Automatic bottom shuttle replacing device

An automatic and bottom shuttle technology, applied in the field of sewing machines, can solve cumbersome problems and achieve the effect of improving efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

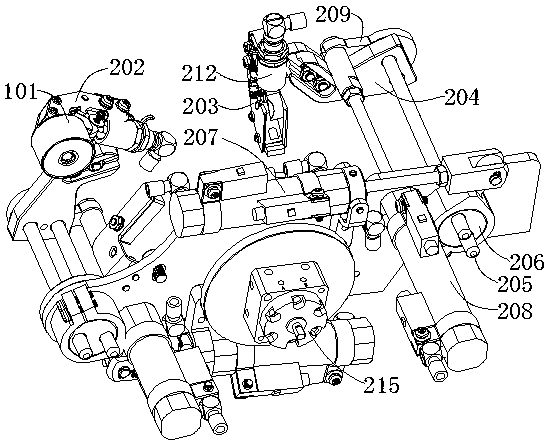

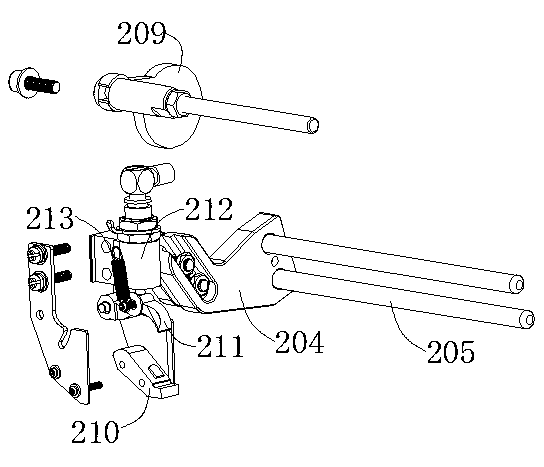

[0032] Figure 1 to Figure 13 Shown is the structural representation of the present invention.

[0033] Wherein the reference numerals are: the first bobbin case 101, the first bobbin core 102, the second bobbin case 103, the rotating disk 201, the first clamping arm 202, the second clamping arm 203, the swing arm 204, the guide shaft 205, the rotating seat 206, swing arm drive cylinder 207, swing arm telescopic cylinder 208, connecting plate 209, fixed splint 210, claw 211, claw drive cylinder 212, first spring 213, fixed shaft 214, shuttle changing motor 215, clamping arm 301 , pulling cylinder 302, fixed clip 303, movable clip 304, clamping cylinder 305, second spring 306, base 401, winding shaft 402, winding motor 403, pneumatic suction cup 404, bobbin claw 405, first telescopic cylinder 406, suction pipe 407, wire hook 409, bobbin-taking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com