Detection structure of shuttle peg upper base line of sewing machine

A detection structure, sewing machine technology, applied in the direction of bobbin winding, sewing machine components, sewing equipment, etc. in the sewing machine, it can solve the problems that the number of bobbin rotations is easy to produce errors, the overall structure of the device is complicated, and the monitoring is not accurate enough, etc. Appropriate remaining thread amount, low cost, and high recognition accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below are specific embodiments of the present invention and in conjunction with accompanying drawing, technical scheme of the present invention is described further, but the present invention is not limited to these embodiments.

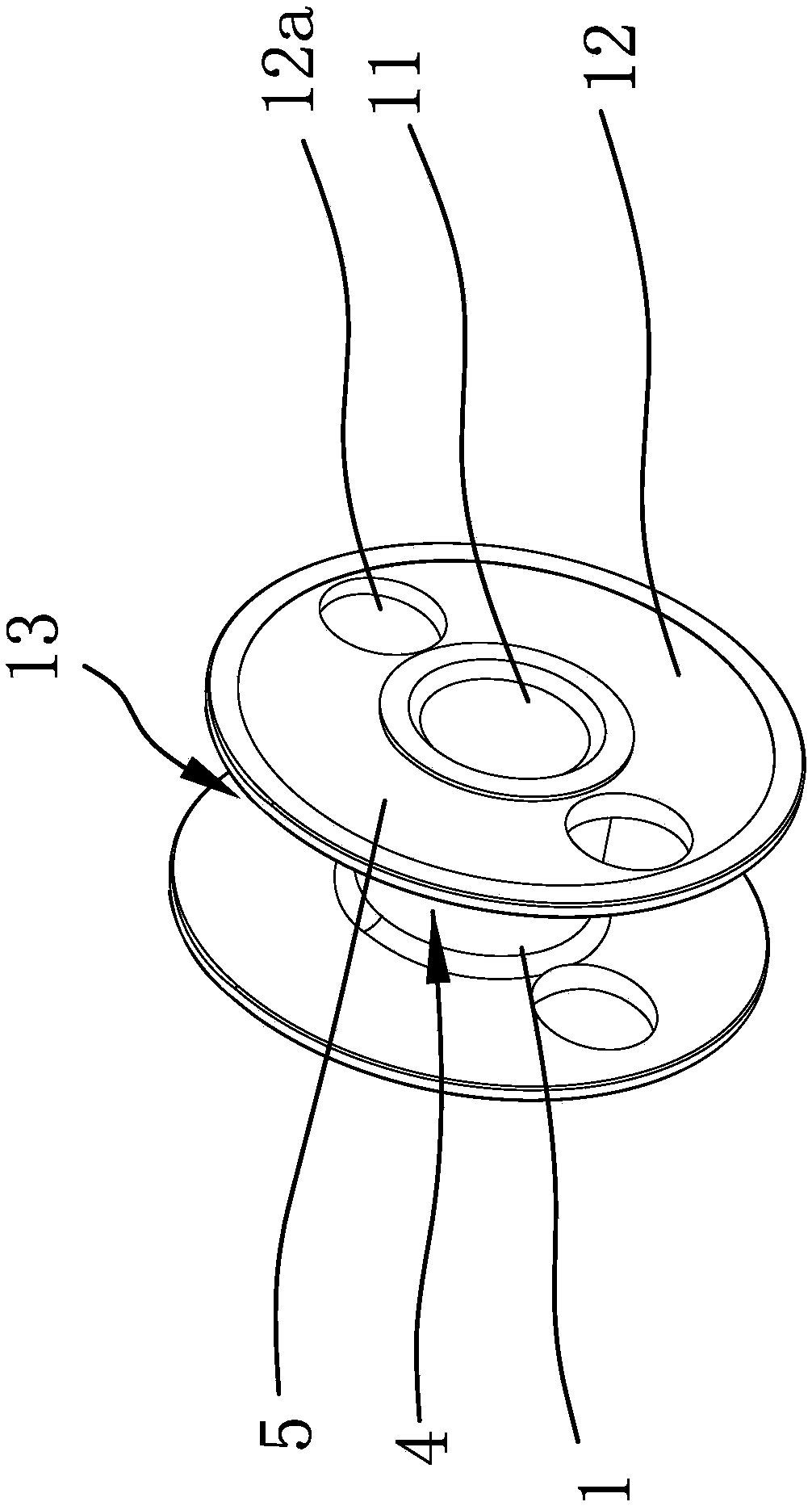

[0024] Such as figure 1 and figure 2As shown, the sewing machine bobbin in this embodiment includes a cylinder 1 with a through hole 11, the through hole 11 is arranged along the axis of the cylinder 1, and both ends of the cylinder 1 have baffles 12 extending radially outward. And a winding groove 13 is formed between the two baffles 12, and the detection structure includes an electric control module 3 and a photoelectric sensor 2; the bottom of the winding groove 13 is provided with a reflective layer-4, and the baffle 12 is provided with a light-transmitting hole 12a; The photoelectric sensor 2 can emit light beams to the first reflective layer 4; the opposite side of the two baffles 12 is the inner side, and the other side is the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com