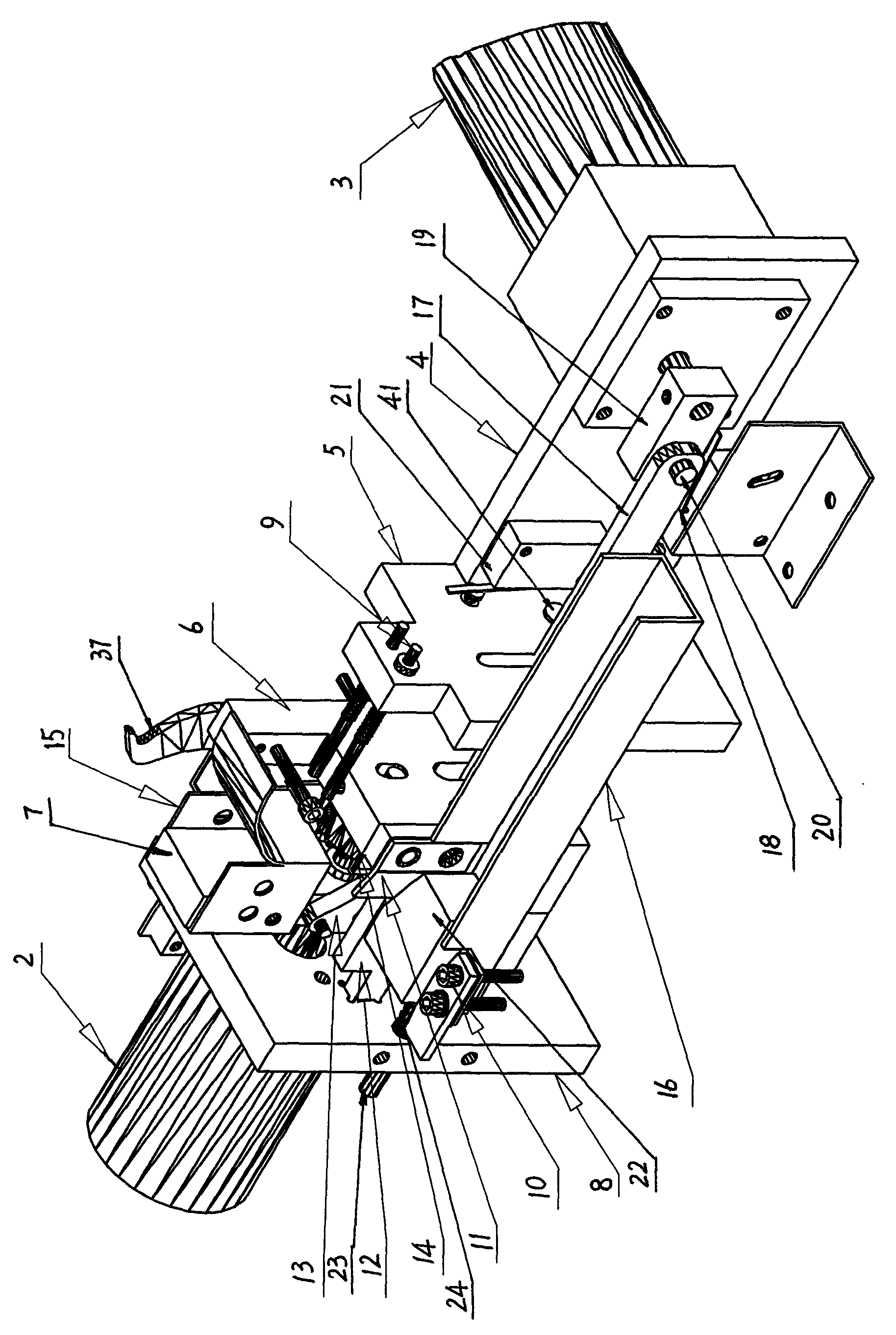

[0022] Such as figure 1 , figure 2 The shown intelligent automatic bobbin winding machine includes base 1, empty bobbin conveying mechanism, winding motor 2, drive motor 3, lead frame 28, bobbin loading and unloading mechanism, thread trimming mechanism, intelligent control mechanism 25, outlet Material tray 16, winding motor 2 rotating shaft ends have expansion device; The bobbin loading and unloading mechanism includes sliding plate 6, mounting plate 7, hanging gear, feed bin mouth 15, sliding plate 6 and mounting plate 7 are fixedly connected by base plate, Sliding plate 6 and mounting plate 7 are movably installed on the slideway 41 in the axial direction of winding motor 2 shafts, which can drive the whole bobbin loading and unloading mechanism to slide back and forth on slideway 41; The end face of the gear faces the direction of the mounting plate 7, and its outer circumference is formed with serrations protruding from the end face toward the direction of the mounting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com